3D-printing: A Future “Magic Wand” for Global Manufacturing

How Can We Benefit from It Today for Sports and Health Care?

Andrey Koptyug, Mikael Bäckström, Lars-Erik Rännar

Sports Tech Research Centre, Mid Sweden University, Östersund, Sweden

Keywords: Additive Manufacturing, Sports Technology, Active Lifestyle, Research and Development, Education.

Abstract: 3D-printing, or as it is also known, additive manufacturing (AM), is promising to be one of the determining

manufacturing technologies of the present century. It is not a single technology but a family of rather

different ones common in the way components are made, adding materials layer by layer. Additive

manufacturing is already quite competitive to existing and well established technologies, but it also can

provide unprecedented flexibility and complexity of shapes making components from the materials as

different as cheese, chocolate and cream, live cells, concrete, polymers and metal. Many more materials we

were not even thinking about few years ago are also becoming available in additive manufacturing, making

it really believable that “only the sky is the limit”. During the time available for the keynote lecture, we will

analyze the present position of AM in relation to other technologies, the features that make it so promising

and its influence upon the part of our life we call sports and health, using the examples relevant to the

Congress areas from computer systems to sports performance. Out of all enormities of materials available

for different representatives of this manufacturing family we will concentrate at polymers and metals. AM

technologies working with these two material families are already providing some unique solutions within

the application areas relevant to the Congress' scope. We will also talk about some limitations inherent to

the AM in polymers and metals to have the awareness that though the limit is somewhere “high in the sky”,

it still exists.

1 INTRODUCTION

Additive Manufacturing (AM) is a proper term

describing technologies that build objects by adding

layer-upon-layer of material (Christensen et al,

2007). 3D printing, the name commonly used in

everyday life, is in fact only one of the technology

types in this family, and many other AM

technologies can hardly be referred to as “printing”.

Materials used in modern additive manufacturing

can range from concrete, rubbers to polymers,

metals, cheese, cream and chocolate. In the big

family of additive manufacturing different

technologies have different levels of “maturity”.

AM in polymers and metals (alloys) represent most

mature methods that already compete with many

other, well established technologies especially in

manufacturing small series or unique products.

Competitive advantages of these methods include

the ability of building components with extremely

complex shapes in a single technological process,

fast design-to-market times, high energy and

material efficiency (Koptyug et al, 2017,

Nanotechnology). Along with materials common

with other technologies additive manufacturing in

metallic materials and polymers introduce new

materials not available for other technologies (e.g.

Koptyug et al, 2013 AM Conf., Pauly et al, 2013),

utilizing unique inherent properties of used

processes. Wide applications of modern computer

and virtual reality technology integrated into “the

design for AM” process allow for unique versatility

in functionalization, individualization and

modification of the manufactured components

almost without increasing production costs. Current

paper presents some of the experiences in integrating

additive manufacturing into the education, research

and development within healthcare, sports and active

lifestyle technology- related applications from

Sports Tech Research Centre at Mid Sweden

University.

Koptyug A., BÃd’ckstrÃ˝um M. and RÃd’nnar L.

3D-printing: A Future â

˘

AIJMagic Wandâ

˘

A

˙

I for Global Manufacturing - How Can We Benefit from It Today for Sports and Health Care?.

DOI: 10.5220/0006810300010001

In Proceedings of the 5th International Congress on Sport Sciences Research and Technology Support (icSPORTS 2017), pages 5-16

ISBN: 978-989-758-269-1

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 MATERIALS AND METHODS

A set of additive manufacturing machines is

stationed at Sports Tech Research Centre, including

one high-end device working with metals and alloys,

two high-end industrial class polymer machines, and

five table-top polymer ones. Table-top polymer

machines are mainly used in education within the

BSc and MSc engineering courses related to modern

design and manufacturing, and graduate exam

projects (Bäckström et al, 2013). High end machines

are used both for research and development, and as

the means of manufacturing of unique parts and

components. Majority of the described examples

relate to the components and parts manufactured

using these machines.

For additive manufacturing in metals and alloys

we use an ARCAM A2 Electron Beam Melting

machine by ARCAM AB (Mölndal, Sweden).

Electron Beam Melting is a powder bed fusion

additive manufacturing method, where successive

layers of metal powder are melted together with a

high power scanning electron beam (Sames et al,

2016, Koptyug et al, 2017, MSF). The process takes

place in a vacuum chamber at high temperatures.

Powder is brought to the working zone forming a

thin layer (commonly 50 to 90 micron- thick). High

intensity electron beam melts the area corresponding

to solid sections at present component height.

Working table is lowered one step (thickness of one

production layer), powder is brushed over the

working area again, and the process of next layer

processing is carried out. More details about the

process stages can be found elsewhere (Sames et al,

2016, Koptyug et al, 2017, MSF). Currently we

mainly work with the titanium alloy Ti6Al4V

(Koptyug et al, 2017, Cronskär et al, 2012, Koptyug

et al, 2013, LSMR), an alloy well known to medical,

aerospace and automotive industry and common to

many powder-bed AM methods, and at introducing

new materials earlier not used in AM (Koptyug et al,

2013, AM Conf., Zhong et al, 2017).

High-end additive manufacturing in polymers is

represented by fused deposition modelling (FDM)

machine Stratasys uPrint and PolyJet machine

EDEN260V, both by Stratasys Ltd (Stratasys Ltd,

2017). FDM machine uses a thin filament made of a

thermoplastic polymer, which is melted and

extruded in thin adjacent “wires” forming

manufactured component layer by layer. It can make

components up to 203 x 203 x 152 mm in size with

the resolution about 0.1 mm. PolyJet machine

operates in a way similar to an old bubble-let printer,

only instead of liquid ink it uses monomers

depositing them layer and curing it by a UV-lamp. It

can make components up to 255 x 252 x 200 mm,

and its precision is given in dpi, as for the true

printer: 600 dpi in the layer plan and 1200 dpi in the

build direction. It means that in the high resolution

mode its precision is about 16 micron. And when the

FDM machines are rather limited to the type of

materials (relatively stiff thermoplastic polymers)

PolyJet ones have much wider choice, from softer

rubber-like to relatively hard polymers, transparent

or having different colours. Table-top polymer

machines MakerBot Replicator (Makerbot LLC,

2017) are also of the FDM type. Though sizes of

components it can manufacture and precision are not

as impressive as for the high-end machines, these are

easy to use and interface. These machines are mainly

used for prototyping, and mainly for education. It

should be noted here, that with manufacturing of

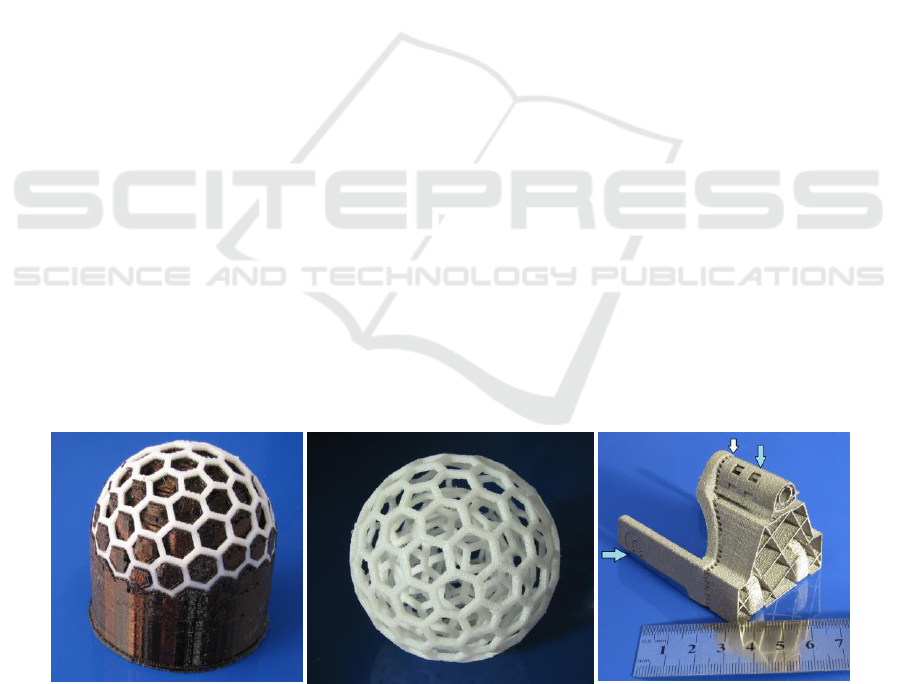

(a)

(b)

(c)

Figure 1: Complex shape components manufactured from ABS polymer in the FDM machine (a, b), and from Ti6Al4V in

the EBM machine (c). Polymer component is shown as it comes out from the machine, when support material covers

essentially all voids (a), and after support removal in the ultrasonic bath (b). Ti6Al4V component (c) is shown after removal

of the surrounding working powder. Arrows mark the position of the wafer supports, and perforated support boundary

where it will be broken off during post-processing.

complex shapes with overhanging features it is not

possible to avoid using supporting elements in the

manufactured component. In case of polymer

machines a second, “support” polymer is used,

commonly removable by water or special water

solutions. In the case of metal machines supports

take shape of wafer-thin elements, which are

mechanically removed in post-processing. Figure 1a

presents an examples of a “ball-in-ball”

manufactured from ABS polymer in the FDM

machine (a, b), and a component manufactured from

Ti6Al4V in ARCAM A2 machine (c). With the

polymer part (Fig. 1 a, b) working material is white

and support material is dark. With the metallic parts

supports are made in the same material. In Fig 1(c)

blue arrows show the positions of the support

wafers, and white arrow marks the perforated

boundary of the supports, along which they will be

broken off in post-processing. It is also clear, that

one of the restrictions in “design for AM” for these

types of machines. If we leave closed voids inside

the components, they will be filled with a support

polymer, or working powder, as it is possible to

remove support materials in post-processing only

through openings and channels.

3 AM IN HEALTHCARE

There are some application areas that already

strongly benefit from actively using additive

manufacturing. Industry is commonly the first to be

mentioned, but areas related medicine, health care,

and rehabilitation are also among clear beneficiaries

(Koptyug et al, 2013, 2017). High competitiveness

of the sport activities and certain risks inherent to

active lifestyle can unfortunately result in injuries.

Injury prevention is of course one of the best

strategies to go for and some contributions of

additive manufacturing to preventive strategies will

be discussed later in this paper. In present chapter it

will be discussed what AM can do for the medical

treatment and rehabilitation.

3.1 Biomedical Implants

Orthopaedics and reconstructive surgery is already

recognizing the advantages of additive

manufacturing. While some other medical

disciplines start discussing future possibilities of the

medical treatment individualization, orthopaedics

and reconstructive surgery already practice it with

the help of additive manufacturing. Today it is

possible to go all the way from medical image to

individualized implants placed into the human body

using design and manufacturing methods developed

for or within AM technologies (Cronskär et al, 2008,

2012, 2013, Koptyug et al, 2013, LSMR). Today the

advanced path from the results of medical scan to

individualized implant looks as follows. During the

first stage a standard image set acquired form

medical 3D imager is transformed to the format that

can be used by engineering and design software.

Next, special software is used to “filter out”

unnecessary features. In the case of designing

individualized metallic implant or fixation plate for

the broken bone one needs to “filter out” all soft

tissues and cartilage from the original image, leaving

only the bone outlines. Though it is not a trivial

operation, number of commercial software packages

capable of doing it is already available. Result of

these operations is an exact computer 3D model of

the bone, with all defects and brakes. From this point

the path splits. “In real world”, a replica of the

broken bone is additively manufactured using a

computer bone model (Fig. 2 a). “In virtual world”,

broken bone is mended using mirrored image of the

symmetrical healthy bone as a template, with all

bone fragments that are to be saved in the exact

places. Next, perfectly fit individualized implant

with screw hole positions and all other demanded

details is designed (Koptyug et al, 2013, LSMR,

Cronskär et al, 2008, 2012, 2013). It should be

noted, that today “virtual world” line does not end

with the shape optimization of the implants. Using

advanced body modelling software packages one

can calculate the values and directions of the forces

applied to the bone by attached ligaments in a

chosen scenario (Fig. 2 b, from Cronskär, 2014).

And it is possible to model and calculate

corresponding stress fields in both the broken bone

and implant attached to it. And implant design now

can be adjusted and optimized for the chosen

functionality (lowest weight with given loading

capacity, minimum thickness with excessive

strength etc., Cronskär, 2014, Cronskär et al, 2013).

Effectively, this is a process combining advanced

shape and function-optimized design and “virtual

surgery” of the broken bone mending. Now the

implant itself is ready to enter the real world, and it

is manufactured in one of the metal AM machines.

At this point a preoperative model of broken bone

“meets” matching metallic implant, both

components additively manufactured in polymer and

metal respectively (Fig. 2c). To speed up a pre-

operative process in complex cases additional model

of the implant can also manufactured in polymer,

allowing surgeons to practice even before the

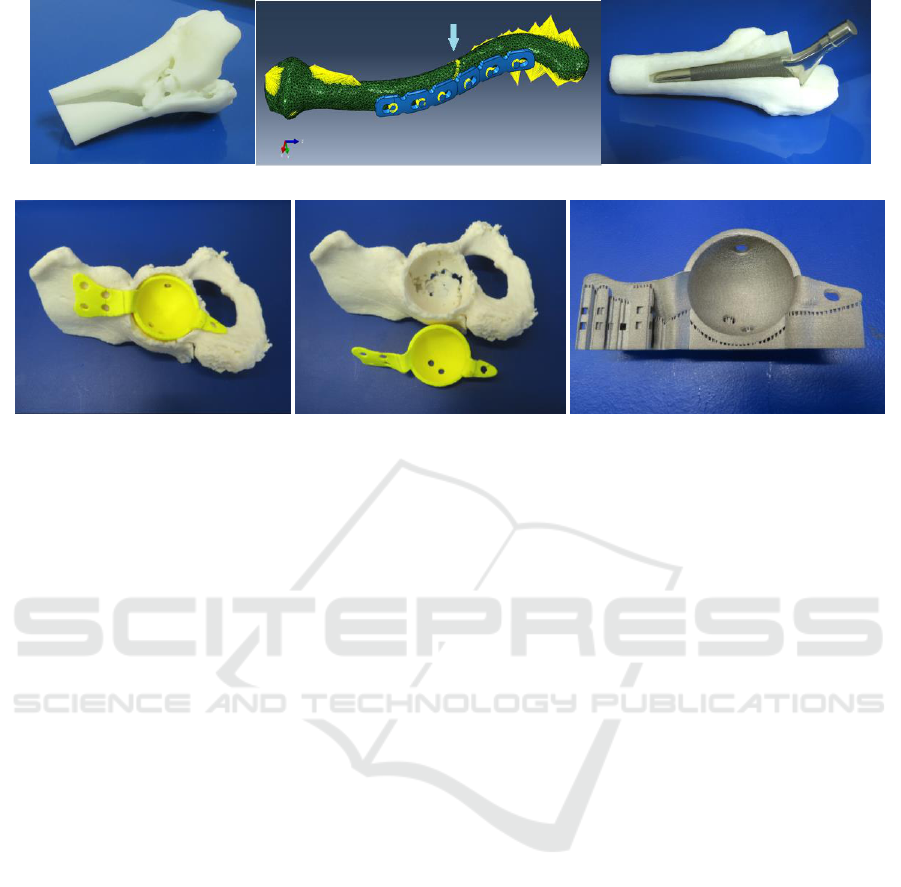

(a)

(b)

(c)

(d)

(e)

(f)

Figure 2: (a) Actual size pre-operative model of the broken bone manufactured from the ABS polymer basing on the

medical image of the patient’s bone. (b) Computer model of the broken collarbone (clavicle) with a fixation plate attached.

Arrow marks the brake position; yellow lines indicate directions and values of forces applied to the bone by attached

ligaments. (c) Actual size ABS model of the thigh bone (femur) section showing the position of the individualized

Ti6Al4V implant designed for the hip replacement surgery. (d, e) Actual size models of the human pelvis section and of a

customized implant used in pre-operative planning; (f) corresponding implant made in EBM machine from Ti6Al4V with

support structures still present. All given examples are from the medical case studies.

metallic implant is made. Figure 2 (e-f) illustrates a

case for the hip replacement operation planning with

the help of additive manufacturing in the case when

pelvic bones are osteoporotic and acetabular cups

with standard fixation cannot be applied. In such

case individualized acetabular cup integrating

fixation elements with the screw holes

corresponding to parts of the pelvis where the bone

is still strong enough is designed and manufactured.

Figure 3(f) shows such cup as it comes after working

powder is removed, but with the support structures

still attached (positioned as it would be oriented in

manufacturing).

Described path allowing “transitions” between

virtual world of computer models and real one can

be extended even further, for example towards

manufacturing individualized surgical support tools.

Using computer models of the bones one can

manufacture saw guides for fast and precise removal

of the damaged bone sections, and screw guides,

allowing putting screws in exact places with precise

orientation. As a result, modern surgeon can obtain a

package of parts including a pre-operative bone

models, optimized in shape and functionality

implants and surgery support tools. And even before

the patient goes to the operation theatre surgeons can

perform a full-scale “dummy surgery” using actual

size plastic bone models, individualized saw guides

and implants- cutting, drilling and putting screws in

place. Such preparation and availability of the

individualized implants can significantly shorten the

operation time and cost, and improve the procedure

outcomes for the patients (Koptyug et al, 2013,

Cronskär et al, 2008, 2012, 2013). Realizing market

opportunities polymer AM machine manufacturers

are now introducing the materials that can be

sterilized and taken directly into the operation

theatre.

Discussions about the benefits of additive

manufacturing for biomedicine always involve

delivery time and cost related issues. It appears that

today design of the individualized implants takes

most of the image-to-product time, and it should be

done in tight cooperation between AM-able

designers and practicing doctors. Polymer pre-

operational models and metallic implants also need

certain time to be manufactured, quality controlled

and properly prepared for transferring to the hospital

environment. Our experience shows that with the

availability of proper resources, image-to-model

times can be as short as 48-72 hours, and image-to-

implant path can take less than 5-7 days (depending

upon the complexity of the implants needed). Our

best achievement was a lead time of 48 hours from

receiving a medical image to the delivery of the

finished implant. With the complex surgical

procedures, where application of the individualized

implants is effective, surgery preparation also takes

time of at least about one-two weeks. Speaking of

the costs, one needs to think of them even in the

cases when individualized implants make a

difference for patient between permanent disability

and relatively normal life for a number of years.

Comparisons of the costs associated with the

additive manufacturing of individualized implants

indicate that they are at least 30-40% cheaper than

individualized implants manufactured using other

technologies (Cronskär et al, 2013), and with

increasing numbers of manufacturing sites capable

of AM this ratio continues to improve. As compared

to the “standardized” implants used in complex

surgical cases additively manufactured implants are

as such more costly. But when the reduction of

surgery time is counted for, overall hospital costs are

either on par or, in many cases, is significantly lower

when using AM implants. Of course it would be

hard for AM implants to compete in cost with

relatively simple, mass-produced items. Thus at

present highest value AM implants usage will bring

in special surgical cases (complex fractures,

osteoporotic bone cases, complex reconstructive

procedures etc.).

Implant manufacturing is among the most

challenging for additive manufacturing. Along with

the issues common with almost all other technology

and engineering applications of AM like: providing

good value for money and acceptable costs,

adequate design-to-market times, exact replication

of the designed shape at the output, securing

mechanical strength, fatigue and corrosion

resistance, biomedical applications impose

additional ones (Koptyug et al, 2012, 2014, 2017,

Nanotechnology). Majority of these additional

demands are related to biocompatibility of the

implant material, its biointegration and longevity in

the human body. For example, corrosion resistance

in technology mainly presumes that component

should not lose its mechanical properties. But even

relatively small amount of ions “leaking” from the

metallic implant into the body may be harmful.

Also, because molten metal in powder- bed AM

methods is surrounded by the working powder,

component outer surfaces are always coming “as

manufactured” rough to some extent and can contain

loosely attached powder grains. Some technological

applications demand much better surface finish and

thus certain post-processing is performed. In ideal

case surface topography control of biomedical

implants should cover the feature dimensions from

nanometres (determining wet ability and water

contact angle important for the earliest stages of

implant integration with cell attachment to the

surface) through micrometers (important at later

stages with cell migration and differentiation) to

millimetres (providing vascularisation and bone

ingrowths for better implant stability; Koptyug et al,

2012, 2014, 2017, Nanotechnology). Such control is

not possible within existing additive manufacturing

processes, and even needed post-processing often

becomes hardly possible. Loosely connected surface

powder grains may potentially become loose during

service life, and thus should be secured or removed.

For solving these issues research and development

work is carried out across the world. Such work is

aiming for example at improving AM processes in

cases when components have solid and lattice

sections, which can be additively manufactured in a

single additive process. Such structures are

important both for the implants (mimicking cortical

bone structures) and for industrial applications (3D

lattices in filters and catalyst carriers, in lightweight

construction elements- integrated with solid

component sections). Also significant efforts are

directed to introducing better biocompatible

materials for AM (Koptyug et al, 2014, 2017,

Nanotechnology), and better methods for metallic

implant surface coating (Surmenev et al, 2014,

Surmeneva et al 2015, Chudinova et al, 2016).

Yet more problems are coming from the fact that

solid implants used to fix and support broken or

weak bones are much stronger than bone tissue. This

often results in the situation when additional stress

appears in the bone sections adjacent to the implant?

For example, when solid titanium rod of the hip

stem implant is sitting inside the osteoporotic thigh

bone (femur) after hip replacement surgery, upper

part of the bone up to the joint is than well protected

from extra loads. But the area, where the “rod” ends

will be under considerable stress, if the patients

occasionally falls in a wrong way, and secondary

brake in this position is quite probable. Differences

in the mechanical properties of the metallic implants

and bones can also lead to the loosening of the

implant in the body after some time, either due to

damaging surrounding bone, or to so-called “stress

shielding”, when bone tissue adjacent to the implant

starts to “dissolve” (Huiskes et al, 1992, Summer,

2015, Koptyug et al, 2014). Today two possible

ways of solving this problem are dominating

research activities: development of new metallic

materials with the mechanical properties closer to

the ones of natural bone (e.g. Niinomi et al, 2011),

and application of the implant sections that are

porous or made of three-dimensional lightweight

constructions (lattices; Heinl et al, 2008, Murr et al,

2010, Koptyug et al, 2012, 2014). But one should

admit that no optimal solution is yet available for the

everyday medical practice.

Though limitations of additive manufacturing in

supporting treatment of broken bones exist, related

progress in practical surgery related to AM

implementation is quite significant allowing one to

speak about introducing “spare parts for human

body” (Bäckström et al, 2012, Zadpoor et al, 2017).

Though such spare parts are not yet ideal and cannot

completely substitute natural bones, they still help to

return to activities and save lives.

3.1 Rehabilitation and Protection

Additively manufactured components significantly

broaden the possibilities in supporting active patient

rehabilitation after illness or injury. Individually fit

protection, fixation and support devices can be

manufactured for example with the help of additive

manufacturing (e.g. Bibb et al, 2014, Palousek et al,

2014, Mills, 2015, Ganesan et al, 2016). Availability

of the inexpensive, often hand-held digital scanners,

availability of affordable and the emergence of free

digital design software, and wide availability of both

professional and table-top “3D printers” working

with polymers boost public access to the

individualized rehabilitation and protection devices.

Because the extreme precision of digital scanning

and manufacturing in many protection devices is

often not needed, it allows keeping their cost

relatively low

It should be noted, that as with many other

additively manufactured components, production of

such devices is not the most expensive stage, and

dominating costs commonly lay with the design

process. This difference is quite pronounced with the

applications of additive manufacturing in prosthetics

(e.g. Jina et al, 2015, Skoglund, 2015). In many

cases individualized prosthetic device is the only

option for having active lifestyle and participation in

sports. As compared to many temporary protection

devices prostheses should be designed for individual

fit baring in mind their functionality, comfort,

possible excessive loads and fatigue during service.

And because in additive manufacturing cost is

mainly associated with amount of used material and

processing time rather than component complexity

(“complexity comes for free”, Fera, 2016),

prosthetic devices now can afford elements of the

artistic design. Figure 3 (a-c) illustrates the process

of an individualized prosthetic socket design and

manufacturing (Skoglund, 2015). Digital model is

designed basing on the individual scan (Fig 3 a) and

is “virtually tested” in realistic loading conditions

(Fig. 3b presents the deformation field in the

Ti6Al4V socket during loading with clamped

fixation element- small pyramid in the bottom of the

socket). Sports Tech Research Centre logotype

(stylized letter S) is incorporated into the socket to

illustrate possibilities of artistic touch to the

individualized prosthetic devices.

Today functional prosthetic devices and

individualized equipment are becoming available

and are actively used by many Para-athletes (e.g.

Pallis, 2003, Technology for Disability Sport, 2016).

For many of them only such devices allow them to

compete. Figure 3(d) presents the low leg prosthetic

device successfully used in training and

competitions by Swedish Nordic skier Helene Ripa

(Helene Ripa, 2017). It has relatively simple

(a)

(b)

(c)

(d)

Figure 3: 3D design model for the manufacturing of the individualized prosthetic socket for a knee amputee (a), computed

deformation field during its loading (b) and final component manufactured using EBM technology in Ti6Al4V (c); lower

leg functional prosthesis for the Nordic skier (e).

mechanical construction and incorporates bicycle air

type adjustable shock absorber with some parts in

this first prototype made in Ti6Al4V using EBM

additive manufacturing. According to Helen, this

device allows for the leg movements much closer to

what she has had before the injury. So the engineers

have done a good technical job, but at the time were

lacking the knowledge on the rules and regulations

for competitions by the International Paralympics

Committee (IPC). According to these rules (see IPC

rules for Nordic Skiing) devices like the one shown

in Fig. 3(d) that are directly connected to the ski

bindings are not allowed in the IPC competitions,

the ski shoe must be always present. So the device

was re-designed and manufactured using simpler

and off-shelf components.

4 INJURY PREVENTION

Additive manufacturing is not only actively helping

with medical treatment and rehabilitation, but

becomes an important tool in injury-prevention

research. It is quite important to understand how

injuries happen in order to prevent them. We realize

that the most important part of the scientific method

is the experiment. But experiments leading to

injuries are belonging to a nightmare scenario. Thus

in many cases the only experimental evidence

available for scientists would be the unfortunate

results of an injury or trauma. Modern science has

certain tools that can be used for reconstructing the

events. Mainly this is done using computer-based

modelling. In modern days such modelling often

involves what we call “virtual reality”, allowing to

“perform experiments” that could be dangerous in

real world (or expensive, or lengthy in time, or under

conditions which never exist in real world). Typical

examples of this approach are related to designing

safety devices protecting human body parts from

injuries resulting from the falls or collisions. Modern

medical equipment is capable of producing detailed

scans (high spatial resolution and specificity to the

type of the tissues) of the body parts. Basing on such

scans computer models of corresponding bones, or

of the whole body parts, are made. In case of

damaged body parts it is possible to make virtual

reconstruction of their “intact” state, and model the

conditions that will cause damage we registered

experimentally. One can also generate models of the

body parts together with safety devices and perform

multiple “virtual experiments” assessing the

efficiency of the protection.

Among various devices protecting us in sports

and other activities with the help of mathematical

modelling and additive manufacturing one can find

the ones designed to protect our legs (e.g. Emerson

et al, 2011, 2013), wrists (e.g. Pain et al, 2013, 2015,

Adams, 2016) and heads (Kleiven, 2002, 2006,

Petrone et al, 2010, Samaka et al, 2013, Taha et al,

2013, Smith et al, 2015, Awad et al, 2015, Hassan et

al, 2015, Antona-Makoshi, 2016, Koptyug et al,

2017). But although significant advances are reached

in mathematical modelling there are certain issues

related to it. First of all, any model is to some extent

simplifying the reality. It is both strength of the

modelling process, but in some cases it may be a

weakness: too many details can mask certain key

features; too little details- and we can miss or

misinterpret significant ones. Another problem is

that modelling demands exact input parameters,

which we often either do not know exactly or they

are changing depending on some conditions. For

example, in typical cases of discussed modelling

mechanical properties of human tissues are needed.

Unfortunately, some of these are not known at all,

some are hard to measure, some are nonlinear and

their values depend on multiple parameters. On the

top of that, mathematical models for such objects as

body parts are extremely complex, and in many

cases there is no guarantee that they are actually

correct. Depending on the models one cannot

experimentally test in designing safety equipment is

at least questionable, and here physical modelling is

coming into play. For example, one can model

animal bones mathematically, and perform

laboratory experiments breaking them. By

comparing the results one can adjust the models

making them better (Taha et al, 2013, Awad et al,

2015, Hassan et al, 2015, Koptyug et al, 2017). But

the problem of not exactly known (or dynamically

changing) input parameters still to some extent will

remain with such tests. Situation changes if we can

make “surrogate” body parts made of the synthetic

materials with known properties (with the

parameters “close to the ones of originals”) basing

on the exact geometry retrieved from the real scans

(Payne et al, 2013, Awad et al, 2015, Adams et al,

2016, Koptyug et al, 2017). Additive manufacturing

today easily produces the real size “surrogates” of

the bones replicating them in high precision. It can

also produce various moulds used for casting and

exact replication of the softer tissue shapes. Thus

quite complex realistic physical models of the body

parts are becoming available today. We can use such

surrogates in experiments, comparing the results to

the ones from mathematical modelling. Obviously, it

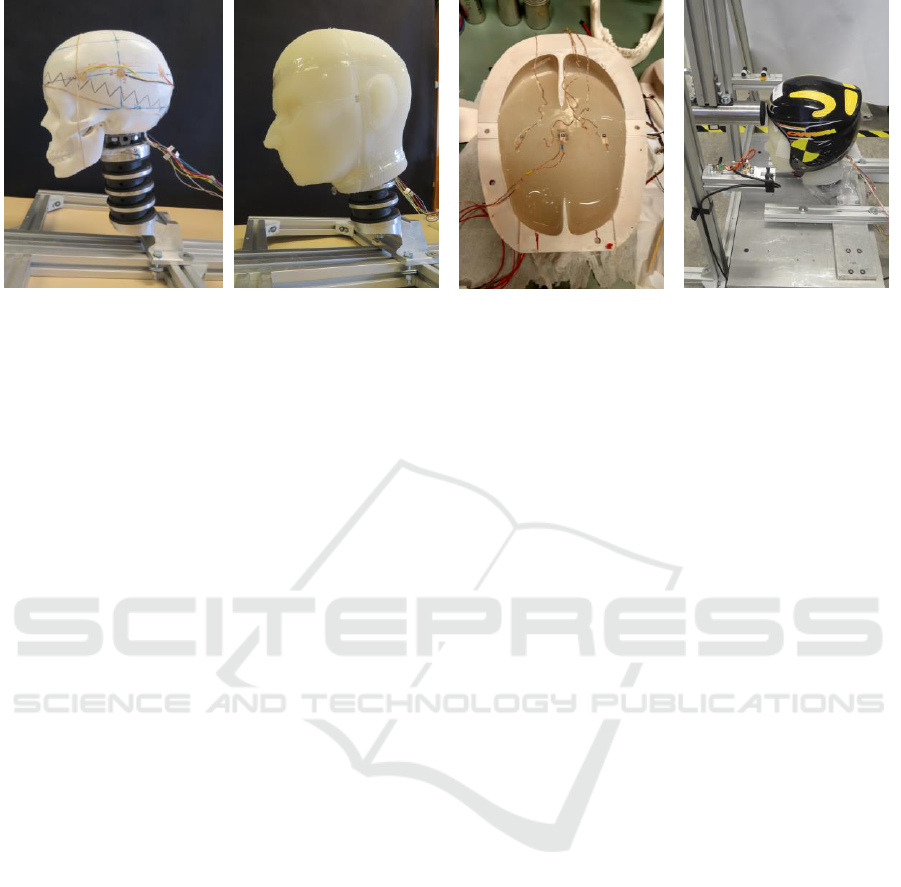

(a)

(b)

(c)

(d)

Figure 4: Surrogate human head with embedded sensors for studying dynamics of the collisions: assembled head on the

hybrid III neck without (a) and with (b) the “soft tissue” in place; mould with partly cast surrogate brain showing sensors

placed in the plane coming through CG point (c); head-neck assembly in the helmet mounted on the impact rig.

is safe to “abuse” surrogate body parts without any

risk to humans. Also, the input parameters for

mathematical modelling will be now exactly known

(or directly measured); geometry will follow actual

body parts and will be exactly transferred into the

model, allowing validating and adjusting our models

and modelling approaches.

Modelling in head injury prevention is used in

similar way (Awad et al, 2015, Koptyug et al, 2017).

Significant improvements in the protection helmet

design are already in place as a direct result of better

understanding how certain impacts can affect the

brain. For example, patented MIPS technology

(MIPS AB, 2017) already implemented in many

helmets, allows to additionally protecting from the

non-central impacts leading to the rotational motions

of the brain and its parts in the cranium and

consequent damage to the axons. But physical

modelling in this research helps to go one step

further. Subjecting the surrogate body parts to

excessive loading and monitoring at the results of

the “injuries” does not bring the full understanding

on how the damage have happened. Embedding

multiple sensors into such surrogates and

reconstructing the dynamics of the events during

surrogate head impacts brings more precise

information (Taha et al, 2013, Awad et al, 2015,

Hassan et al, 2015, Koptyug et al, 2017). Now it also

becomes possible to correlate the values measured

by wearable sensors placed outside the “head” to

what is happening inside it, adding more validity

tothe empirical criteria used by multiple monitoring

devices used in modern sports and training.

An advanced head surrogate with multiple

embed sensors is developed at Mid Sweden

University for studying concussion mechanisms and

ways of better head protection (Fig. 4). It consists of

the anatomically correct scull additively

manufactured from the ABS polymer (Fig. 4a)

surrounded by the surrogate tissue, made from

silicone rubber in additively manufactured mould

(Fig. 4b). Scull hosts a surrogate brain, made from

soft silicone rubber cast in additively manufactured

mould. Scull with the brain inside is filled with

silicone oil, a surrogate of cerebral fluid. Scull,

tissue and brain surrogates were designed basing on

medical 3D scans. Surrogate brain was made in

sequential steps, allowing sensor embedding at

specific positions (Fig. 3c). Two three-axial

accelerometer chips are embedded in the top part of

the brain lobes, three- in the plane coming through

the centre of gravity (CG) plane of the brain (Fig.

4c), and three- in the medial plane of the cerebellum

(“small brain”). Additional three-axis gyroscope

chip is positioned at the CG point, to monitor the

motion of the brain surrogate together with

acceleration sensors. Seven pressure sensors are

placed across the scull at different positions to

monitor changes in the surrogate cerebral fluid

during the impact. Materials were selected to have

properties as close as possible to the “natural” parts

of human anatomy.

Preliminary impact tests carried out using home-

made pendulum type rig (Fig. 3c) indicate that

chosen sensors allow monitoring relative brain

motion in the cranium under impact with a

millisecond time resolution, and pressure sensors

can simultaneously monitor the dynamics of the

cerebral fluid pressure at different locations. Large

amount of data acquired in these experiments is still

analyzed, but qualitative analysis already confirms

that significant rotational motion of the brain as a

whole caused by non-central impacts to the head can

cause significant strain in the axons of the brain

stem. Non-central impacts to the head or head

protection can also cause different movements of the

brain lobes, and rotation of the cerebellum, which

also can present certain danger for brain tissue

damage. At the moment new improved version of

the surrogate head model is under development.

5 TECHNOLOGY

Within the diversity of additive manufacturing

applications for sports and active lifestyle we will

only discuss two examples related to the prototyping

and manufacturing of experimental equipment. It is

clear, that such advantages of the AM and design for

AM as ease of construction alterations, “virtual

tests” of mechanical properties and functionality,

possibility of cost-effective manufacturing polymer

and metallic components of extremely complex

shapes not available with other manufacturing

methods, brings significant benefits for research and

development work in multiple application areas.

Extra dimension is added here by the possibilities of

designing construction elements with embedded

sensors (strain gauges, force and pressure sensors,

accelerometers, gyros etc.) purpose-designed or

substituting original elements of the existing

construction.

Prototyping is a major part of experimental

development of the devices and components based

on new ideas. It is also a critical stage of product

development process in industry. Flexibility, fast

manufacturing of test components implementing

design changes with relatively low cost processes

makes additive manufacturing an ideal support tool

for innovative development. One of the examples

demonstrating such process in action is the

development of novel ski pole handles done initially

as a project within the Mid Sweden University

research environment and later turned into

successful commercial product (Kuzmin Ski

Technology AB, 2017). Measurements performed

during the World Cup biathlon event held in

Östersund indicated that one of the factors slowing

the athlete’s progress through the race is excessive

time spent for taking off ski poles at the shooting

station and putting them back on again. So ideas for

the new ski pole handles for better grip and faster

mounting-dismounting were put forward. Tens of

prototypes in ABS polymer were designed,

additively manufactured and tested in the lab and in

the field. Final design (Fig. 5a-c) incorporates few

innovations, including the pen-like clip on the ski

pole handle and added loop on the inner side of the

glove for fast “connection”, and better positioning of

the thumb over the ski pole top providing better grip

and power transfer in active poling.

Another typical example is development of the

new roller ski design, initially done as a part of the

research project and later turned into a patented

(a)

(b)

(c)

(d)

(e)

Figure 5: Novel design of a ski pole handle: (a) additional loop added to the glove, (b) pencil-like clip is inserted into the

glove loop, (c) thump positioning on the pole handle support element; novel roller ski design: (d) test version with

embedded load cells (d, top) and final version (d, bottom), friction mechanism with slip adjustment (e).

product (Tinnsten et al, 2010, Ainegren et al, 2012,

2013). Many of active skiers complained that

training in summer using roller skis presumes very

different patterns of motion and leg muscle activity

as compared to training in winter (Ainegren et al,

2012, 2013). Cross country skis used in winter have

a camber: free gliding happens with only front and

rear of the ski running surface having the contact

with the snow, and these parts of the ski are covered

with so-called “gliding wax”. To push back in

classic style skiing athlete needs to load the skis

forcing the central part covered with the “grip wax”

getting in contact with the snow. To push back with

traditional roller ski having a ratchet mechanism on

the rollers one only needs backward sliding motion.

Also, with the “winter skis” pushback action

happens with partial slipping depending on the

loading pressure, particular wax type, snow

conditions, ambient temperature and humidity etc.

With the ratcheted roller skis there is almost no

pushback slipping, as the friction between the rubber

roller and road surface is quite high. Two types of

prototype roller skis were manufactured using AM

technology: research ones with embedded load cells

for measurement forces involved, and the ones with

pushback slip action (Fig 5 d-f). New roller skis also

need to be loaded like the “winter” for pushing back,

and the pushback friction (extent of slipping) can

also be adjusted. Extensive tests performed in the

laboratory conditions and in the field indicate that

roller skis of new design much better represent

winter skiing, and feedback given by athletes using

them is very positive.

6 SOME CONCLUSIONS

Some conclusions can already be drawn from our

experiences of using additive manufacturing in

education and research related to sports technology

and active lifestyle. Additive manufacturing can be

successfully used as one of the powerful support

tools enabling the applications not available before,

speeding up development processes in many

different application areas, and even saving lives.

Possibility to utilize significant competitive

advantages of modern AM strongly depend on the

knowledge of corresponding technologies, their

strong points and limitations, and on practice of

designing for AM. Thus incorporating additive

manufacturing into the study programs for all

engineering specialists, including the ones

specializing in sports and active lifestyle related

subjects is quite important. Involvement with

additive manufacturing also helps specialists to be

more innovative, to rethink old design paradigms in

a novel way, to develop new research setups and

methodologies and to design new products. We

believe that the penetration of additive

manufacturing into applications related to sports

technology and active lifestyle will dramatically

increase in the years to come.

ACKNOWLEDGEMENTS

Authors acknowledge the efforts of all people from

Sports Tech Research Centre: without their active

contribution many of the results described in the

paper would not be possible. We also acknowledge

the financial support from Mid Sweden University,

Östersund Municipality, Region Jamtland-

Herjedalen, Swedish Innovation Agency (Vinnova),

Swedish Agency for Economic and Regional

Growth (Tillväxtverket) and Rolf and Gunilla

Enström Foundation for Research and Development

for their contributions to many projects related to

additive manufacturing applications referred to in

present paper.

REFERENCES

Adams, C., James, D., Seniora, T., Allen, T. and

Hamilton, N. (2016). Development of a method for

measuring quasi-static stiffness of snowboard wrist

protectors. Procedia Engineering, 147, pp. 378 – 383.

Ainegren, M., Carlsson, P., Laaksonen, M. and Tinnsten

M. (2012). The influence of grip on oxygen

consumption and leg forces when using classical style

roller skis. Scand J Med Sci Sports, 24(2), pp. 301-

310.

Ainegren, M., Carlsson, P. and Tinnsten, M. (2013).An

experimental study to compare the grip of classical

style roller skis with on-snow skiing. Sports

Engineering, 16(2), pp. 115-122.

Antona-Makoshi, J. (2016). Traumatic Brain Injuries:

Animal Experiments and Numerical Simulations to

Support the Development of a Brain Injury Criterion.

Doctoral Thesis, Chalmers University of Technology,

Gothenburg, Sweden. Download available at:

http://publications.lib.chalmers.se/records/fulltext/235

126/235126.pdf

Awad, N., El-Dakhakhni, W. and Gilani, A. (2015). A

Physical Head and Neck Surrogate Model to

Investigate Blast-Induced Mild Traumatic Brain

Injury. Arab J Sci Eng., 40, pp. 945-958.

doi:10.1007/s13369-015-1583-3

Bibb, R. Eggbeer, D. and Paterson, A. (2014). Medical

Modelling: The Application of Advanced Design and

Rapid Prototyping Techniques in Medicine.

Woodhead Publishing, 516 pages.

Bäckström, M., Tinnsten, M., Koptyug, A., Rännar, L.-E.,

Carlsson, P., Danvind, J. and Wiklund, H. (2013).

Sports technology education at Mid Sweden

University. Procedia Engineering; 60, pp. 214-219

.

Bäckström, M., Rännar, L.-E. and Koptyug, A. (2012).

Spare Parts for Human Body. Science First Hand;

2(44) pp. 44-57. File download available at:

https://www.researchgate.net/publication/313367815_Spar

e_Parts_for_Human_Body

Christensen, A., Lippincott, A. and Kircher, R. (2007). An

Introduction to Electron Beam Melting with Ti6Al4V-

ELI for the Orthopaedic Device Industry. BONEZone;

6, pp 14-17.

Chudinova, E., Surmeneva, M., Koptioug, A., Skoglund,

P. and Surmenev, R. (2016). Additive manufactured

Ti6Al4V scaffolds with the RF-magnetron sputter

deposited hydroxyapatite coating. Journal of Physics:

Conference Series; 669, 012004.

Cronskär, M., Rännar, L.-E., Bäckström, M. and Koptyug,

A. (2008). Application of electron beam melting to

titanium hip stem implants. In: Proc Intl Conference

on Additive Technologies, Vienna, DAAAM

International; p. 1559.

Cronskär, M., Rännar, L.-E. and Bäckström, M. (2012).

Implementation of Digital Design and Solid Free-

Form Fabrication for Customization of Implants in

Trauma Orthopaedics. Journal of Medical and

Biological Engineering; 32(2), pp. 91-96.

Cronskär, M., Bäckström, M. and Rännar, L.-E. (2013).

Production of customized hip stem prostheses – a

comparison between conventional machining and

electron beam melting (EBM). Rapid Prototyping

Journal; 19(5), pp.365-372.

Cronskär, M. and Bäckström M. (2013). Modeling of

fractured clavicles and reconstruction plates using

CAD, finite element analysis and real musculoskeletal

forces input. WIT Transactions on Biomedicine and

Health; 17, pp. 235 - 243.

Cronskär, M. (2014). Mid Sweden University Doctoral

Thesis 191: On customization of orthopedic implants -

from design and additive manufacturing to

implementation. Mid Sweden University, Sweden

http://miun.diva-

portal.org/smash/get/diva2:745912/FULLTEXT01.pdf

Emerson, N., Carré, M., Reilly, G. and Offiah, A. (2011).

Geometrically accurate 3D FE models from medical

scans created to analyse the causes of sports injuries.

Procedia Engineering; 13, pp. 422-427.

Emerson, N., Carré, M., Reilly, G. and Offiah, A. (2013).

Simulation based upon medical data offers a fast and

robust method for the prediction of fracture risk.

Procedia Engineering; 60, pp.459 – 466.

Emerson, .N., Offiah, A., Reilly, G. and Carré, M. (2013).

Patient-specific finite element modelling and

validation of porcine femora in torsion. Strain; 49 (3),

pp. 212-220.

Fera, M., Fruggiero, F., Lambiase, A. and Macchiaroli, R.

(2916). State of the art of additive manufacturing:

Review for tolerances, mechanical resistance and

production costs. Cogent Engineering; 3: 1261503, 16

pages.

Ganesan, B., Al-Jumaily, A. and Luximon, A. (2016). 3D

Printing Technology Applications in Occupational

Therapy. Phys Med Rehabil Int.; 3(3), pp. 1085-1088.

Hassan, M.H.A. and Taha, Z. (2015). Finite Element

Analysis of Soccer Heading. Procedia Engineering,

112, pp. 46–51.

Heinl, P., Müller, L., Körnera, C., Singera, R. and Müller,

F. (2008). Cellular Ti–6Al–4V structures with

interconnected macro porosity for bone implants

fabricated by selective electron beam melting. Acta

Biomaterialia; 4(5), pp. 1536–1544.

Helene Ripa (2017),

https://en.wikipedia.org/wiki/Helene_Ripa

Huiskes, R., Weinans, H. and van Rietbergen B. (1992).

The relationship between stress shielding and bone

resorption around total hip stems and the effects of

flexible materials. Clin Orthop Relat Res.; 274,

pp.124-34.

IPC regulations on Nordik Skiing,

https://www.paralympic.org/nordic-skiing/rules-and-

regulations

Jina, Y., Plotta, J., Chena, R., Wensmanc, J. and Shih, A.

(2015). Additive Manufacturing of Custom Orthoses

and Prostheses – A Review. Procedia CIRP; 3,6 pp.

199 – 204. Available online at

http://www.sciencedirect.com

Kleiven, S. and Hardy, W. (2002). Correlation of an FE

Model of the Human Head with Local Brain Motion –

Consequences for Injury Prediction. Stapp Car Crash

Journal, 46, pp. 123-144.

Kleiven, S. (2006). Evaluation of head injury criteria using

a finite element model validated gainst experiments on

localized brain motion, intracerebral acceleration, and

intracranial ressure

International Journal of Crashworthiness, 11(1), pp 65-79.

Koptyug, A., Rännar, L.-E., Bäckström, M. and Klingvall,

R. (2012). Electron Beam Melting: Moving from

Macro- to Micro- and Nanoscale. Materials Science

Forum; 706-709, pp. 532-537.

Koptyug, A., Rännar, L.-E., Bäckström, M., Franzén, S.

and Dérand, P. (2013). Additive Manufacturing

Technology Applications Targeting Practical Surgery.

Int. J. Life Science and Medical Research; 3(1), pp.15-

24.

Koptyug, A., Rännar, L.-E., Bäckström, M. and Langlet,

A. (2013). Bulk Metallic Glass Manufacturing Using

Electron Beam Melting. In: Proc. International

Conference on Additive Manufacturing & 3D Printing,

Nottingham; July 9-10

Koptyug, A., Bergemann, K., Lange, R., Jaggi, V.-E.,

Rännar, L.-E. and Nebe B. (2014). Osteoblast

Ingrowth into Titanium Scaffolds made by Electron

Beam Melting. Materials Science Forum; 783-786, pp.

1292-1297.

Koptyug, A., Rännar, L.-E., Bäckström, M. and Cronskär,

M. (2014). Additive Manufacturing for Medical and

Biomedical Applications: Advances and Challenges.

Materials Science Forum; 783-786, pp.1286-1291.

Koptyug, A., Rännar, L.-E., Bäckström, M. and

Surmenev, R. (2017). Additive manufacturing in

metal: advances generate new research challenges.

Nanotehnology: development and applications in XXI

century; 8(4), pp. 12-36.

Koptyug, A., Rännar, L.-E., Bäckström, M. and Shen, Z.

(2017). New metallurgy of Additive Manufacturing in

Metal: Experiences from the Material and Process

Development with Electron Beam Melting

Technology (EBM). Materials Science Forum; 879,

pp. 996-1001.

Koptyug, A., Bäckström, M. and Petrone, N. (2017).

Developing an Instrumented Physical Model of the

Human Head for Studying Concussion Mechanisms.

Proc. 22nd Congress of the International Society for

Skiing Safety, Innsbruck, April, 17 – 22 2017, p. 81.

Kuzmin Ski Technology AB (2017)

http://www.kuzmin.se/pgs/skiing_en.html

MakerBot Industries, LLC (2017)

https://www.makerbot.com/products/3d-printers/

Mills, D. (2015). Future Medicine: The Impact of 3D

Printing. J Nanomater Mol Nanotechnol 4:3.

MIPS AB, http://www.mipsprotection.com/

Murr, L,. Gaytan, S., Medina, F., Lopez, H., Martinez, E.,

Machado, B., Hernandez, H., Martinez, L., Lopez, M.,

Wiker, B. and Bracke, J. (2010). Next-generation

biomedical implants using additive manufacturing of

complex, cellular and functional mesh arrays”, Phil.

Trans. Roy. Soc. A; 368, pp. 1999-2032.

Niinomi, M. and Nakai, M. (2011). Titanium-Based

Biomaterials for Preventing Stress Shielding between

Implant Devices and Bone. Intl. J. Biomater.; 2011,

Article ID 836587.

Pallis, J. Materials in Paralympic Sports. Chapter 14, in:

Materials in Sports Equipment, Volume 1. Ed. Mike

Jenkins, Elsevier, 2003 - Technology & Engineering -

424 pages

Palousek, D., Rosicky, J., Koutny, D., Stoklasek, P. and

Navrat, T. (2014). Pilot study of the wrist orthosis

design process. Rapid Prototyping Journal; 20(1), pp.

27-32.

Pauly, S., Löber, L., Petters, R., Stoica, M., Scudino, S.,

Kühn, U., and Eckert J. (2013). Processing metallic

glasses by selective laser melting. Materials Today;

1(1-2), pp. 37-41.

Payne, T., Mitchell, S. and Bibb, R. (2013). Design of

human surrogates for the study of biomechanical

injury: a review. Critical Reviews in Biomedical

Engineering; 41 (1), pp. 51-89.

Payne, T., Mitchell, S., Halkon, B.; Bibb, R. and Waters,

M. (2015). Development of novel synthetic muscle

tissues for sports impact surrogates. J. Mechanical

Behavior of Biomedical Materials; 41, pp. 357-374.

Petrone, N., Tamburlin, L., Panizzolo, F. and Atzori, B.

(2010). Development of an instrumented

anthropomorphic dummy for the study of impacts and

falls in skiing. Procedia Engineering, 2(2), pp.2587-

2592.

Samaka, H. and Tarlochan, F. (2013). Finite Element (FE)

Human Head Models / Literature Review. Intern. J. of

Sci. Tech. Research, 2(7), pp. 17-21.

Sames, W., List, F., Pannala, S., Dehoff, R and Babu, S.

(2016). The metallurgy and processing science of

metal additive manufacturing. International Materials

Reviews; 6 (5), pp. 315-360.

Skoglund, P. (2915). Prosthetic socket in Titanium, Mid

Sweden University Master Thesis. Download

available at: https://www.diva-

portal.org/smash/get/diva2:901421/FULLTEXT01.pdf

Smith, T., Halstead, P., McCalley, E., Kebschull, S.,

Halstead, S. and Killeffer, J. (2015) Angular head

motion with and without head contact: implications for

brain injury. Sports Engineering, 18(3), pp. 165-175.

Special issue: Technology for Disability Sport. (2016).

Sports Engineering; 9(3); Eds. Koptyug, A., Burkett,

D. pp 139.

Stratasys Ltd. (2017) http://www.stratasys.com/3d-

printers

Sumner, D. (2015). Long-term implant fixation and stress-

shielding in total hip replacement. J Biomech.; 48(5),

pp. 797-800.

Surmenev, R., Surmeneva, M. and Ivanova, A. (2014).

Significance of calcium phosphate coatings for the

enhancement of new bone osteogenesis–A review.

Acta biomaterialia; 10 (2), pp. 557-579.

Surmeneva, M., Chudinova, E., Syrtanov, M., Koptyug, A.

and Surmenev, M. (2015). Investigation of the HA

film Deposited on the Porous Ti6Al4V Alloy Prepared

via Additive Manufacturing. IOP Conference Series:

Material Science and Engineering; 98, 012025.

Taha, Z., Hassan, M., Aris, M. and Anuar, Z. (2013).

Predicting brain acceleration during heading of soccer

ball. IOP Conf. Series: Materials Science and

Engineering, 50(1), 012023.

Tinnsten, M., Peter Carlsson, P., Ainegren, M., and

Sandberg, S. (2010). Arrangement for a roller ski and

a roller ski. European patent EP 2418006.

Zadpoor, A. and Malda, J. (2917). Additive Manufacturing

of Biomaterials, Tissues, and Organs. Annals of

Biomedical Engineering; 45(1), pp. 1–1.

Zhong, Y., Rännar, L.-E., Liu, L., Koptyug, A., Wikman,

S., Olsén, J., Cui, D. and Shen, Z. (2017) Additive

manufacturing of 316L stainless steel by electron

beam melting for nuclear fusion applications. Journal

of Nuclear Materials; 486, pp. 234-245.

Zhong, Y., Rännar, L.-E., Wikman, S., Koptyug, A., Liua,

L., Cui, D. and Shen, Z. (2017). Additive

manufacturing of ITER first wall panel parts by two

approaches: Selective laser melting and electron beam

melting. Fusion Engineering and Design; 116, pp. 24–

33.