Development of a Vibration Measurement Device based on a MEMS

Accelerometer

Chinedum Anthony Onuorah, Sara Chaychian, Yichuang Sun and Johann Siau

School of Engineering and Technology, University of Hertfordshire, Hatfield, U.K.

Keywords: Vibration Measurement, Accelerometer, System Design.

Abstract: This paper proposes a portable and low cost vibration detection device. Enhanced vibration calculation,

reduction of error and low storage memory are complementary accomplishments of this research. The device

consists of a MEMS capacitive accelerometer sensor and microcontroller unit, which operates based on a

novel algorithm designed to obtained vibration velocity, bypassing the usual time-based integration process.

The proposed algorithm can detect vibrations within 15Hz - 1000Hz frequencies. Vibration in this frequency

range cannot be easily and accurately evaluated with conventional low cost digital sensors. The proposed

technique is assessed and validated by comparing results with an industrial grade vibration meter.

1 INTRODUCTION

Advancement and Development of technology and

smart devices increases the demand for comfort and

safety, especially in transportation, where more

emphasis is placed on ride comfort and safety by

vehicle manufacturers. The ability to measure lower

frequency vibration with high precision can cooperate

in this regard. Human and environmental safety

(Kuntiyawichai and Burdekin, 2003), vehicle comfort

(Barone et al. 2016), engine performance (Dayyani et

al., 2016), road profiling (Abulizi et al., 2016) and

many more, necessitate vibration measurement for

their analysis and evaluations.

Numerous types of vibration sensors are

available, but the most common and advantageous

way of detection is based on accelerometer. They can

sense changes in velocity while oscillating in

particular frequency ranges; although, the orientation

of the sensor in this case is important and must be

considered (Stein et al., 2007). Depending on the

application, different types of accelerometer may be

used, for instance, Piezo-electric accelerometers are

well known for their precise measurement, however,

these are expensive (Jamil et al., 2014). On the other

hand, MEMS (Micro Electromechanical Systems)

accelerometers have better dynamic specification and

due to their small sizes, may be easily integrated in

different environments; however, they present noisy

outputs (Helal et al., 2015).

(Jamil et al., 2014), presents a vibration device based

on an accelerometer, and uses a microcontroller and

computer to visualize the vibration graphically. Their

device measure vibrations below 5KHz with

applications aimed towards medium range vibration

analysis.

This paper presents a low-cost vibration device,

which is based on a novel algorithm. The proposed

system optimizes the evaluation process for velocity

calculation, while using less memory by bypassing

the time-based integration process that requires an

extra buffer to be stored, and prevents potential

integration error, imposed in the computation.

Obtaining velocity and displacement information is

certainly possible by integration and double

integration (respectively) of the acceleration data in

the time domain. However, small DC offsets, or low

frequency signals present in the input samples

(acceleration data), will result in large cumulative

error, post integration.

2 SYSTEM SET UP AND DESIGN

Vibration can be measured as either acceleration

(which is the rate of change of speed in mm/s/s or G),

velocity (the distance moved per time in mm/s), or

displacement (inches or mm) in the x, y, z plane of a

3-dimensional space. The method described in this

paper evaluates vibration in terms of velocity. As

Onuorah, C., Chaychian, S., Sun, Y. and Siau, J.

Development of a Vibration Measurement Device based on a MEMS Accelerometer .

DOI: 10.5220/0006340902930299

In Proceedings of the 3rd International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2017), pages 293-299

ISBN: 978-989-758-242-4

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

293

shown in equations (1) and (2), there is a relationship

between acceleration, velocity and displacement,

although, velocity has the most direct relationship

between how much a body is displaced per unit of

time (which is ideal, as the severity of vibration is a

factor of moved distance and frequency of the

movement). Hence, vibration measurement based on

velocity is the most common and preferred method in

monitoring vibration related to mechanical problems

such as unbalance, misalignment, etc.

=+∆

=∆+

1

2

(

∆

)

(1)

(2)

Where is velocity, is previous velocity, is

acceleration, and ∆ is the change in time.

The device developed for this research consists of

a MEMS accelerometer (ADXL345) and a

Microcontroller Unit (MCU)

(dspic33EP256MC202), where the MCU is used to

sample and process acceleration data at a rate

dependent on the expected maximum vibration

frequency. Considering the ADXL345 has a

maximum sampling rate of 3200Hz, the theoretical

maximum frequency for vibration that can be

measured is 1600Hz, which is determined based on

Nyquist theorem in Equation (3). For this experiment,

the frequency range is between 15 – 100 Hz, therefore

the minimum sampling rate must be 200Hz.

≥2

(3

)

Where

is frequency of sampling and

is the

maximum frequency level for detection.

Note that the frequency range considered for this

experiment is not due to a limitation in the method

described, but on the memory constraints of the

selected MCU. The amount of memory required to

perform a Fast Fourier Transform (FFT) analysis on

the signal is a factor of the measurement sampling

rate, and the number of samples required.

The industrial grade vibration meter (HS-620)

manufactured by Hansford Sensors was used to verify

all test results in this experiment.

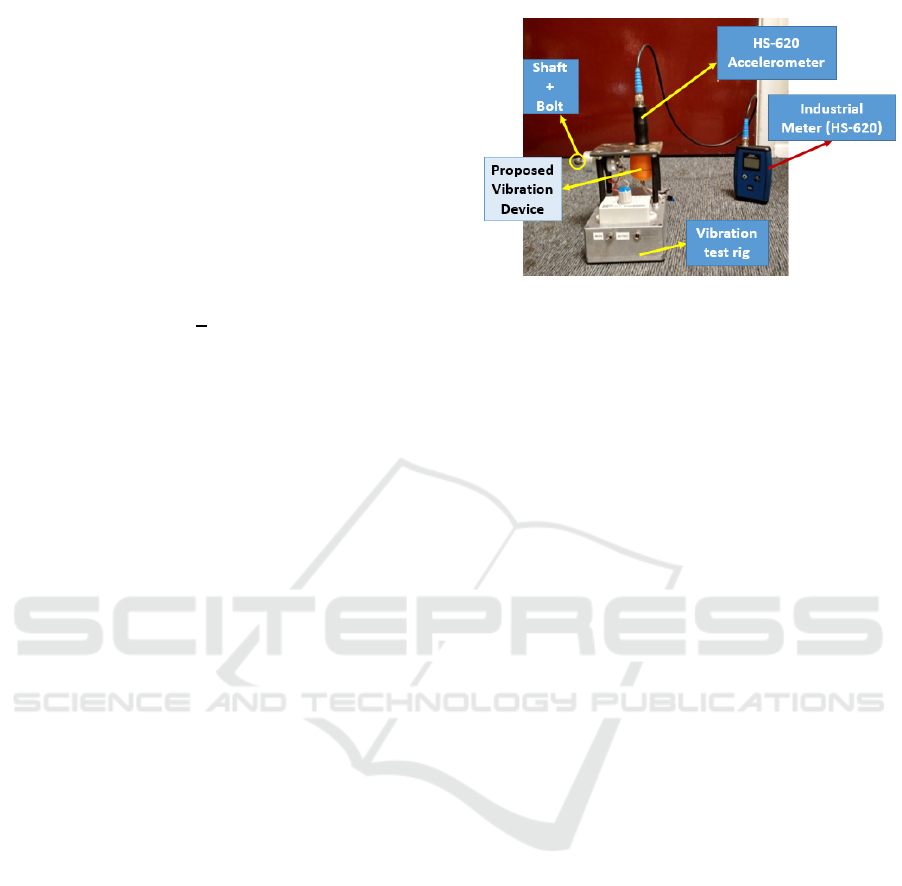

Figure 1 displays the setup used to verify the

results of this experiment. The image shows the HS-

620 vibration meter, the custom MEMS meter

(designed for this research) and vibration test rig

developed to simulate various vibration levels.

Figure 1: Experiment setup.

The test rig is battery operated (12v input) which

consists of a DC motor (to generate the vibration) and

a potentiometer (to vary the speed of the motor,

increasing the frequency and magnitude of vibration).

The motor is fitted to a metal plate, which is

connected to the base of the unit using rubber stands

(allowing pronounced vibration magnitudes to be

sensed on the plate). To vary the intensity of vibration

at specific frequencies, bolts of different sizes and

weights were connected to the shaft of the motor,

which creates the force needed to generate the

required vibration level.

The HS-620 and MEMS meter were mounted at

the same point, on opposite sides of the plate to ensure

the sensed vibration is consistent. The results

obtained during the tests confirms that this

configuration lets both meters receive similar

vibration levels, allowing accurate verification. Other

configurations, like, mounting both meters side by

side, on different areas of the plate, resulted in false

data, since the vibration sensed across the plate is

uneven. It is also important to ensure there are no

moving parts in the MEMS unit during measurement,

as this will reflect false vibrations. The experimental

unit was potted with epoxy to guarantee this.

3 IMPLEMENTATION

Common practice integrates the acceleration samples,

deriving a velocity waveform. This waveform is then

passed through number of filters to minimize the

effect of the error obtained from the integration

process, before any vibration analysis is carried out.

The method described in this paper attempts to

improve the accuracy of MEMS based vibration

systems, by bypasses the effect of integration error on

the results, calculating the velocity of the signal

directly from the acceleration’s frequency domain.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

294

This process obtains the acceleration samples

from the sensor, performs an FFT analysis on the

acceleration, and evaluates the velocity based on this

analysis.

3.1 Acceleration Measurement

The first step is obtaining the samples from the

accelerometer. A common source of error is having

uneven period between each sample. It is vital to

ensure consistency in the time difference between

each sample that make up the signal to be processed,

because irregularities will result in false frequency

domain representations. For example, using Equation

(4), for a sampling rate of 250Hz, the period between

each sample is expected to be 4ms. The aim here is to

measure vibration irrespective of the orientation of

the accelerometer, to achieve this, each sample from

the x, y, and z plane was consolidated using vector

summation (5), to obtain a single value that

represents the acceleration in a 3-dimensional space.

=

1

=

+

+

(4)

(5)

Where is the frequency of the signal, is the period,

is the acceleration on the x axis, is the

acceleration on the y axis, is the acceleration on the

z axis, and is the equivalent acceleration of all axis.

After obtaining data from the accelerometer, the

next step is to run the acceleration signal through a

band-pass filter (consisting of a high-pass and low-

pass filter). The filter cut-off frequencies are selected

based on the required measurement frequencies as

indicated in equation (6). In this experiment, the

frequency range explored is between 10Hz – 100Hz.

≤

<

≤

(6)

Since MEMS accelerometers are good at detecting

the earth’s gravitational pull, this produces an offset

equivalent to the gravity’s magnitude (approximately

9.81(m/s

2

)) to the axis acting against this force. This

causes the resulting signal to contain a DC offset even

when static, hence the high-pass filter is needed to

eliminate this offset.

3.2 Fast Fourier Transform (FFT)

Analysis

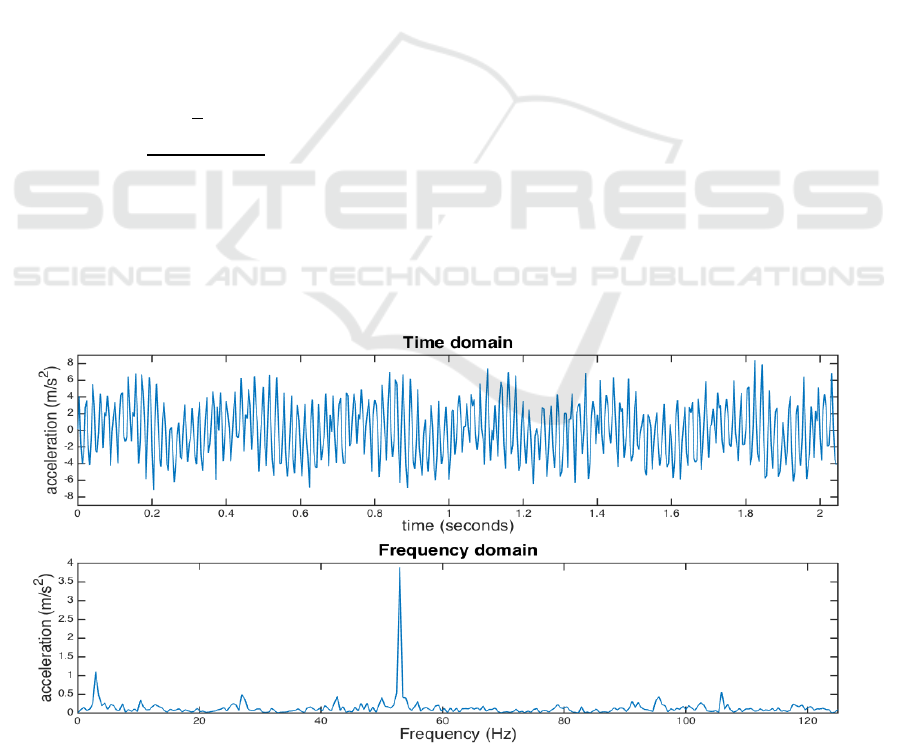

Up until this point, the acceleration samples measured

has been visualized in the time domain. A big part of

vibration analysis is investigating the signal in the

frequency domain (Figure 2) which is done using a

Fast Fourier Transform (FFT) algorithm (Rao et al.,

2011). The purpose of this is to determine the

magnitude and frequency of the various signals that

produce the waveform, making it easier to identify the

nature and source of vibration.

Figure 2: Vibration signal in time and frequency domain.

Development of a Vibration Measurement Device based on a MEMS Accelerometer

295

Figure 3: Velocity FFT derived from acceleration FFT.

Before performing an FFT analysis on the original

signal, the sampling rate, and number of samples

should be decided. This decision is based on the

length of time, and expected frequency range which

needs to be analysed. In vibration measurement, for

accuracy and consistency, analysing short time

intervals (i.e. < 3 seconds) is preferred, especially in

a vehicular environment where the speed of travel

determines the length of the road scanned per time.

For example, surface irregularities (which may cause

increased vibration) present in small sections of the

road will be overshadowed, if a much larger portion

of the road is scanned as a single waveform.

In common FFT algorithms, the number of

samples (FFT size) evaluated are in powers of two

(i.e. 64, 128, 256, 512 etc.), otherwise, zeros are

added to the end of the signal to generate the desired

length. This is a common source of error that can

easily be avoided by acquiring the right number of

samples.

The FFT size defines the number of bins (amount

of samples in the frequency domain), and the

sampling rate determines the maximum frequency

that can be identified. According to equation (7),

the number of bins is half the FFT size, where each

bin has a resolution (frequency difference per bin)

calculated using equation (8). For this experiment,

a sampling rate of 250Hz and FFT size of 512 was

chosen. This was preferred based on several factors,

including, required measurement frequencies,

resolution, and memory capabilities of the selected

MCU.

=

2

(∆

)=

(7)

(8)

Where

is the number of bins, is the total

number of samples (FFT size), ∆ is the FFT

resolution, and

is the sampling rate.

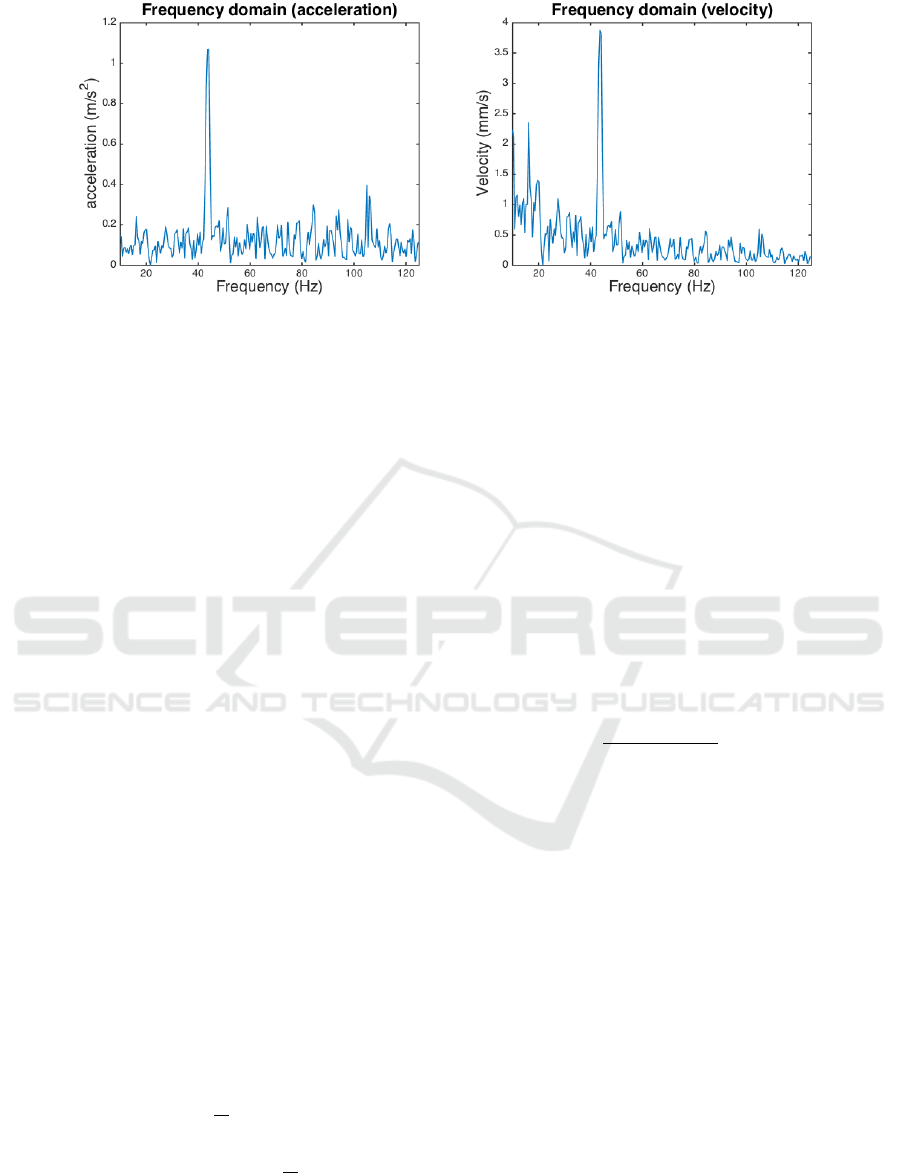

3.3 Conversion of Acceleration FFT to

Velocity

When the FFT for the acceleration samples is

calculated, the next phase is to evaluate the velocity

(in mm/s) of each frequency bin using equation (9).

The samples obtained for acceleration are in the unit

of metres per second squared (m/s

2

), hence, the

derived velocity is multiplied by 1000 to evaluate its

value in millimetre per second (mm/s).

Figure 3 shows

the derived velocity’s frequency domain.

(

)

=

(

)

2∗∗∆

∗

∗1000

(9)

Where is the velocity, is the acceleration, ∆

is the FFT resolution, and is the index of the sample

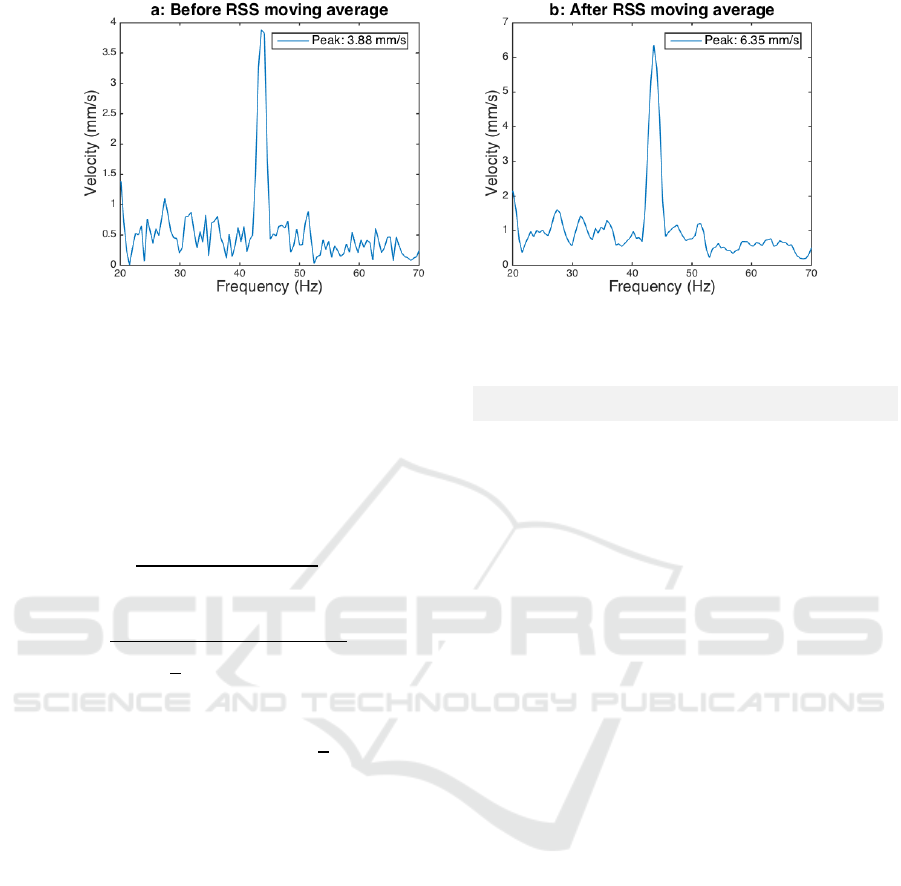

3.4 Root Sum Squared (RSS) Moving

Average

After calculating the equivalent velocity for each

frequency, due to the resolution of the FFT bins, and

irregularity of the vibration signals, in some cases, the

magnitude of the vibration (after the FFT analysis)

spans across neighbouring frequencies. This causes a

reduced amplitude to be reflected on the frequency

domain as shown in Figure 4a. Running an RSS

moving average (equations (10

) and (11)) on the

samples corrects this problem as illustrated in Figure

4b, producing accurate and consistent results.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

296

Figure 4: Derived velocity FFT showing the effect of RSS moving average (signal vibration = 6.32 mm/s).

The moving average requires a window length,

which indicates the number of samples to evaluate

when computing the average. In this application, it is

advisable to select an even number for the window

length; this is to maintain uniformity on either side of

() in equation (11). For this experiment, a

window length of two was chosen, as tests taken

proved more accurate.

=

1

+2

+⋯+

()=

−

2

+⋯+

(

−1

)

+

(

)

+

(

+1

)

+⋯+

+

2

(10)

(11)

Where is the number of values to be averaged,

is the calculated RSS average, is the velocity, is

the moving average’s window length, and

∈

ℝ

|

1≤≤}.

The equivalent vibration (in mm/s) and frequency

of the measured samples is then evaluated based on

the maximum value detected across the different

frequencies i.e. the vibration calculated for Figure 4

is 6.35 mm/s at 44Hz.

4 RESULTS

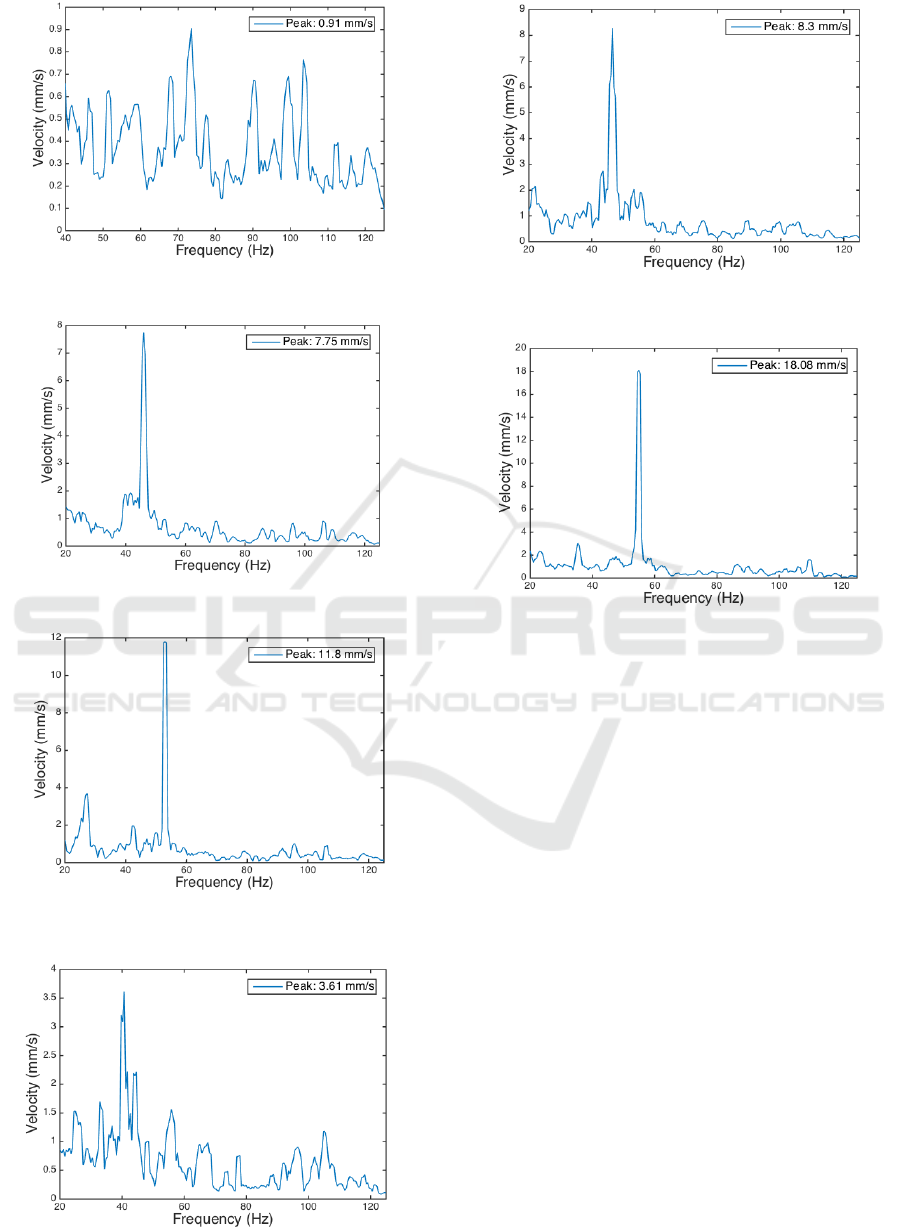

Figures 5 – 10, show the results obtained while taking

measurements for different vibration levels at varying

frequencies. Using the HS-620 Hansford meter as the

benchmark for the error analysis, Table 1 compares

both results obtained from the MEMS meter and the

HS-620, showing the percentage error in each case.

Table 1: Experimental results with percentage error.

HS-620 MEMS meter % Error

1.08 mm/s

3.42 mm/s

5.02 mm/s

7.72 mm/s

8.3 mm/s

11.7 mm/s

17.9 mm/s

0.91 mm/s

3.61 mm/s

5.06 mm/s

7.75 mm/s

8.3 mm/s

11.8 mm/s

17.9 mm/s

15.7%

5.6%

0.8%

0.4%

0%

0.9%

0%

The images below show the peak amplitudes

obtained after the RSS averaging, and these

amplitudes define the vibration levels in velocity. As

shown in Figure 5, there are instances where the

frequency analysis produces multiple peaks at various

frequencies, and this indicates the presence of

vibration from different sources. In this instance, the

RMS velocity is calculated (based on Parseval’s

theorem) on all the peaks.

Currently, the consistency of the algorithm is

between ±1 mm/s, which is based on the accuracy and

sensitivity of the accelerometer. Other filtering and

processing methods are been considered to improve

this consistency. One of these include using an

exponentially weighted moving average on the raw

samples to reduce the effect of sudden peaks and high

frequencies. Another method considered, is applying

a window to the samples used for the FFT analysis, to

help with signal discontinuity, comparing the various

windowing techniques, with and without

overlapping.

Development of a Vibration Measurement Device based on a MEMS Accelerometer

297

Figure 5: Vibration signal (1.08 mm/s @75Hz).

Figure 6: Vibration signal (7.72 mm/s @46Hz).

Figure 7: Vibration signal (11.7 mm/s @53Hz).

Figure 8: Vibration signal (3.42 mm/s @42Hz).

Figure 9: Vibration signal (8.3 mm/s @46Hz).

Figure 10: Vibration signal (17.9 mm/s @56Hz).

5 CONCLUSIONS

Vibration monitoring has a wide range of applications

in machine mentoring, ranging from industrial to

domestic use cases. This paper proposes a novel

process of achieving accurate and precise vibration

measurement using MEMS accelerometers. Results

show an error rate of <1% for vibrations greater than

5 mm/s. While error rates of up to 15% was achieved

for vibrations less than 1 mm/s, which according to

the International Organization for Standardization

(ISO), is insignificant in machine based monitoring,

since unsatisfactory conditions begin at ~3 mm/s.

REFERENCES

Abulizi, N. et al., 2016. Measuring and evaluating of road

roughness conditions with a compact road profiler and

ArcGIS. Journal of Traffic and Transportation

Engineering (English Edition), 3(5), pp.398–411.

Available at:

http://dx.doi.org/10.1016/j.jtte.2016.09.004.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

298

Barone, V. et al., 2016. Vibrational Comfort on Board the

Vehicle : Influence of Speed Bumps and Comparison

between Different Categories of Vehicle. , 2016(iii).

Dayyani, K., Chaychian, S. & Esat, I., 2016. Vibration

Suppression System for a Real Petrol Engine Exploiting

Optimum Shaker Position. , (7), pp.112–120.

Helal, I.A. et al., 2015. VIBRATION MONITORING

BASED ON MEMS ACCELEROMETERS. , pp.240–

245.

Jamil, I.A. et al., 2014. Vibration data acquisition and

visualization system using MEMS accelerometer. 2014

International Conference on Electrical Engineering

and Information & Communication Technology,

(APRIL), pp.1–6. Available at:

http://ieeexplore.ieee.org/lpdocs/epic03/wrapper.htm?

arnumber=6919090.

Kuntiyawichai, K. & Burdekin, F.M., 2003. Engineering

assessment of cracked structures subjected to dynamic

loads using fracture mechanics assessment.

Engineering Fracture Mechanics, 70(15), pp.1991–

2014.

Rao, K.R., Kim, D.N. & Hwang, J.J., 2011. Fast Fourier

Transform - Algorithms and Applications, Springer

Science & Business Media.

Stein, G.J., Chmurny, R. & Rosík, V., 2007. Measurement

and Analysis of Low Frequency Vibration.

Measurement Science Review, 7(3), pp.47–50.

Development of a Vibration Measurement Device based on a MEMS Accelerometer

299