Design and Fabrication of Optical Devices based on New

Polyfunctional Photo-thermo-refractive Glasses

Nikolay Nikonorov, Vladimir Aseev, Victor Dubrovin, Alexander Ignatiev, Sergey Ivanov,

Yevgeny Sgibnev and Alexander Sidorov

Department of Optoinformatic Technologies and Materials, ITMO University, St.Petersburg, Russia

Keywords: Photo-thermo-refractive Glass, Ion-exchangeable Glass, Photoetchable Glass, Bragg Grating, Waveguide,

Phosphors, Down-converter, Thermo-sensor, Biosensor.

Abstract: Novel optical elements and devices (holographic volume Bragg gratings, gradient optical elements, optical

and plasmonic waveguides, hollow structures, thermo-and biosensors, phosphors for LEDs, down-converters

for solar cells) have been designed and fabricated based on new polyfunctional photo-thermo-refractive

glasses. Some technologies (photo-thermo-induced crystallization, holograms recording, laser treatment, ion

exchange, chemical etching) have been used. Shown that photo-thermo-refractive glasses can be used as a

basic optical material for many photonics applications with the characteristics comparable with other

commercially available materials.

1 INTRODUCTION

The current stage of development of optical, photonic

and plasmonic devices calls for new and most likely

miniature optical elements that cannot be fully

implemented on the basis of traditional materials and

technologies. Therefore, the great attention is being

paid worldwide to the development of novel optical

materials.

The novel fluorine, chlorine and bromine photo-

thermo-refractive (PTR) glasses developed in ITMO

University (St. Petersburg, Russia) are very

promising optical materials for optical, photonic and

plasmonic applications (Nikonorov et al., 2010).

PTR glass is a multicomponent photosensitive

sodium-zinc-aluminosilicate glass doped with

halogens (fluorine, chlorine or bromine) and also

antimony, cerium, and silver (Dubrovin et al., 2014).

The PTR glass changes its refractive index after an

exposure to the near UV radiation followed by

thermal treatment at temperatures close to the glass

transition one (Tg). For example, in case of fluorine

PTR glass, that results in the precipitation of nano-

crystalline phases of NaF in glass host and negative

increment of RI (∆n = - 1000 ppm). In other words, it

results in decrease of RI in UV irradiated area in

comparison with unirradiated area of glass. In case of

chlorine and bromine PTR glasses that results in

growth of AgCL and AgBr nanocrystals and positive

increment of RI (∆n = + 1500 ppm).

The sizes of NaF, AgCL and AgBr nanocrystals

are relatively small (10-20 nm), that is why PTR

glasses exhibit rather a low level of scattering. The

fluorine PTR glass is successfully used for the

fabrication of holographic optical elements (HOEs)

that dramatically enhance properties of numerous

laser systems and spectrometers. It shows high

photosensitivity, high thermal stability of the

recorded phase holograms, and high tolerance to

optical and ionizing irradiation. Basic optical and

spectral properties of fluorine PTR glass are

described in (Glebova et al., 2008; Efimov et al.,

2011). The HOEs recorded in the fluorine PTR glass

reveal high chemical stability, thermal, mechanical

and optical strength, and from this point of view

practically reveal no difference with the commercial

optical glass BK7 (Schott). The optical and spectral

parameters of the HOEs and GRIN-elements do not

change after its multiple heating to the high

temperature (500ºC). The important advantages of the

fluorine PTR glass as the optical medium are

following: (i) high optical uniformity (the refraction

index fluctuations across the glass volume have the

scale of some 10

-5

), (ii) reproducibility of its

parameters during the starting glass synthesis and

during the photo-thermo-induced crystallization, (iii)

similarity to optical glass BK7, the PTR glass can be

20

Nikonorov, N., Aseev, V., Dubrovin, V., Ignatiev, A., Ivanov, S., Sgibnev, Y. and Sidorov, A.

Design and Fabrication of Optical Devices based on New Polyfunctional Photo-thermo-refractive Glasses.

DOI: 10.5220/0005676700180025

In Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), pages 20-27

ISBN: 978-989-758-174-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

subjected to various methods of mechanical

processing like grinding and polishing as well as

various formation technologies like molding,

aspheric surface production, and drawing fiber, (iv)

one can fabricate the PTR glass both in laboratory

(some hundreds grams) and in industrial (some

hundreds kilograms) conditions with the use of

simple and non-toxic technology. The chemical

reagents, which are necessary for glass fabrication,

are commercially available and not too expensive.

One has also to note some features of the fluorine

PTR glass, which are unusual for recording media.

For example, such media can be subjected to the ion-

exchange technology, that providing the possibility to

fabricate the ion-exchanged optical or plasmonic

waveguides and the surface strengthening to improve

the mechanical strength, chemical stability, thermal

and optical strength of the PTR glass. Moreover, the

photoetchable technology can be used in PTR glass to

provide the possibility to fabricate “lab-on-a-chip”

systems and optical microfluidic devices. PTR glass

doped with rare earth ions reveals good laser

characteristics (Aseev and Nikonorov, 2008; Glebova

et al., 2011).Recording the Bragg gratings in laser

PTR glass opens up a possibility to develop lasers

with distributed feedback. In (Hofmann et al., 2013),

possibilities to draw optical fibers from PTR glass

and record the Bragg gratings in the fiber are shown.

Some characteristics of fluorine PTR-glass and

VBGs are demonstrated in Table 1.

Table 1: Characteristics of fluorine PTR-glass.

Transparency range, nm 350-3000

Photosensitivity spectral range, nm 280-350

Photosensitivity, mJ/cm2 50

RI change, Δn

1×10

-3

RI modulation amplitude, δn 5×10

-4

Induced optical loss, cm-1

- visible range

- near IR range

0.1

0.001

Space frequency, mm-1 up to 5000

Diffraction efficiency, % 95

Hologram thickness, mm 0.1-10

Angular selectivity, ang. min <1

Bandwidth FWHM, nm 0.1

Size, mm up to 25×25

VBGs are completely stable at temperature,

o

C 200

2 DESIGN AND FABRICATION

OF OPTICAL DEVICES

2.1 Holographic Optical Elements

2.1.1 Volume Bragg Gratings for Laser

Diodes

Wide spread of laser diodes connected with its high

energy conversion efficiency, small size, simplicity

of use and low cost. However, as it well known laser

diodes has wide emission spectra and absence of

spectral stability caused by temperature shifts during

operation. This problem can be solved by mean of

VBG, due to high spectral selectivity of recorded

holograms implementation of such grating inside

external cavity of laser diode can significantly narrow

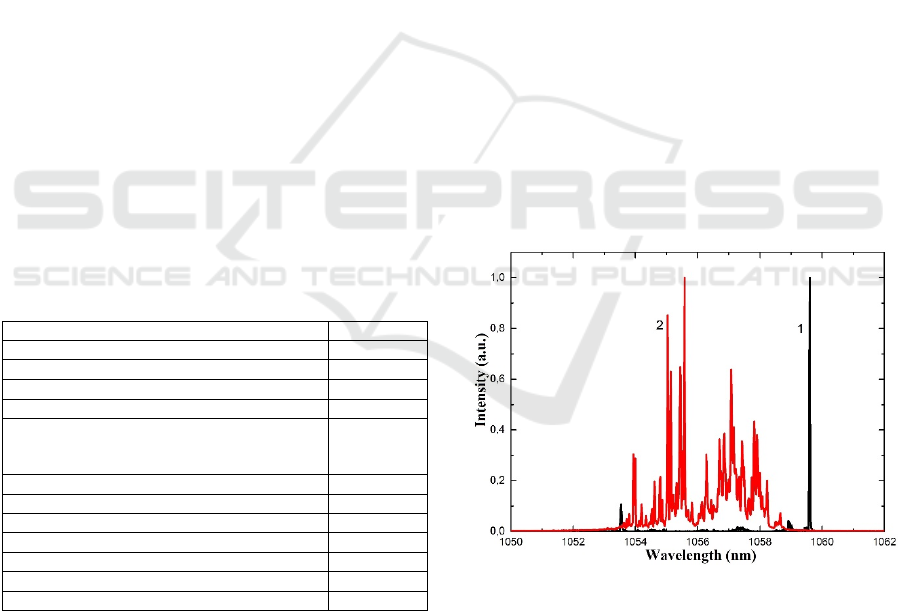

the output spectra. On the picture below is shown

emission of laser diode with and without grating. As

one can see grating narrows emission spectra from

6nm down to 6pm. Furthermore, due to high

transparency of HOE on PTR glass there’s almost no

losses in resulting output power. Moreover, gratings

can provide tunability for such lasers. By simple

rotation of the element one can change output

wavelength in a wide range. As experiments shows

such laser can be tuned in the whole range of diode

gain spectral range, which is about 10 nm.

Figure 1: Emission spectra of laser diode source with (1)

and without (2) grating.

2.1.2 Imaging Holograms for Collimator

Sight

High transparency of novel material in visible range

(above 90% without AR) opens a new field of

applications with strict requirements to transmission

in observation channel such as collimator sight.

Application of PTR glass can solve problem of mark

Design and Fabrication of Optical Devices based on New Polyfunctional Photo-thermo-refractive Glasses

21

image stabilization, which is necessary due to the

instability of laser diode source used in such scopes.

To date this problem is solved by addition in optical

scheme achromatizing diffraction elements such as

additional thin gratings, complex two-cavity mirrors

or compound objectives. Wavelength shift, caused by

laser diode temperature changes, can be nullified by

spectral selectivity of thick hologram recorded on

PTR glass. While the central wavelength of laser

diode shifts, recorded hologram continues to

reconstruct image of mark on proper angle – thus

maintaining the position of mark in target plane.

Moreover, redistribution of energy in diode output

spectra leads to insignificant lowering of intensity of

the mark that can be easily leveled by diode power

output adjustment. Since the diffraction efficiency of

holograms on PTR glass can achieve values of 99%,

intensity required for mark observation is pretty low.

Worth noting that up to date materials used for mark

recording are vulnerable to external impact such as

moisture and mechanical damage, that leads to need

in additional cover for holograms. With application

of PTR glass, since it is high resistant to external

impacts, there is no need in additional protection of

observation channel. In Figure 2 observable image of

holographic mark is demonstrated.

Figure 2: Photo of a reconstructed image of a volume

holographic mark.

2.2 Optical Amplifiers

We have demonstrated an optical amplification in the

laser PTR glass doped with rare earth ions (Er

3+

and

Yb

3+

). The concentration of ytterbium ions was

equaled to 17.8×10

20

cm

-3

. The concentration of

erbium ions was varied from 0 to 2.26×10

20

cm

−3

. The

introducing rare earth ions into the virgin PTR glasses

did not change its photosensitive properties.

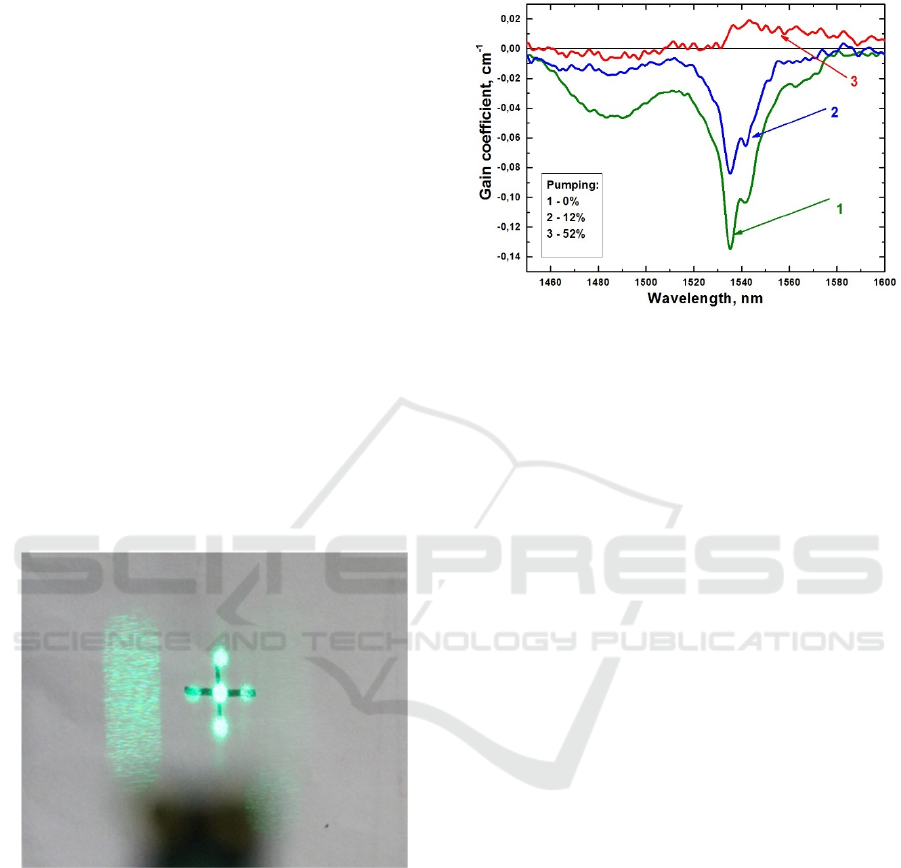

The experimental spectral dependences of the

gain/loss coefficient for various pump power are

shown in Fig. 3.

Figure 3: Gain/loss spectrum of PTR glass ceramics with

various pump power

.

N

Er

=0.26×10

20

cm

−3

, N

Yb

=17.6×10

20

cm

−3

.

As the pumping power increases, the absorption

spectrum transforms into a gain spectrum. The gain

coefficient at wavelength of 1.55 μm was close to

commercial Yb-Er silicate glass and achieved

g=0.016 cm

-1

. The gain is obtained on the samples

with a minimum erbium-ion concentration

N

Er

=0.26×10

20

cm

−3

and N

Er

=0.56×10

20

cm

−3

.

Increasing the erbium-ion concentration reduces the

gain.

The combination of laser and holographic

photorefractive properties into the laser PTR glass

substrate allowed us to realize a monolithic

integration of optical amplifier with Bragg grating

playing a role of spectral flattening filter.

2.3 Optical Waveguides

The virgin PTR glass contains 15-20 mol % of Na

2

O.

That fact allowed us to consider the PTR glass as ion-

exchangeable medium and use an ion-exchange

technology for optical and plasmonic waveguides

fabrication. The optical waveguides have been

prepared with the use of exchange of Na

+

(glass)

↔Ag

+

,

K

+

, Rb

+

, Cs

+

(salt)

from melt of corresponding nitrate.

In the case of Na

+

(glass)

↔Ag

+

(salt)

optical waveguides

reveal no birefringence and RI increment caused by

differences in the polarizabilities of cations

exchanged achieves Δn=0.014. In case of replacing

the sodium ions in glass by other alkali cations

(potassium, rubidium, and cesium), the refractive

index profile in waveguides formed by not only

differences of ions’ in the polarizabilities of ions

under exchange but also due to the photoelastic effect

arising at the expense of the compressive mechanical

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

22

stresses under the exchange of ions with various ionic

radii. Such mechanical stresses can improve

physicochemical properties of glass surface

(mechanical strength, microhardness, thermal

stability, and optical durability). For example, our

measurements showed an increase in Vickers

microhardness of PTR glass from 554 MPa before the

potassium IE to 655 MPa after the IE (temperature

and duration being 350

о

С and 6h). The RI increment

reaches 0.01 for K

+

-waveguides, 0.025 for Rb

+

-

waveguides and 0.05 for Cs

+

-waveguides. The optical

losses of the waveguides do not exceed 0.5 dB/cm.

Thus, we made a conclusion that the ion-

exchangeable properties of the PTR glass are

comparable with ones of commercial optical glass of

BK7 used for optical waveguides fabrication. In case

of Ag

+

-waveguides the silver ions can be transformed

into silver metallic nanoparticles by thermal

treatment in reducing atmosphere. This technology

allowed us to fabricate plasmonic waveguides with a

strong surface plasmon resonance used for chemical

and biological sensors.

2.4 Photoetchable Media for

Microfluidic, MEMS and MOEMS

Devices

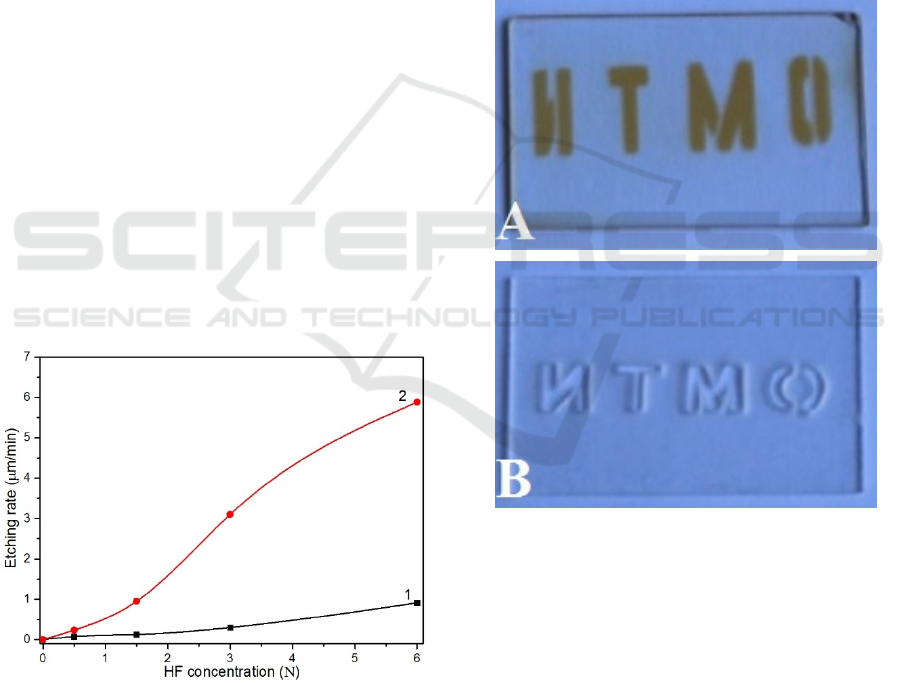

A technology of chemical etching of the fluorine PTR

glass has been developed for the first time. The rate

of etching of the crystalline phase is much higher than

one for the glass host by factors of 6-10.

Figure 4: Dependences of etching rates for PTR glass (1)

and fluorine glass ceramics (2) on the HF concentration in

aqueous solution.

In Fig. 4 are shown dependences of etching rate

on the HF concentration in aqueous solution for glass

and fluorine glass ceramics. It’s obvious that glass

ceramics reveal the higher etching rate than the

unirradiated fluorine PTR glass. So, the fluorine PTR

glass can be compared with well known

photoceramics of Foturan

TM

(Schott, Germany),

Fotoform

TM

(Corning, USA) and PEG3

TM

(Hoya,

Japan) with etching rates of 15-20 between the

crystalline phase and the glass host, that are

successfully used for fabrication of 3D hollow

microstructures, microfluidic devices, micro-total

analysis systems (μTAS), micro-electro-mechanical

systems (MEMS) and micro-opto-electro-mechanical

systems (MOEMS). At the same time holographic

properties of the Foturan

TM

and PEG3

TM

(Kösters et

al., 2005) greatly concede ones of the PTR glass.

To demonstrate photostructable properties of the

PTR glass the Russian abbreviation of the ITMO

University was chemically etched.

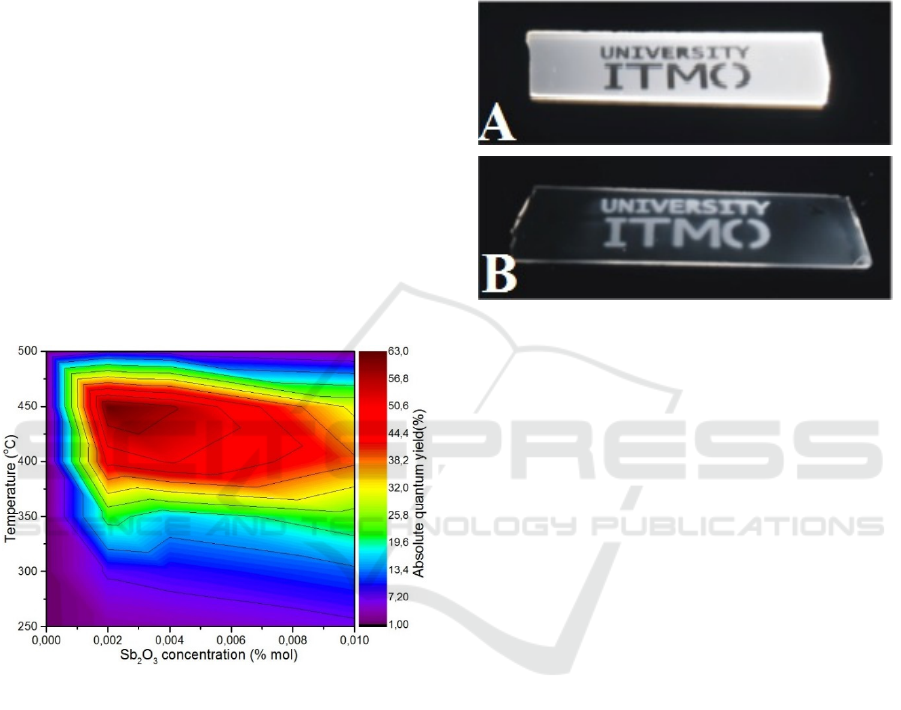

Figure 5: UV irradiated through mask and heat treated 1

mm PTR glass (A). Subsequently chemically etched PTR

glass (B).

Moreover, combination of photoetchable and ion

exchangeable properties of the PTR glass could open

new prospects for developing new microfluidic and

plasmonic devices. It’s well known that first

application of the ion exchange technology was a

glass strengthening (Nordberg et al., 1964). In

(Razzaghi et al., 2013) was shown that silver ion

exchange also can impart the hydrophobic properties

to glass surface. So it’s possible to improve chemical

durability, microhardness and hydrophilicity of

microfluidic channels formed in the PTR glass

Design and Fabrication of Optical Devices based on New Polyfunctional Photo-thermo-refractive Glasses

23

substrate. Besides that, silver ions in the ion

exchange layer can be transformed into either

luminescent silver molecular clusters or plasmonic

silver nanoparticles that allows developing integrated

microfluidic-plasmonic sensors.

For example, we realized luminescent clusters and

plasmonic nanoparticles inside of the hollow

structures in volume of the PTR glass by ion

exchange of Na

+

(glass)

↔Ag

+

(salt)

and following

thermal treatment.

Figure 6: Luminescent silver clusters (A) and plasmonic

silver nanoparticles (B) formed by silver ion exchange and

subsequent heat treatment inside of the hollow structures in

volume of the fluorine PTR glass.

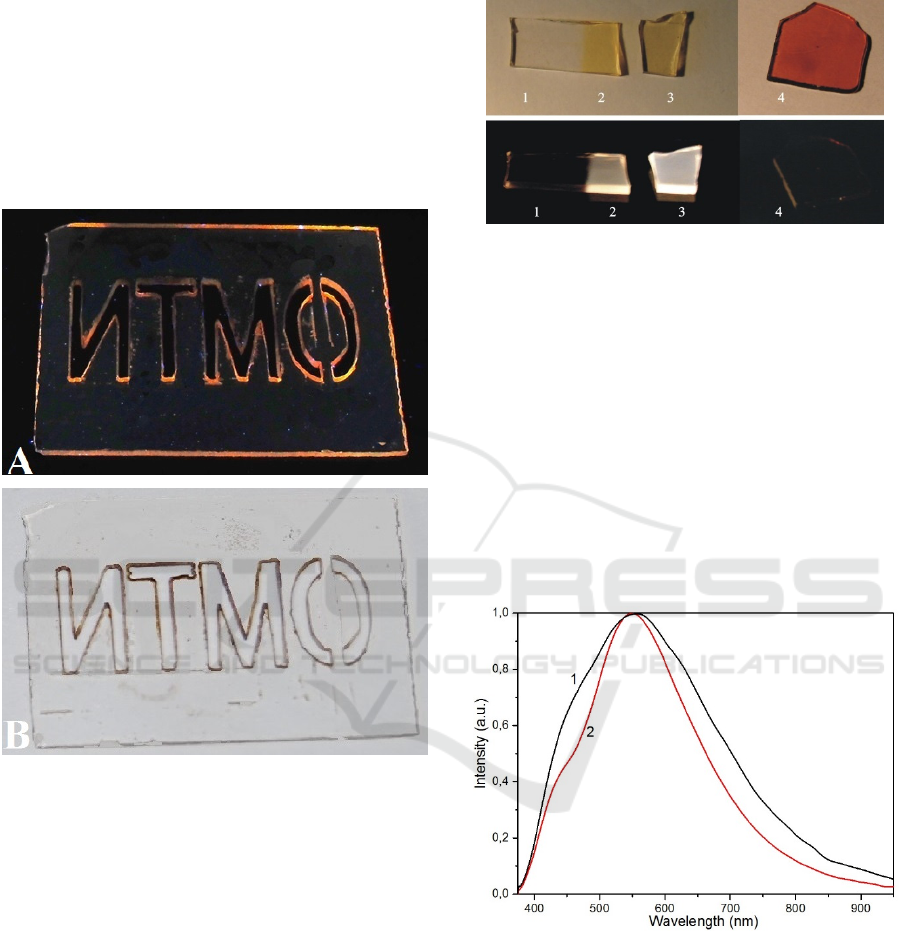

2.5 Phosphors for LEDs and

Down-converters for Solar Cells

Luminescent silver molecular clusters and

complicated complexes like “silver-bromine” or

“silver-chlorine” can be precipitated in the PTR

glasses by using ion-exchange technique or can be

embedded in glass host during glass synthesis. These

clusters and complexes have a broadband

luminescence in the visible and NIR ranges under

UV) excitation (Dubrovin et al., 2014).

In the same time luminescent properties of the

PTR glasses have a strong dependence on glass

composition and treatments (UV irradiation, heat

treatment) parameters (Fig. 7).

Figure 7: Chlorine PTR glass samples and effects caused by

their treatment. (1) virgin glass, (2) UV irradiated glass, (3)

sample after the UV irradiation and heat treatment at T =

400°C for 3 h and (4) sample after the UV irradiation and

heat treatment at T = 500°C for 3h. Excitation wavelength

is 360nm.

An increase in luminescence intensity of the PTR

glass after UV irradiation is caused by transform of

silver ions Ag

+

, and charged molecular clusters Ag

n

+m

to neutral state during UV irradiation and also by

increasing neutral silver clusters number and size

during subsequent heat treatment. Formation of silver

nanoparticles results to decreasing luminescence

intensity. Absolute quantum yield of silver clusters

formed in bulk of PTR glass reaches 50%.

Figure 8: Luminescence spectra of heat treated at 400

o

C for

3h PTR glasses with silver clusters formed in the bulk (1)

and in ion exchanged layer (2), λ

ex

=360nm.

Thin layers with high concentration of

luminescent silver molecular clusters can be formed

by the silver ion exchange. Intensity, shape and

efficiency of the luminescence strongly depends on

the temperature and duration of subsequent heat

treatment. Luminescence efficiency grows with

increasing heat treatment temperature up to 450

o

C

that can be associated with increasing concentration

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

24

of silver molecular clusters. Heat treatment at

temperature higher than the glass transition

temperature (464

o

C) results to formation of silver

nanoparticles and luminescence quenching in the

visible. Concentration of reducing agents (Ce

3+

, Sb

3+

)

existing in the PTR glass also significantly effects on

the luminescence efficiency. Increasing CeO

2

or

Sb

2

O

3

concentration in the PTR glass composition

leads to luminescence quenching that can be caused

by the formation of larger clusters that have weak

luminescence in the visible and/or concentration

quenching. Ion exchanged PTR glasses with silver

molecular clusters reveal white light emission and

high absolute quantum yield (up to 63%).

As conclusion, the PTR glass can be successfully

used as phosphors for white LEDs or down-

converters for solar cells. It should be pointed out,

that these luminescent clusters and complexes can be

formed in defined local spot of the PTR glass

substrate by laser radiation. It allowed us to create

complicated light architecture from luminescent

centers.

Figure 9: Dependence of absolute quantum yield on the

antimony oxide concentration in PTR glass composition

and temperature of heat treatment.

2.6 Media for Optical Information

Storage

The bright luminescence of neutral silver molecular

clusters in PTR glasses makes possible to record

optical information in them by UV nanosecond laser

irradiation. If the PTR glass was preliminary

irradiated by the UV radiation into the absorption

band of Ce

3+

ions the UV nanosecond laser irradiation

results in the silver clusters luminescence quenching

(Fig. 10A). If the PTR glass was not preliminary

irradiated by the UV radiation into the absorption

band of Ce

3+

ions the UV nanosecond laser irradiation

results in the neutral silver clusters luminescence

appearance (Fig. 10B). The subsequent thermal

treatment above the glass transition temperature

results in the silver nanoparticles growth in the

irradiated zones. The described effects can be used for

the optical information recording by the local change

of glass luminescence or absorption.

Figure 10: Negative and positive luminescent images in

PTR glass plates irradiated through the mask by the UV

nanosecond laser radiation with (A) and without (B) the

preliminary irradiation by the UV mercury lamp.

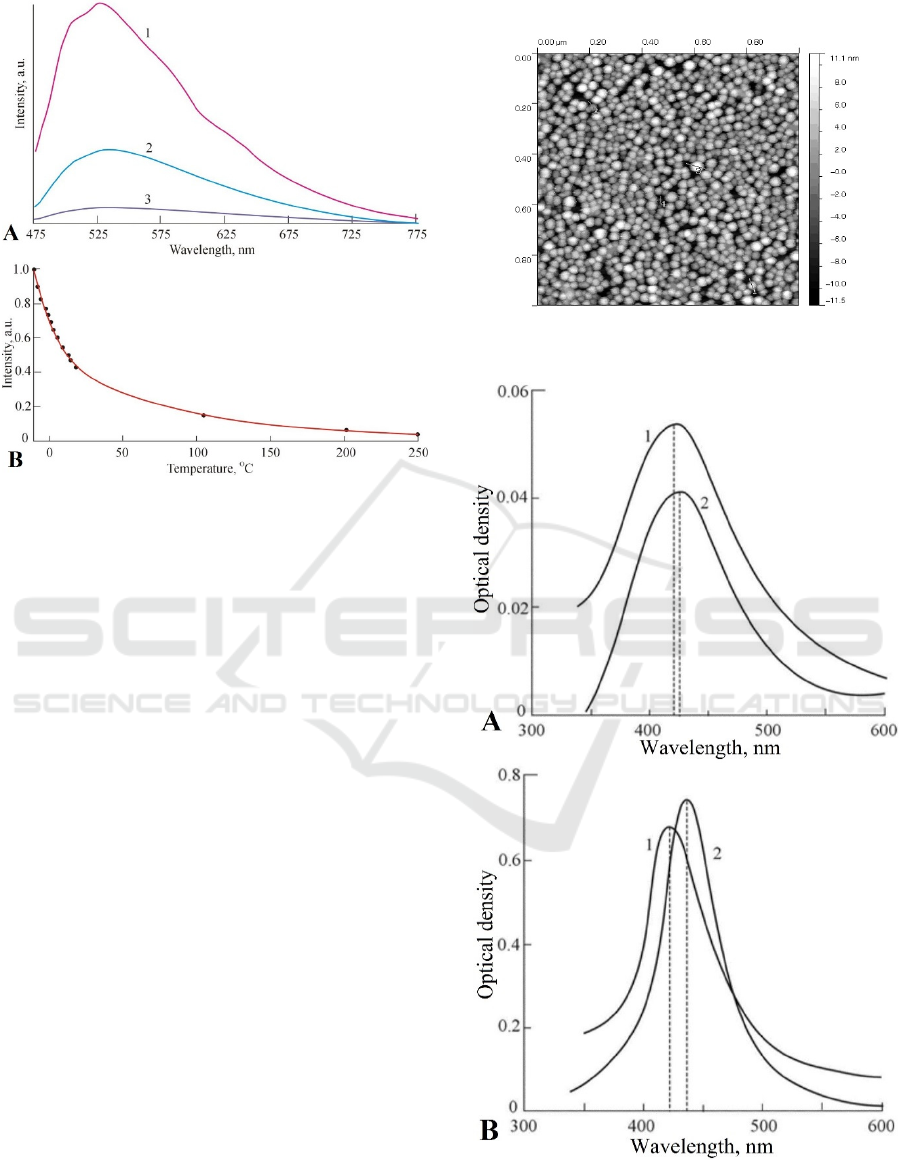

2.7 Luminescent Thermo-sensors

PTR glasses can be successfully use for fabrication of

luminescent thermo-sensors. The effect of

temperature on the luminescence of neutral MC in

PTR glasses is illustrated in Fig. 11. As seen, the

shape and location of the luminescence maximum on

the wavelength scale remain intact under an increase

in temperature (Fig. 11A), whereas the intensity of

luminescence decreases. In particular, an increase in

temperature from -10 to +250

o

C causes a decrease in

the integrated intensity of luminescence by a factor of

25. Notably, the temperature dependence of the

luminescence intensity shows no hysteresis and can

be multiply reproduced. Such properties of PTR

glasses make them promising materials for the

luminescent temperature sensors. The temperature

dependence of luminescence intensity of PTR glass in

-10 - +250

O

C temperature range can be approximated

quite satisfactorily (see Fig. B) by empirical function

as follows:

I=0.9(0.55*exp(-T/25))+0.25*exp(-T/150) (1)

the former term being responsible for the low-

temperature section of the dependence and the latter

term for the high-temperature one. Complex nature of

the function is associated with the presence of several

types of MC in a glass.

Design and Fabrication of Optical Devices based on New Polyfunctional Photo-thermo-refractive Glasses

25

Figure 11: The effect of temperature on the luminescence

of PTR glass subjected to the UV irradiation and

subsequent heat treatment. A: The luminescence spectra

recorded at temperatures of (1) -10

O

C, (2) +25

O

C and (3)

+200

O

C. B: Normalized dependence of the integrated

intensity of luminescence on temperature.

Also the fluorine PTR glasses doped with rare

earth ions (for example, Er

3+

) can be used for

fabrication of luminescent thermo-sensors operating

in a wide temperature range (from - 200

o

C up to

+500

o

C). In this case, several effects can be used for

measurement of temperature: (i) temperature

dependence of erbium luminescence life time, (ii)

temperature deformation of profile of luminescence

spectra, and (iii) change of luminescence peaks of

thermo-coupling levels.

2.8 Plasmonic Sensors

Some technologies of control of concentration, size

and shape of silver metallic nanoparticles in bulk of

the PTR glass and on its surface (Fig. 12) have been

developed for plasmonic sensors. The technologies

allowed us to precipitate high concentration of silver

nanoparticles with size of 4-8 nm in the PTR glass

host. The absorption coefficient of the plasmonic pick

achieves more than 1000 cm

-1

. These silver

nanoparticles can have different shape: spherical,

ellipsoidal and cubical. These metallic particles can

be covered by dielectric (NaF) or semiconductor

(AgCl, AgBr) shells. Some applications of the

material have been demonstrated: chemical and

biological sensors based on localized surface plasmon

resonance.

Figure 12: AFM-image of silver nanoparticles on surface of

the PTR glass.

Figure 13: Spectral position of the plasmon resonance peaks

for the silver nanoparticles with (a) and without (b)

dielectric shell on a PTR glass surface in air (1) and in water

(2).

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

26

Silver nanoparticles can be formed on the surface

of PTR glasses by the thermal treatment in the

reducing atmosphere or by the laser ablation of the

surface of PTR glass. In the last case silver

nanoparticles are covered by the SiO

2

shell 3-5 nm

thick. Figure 13 shows the spectral position of the

plasmon resonance peaks for the silver nanoparticles

with (a) and without (b) dielectric shell on a PTR

glass surface in air and in water. In the first case the

plasmon resonance spectral shift is 6 nm, in the

second case – 13 nm. It is enough for the application

in the sensors for the environment refraction index

measurements.

3 CONCLUSIONS

We have demonstrated some examples of design and

fabrication of optical, photonic and plasmonic

devices based on new fluorine, chlorine and bromine

PTR glasses: holographic volume Bragg gratings for

diode lasers, optical amplifier, optical and plasmonic

waveguides, hollow structures, thermo- and

biosensors, phosphors for LEDs and down-converters

for solar cells.

ACKNOWLEDGEMENTS

This work has been supported by the Ministry of

Education and Science of Russian Federation (Project

No.RFMEFI58114X0006).

REFERENCES

Aseev, V.A., Nikonorov, N.V., 2008. Spectroluminescence

properties of photothermorefractive nanoglass-

ceramics doped with ytterbium and erbium ions.

Journal of Optical Technology, 75(10), p.676.

Dubrovin, V., Ignatiev, A., Nevedomskii, V., Nikonorov,

N., Sidorov, A. & Tsekhomskii, V., 2014. The

influence of synthesis conditions and ultraviolet

irradiation on the morphology and concentration of

silver nanocrystals in photothermo-refractive glasses.

Glass Technology-European Journal of Glass Science

and Technology Part A, 55(6), pp.191–195.

Dubrovin, V.D., Ignatiev, A.I., Nikonorov, N. V., Sidorov,

A.I., Shakhverdov, T.A. & Agafonova, D.S., 2014.

Luminescence of silver molecular clusters in photo-

thermo-refractive glasses. Optical Materials, 36(4),

pp.753–759.

Efimov, A.M., Ignatiev, A.I., Nikonorov, N. V. &

Postnikov, E.S., 2011. Quantitative UV-VIS

spectroscopic studies of photo-thermo-refractive

glasses. I. Intrinsic, bromine-related, and impurity-

related UV absorption in photo-thermo-refractive glass

matrices. Journal of Non-Crystalline Solids, 357(19-

20), pp.3500–3512.

Glebova, L., Lumeau, J. & Glebov, L.B., 2011. Photo-

thermo-refractive glass co-doped with Nd 3+ as a new

laser medium. Optical Materials, 33(12), pp.1970–

1974.

Glebova, L., Lumeau, J., Klimov, M., Zanotto, E.D. &

Glebov, L.B., 2008. Role of bromine on the thermal and

optical properties of photo-thermo-refractive glass.

Journal of Non-Crystalline Solids, 354(2-9), pp.456–

461.

Hofmann, P., Amezcua-correa, R., Antonio-lopez, E., Ott,

D., Segall, M., Divliansky, I., Lumeau, J., Glebova, L.,

Glebov, L., Peyghambarian, N., et al., 2013. Strong

Bragg gratings in highly photosensitive photo-thermo-

refractive-glass optical fiber. IEEE Photonics

Technology Letters, 25(1), pp.25–28.

Kösters, M., Hsieh, H.-T., Psaltis, D. & Buse, K., 2005.

Holography in commercially available photoetchable

glasses. Applied optics, 44(17), pp.3399–3402.

Nikonorov, N., Aseev, V. & Ignatiev, A., 2010. New

polyfunctional photo-thermo-refractive glasses for

photonics applications. In ODF’10. pp. 209–210.

Nordberg, M.E., Mochel, E.L., Garfinkel, H.M. & Olcott,

J.S., 1964. Strengthening by Ion Exchange. Journal of

the American Ceramic Society, 47(5), pp.215–219.

Razzaghi, A., Maleki, M. & Azizian-Kalandaragh, Y.,

2013. The influence of post-annealing treatment on the

wettability of Ag+/Na+ ion-exchanged soda-lime

glasses. Applied Surface Science, 270, pp.604–610.

Design and Fabrication of Optical Devices based on New Polyfunctional Photo-thermo-refractive Glasses

27