Periodic and Metallic Nano-structures Patterned by Contact Transfer

Lithography with Application on Localized Surface Plasmon

Resonance

Hao-Yuan Chung, Chun-Ying Wu and Yung-Chun Lee

Department of Mechanical Engineering, National Cheng-Kung University, Tainan, Taiwan

Keywords: Localized Surface Plasma Resonance, Metallic Nano-structures, Contact Transfer Lithography.

Abstract: In this study, we demonstrate a rapidly, low cost, and mass production process to fabricate arrayed metallic

nanoparticles on a variety of substrates based on contact transfer and metal mask embedded lithography

(CMEL). A hexagonal arrayed metallic nanoparticles deployed on ITO/glass substrate with sub-micron

periodicity is achieved. It is observed in optical transmittance measurements that noble metallic arrayed

nanoparticles deployed on ITO/glass substrate result in a spectrally narrowband of extinction in visible

range, and is in good agreement with the simulated results using finite-element method (FEM). It is found

that the narrowband extinction spectrum is associated with electromagnetic field coupling between the

arrayed metallic nanostructures and the ITO layer. This electromagnetic field coupling induces significant

plasmon resonance in the ITO layer underneath the arrayed metallic nanostructures. Based on this observed

phenomenon and our innovative large-area nano-fabrication processes, optoelectronic devices with arrayed

metallic nanostructures can be easily designed and developed.

1 INTRODUCTION

Arrayed metallic nanoparticles have gained lots of

attentions in both scientific researches as well as

engineering application during last few decades.

Metallic nanostructures exhibit a rich variety of

intriguing optical properties due to the interaction of

the electromagnetic field with the free electrons of

the metal. Such an excitation can occur at a metal-

dielectric interface and is called surface-plasmon

polariton or at a metallic nanoparticle, and in this

case it is termed as particle-plasmon polariton

(Linden, Kuhl, and Giessen, 2001; Hutter and

Fendler, 2004; Yannopapas and Stefanou, 2004)

There are several ways to achieve metallic

nanoparticles, such as laser ablation method,

chemical reduction method and pyrolysis method

(Mafune et al., 2001; Pillai et al., 2007). These

methods can produce nanoparticles over large area

but have limitations to efficiently deploy

nanoparticles in specified arrangements. Electron

beam lithography is an excellent method to fabricate

arrayed metallic nanoparticles. The size of

nanoparticle can be well controlled to about several

tens of nanometers and arranged into square or

triangular lattice (Linden, Kuhl, and Giessen, 2001).

However, the costs of equipment and time-

consuming issues limit the capability to mass

produce large-area devices.

In this study, we demonstrate a rapidly, low cost,

and mass productive process to deploy arrayed

metallic nanoparticles on a variety of substrates

based on contact-transfer and mask-embedded

lithography (CMEL). A hexagonal arrayed metallic

nanoparticles deployed on an ITO/glass substrate

with sub-micron periodicity is obtained. Moreover,

the optical transmittance spectrum of the sample is

measured via spectrophotometer experimentally and

a numerical simulation using finite-element method

(FEM) is carried out to identify the mechanisms of

observed resonance characteristics.

2 EXPERIMENTAL DETAILS

AND RESULTS

This section describes the experimental details to

fabricate arrayed metallic nanoparticles on a variety

of substrates. A nanoimprinting process presented in

our previous study (Lee and Chiu, 2008), CMEL, is

applied to define and pattern arrayed metallic

structures which have feature sizes in sub-micron or

nanometer scales. First of all, a hexagonal arrayed

20

Chung H., Wu C. and Lee Y..

Periodic and Metallic Nano-structures Patterned by Contact Transfer Lithography with Application on Localized Surface Plasmon Resonance.

DOI: 10.5220/0005333500200025

In Proceedings of the 3rd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2015), pages 20-25

ISBN: 978-989-758-092-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

structured silicon mold is prepared using electron

beam lithography. The diameter of each holed

structure is 200 nm and the periodicity of hexagonal

array is 400 nm. A flexible h-PDMS mold replicated

from the silicon mold is then obtained to act as the

imprinting mold used in CMEL process. This h-

PDMS mold is inexpensive compared to the primary

silicon mold thus could be disposable after being

contaminated or damaged during the imprinting

process. Furthermore, this flexible mold has benefit

to minimize the contact issue in imprinting process

and utilize large-area pattern transfer successfully.

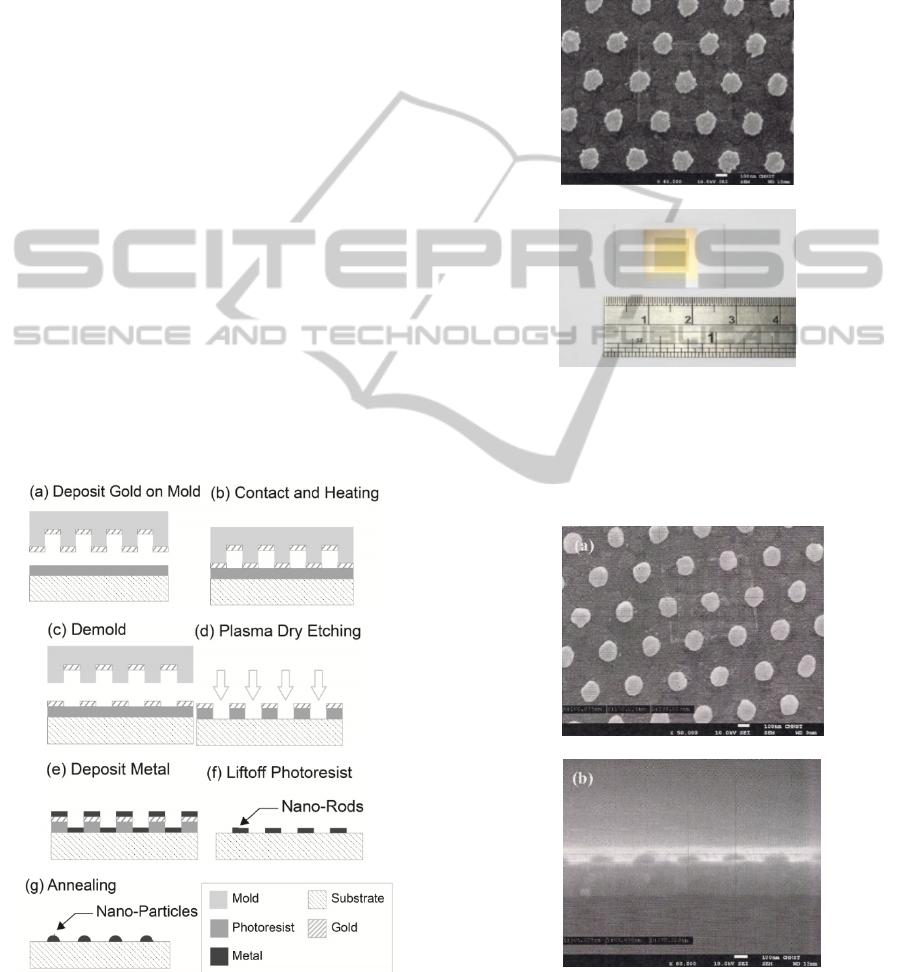

Figure 1 illustrates the procedures to fabricate

arrayed metallic nanostructures. An h-PDMS

concave mold deposited with gold film is contacted

to the top surface of polymer film coated on

substrate and then heating to the glass transition

temperature (Tg) of the polymer film. After cooling

down to room temperature, the patterned gold film is

transferred from the h-PDMS mold to the polymer

film owing to the good adhesion between metal-

polymer interfaces. This patterned gold film is then

acted as etching mask in dry etching process to

obtain a patterned polymer nanostructure.

Combining with lift-off and thermal annealing

processes, it is possible to fabricate arrayed metallic

nano-disks and nanoparticles on a variety of

substrates.

Figure 1: The procedure of using: (a-d) CMEL process, (e-

f) lift-off, and (g) thermal annealing processes, to achieve

an arrayed metallic nanoparticle.

Figure 2 shows the SEM image of the hexagonal

arrayed Au nano-disks (AuNRs) deployed on a 230

nm thick ITO film deposited on a soda-lime glass

substrate. The periodicity of hexagonal array is 400

nm; the dimensions of AuNRs are 200 nm in

diameter and 40 nm in thickness. The overall size of

arrayed metallic nanostructures is about 1 cm

2

.

(a)

(b)

Figure 2: (a) SEM images of the hexagonal arrayed

AuNRs deployed on 230 nm thick ITO film on top of a

glass substrate. The periodicity of hexagonal array is 400

nm; the dimensions of AuNRs are 200 nm in diameter and

40 nm in thickness. (b) The overall size of arrayed AuNRs

is about 1 cm

2

.

(a)

(b)

Figure 3: SEM images of (a) the top view and (b) the side

view of hexagonal arrayed AuNPs deployed on a 230 nm

thick ITO film on top of a glass substrate. Periodicity of

hexagonal array is 400 nm; the radius of AuNPs is 85 nm.

PeriodicandMetallicNano-structuresPatternedbyContactTransferLithographywithApplicationonLocalizedSurface

PlasmonResonance

21

Figure 3 shows the SEM images of the hexagonal

arrayed Au nanoparticles (AuNPs) deployed on an

ITO/glass substrate. During rapidly thermal

annealing process, the disk-liked AuNRs were

transformed into hemispherical AuNPs. The

periodicity of hexagonal array is 400 nm and the

radius of AuNPs is 85 nm. According to the

experimental results, arrayed metallic nanoparticles

deployed on ITO/glass substrates can be achieved.

The dimensions, shapes, and arrangements of these

arrayed metallic nanostructures can be easily

adjusted by using different type of imprinting molds.

The size and material combination of the obtained

metal particles can be controlled by the thicknesses

and varieties of metallic films deposited during the

lift-off process.

3 OPTICAL MEASUREMENTS

AND SIMULATIONS

The optical transmittance spectrum measurement of

these arrayed metallic nanoparticles is obtained

using a Hitachi U-3010 spectrophotometer. An

unpolarized light with wavelength λ

0

ranging from

400 nm to 1000 nm is normally incident onto the

metal side of these samples and the transmitted

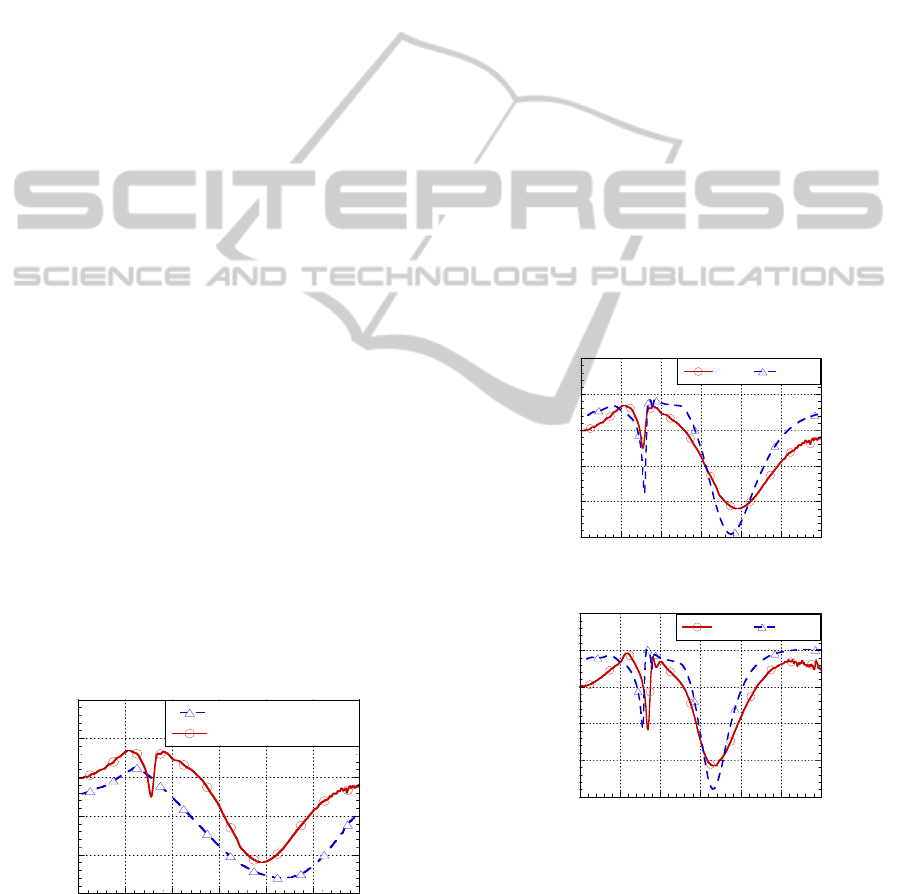

power is collected at the substrate side. Figure 4

shows the transmittance spectrum of arrayed AuNRs

deployed on a glass substrate and on a 230 nm thick

ITO film coated on a glass substrate. It is observed

that the transmittance spectrum of both samples

exhibits a spectrally wideband extinction in near-IR

range due to localized surface plasmon resonance.

Moreover, significant narrowband extinction in

visible range is observed in case of arrayed AuNRs

deployed on ITO/glass which means a strong

electromagnetic field coupling between the arrayed

metallic nanostructures and the ITO layer.

Figure 4: The normal incidence transmittance spectrum

measurements of hexagonal arrayed Au nanorods on glass

substrate (dashed line) and on a 230 nm thick ITO film on

top of a glass substrate (solid line).

A numerical simulation using finite-element method

is carried out to identify the resonance phenomenon.

Both the transmittance spectrum and the

electromagnetic field distribution are obtained to

clarify the different mechanisms of resonances in

visible and near-IR spectrum. The dielectric

functions of Au and ITO are described as Drude

model (Rakic et al., 1998; Bender et al., 1998). The

dielectric constants of air and glass substrate are ε

air

= 1 and ε

glass

= 2.31, respectively.

Figure 5(a) and 5(b) demonstrate the

comparisons between the calculated transmittance

spectrums and experimental results of arrayed

AuNRs and AuNPs on a 230 nm thick ITO film on

top of a glass substrate. Figure 6(a) and 6(b) show

the simulated and experimental transmittance

spectrum of arrayed AgNRs and AgNPs on a 230

nm thick ITO film deposited on a glass substrate,

respectively. It is shown that the simulated results

are in good agreement with the experimental results.

The arrayed metallic nanoparticles deployed on

ITO/glass substrate result in a spectrally narrowband

extinction in visible and a wideband extinction in

near-IR both in experiments and in simulations.

0

20

40

60

80

100

400 500 600 700 800 900 1000

exp. simu.

Transmittance (%)

Wavelength (nm)

( a ) Au, Before Annealing

0

20

40

60

80

100

400 500 600 700 800 900 1000

exp. simu.

Transmittance (%)

Wavelength (nm)

( b ) Au, After Annealing

Figure 5: The normal incidence transmittance spectrum

measurements (solid line) and the simulated results

(dashed line) using FEM. (a) Before annealing, and (b)

after annealing.

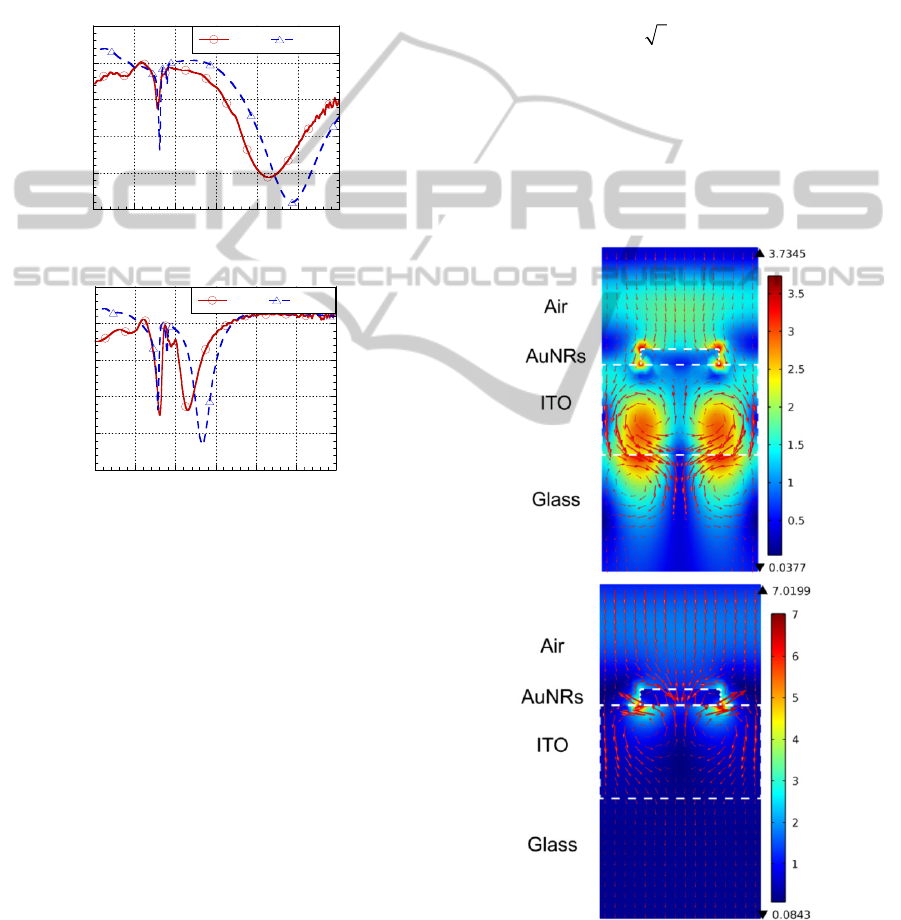

Figure 7(a) and 7(b) reveal the simulated

electromagnetic field distribution of arrayed AuNRs

0

20

40

60

80

100

400 500 600 700 800 900 1000

AuNRs on glass

AuNRs on ITO/glass

Transmittance (%)

Wavelen

g

th

(

nm

)

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

22

on a 230 nm thick ITO film deposited on a glass

substrate. While the incident wavelength λ

0

= 775

nm, as shown in Fig. 7, an enhanced electric field

around the metallic nano-disks due to localized

surface plasmon resonance is observed.

Furthermore, Fig. 8(a) and 8(b) show the significant

guided mode resonance in the ITO layer underneath

the arrayed metallic nanostructures when λ

0

= 556

nm.

0

20

40

60

80

100

400 500 600 700 800 900 1000

exp. simu.

Transmittance (%)

Wavelength (nm)

( a ) Ag, Before Annealing

0

20

40

60

80

100

400 500 600 700 800 900 1000

exp. simu.

Transmittance (%)

Wavelength (nm)

( b ) Ag, After Annealing

Figure 6: The normal incidence transmittance spectrum

measurements (solid line) and the simulated results

(dashed line) using FEM. (a) Before annealing, and (b)

after annealing.

Figure 7(a) and 7(b) reveal the simulated

electromagnetic field distribution of arrayed AuNRs

on a 230 nm thick ITO film deposited on a glass

substrate. While the incident wavelength λ

0

= 775

nm, as shown in Fig. 7, an enhanced electric field

around the metallic nano-disks due to localized

surface plasmon resonance is observed.

Furthermore, Fig. 8(a) and 8(b) show the significant

guided mode resonance in the ITO layer underneath

the arrayed metallic nanostructures when λ

0

= 556

nm.

A more detail discussion about the guided mode

resonance is started from a simple empty-lattice

approximation (Christ et al., 2004). As a first step of

this approximation, the energy dispersions of the

lowest transverse electric (TE0) and transverse

magnetic (TM0) guided modes of a homogeneous

ITO layer could be found from the solution of the

transcendent equations for the asymmetric

waveguide slab (Barnoski, 1973, pp. 53-72). It is

shown that the calculated dispersions of TE0 and

TM0 guided mode of a 230 nm thick ITO slab on

thetop of a soda-lime glass substrate. When

assuming a surface corrugation with periodicity d of

hexagonal array in a second step (in this case, d =

400 nm), the propagation constant is normalized to

the reciprocal lattice of the 2D photonic crystal slab

which equals to 4π/d

3

. While the propagation

constants of TE

0

and TM

0

equal to the reciprocal

lattice, it is shown that the photon energy of TE0

guided modes equal to 2.128 eV. These calculated

photon energy of TE

0

guided modes are in good

agreement with the simulated results using FEM.

The shifts of central wavelength might be caused by

the neglecting of material and geometry of metallic

deployed on the homogeneous ITO waveguide slab.

(a)

(b)

Figure 7: The electromagnetic field distribution of arrayed

AuNRs (before annealing) deployed on ITO layer; (a)

incident wavelength is 559 nm, and (b) incident

wavelength is 775 nm.

PeriodicandMetallicNano-structuresPatternedbyContactTransferLithographywithApplicationonLocalizedSurface

PlasmonResonance

23

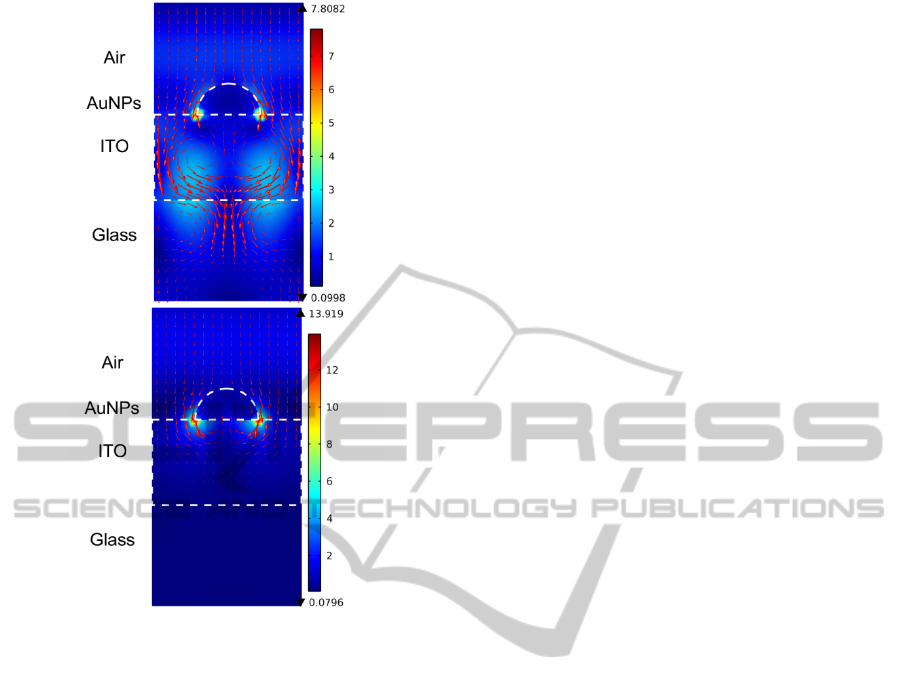

(a).

(b).

Figure 8: The electromagnetic field distribution of arrayed

AuNPs (after annealing) deployed on ITO layer; (a)

incident wavelength λ

0

= 556 nm, and (b) incident

wavelength λ

0

= 730 nm.

According to the FEM simulation and empty-

lattice approximation discussed above, it suggests

that the spectrally narrowband in visible range

owing to the guided mode resonance has quite

different resonance mechanism with respect to the

wideband extinction in near-IR range due to the

localized surface plasmon resonance. When an

electromagnetic wave normally incident onto

arrayed metallic nanostructures, a Bragg’s

diffraction phenomenon occurs and then couples the

electromagnetic wave into the waveguide slab. At

certain photon energies of the propagating guided

waves which the propagation constant equal to the

reciprocal lattice of arrayed nanostructures, a guided

mode resonance happens and enhanced electric field

distributes within waveguide slab can be observed.

4 CONCLUSIONS

In this study, we demonstrate a rapidly, low-cost,

large-area, and mass productive fabrication process

to obtain arrayed metallic nanostructures on a

variety of substrates. The key element in this

fabrication method is to combine an innovative

metal contact printing lithography with conventional

lifting-off and thermal annealing processes.

Hexagonal arrays of metallic nanoparticles with sub-

micron periodicity are successfully deployed on an

ITO/glass substrate. The dimensions, shapes, and

arrangements of these arrayed metallic

nanostructures and nanoparticles can be easily

adjusted by using different pattern designs in the

imprinting molds. The sizes and material

compositions of the obtained metal nanoparticles

can be easily controlled by the deposition

thicknesses and material varieties of films deposited

during the sample preparation process.

Optical transmittance measurements show that

certain kinds of noble metallic arrayed nanoparticles

deployed on an ITO/glass substrate can result in a

phenomenal narrowband of extinction in spectral

range of visible light. Theoretical analysis indicates

this narrowband extinction spectrum is associated

with electromagnetic field coupling between the

arrayed metallic nanostructures and the underlying

ITO layer. Numerical simulation based on finite

element method is carried out to demonstrate the

electromagnetic field distributions of the localized

surface plasmon resonance of arrayed metallic

nanostructures and the excited waveguide modes

within the ITO layer. This electromagnetic field

coupling induces significant plasmon resonance in

the ITO layer underneath the arrayed metallic

nanostructures. A further evidence is attained by

comparing the measured transmittance spectrum of a

similar noble metallic arrayed nanoparticles

deployed on a glass substrate. Experimental results

show that the narrowband extinction in visible

spectrum is vanished since there is no ITO layer to

support guided modes resonance. Based on this

observed phenomenon and our innovative large-area

nano-fabrication processes, optoelectronic devices

with arrayed metallic nanostructures can be easily

designed and implemented in the future.

REFERENCES

Bender, M., Seelig, W., Daube, C., Frankenberger, H.,

Ocker, B. & Stollenwerk, J. 1998 ‘Dependence of

oxygen flow on optical and electrical properties of

DC-magnetron sputtered ITO films’, Thin Solid Film,

vol. 326, pp.72-77.

Barnoski, M. K. 1973. Introduction to Integrated Optics,

Plenum Press, New York.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

24

Christ, A., Zentgraf, T., Kuhl, J., Tikhodeev, S. G.,

Gippius, N. A. & Giessen, H. 2004 ‘Optical properties

of planar metallic photonic crystal structures:

Experiment and theory’, Phys. Rev B, vol. 70, p.

125113.

Hutter, E., Fendler, J. H. 2004 ‘Exploitation of localized

surface plasmon resonance’, Adv. Mater., vol. 16, pp.

1685-1706.

Lee, Y. C. & Chiu, C. Y. 2008 ‘Micro-/nano-lithography

based on the contact transfer of thin film and mask

embedded etching’, J. Micromech. Microeng., vol. 18,

p. 075013.

Linden, S., Kuhl, J., & Giessen H. 2001 ‘Controlling the

interaction between light and gold nanoparticles:

Selective suppression of extinction’, Phys. Rev. Lett.,

vol. 86, pp. 4688-4691.

Mafune, F., Kohno, J. Y., Takeda, Y., & Kondow, T. 2001

‘Dissociation and aggregation of gold nanoparticles

under laser irradiation’, J. Phys. Chem., vol. 105, pp.

9050-9056.

Pillai, S., Catchpole, K. R., Trupke, T. & Green, M. A.

2007 ‘Surface plasmon enhanced silicon solar cells’, J.

Appl. Phys., vol. 1019, p. 093105.

Rakic, A. D., Djurisic, A. B., Elazar, J. M. & Majewski,

M. L. 1998 ‘Optical properties of metallic films for

vertical-cavity optoelectronic devices’, Appl. Opt.,

vol. 37, pp. 5271-5283.

Yannopapas, V., Stefanou, N. 2004 ‘Optical excitation of

coupled waveguide-particle plasmon modes: A

theoretical analysis’, Phys. Rev. B, vol. 69, p. 012408.

PeriodicandMetallicNano-structuresPatternedbyContactTransferLithographywithApplicationonLocalizedSurface

PlasmonResonance

25