Towards an Integrated Architecture Model of

Smart Manufacturing Enterprises

Thijs Franck

1

, Maria-Eugenia Iacob

2

, Marten van Sinderen

2

and Andreas Wombacher

1

1

Wipro Technologies, Eindhoven, The Netherlands

2

Centre for Telematics and Information Technology, University of Twente, Enschede, The Netherlands

{thijs.franck, andreas.wombacher}@wipro.com, {m.e.iacob, m.j.vansinderen}@utwente.nl

Keywords: ArchiMate 3.0, Enterprise Architecture, ISA-95, Smart Manufacturing, Industry 4.0.

Abstract: With the introduction of smart manufacturing, the scope of IT expands towards physical processes on the

shop floor. Enterprise architects, software engineers and process engineers will have to work closely together

to build the information systems that are connected to the shop floor and aligned with the business needs of

smart manufacturers. However, it is unclear whether they have the means to do so. This research aims to

provide enterprise architecture modelling support for smart manufacturers by investigating ArchiMate 3.0’s

fitness for this purpose. ArchiMate 3.0 meta-model is compared to the ISA-95 standard for enterprise systems

and control systems integration. Modelling patterns are introduced, along with some new modelling concepts,

to compensate for deficiencies found. The patterns proposed are validated as part of a case study.

1 INTRODUCTION

Manufacturing companies worldwide are facing the

need to improve productivity and quality, as well as

implement new products, while shortening

innovation cycles. To this end, the manufacturing

industry is currently in the process of adopting the

new Smart Manufacturing paradigm, also known as

the Industry 4.0 paradigm. Smart Manufacturing

promises smart machine line operations, high-fidelity

models of production processes and improved

decision-making support (Davis et al., 2005).

For the benefits of Smart Manufacturing to

materialize, manufacturers will need some way to

maintain alignment between their business needs and

the information systems that permeate increasingly

through all levels of their operations (Henderson and

Venkatraman, 1993, Wagner and Weizel, 2006).

Maintaining alignment between a company’s strategy

(the business domain) and its supporting IT is one of

the main benefits of enterprise architecture (EA)

(Boucharas et al., 2010).

The management of processes at the shop floor

and the systems used to operate the industrial control

devices have traditionally fallen under the Operations

Technology (OT) domain of process engineers. As

OT increasingly starts to overlap with IT, it makes

sense to consider the physical domain from an IT

perspective. As a result, the dichotomy between IT

and OT fades, in favour of a single EA for the

manufacturing domain.

To make this integration between business, IT and

OT successful, enterprise architects and process

engineers must have a shared modelling language that

can express all concepts required for modelling the

EA of the manufacturing domain. One of the major

requirements introduced by Smart Manufacturing is

the modelling of cyber-physical systems (ISCPS).

CPS is a type of information system that integrates

computational and physical processes and allows

these processes to interact (Lee, 2008). For example,

an oven may report real time its temperature curve. If

this curve is sub-optimal, the oven wastes energy.

Such an insight could be used as input for operational

excellence programs, or preventive maintenance.

The modelling of such systems will involve not

just viewpoints and concepts related to applications

and IT infrastructure, but also to the physical

environment (i.e., conditions on the shop floor)

(Sacala and Moisescu, 2014).

For this research, we adopt the international open

standard ArchiMate as our EA modelling language of

choice. The most recently published version of the

standard, ArchiMate 3.0 (The Open Group, 2016),

already includes several concepts for modelling the

physical environment of enterprises. Being a new

61

release, however, it has not been seriously validated

or applied in the manufacturing domain.

To ensure that ArchiMate enables the modelling

of a smart manufacturer’s EA, the standard needs to

be validated for that particular purpose. We adopt a

process framework and a common object model

published as part of the standards suite ANSI/ISA-95

(ISA, 2010a, ISA, 2010b) (alternatively, ISO/IEC

62264), or ISA-95 for short, to represent the

manufacturing domain. The ISA-95 common object

model (ISA, 2010b) describe entities at the shop floor

level, where IT and OT interact, whereas the ISA-95

process framework describes exactly this interaction.

Conversely, while ISA-95 describes the physical

domain, it does not describe the business or IT

domains very well, nor was it intended to model EAs

in the first place. Thus, to be capable of modelling the

EA of a smart manufacturer, ArchiMate 3.0’s meta-

model needs to be able to express all architectural

concepts from ISA-95. To that end, this paper tries to

answer the following questions:

RQ1. To what extent can ArchiMate 3.0 express

the EA of any smart manufacturer per ISA-95?

RQ2. If ArchiMate 3.0 cannot fully express the EA

of any smart manufacturer per ISA-95, what changes

to the meta-model of ArchiMate 3.0 are necessary to

make this possible?

Thus, the contribution of this research concerns an

analysis of whether the meta-model of ArchiMate 3.0

is expressive enough to model an EA in the

manufacturing domain. Secondly, we propose a set of

modelling patterns describing how ISA-95 concepts

can be expressed in ArchiMate. These patterns can be

simple direct mappings, or may involve a grouping of

Archimate concepts. Finally, to enhance ArchiMate’s

expressiveness and enable the modelling of certain

smart manufacturing concepts some change

suggestions are made.

The remainder of the paper is organised as

follows. In Section 2 we explain the methodology we

followed to define a mapping from ISA-95 to

ArchiMate, and to analyse the expressiveness of

ArchiMate. Section 3 describes the results of the

analysis, and contains the main contribution of the

paper. Section 4 gives an account of how we validated

our findings. We conclude the paper with a discussion

of the related work in Section 5 and with conclusions

and some pointers to future work in Section 6.

2 METHODOLOGY

To define a mapping from ISA-95 to ArchiMate and

answer research questions, we followed a four-step

approach. Firstly, we derived a subset of architectural

concepts from the concepts defined by ISA-95. ISA-

95 was written with IT/OT integration in mind. To

apply its concepts to architecture modelling, an

assessment is necessary to find out which concepts

qualify as architectural. For this assessment, the same

criteria that were used to define the current set of

concepts in ArchiMate are applied to each concept in

ISA-95. These criteria are explained in section 3.1.

Secondly, we make a comprehensive mapping of

the architectural ISA-95 concepts onto ArchiMate

3.0. Criteria used for the mapping are the similarity of

concept definitions, as well as similarity of direct

relationships to other concepts (depth = 1).

Thirdly, the ArchiMate’s expressiveness

concerning the smart manufacturing domain is

investigated by identifying semantic deficiencies in

terms of the types defined by Wand & Weber (2002)

(see Section 3.3). We assume that the ISA-95

common object model is a complete representation of

entities at the shop floor level. Given our goal of

representing this same domain in ArchiMate 3.0, the

ISA-95 common object model should fully map onto

ArchiMate 3.0. Whether ISA-95 can fully express

ArchiMate is not of interest. Thus, we only consider

deficiencies of type construct overload, where several

ISA-95 constructs map to one ArchiMate construct,

and type construct deficit, where an ISA-95 construct

does not map to any ArchiMate construct.

The deficiencies identified are subsequently

analysed and, if necessary, addressed. In the case of

construct overload, an assessment is made concerning

critical expressiveness loss as result of the higher

abstraction level. In the case of construct deficit, it

must be determined whether the intended meaning of

the ISA-95 concept can be expressed using a

combination, or ‘pattern’, of constructs currently

present in ArchiMate 3.0’s meta-model. If the current

meta-model is found insufficiently expressive, we

suggest a pattern that includes new constructs (i.e.,

new relationships or concepts).

Finally, the identified patterns are validated as

part of a case study at SteelCorp. The validation aims

to prove the usefulness of the patterns in modelling

the EA of a manufacturer, as well to demonstrate the

usefulness of such a model through two common

manufacturing use cases: an impact of change

analysis and an operational excellence analysis.

3 ANALYSIS

The results of several parts of the analysis have been

summarized in a spreadsheet (from here on referred

Seventh International Symposium on Business Modeling and Software Design

62

to as ‘the spreadsheet’) which is made available

online via http://bit.ly/2amGJqi.

3.1 Excluding Non-Architectural

Concepts from ISA-95

To determine the architectural concepts in the ISA-95

common object model, it is necessary to perform a

‘normalization’ of the ISA-95 concepts to a level of

abstraction that coincides with that of ArchiMate

concepts. The criteria for normalization are the same

as those originally used to determine the ArchiMate

concepts. ArchiMate uses for this a layered structure

(Lankhorst et al., 2010). Starting at the lowest

specialization level, concepts are simply highly

abstract entities and their relationships. At the next

level, concepts are specialized as either passive

structure concepts, behaviour concepts or active

structure concepts, corresponding to the basic

structure of the ArchiMate language (dynamic system

level). Concepts are then further specialized as EA

concepts used to design architecture models.

ArchiMate defines implementations of concepts in

architecture models as its lowest level of abstraction.

At each specialization step, the utility of the

specialization must be argued based on the modelling

goals that the modeller has in mind. Following this

structure, any ISA-95 concept that is architectural

will need a specialization relationship to one of the

concept types at ArchiMate’s dynamic system level.

The concepts at the dynamic system level are defined

as follows (Table 1):

Table 1: Dynamic System Level Concept Types (Lankhorst

et al., 2010).

Concept type Description

Active Structure

Concept

An entity that is capable of performing

behaviour

Behaviour

Concept

A unit of activity performed by one or

more active structure elements

Passive Structure

Concept

An object on which behaviour is

performed

By eliminating all ISA-95 concepts that do not

have a specialization relationship to one of these

concepts, we end up with a normalized set of

architectural concepts. The normalization analysis

reveals that 66% of ISA-95 concepts are architectural.

The remaining 33% are non-architectural. For

example, ‘person’ qualifies as architectural concept

since a person can perform behaviour. Properties

describing that person are non-architectural concepts.

To review specifically which concepts classify as

architectural, please refer to the spreadsheet.

3.2 Mapping ISA-95 to ArchiMate 3.0

To define a mapping from ISA-95 concepts to

ArchiMate we follow a two-step approach: Firstly,

for each architectural ISA-95 concept, a comparison

is made between its definition and the definition of

every ArchiMate concept. Secondly, if there is a fit

with one or more definitions, a further comparison is

made. In this comparison, each direct relationship

(depth=1) of the ISA-95 concept is compared to each

of the concepts directly surrounding the ArchiMate

concept. This includes both the definition of the

surrounding object and the definition of the

connecting relationship. If these relationships are also

in alignment, an ISA-95 concept maps to ArchiMate.

For 12% of ISA-95’s architectural concepts the

mapping to ArchiMate concepts is straightforward.

75% can be fit based on definition, but have one or

more relationships that cannot be mapped. Finally,

13% of the concepts cannot be matched based on their

definition. For an exact specification of the ISA-95

concepts that can be mapped onto specific ArchiMate

3.0 concepts, please refer to the spreadsheet.

N-to-M mappings

In some cases, it turns out that that several concepts

from ISA-95 map to several other concepts from

ArchiMate. These mappings are ambiguous, causing

uncertainty with regards to which concept to use.

According to the mapping, several concepts would be

correct. These n-to-m mappings need to be addressed

before moving forward. Particularly, this concerns

the following two mapping scenarios.

Process Segment:

Process Segment, Process Segment Dependency,

Operations Segment, Operations Segment Dependency

Map to

Business Process, Business Function, Business

Interaction, Business Event

There appears to be an n-to-m mapping in this

scenario. However, strictly comparing the definitions

of the ISA-95 concepts, as well as the relationships

they share to surrounding concepts (depth = 1), the

ISA-95 concepts turn out to be synonymous. This

resolves the n-to-m mapping to concept redundancy,

which will be addressed in section 3.3. This case shall

be further referred to as Process Segment.

Equipment:

Equipment Class, Equipment

Map to

Business Role, Location, Equipment, Facility

In this second scenario, Equipment and

Equipment Class are not synonymous per the ISA-95

meta-model. However, given that ArchiMate does not

distinguish between classes and instances, Equipment

Class and Equipment can safely be abstracted to mean

Towards an Integrated Architecture Model of Smart Manufacturing Enterprises

63

the same thing. This, again, resolves the n-to-m

mapping to concept redundancy, which will be

further discussed in section 3.3. This case shall be

further referred to as Equipment.

3.3 Classifying Deficiencies in

ArchiMate 3.0

Based on the previously established mapping of ISA-

95 onto ArchiMate, several deficiencies in ArchiMate

3.0 can be identified. Classifying each deficiency will

help find a suitable solution at a later stage. Four types

of deficiency exist (Wand and Weber, 2002). Table 2

describes each type.

We assume that the ISA-95 common object model

is a complete representation of the entities on the shop

floor. Thus, if ArchiMate is capable of modelling the

EA of a smart manufacturer, its meta-model should

be capable of expressing ISA-95. Based on this

analysis, several cases of construct overload, as well

as construct deficit, are uncovered. The following

sections discuss the occurrences of each type.

Table 2: Types of deficiencies (Wand and Weber, 2002).

Type Descri

p

tion

Construct

overload

Several ontological constructs map to

one grammatical construct

Construct

redundanc

y

Several grammatical constructs map to

one ontolo

g

ical construct

Construct

excess

A grammatical construct might not

ma

p

to an

y

ontolo

g

ical construct

Construct

deficit

An ontological construct might not

map to any grammatical construct

Cases of construct overload

Construct overload (i.e., more ISA-95 concepts

map onto one ArchiMate 3.0 concept) occurs in the

case of the following ArchiMate concepts:

Business Object is used to represent information

objects that are used on the shop floor and may serve

as a placeholder for more complex entities like a

schedule or a bill of materials. Specifically, Table 3

describes the objects that map to Business Object.

Where a business object is used, the model will

depend on relationships to other entities to provide

the expressiveness needed to model the meaning that

the user intends. If this level of expressiveness cannot

be achieved, this causes a construct deficit.

Business Role - Personnel Class and Equipment

map to Business Role. This happens specifically in

the case where Equipment refers to an automated

production unit. This abstraction loses the direct

distinction between a manual and an automated role.

However, depending on whether a given role depends

on an actor or not, this distinction can still be derived.

Material - Material Class, Material Definition,

Material Lot and Material Sublot map to Material in

ArchiMate. Because of this, the distinction between a

class of material and a specific type of material used

as part of a process is lost. Furthermore, the difference

between a class of material and an identifiable (group

of) its instances is also lost.

Table 3: Construct overload to Business Object.

Qualification Test

Specification

Operations Material Bill

Equipment Capability Test

Specification

Personnel Specification

Physical Asset Capability

Test Specification

Equipment

Specification

Material Test Specification Physical Asset

Specification

Material Assembly Material Specification

Material Definition

Assembly

Material Specification

Assembly

Material Class Assembly Operations Schedule

Personnel Segment

Specification

Segment Requirement

Equipment Segment

Specification

Personnel Requirement

Material Segment

Specification

Equipment Requirement

Material Segment

Specification Assembly

Physical Asset

Requirement

Physical Asset Specification Material Requirement

Cases of construct deficit

Several deficits have been identified as part of the

mapping analysis. When a deficit occurs, the ISA-95

concept cannot be expressed in ArchiMate. Each

deficit is explained in the paragraphs below.

Test Specifications - Various concepts in ISA-95

are related to a test specification that is used to test

certain properties of said concepts. A Test

Specification maps to a Business Object. The

ArchiMate meta-model only allows for an association

relationship between Active Structure concepts and a

Business Object. The dependency in ISA-95 is,

however, stronger (<is tested by>).

Assemblies - An assembly is a collection or set of

related elements. In ISA-95, they are represented as

classes related to aggregation relationships between

elements. In ArchiMate, every element can also have

an aggregation relationship with an element of the

same type. There is, however, no class that represents

information about this relationship.

Process Segment Parameters - A process

segment (maps to business process) in ISA-95 is a

collection of several concepts, including specific

parameters that do not fall into the category of

personnel, equipment, physical asset or material. The

Seventh International Symposium on Business Modeling and Software Design

64

‘other’ parameters are known as process segment

parameters. ArchiMate allows only well-defined

concepts to be related to a business process.

Material Lots - While an ISA-95 Material can be

directly mapped to an ArchiMate material, a problem

occurs when attempting to map a Material Lot. A

requirement for a Material Lot is that it should be

possible to determine its current state based on the lot

ID. This requires traceability to an information object,

i.e., a Business Object. While it is possible to relate

a Material Lot to a Business Object through an

association, the relationship between a physical and

an information object is deemed more meaningful.

Operations Definitions - The operations

definition describes the relation between a

production, maintenance, inventory or quality

operation, the way in which it is implemented and the

resources that are needed. A framework for these

kinds of manufacturing operations is defined by the

first part of ISA-95 (International Society of

Automation, 2010a). ArchiMate only loosely defines

business processes, independent of their context.

Operations Schedule - ISA-95 defines a schedule

concept. It is implemented as a set of operations

requests, which directly relate to an operations

definition. There is no similar concept in ArchiMate.

Operations Performance - ISA-95 makes a

distinction between the definition of a process, the

planned process and the actual process. Once

executed, Operations Responses are returned for

every Operations Request (which make up the

schedule). In ArchiMate, an Operations Response can

be represented as either a Business Object or Data

Object, depending on whether this information is

collected digitally or not. The actual production

information is, however, much too volatile to model

as part of the architecture.

3.4 Addressing the Deficiencies Found

Now that several deficiencies have been identified,

solutions can be defined that allow ArchiMate to

express all the architectural concepts in ISA-95, thus

making the language suited to model the shop floor

and, by extension, the EA of a smart manufacturer.

The solutions to the deficiencies identified will be

discussed below as modelling patterns. A pattern is a

set of constructs from ArchiMate that expresses a

certain aspect of ISA-95. Preferably, only existing

constructs will be included in these patterns. If a new

construct must be introduced, it will conform to the

requirements for constructs in ArchiMate (The Open

Group, 2016). The following paragraphs discuss the

solutions per deficiency.

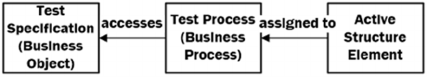

Test Specifications

Various concepts in ISA-95 are related to a test

specification that is used to test certain properties of

said concepts. Often, these concepts are mapped to

active structure concepts in ArchiMate. For example,

a Person (maps to Actor) relates to a Qualification

Test Specification (maps to Business Object). A

Business Object is, however, a passive structure

concept. The ArchiMate meta-model only allows for

an association relationship between Active Structure

concepts and a Business Object. As discussed in

section 3.3, we must rely on the context of the

ArchiMate model to define the meaning of a Business

Object. For a Test Specification, which has a very

specific purpose in ISA-95, we deem an association

relationship insufficient, since this association

without context can be interpreted in many ways.

A stronger relationship (van Buren et al., 2004)

between an Active Structure concept and a Business

Object can only be established via a Behaviour

concept, specifically the assigned to relationships (for

Active Structure concepts) and access relationships

(for Business Objects) to Business Service, Business

Event and Business Process.

Since relationships from the physical layer are

only allowed to Business Process, Business Function

and Business Interaction (and not Business Service or

Business Event), this leaves Business Process as the

only option. Given this limitation, we define the Test

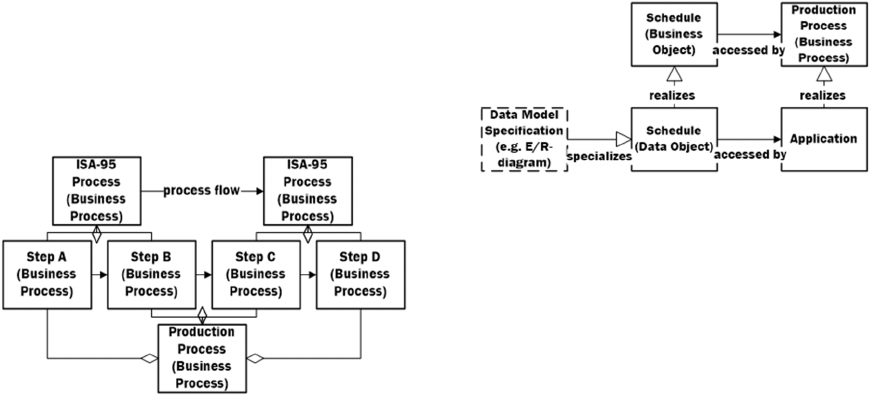

Specification Pattern as shown in Figure 1.

Figure 1: Test Specification Pattern for ArchiMate 3.0

.

Assemblies

An assembly is a collection or set of related

elements. In ISA-95, they are represented as classes

related to aggregation relationships between

elements. In ArchiMate, every element can also have

an aggregation relationship with an element of the

same type. There is no class that represents

information about this relationship. For example, to

express the size of an assembly in ArchiMate, it

would be necessary to model an entity for each

element in the collection. This makes sense in a

scenario where each instance of a class is

meaningfully different. For example, since every

person has different qualifications, it is meaningful to

model people separately as part of a team. However,

in the case where the elements of a collection are not

meaningfully different, e.g. a set of materials used for

the production of a batch (bill of materials), it makes

more sense to model each material as a class rather

than as separate instances. When modelling only a

class, however, the quantity of the material used for

the production of e.g. a batch is still meaningful

information. Both alternatives below present a

Towards an Integrated Architecture Model of Smart Manufacturing Enterprises

65

solution that makes use of a parameter to a

relationship to express meaning. Such a pattern can

also be used to express the Operations Material Bill

Item concept per ISA-95.

Figure 2: Implicit Bill of Materials pattern for ArchiMate.

Alternative 1

To model such information relevant to an

assembly, parameters for the relationship between the

class (e.g. a material) and the assembly (e.g., a bill of

materials) is proposed. While ISA-95 defines

assemblies broadly, in the specification they only

occur in relation to materials. A placeholder mapping

for assembly would be a business object. Currently,

there exists an indirect relationship between Business

Object and Material through Business Process. The

information relevant to an assembly could be attached

to the relationship between Material and Business

Process as a (set of) parameter(s).

Alternative 2

Figure 3: Explicit Bill of Materials pattern for ArchiMate.

This implementation eliminates the need for a

separate Business Object by modelling the bill of

materials implicitly through the set of relationships

between said Business Process and the Materials

used. Figure 2 illustrates the proposed pattern.

However, the solution presented in alternative 1

does not allow for a bill of materials to be modelled

explicitly. A bill of materials is quite common in

manufacturing, so the capability to include this

concept explicitly may be desirable. To do so, a direct

relationship between Business Object and Material is

necessary. An association relationship is currently

available between Material and Business Object.

However, as explained in section 3.3, we feel that the

use of an association relationship in this case is not

sufficiently expressive.

Instead, an aggregation relationship is proposed.

An aggregation relationship indicates that a concept

(the bill of materials) groups a number of other

concepts (materials). While Materials are meaningful

independent of one another, the bill of materials

groups them for the purposes of use in a production

process.

The proposed parameters would be attached to

this relationship. This solution is, however, not

perfect either. The relationship between Business

Object and Material makes the relationship between

Business Process and Material redundant, since the

Bill of Materials will always be related to a

production process (Business Process).

Figure 3 shows a pattern for the modelling of an

explicit bill of materials. There are two major

differences between this pattern and the pattern for an

implicit bill of materials. Firstly, this pattern includes

a Business Object that denotes the bill of materials.

This Business Object is related to the Business

Process via an access relationship. This relationship

currently exists in ArchiMate. The bill of materials

lists one or more Materials via an aggregation

relationship. This aggregation relationship is newly

introduced for this purpose. Secondly, the

information describing the assembly is related to the

aggregation relationship between Material and

Business Object, as denoted by the dotted line.

Process Segment Parameter

A process segment (maps to business process) in

ISA-95 is a collection of several concepts, including

specific parameters that do not fall into the category

of personnel, equipment, physical asset or material.

The ‘other’ parameters are known as process segment

parameters. For a production process, an example

might include the known lead time of a process step

(e.g. the steel coil needs to be in the oven for 10

minutes). For a quality process, a parameter might be

the size of the sample to be pulled (e.g., 1 coil).

ArchiMate allows only well-defined concepts to

be related to a business process. The only concepts

that fit with the description of Process Segment

Parameter (i.e. related to business process and not a

person, equipment or material) are Business Service

and Business Event (behaviour), or Business Object

(passive structure). A timer like in the oven example

would typically be modelled as an event, but a

parameter like sample size cannot be expressed

formally in ArchiMate. If needed, such information

can be included as part of the sub-process name (e.g.

take a quality sample, size 1). Modelling this

information as such works as a way to capture it

Seventh International Symposium on Business Modeling and Software Design

66

informally, e.g. for presentation purposes. However,

for analysis purposes, a more formal approach will be

required, since information stored in a concept name

cannot be queried easily.

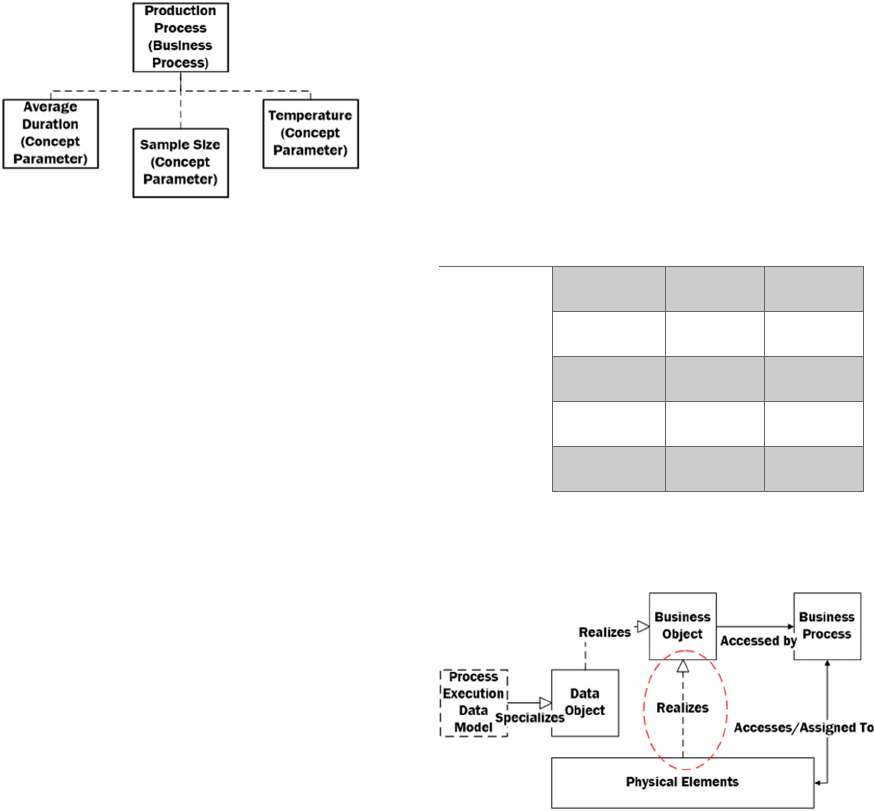

Figure 4: Process Parameter pattern for ArchiMate 3.0.

The proposed solution is to introduce parameters

related to a business process. This is similar to the

solution introduced to model assemblies, with the

difference being that the parameters are related to a

concept rather than a relationship. Examples of

parameters are average duration, sample size or

temperature. This parameter pattern can also be used

to model other manufacturing object parameters, per

the ISA-95 object properties. The parameter pattern

for concepts is illustrated in Figure 4.

Material Lot

While an ISA-95 Material can be directly mapped

to an ArchiMate Material, a problem occurs when

attempting to map a Material Lot. The current state of

a Material Lot should be accessible via its ID. This

requires traceability to an information object, i.e. a

Business Object. It is possible to associate a Material

with a Business Process and a Business Object with a

Business Process. It is even possible to draw an

association between Material and Business Object. In

the case of a Material Lot, however, the relationship

between Physical Object and Information Object is

more meaningful than an association. The

relationship should describe how the informational

object reflects the state of the physical object it

represents.

To add this expressiveness, a realization

relationship is proposed. A realization relationship

links a logical entity with a more concrete entity that

realizes it. Thus, a realization relationship could

describe how a physical object is represented by an

information object. Furthermore, a Data Object may

realize a Business Object. This Data Object can, by

means of an indirect relationship, be considered as the

digital representation of said Material stored in some

information system. This extrapolation would not be

valid if a weaker relationship should be used between

the physical object and the Business Object. Finally,

by linking the data model of said Data Object to the

architecture, it becomes possible to perform analyses

of a material’s production lifecycle.

The same logic also applies to other physical

elements. For example, a piece of equipment may be

used as part of a business process, causing it to change

state (e.g. from ‘idle’ to ‘in use’). Per ISA-95, entities

associated with processes include materials, as well

as physical assets, equipment and people. Because of

this relationship in ISA-95, the same realization

relationship that is proposed for ArchiMate between

Material and Business Object is also proposed as a

relationship between Business Object and Business

Role, Business Actor, Equipment and Facility (see

Table 4).

Table 4: Proposed relationships.

ArchiMate

Concept

ISA-95

Concept

Relation-

ship

Concept

Material Material Lot Realizes Business

Object

Business

Role

Personnel

Class

Realizes Business

Object

Business

Actor

Person Realizes Business

Object

Equipment Equipment

Class

Realizes Business

Object

Facility Physical

Asset

Realizes Business

Object

Finally, the Business Process concept is included

to show that the newly added realization relationship

is only intended for those concepts that have an access

or assigned to relationship with Business Process.

Figure 5: Informational Representation of a Material.

Figure 5 illustrates the proposed extension. The

newly added realization relationship is marked with a

red circle. For the sake of legibility, the ‘Physical

Elements’ block serves as a placeholder for the

ArchiMate concepts listed in Table 4. The figure also

shows how an indirect realization relationship

between Data Object and a Physical element can be

derived using the realization relationship between

Data Object and Business Object.

Operations Definition

The operations definition describes the relation

between a production, maintenance, inventory or

quality operation, the way in which it is implemented

Towards an Integrated Architecture Model of Smart Manufacturing Enterprises

67

and the resources that are needed to carry out the

process. A framework for these kinds of

manufacturing operations is defined by the first part

of ISA-95. ArchiMate only loosely defines business

processes, independent of their context. However, the

ISA-95 process framework (International Society of

Automation, 2010a) can be implemented in

ArchiMate. It can then provide structure through

composition relationships from framework processes

to processes that are company-specific.

Figure 6 shows a pattern for how to apply the

ISA-95 process framework to company-specific

business processes. Such processes are modelled as

sub-processes (hence the composition relationship) of

processes from the ISA-95 process framework. Since

both ISA-95 processes and their sub-processes have

flow relationships between them, sub-processes

cannot compose more than one ISA-95 process. If a

process in a currently existing model cannot fulfil this

requirement (e.g. Batch Annealing in Figure 6), that

process needs to be decomposed such that each sub-

process only has one relation to an ISA-95 process.

Figure 6: Operations Definition Pattern (incl. example).

ISA-95 also explicitly defines a Bill of Materials

in relation to an Operations Definition. A business

object best fits the definition, but a business object

cannot have a relationship to a material (except

through a business process). ArchiMate does

implicitly define a bill of materials through the access

relationship between business process and material.

The pattern introduced for Assemblies solves this

issue.

Operations Schedule

ISA-95 defines a schedule concept. It is

implemented as a set of operations requests, which

directly relate to an operations definition. There is no

particular ordering (time sequence) to the set. There

is no similar concept in ArchiMate. While the

schedule itself could be modelled as a business object,

another issue arises with regards to the relationship

between a business object and a business process. A

business process is typically modelled as a class in

ArchiMate, while the schedule must relate to

instances to be meaningful. It would either be

necessary to model each instance of the process

separately, or to model no relationships to business

processes at all, effectively making the schedule a

placeholder object. The first is preferable from an

analysis standpoint, while the second is preferable

from a complexity standpoint. A compromise

between these two options is to, rather than model

each instance as part of the architecture, include a

reference to the data model used to store each instance

(Figure 7). This data model can then serve as the basis

for a query. The way in which this query is structured

shall depend on the viewpoint for which the

information is required. For example, a query based

on product ID may reveal which execution path was

followed for the production of that unit.

Figure 7: Operations Schedule Pattern.

Operations Performance

ISA-95 makes a distinction between the definition

of a process (operations definition), the planned

process (operations schedule) and the actual process

(operations performance). Once executed, Operations

Responses are returned for every Operations Request

(which make up the schedule). An Operations

Response is made up of ‘actuals’, which represent the

people, equipment, materials and physical assets that

were utilized. In ArchiMate, an Operations

Responses can be represented as either a Business

Object or Data Object, depending on whether this

information is collected digitally or not. The actual

production information, such as the actual execution

of the process, any errors that may have occurred, is

however much too volatile to model as part of the

architecture. Instead, it is recommended to relate an

Operations Response object to a specification of the

data model, describing how the data can be obtained

externally (e.g. an E/R-diagram). Based on this

specification and the relationship to a data object

accessed by some application, it will be possible to

generate a query for analysis purposes. The proposed

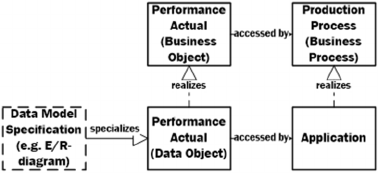

pattern is shown in Figure 8.

4 VALIDATION

A case study has been done to validate whether

Seventh International Symposium on Business Modeling and Software Design

68

ArchiMate (plus ISA-95 based modelling patterns)

effectively introduces EA modelling capability to

manufacturers. The case concerned a large steel

manufacturer (named SteelCorp for the sake of

anonymity) that intends to make a change in one of

its production processes. Due to space limitations we

do not provide here modelling details of this case

study. Instead we discuss the results and main

conclusions of the case.

Figure 8: Performance Actual Pattern.

The process modelled as part of this case study

concerns a batch annealing process for steel coils at

one of SteelCorps factories. During batch annealing,

a group of three coils is placed into an oven. Heat is

applied over a period of time to change certain

qualities of the steel. SteelCorp is looking to optimize

this process and to harmonize its surrounding

application landscape.

Proposed optimizations include the integration of

information used in several activities preparatory to

production into the production planning system

(PPS). The PPS is used to manage the utilization of

the ovens. Secondly, to increase oven utilization,

SteelCorp plans to generate optimized batches of

coils from the PPS, rather than having employees

combine each batch manually. Thirdly, to minimize

waiting times once a batch leaves the oven, SteelCorp

wants to know how long it takes for a coil to cool

down in inventory. For this reason, they will install

thermometers that monitor each coil periodically.

Finally, actual oven temperature curves will be

recorded and stored in the data warehouse with the

intent of using this data to optimize energy efficiency.

Creating a model of this process involved

establishing the batch annealing process formally as

part of the business domain, as well as modelling its

relationship to the physical, digital and IT

infrastructure domains. Notable physical objects

include the steel coils and the ovens. Information is

associated with these objects at several stages in the

process and this information moves through several

systems throughout the production lifecycle.

An as-is process model was made. This model

could successfully be used to demonstrate the

challenges SteelCorp was facing and to motivate the

proposed changes. Finally, a to-be process model was

presented to show how the proposed changes would

contribute to the goals set forth by SteelCorp.

The proposed modelling patterns proved useful in

several instances. Patterns based on existing

ArchiMate concepts were enough to model most of

the case. However, some aspects of the case could not

be modelled and required the use of modelling

patterns that make use of new elements. For example,

the current utilization of an oven (and the discrepancy

between the perceived utilization of an oven and its

actual utilization) could not be modelled. This

required a realization relationship to a business object

per the pattern introduced in section 5.4.4. Another

example of this is the temperature data related to a

steel coil that is monitored at regular intervals during

the process. Finally, usefulness of the model was

successfully demonstrated through its application to

two common manufacturing use-cases: an impact of

change analysis, as well as an operational excellence

analysis. Both analyses proved to be possible.

5 RELATED WORK

Urbaczewski & Mrdalj (2006) reviewed the EA

frameworks available at that time. They identified

DoDAF as the only framework that allows for the

modelling of physical elements. In another literature

review Hermann et al (2015) identify CPS as major

principle behind smart manufacturing/industry 4.0.

Furthermore, in, Sacala & Moisescu (2014) argue that

modelling a CPS as part of an overall enterprise

systems landscape requires a physical entity, an

association with a business entity and an application

with interfaces to both the business and the physical

entity. Finally, The Open Group released in 2016

ArchiMate 3.0 (The Open Group, 2016), which

introduced (among other things) several modelling

concepts to describe physical elements and how these

elements relate to applications and business entities.

The current research draws upon all the above and

relates ArchiMate to ISA-95, by exploring its current

modelling capabilities for smart manufacturing.

6 CONCLUSIONS

With the introduction of smart manufacturing (or

Industry 4.0), IT and operations technology

increasingly intertwine. For large manufacturers, this

means increasing digitization of the shop floor and,

consequently, the need to control the information

flowing from the physical domain and to manage

changes from a multidisciplinary (IT and OT)

perspective. This is where EA helps, but existing EA

Towards an Integrated Architecture Model of Smart Manufacturing Enterprises

69

frameworks and languages were not designed with

this type of requirements in mind.

This research provides EA modelling support for

smart manufacturing companies. Based on the ISA-

95 standard for the integration of enterprise systems

and control systems in the manufacturing industry

(International Society of Automation, 2010a,

International Society of Automation, 2010b), this

research has presented an analysis of ArchiMate 3.0

(The Open Group, 2016) in terms of its coverage of

the manufacturing domain. The results of the analysis

lead to the following answers to the research

questions formulated in in the introduction:

RQ1: Since ISA-95 was written on a different

abstraction level than ArchiMate, not all of its

concepts may be of architectural nature. To determine

which concepts are architectural, the ISA-95 concepts

were normalized using the criteria used to determine

which concepts should be part of the ArchiMate

language (Lankhorst et al., 2010). The normalization

revealed that only 66% of ISA-95 concepts qualify as

such. Given the set of architectural concepts

identified, a mapping was made of each architectural

ISA-95 concept to ArchiMate 3.0. To be able to

express the EA of any smart manufacturer,

ArchiMate should be able to express each

architectural ISA-95 concept. The mapping analysis

revealed that, while 12% of concepts can be mapped

one-to-one, construct overload or deficit (Wand and

Weber, 2002) occurs in 75% of cases. Solving these

issues requires the use of modelling patterns based on

either indirect relationships or on new constructs.

RQ2: When a concept from the manufacturing

domain cannot be mapped to ArchiMate, this will

invariably cause issues when attempting to model the

architecture of a manufacturing enterprise. Thus, this

second question asks for a solution to the mapping

difficulties uncovered as part of the mapping analysis.

For each identified issue, a pattern has been

proposed that resolves the problem by using some

combination of ArchiMate concepts to express the

intended meaning of the ISA-95 concept, and/or by

introducing some new constructs if ArchiMate’s

meta-model does not have sufficient expressive

power. The following concepts are introduced:

• Concept Parameter and Relationship Parameter.

These concepts describe information about a

concept (e.g. a steel coil) or relationship (e.g., an

item on a bill of materials) respectively.

• An aggregation relationship between Material

and Business Object is proposed to enable the

modelling of an explicit bill of materials.

• A realization relationship between Business

Object and Business Actor, Business Role,

Material, Equipment and Facility will allow for

both the current physical and informational state

of a physical object to be modeled.

The proposed modelling patterns enhance

ArchiMate 3.0’s coverage of ISA-95 architectural

concepts from 12% to 92%, and were validated as

part of a case study. They proved useful in modelling

part of the production process at a steel manufacturer.

The models could also effectively be used to perform

two common analysis use-cases: impact analysis and

operational excellence analysis.

Note that the proposed modelling patterns are

applicable to ArchiMate only. Furthermore, the

patterns should be further validated by testing them in

more cases, also covering discrete and continuous

processes, since SteelCorp is a batch process.

REFERENCES

Boucharas, V., van Steenbergen, M., Jansen, S.,

Brinkkemper, S., 2010. The Contribution of Enterprise

Arhcitecture to the Achievement of Organizational

Goals: A Review of the Evidence. TEAR 2010, 1-15.

Van Buuren, R., Jonkers H., Iacob, M-E. & Strating, P.,

2004. Composition of relations in enterprise

architecture models. Lecture Notes in Computer

Science 3256, Springer, 39–53.

Davis, J., Edgar, T., Graybill, R., Korambath, P., Schott, B.,

Swink, D., Wang, J., Wetzel, J., 2015. Smart

Manufacturing. Annual Review of Chemical and

Biomolecular Engineering, 6, 141–160.

Henderson, J.C., Venkatraman, H., 1993. Strategic

alignment: Leveraging information technology for

transforming organizations. IBM Systems Journal, 31,

1, 472-484.

Hermann, M., Pentek, T., & Otto, B., 2015. Design

Principles for Industrie 4.0 Scenarios: A Literature

Review. Technische Univ. Dortmund, 01(01), 4–16.

International Society of Automation, 2010a. Enterprise-

Control System Integration. ANSI/ISA standard

95.00.01-2010.

International Society of Automation, 2010b. Enterprise-

Control System Integration. ANSI/ISA standard

95.00.02-2010.

Lankhorst, M. M., Proper, H. A., Jonkers, H., 2010. The

Anatomy of the ArchiMate Language. Int. J. of Inf. Syst.

Modelling and Design archive, 1(1), 1-32.

Lee, E.A., 2008. Cyber Physical Systems: Design

Challenges. In proc. Of 2008 11

th

IEEE International

Symposium on Object and Component-Oriented Real-

Time Distributed Computing (ISORC), 363-369.

Sacala, I.S., Moisescu, M.A., 2014. The Development of

Enterprise Systems based on Cyber-Physical Syst.

Principles. Romanian Statistical Review, 4, 29–39.

The Open Group, 2016. ArchiMate 3.0 Specification.

Urbaczewski, L., Mrdalj, S., 2006. A comparison of

enterprise architecture frameworks. Issues in

Information Systems, 7(2), 18–23.

Seventh International Symposium on Business Modeling and Software Design

70

Wagner, H.-T, Weitzel, T., 2006. Operational IT Business

Alignment as the Missing Link from IT Strategy to

Firm Success. 12

th

Americas Conference on

Information Systems (AMCIS 2006). AISeL, 570-578.

Wand, Y. & Weber, R., 2002. Research commentary:

Information systems and conceptual modelling - A

research agenda. Information Systems Research, 13(4),

363–376.

Towards an Integrated Architecture Model of Smart Manufacturing Enterprises

71