Supply Chain Tracing of Multiple Products under Uncertainty and

Incomplete Information

An Application of Answer Set Programming

Monica L. Nogueira and Noel P. Greis

Kenan-Flagler Business School, The University of North Carolina at Chapel Hill,

Kenan Center CB#3440, Chapel Hill, NC, 27599 U.S.A.

Keywords: Answer Set Programming, Knowledge Representation, Supply Chain, Traceability, Food Recall Process.

Abstract: Food supply chains are complex networks involving many organizations and food products from the farm to

the consumer. The ability to quickly trace the trajectory of a tainted food product and to identify the origin

of the contamination is essential to minimizing the economic and human costs of foodborne disease.

Complexities arise when multiple products traverse multiple states and/or countries and when products cross

multiple intersecting supply chains. In this paper we use the example of a recent Salmonella contamination

involving tomatoes and peppers imported from Mexico into the U.S. to demonstrate the use of Answer Set

Programming to localize the source of contamination in a complex supply chain characterized by

uncertainty and incomplete information.

1 INTRODUCTION

Traceability of food products through the supply

chain is a key problem for public health officials

worldwide as supply chains have become larger,

more complex, and increasingly span both national

and international jurisdictions. Globalization,

international trade, and new eating habits, are

contributing factors to a reduced shelf life and a

potentially higher risk of contamination. Control of

scale and scope of a foodborne illness outbreak is

directly linked to authorities’ ability to track and

trace tainted products in the supply chain quickly

and accurately thus ensuring their removal and

disposal before further harm occurs. But even in

developed countries no single traceability scheme

has been widely adopted and adequate track and

trace methods are yet to be identified (Fritz and

Schiefer, 2008; Regattieri et al., 2007).

This paper addresses the challenge of tracing

multiple food products across complex supply

chains by extending previous work of (Nogueira and

Greis, 2013) that demonstrated the use of the logic

programming approach Answer Set Programming

(ASP) (Marek and Truszczynski, 1999) to the food

safety domain. Our contribution herein is to apply

ASP to solve other common practical traceability

problems motivated by a past multiple product

outbreak event in the United States—the 2008

tomatoes and peppers outbreak (CDC, 2008). First,

we demonstrate how to compute the effects of a food

recall and its impact on firms and states, and how to

trace products within a geographically targeted

supply chain. Second, we trace concurrently recalled

(multiple) products through diverse food chains and

identify any points of intersection between these

chains. Third, we simulate, or “probe,” the tracing of

suspected tainted products before confirmation or

any recalls are issued, and identify firms that may be

potentially involved in the outbreak.

Section 2 discusses motivation for this research

and related work. Section 3 defines a complex

supply chain and its encoding in ASP. Section 4

shows how to compute effects of a recall within a

geographic area through the use of aggregate

functions of the ASP solver DLV. Section 5 presents

our ASP-based solution to the traceability problems

linking multiple products and supply chains. Section

6 concludes the paper and presents future research.

2 MOTIVATION AND RELATED

WORK

The U.S. Centers for Disease Control and Prevention

399

L. Nogueira M. and P. Greis N..

Supply Chain Tracing of Multiple Products under Uncertainty and Incomplete Information - An Application of Answer Set Programming.

DOI: 10.5220/0004627603990406

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2013), pages 399-406

ISBN: 978-989-8565-81-5

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

(CDC) define a foodborne disease outbreak as two

or more illnesses caused by consumption of a

common food. Annually 48 million Americans, fall

ill due to a foodborne illness (Scallan et al., 2011).

The number of outbreaks reported to CDC by state

health officials for 2009 and 2010 (1,527 in total)

show that no food commodity was identified for

approximately 58% (or 892) outbreaks (CDC, 2013).

Due to delays of one to two weeks between the

consumption of a tainted food and the onset of

illness, patients usually do not remember the foods

they ate. Hence, new methods must be developed

that can deal with incomplete information yet still

generate candidate sources of contamination and

thereby reduce the burden of illness and the

economic impact to populations and businesses.

Traceability refers broadly to the ability, for any

product at any stage within the food chain, to

identify the initial source (backward tracing) and,

eventually, its final destination (forward tracing)

(Fritz and Schiefer, 2009). Tracking refers to the

ability to identify, for any product, its actual location

at any given time. Together these two capabilities

provide the functionality of a “track-and-trace”

system for the food supply chain. In this work we

tackle the traceability problem by utilizing a logic

formalism to encode and generate likely trajectories

for contamination due to a recall and to identify all

possibly affected companies and their products.

In this paper we model the recent “Tomatoes and

Jalapeño Peppers” outbreak. From May to August

2008, the CDC recorded a large foodborne disease

outbreak with 1,442 cases, counting 286

hospitalizations and possibly two deaths, affecting

43 states, the District of Columbia, and Canada.

Several case-control studies conducted to identify

the contamination source(s) produced mixed results,

pointing to jalapeño peppers as a major transmission

vehicle, and serrano peppers and tomatoes as other

possible vehicles (CDC, 2008). In July 2008

jalapeño peppers were traced by FDA to a farm in

Mexico which also grew serrano peppers. For

encoding simplicity, different types of tomatoes or

peppers are not considered here. Lack of publicly

available data on international food firms, led us to

restrict our representation to the U.S. supply chain.

In the last decade, developed countries have

approved more stringent legislation to improve the

safety standards of the food they produce (Kher et

al., 2010; McEntire and Bhatt, 2012). However, the

quality and safety of food products produced in

developing countries are less regulated and, thus, in

many cases more lax. Currently supply chains cross

developed and developing countries which

complicates traceability requirements. Hence,

traceability methods based on unique identification

schemes must work globally, and interoperability of

radio frequency identification-based and other

barcode schemes must be seamless (GS1, 2010;

Thakur et al., 2011). Our approach to the traceability

problem is independent of the availability of such

identifiers. We employ publicly available

information about food businesses, e.g. type of

products sold and company role in the supply chain,

in conjunction with food ontologies, to trace

possible trajectories paths of food distribution and

narrow down affected firms and areas.

3 REPRESENTING COMPLEX

SUPPLY CHAINS IN ASP

A supply chain is the entire network connecting,

directly or indirectly, different companies that

participate in the coordinated production,

manufacture, handling, distribution and/or retail of a

specific product to fulfill a customer request.

Specifically, a food supply chain consists of all the

steps required to transform a (raw) food commodity

into a product ready for consumption.

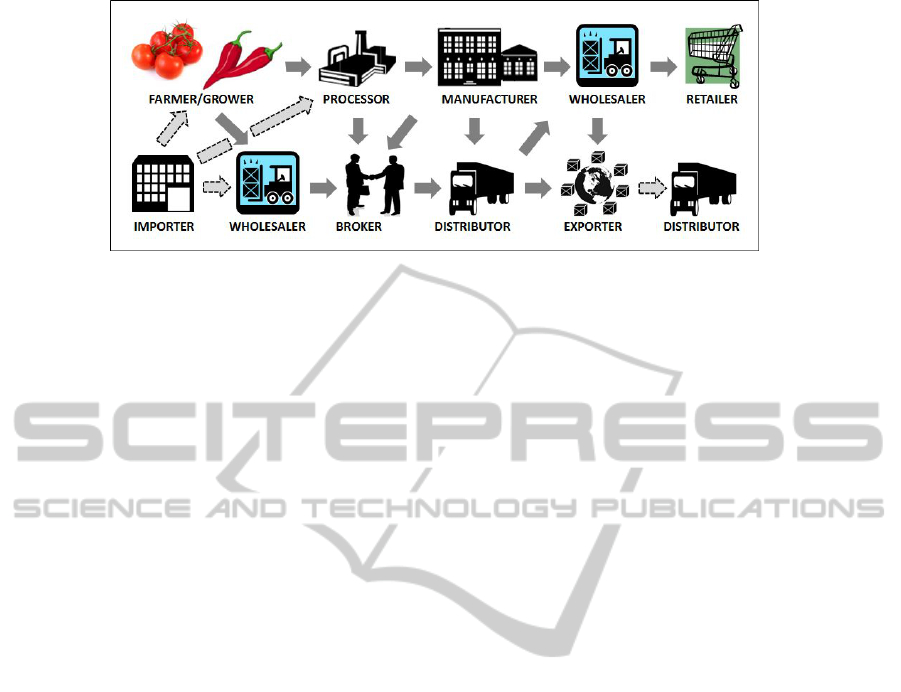

An illustrative

example of a generic, complex supply chain crossing

national borders is shown in Figure 1.

The food

chain encompasses farmers or growers of raw food

commodities, processors or manufacturers

who

convert raw food into products, wholesalers that

store and commercialize products, and distributors

that deliver it to retailers who sell the product

directly to consumers, as well as brokers, importers,

and exporters. A supply chain is dynamic and there

is a constant flow of product, information, and

capital between its stakeholders. This directed flow

is represented in Figure 1 by the arrows linking the

different company types. This abstract view of a

supply chain serves as the basis for building our

ASP representation and program to solve common,

practical traceability problems.

3.1 ASP Basic Syntax and Semantics

The ASP paradigm is based on the stable models/

answer sets semantics of logic programs (Gelfond

and Lifschitz, 1988, 1991) and has been shown to be

a powerful formalism for knowledge representation

including defaults, inheritance reasoning, reasoning

about actions and their effects, and to be particularly

useful in solving challenging search problems. ASP

reduces search problems to the computation of the

KEOD2013-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

400

Figure 1: An Example of a Generic, Complex Supply Chain Crossing National Borders.

stable models of the problem and a growing number

of ASP solvers — programs that generate the stable

models of a given problem encoded in the ASP

formalism, e.g. clasp, DLV, Pbmodels, Smodels,

etc., are available. Syntax and semantics of the

language is found in (Gelfond and Lifschitz, 1991).

Language signature Σ contains predicates,

constants, and function symbols. Terms and atoms

are formed as habitual in first-order logic. A literal is

either an atom (positive literal) or an atom preceded

by classical or strong negation), a negative literal.

Literals l and l are called contrary. Ground literals

and terms are those not containing variables. A

consistent set of literals does not contain contrary

literals. The set of all ground literals is denoted by

lit(Σ). A rule is a statement of the form:

h

1

... h

k

l

1

, ..., l

m

, not l

m+1

, ..., not l

n

. (1)

where h

i

’s and l

i

’s are ground literals, not is a logical

connective called negation as failure or default

negation, and symbol is the disjunction operator.

The rule head appears to the left of symbol , and

the body on its right side. Intuitively, the rule means

that if a reasoner believes {l

1

, … , l

m

} and has no

reason to believe {l

m+1

, …, l

n

}, then it must believe

one of the h

i

’s. If the head is replaced by (falsity)

then the rule is called a constraint. The intuitive

meaning of a constraint is that its body must not be

satisfied. Rules with variables (denoted by capital

letters) are used as a short hand for the sets of their

ground instantiations. An ASP program is a pair of

Σ, Π, where Σ is a signature (usually implicit) and

Π is a set of rules (a program) over Σ. A stable

model (or answer set) of a program Π is one of the

possible sets of literals of its computable

consequences under the stable model/answer set

semantics.

Our encoding, the set of rules of program Π,

contains roughly 50 rules, while there are thousands

of records—in ASP, rules with an empty body, also

called “facts”—corresponding to the database of

companies, and food and geographic ontologies. The

ASP solver used is DLV (Calimeri et al., 2002). The

solver is tasked with computing the set of firms in a

target area affected by a single or multiple recalls,

and firms that could be affected when more than

one product is suspected but no recall has been

issued. Advantages of encoding the food supply

chain traceability problem as an ASP program

include: (1) ASP allows easy encoding of many

forms of domain knowledge and generating

hierarchical ontologies for diferent types of domain

relevant information, e.g. geographical, disease

(Nogueira and Greis, 2011). Encoding of heuristics

makes it possible to prune the search space and

increase the efficiency of tracking and tracing a

contaminated product in the supply chain; (2)

Modular ASP programs, where each module will or

will not be executed depending on the solution

sought, provide added flexibility for execution that

helps control innefficiency and avoid combinatorial

explosion; (3) ASP is well-suited to represent action

and change. A food supply chain is an intrinsically

dynamic environment where food products move

from one node to the next in the chain, and the track-

and-trace of contaminated products posing risk to

human lives should be highly efficient to curb a

contamination event that may spread very rapidly;

and (4) ASP is well-suited to deal with incomplete

information—an inherent problem of this domain as

food enterprises are averse to sharing information

about their supplier and customer bases which

represents competitive advantage to their business.

3.2 Supply Chain as an ASP Program

We leverage publicly available information on U.S.

food companies to build the database of entities that

form our supply chain. Since food companies may

have multiple roles in the chain and produce more

than one product, they are represented in our ASP

SupplyChainTracingofMultipleProductsunderUncertaintyandIncompleteInformation-AnApplicationofAnswerSet

Programming

401

program by rules of form (2)-(4). A food recall by a

given company is encoded as (5). A conceptual

model for supply chains is that of an acyclic,

directed graph as illustrated in Figure 1. Knowledge

about supply chain operations provides the

semantics for the graph’s vertices and edges. Each

vertex, except for a point of origin or food source

such as the grower or importer, corresponds to a

firm A that performs a transformative step on a less

processed product to generate a more refined

product supplied to firm B located down-stream in

the chain and to whom A is directly connected by an

edge in the graph. Clearly, if A supplies B—who in

turn supplies another firm or a final consumer, then

their products are derived from the same food

commodity. Rule (6) encodes the supply functions.

Each edge of the graph represents a valid flow of

ingredients or final product(s) for resale from a firm

A set upstream in the chain and directly connected to

a firm B by an edge in the graph, i.e. a supply

operation between the two types of entities

connected in that supply chain. Figure 1 contains

17 edges with 4 dashed edges corresponding to

foreign supplying functions. The U.S. supply chain

defined by 13 solid edges is encoded by 13

individual rules of the form of (7) or (8), depending

on whether an ingredient or final product is supplied.

We omit some of the rules to avoid repetition and

save space. Tracing products forward, and similarly

backward, in the supply chain is achieved by (9)-

(14), which also compute the transitive closure of

these relations. Our knowledge base contains a

simple ontology which models the main stages of a

food product as it evolves from raw, unprocessed

food at the farmer/grower level of the supply chain

to a processed food ready for consumption at the

retail point-of-sale. The ontology is built with rules

of form (15)-(16) for each food supply chain (47) to

represent a product’s primary ingredient(s) and its

derivative products as illustrated by facts (17)-(46).

The ASP program described and below is based on

work from (Nogueira and Greis, 2012 and 2013).

firm(Idcode,Name,State). (2)

type_firm(Idcode,Type). (3)

prod_supplied(Idcode,Product).

(4)

recall(Product,Idcode). (5)

supplies(A,I1,B) :- (6)

valid_supply(F,A,B),

is_of(I1,F),prod_supplied(A,I1),

is_of(I2,F),prod_supplied(B,I2).

valid_supply(F,A,B) :-

(7)

type_firm(A,grower),

type_firm(B,processor),A!=B,

sc(F),is_ingr(I1,I2),

is_of(I1,F),prod_supplied(A,I1),

is_of(I2,F),prod_supplied(B,I2).

valid_supply(F,A,B) :- (8)

type_firm(A,grower),

type_firm(B,wholesaler),A!=B,

sc(F),prod_supplied(A,I),

is_of(I,F),prod_supplied(B,I).

fwtrace(C,LC,F,A,LA) :- (9)

recall(F,C),supplies(C,F,A),

firm(C,_,LC),firm(A,_,LA), C!=A.

fwtrace(B,LB,F1,A,LA) :- (10)

is_ingr(F,F1),supplies(B,F1,A),

fwtrace(C,LC,F,B,LB),

firm(C,_,LC),firm(B,_,LB),

firm(A,_,LA),B!=C,B!=A,A!=C.

fwtrace(B,LB,F,A,LA) :- (11)

supplies(B,F,A),

fwtrace(C,LC,F,B,LB),

firm(B,_,LB),firm(A,_,LA),

firm(C,_,LC),B!=C,B!=A,A!=C.

bktrace(A,LA,F,C,LC) :- (12)

recall(F,C),supplies(A,F,C),

firm(C,_,LC),firm(A,_,LA),C!=A.

bktrace(B,LB,F1,C,LC):- (13)

is_ingr(F1,F),supplies(B,F1,C),

bktrace(C,LC,F,A,LA),

firm(B,_,LB),firm(C,_,LC),

firm(A,_,LA),B!=C,B!=A,A!=C.

bktrace(B,LB,F,C,LC) :- (14)

supplies(B,F,C),

bktrace(C,LC,F,A,LA),

firm(B,_,LB),firm(C,_,LC),

firm(A,_,LA),B!=C,B!=A,A!=C.

is_of(Product,Chain). (15)

is_ingr(Product1,Product2). (16)

is_of(ttfresh, tomatoes). (17)

is_of(ttketchup, tomatoes). (18)

is_of(ttpastepuree, tomatoes).

(19)

…

is_of(pepper, peppers). (27)

is_of(ppfresh, peppers). (28)

is_of(ppchili, peppers).

(29)

is_ingr(ttfresh, ttpastepuree). (30)

is_ingr(ttpreserved, ttketchup).(31)

is_ingr(ttpreserved, ttsauce). (32)

…

is_ingr(ppfresh, pepper). (43)

is_ingr(ppgreenfrsh, ppcrshgrd).(44)

is_ingr(ppcrshgrd,ppdrycrshgrd).(45)

is_ingr(ppchili, ppdrycrshgrd). (46)

supply_chain(Chain). (47)

KEOD2013-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

402

supply_chain(tomatoes). (48)

supply_chain(peppers). (49)

4 AGGREGATE FUNCTIONS TO

COMPUTE RECALL EFFECTS

Assume that a firm, identified by code “cp58” in our

firms’ database, has a dual role of produce grower

and processor and recalls its fresh tomatoes product

as denoted by fact (50) added to the program. The

solution for this traceability problem contains 4,132

atoms “fwtrace” and “bktrace,” with 3,255 possible

paths of contamination forward in the chain, and 877

backward from the point of recall. A portion of the

solution for this tracing exercise appears below.

recall(ttfresh,cp58). (50)

{fwtrace(cp58,ca,ttfresh,cp14,az),

fwtrace(cp58,ca,ttfresh,cp112,ca),…

bktrace(cp58,ca,ttfresh,cp431,ca),

bktrace(cp58,ca,ttfresh,cp755,az),…}

4.1 Track and Trace of Single Recalled

Products

An important question for public health officials is

to determine how many firms are affected by this

recall forward in the supply chain, i.e. how many

received the recalled product. DVL authors have

extended its language to provide constructs that

enable arithmetic operations over a set of atoms, like

sum and count, and allow answering such questions.

Incidentally, other ASP solvers, e.g. Smodels,

provide comparable constructs with slightly different

semantics and syntax.

Hence, the language described in Section 3.1 is

extended by sets, aggregate functions, atoms, and

literals as defined in (Dell’Armi et al., 2003). A set

is a pair of the form {T:Conj}. In a symbolic set, T is

a list of variables and Conj is a conjunction of

standard literals. In a ground set, T consists of a list

of constants, and Conj is ground (variable free).

Aggregate functions are of the form f(S), where S is

a set and f is a function name among #count, #min,

#max, #sum, #times. An aggregate atom is formed

by aggregate functions, written as L

g

1

f(S)

2

R

g

,

where

1

,

2

{=, <, ≤, >, ≥}, and L

g

and R

g

are

terms (one being possibly omitted). Atoms can be

either standard or aggregate, and literals constructed

from aggregate atoms are aggregate literals.

Rule (51) shows the use of the aggregate

function “#count{T:Conj}=N” to answer the

pending question and to compute how many N firms

are affected forward in the supply chain by the recall

of fresh tomatoes from firm “cp58”. The solution

computed by the DLV solver shows that overall 94

firms have received the contaminated product

directly from company “cp58”, or indirectly from

other firms located more than one step forward in

the chain. Rule (52) computes how many firms

received the contaminated product directly from

recalling firm “cp58”. The DLV solver finds that 56

of the 94 firms were directly supplied by “cp58”. A

natural question is how many states are affected by

this recall, i.e. in how many states are these 94 firms

located. Rule (53) performs this computation

resulting in 23 states. Similarly, rule (54) computes

the number of states where the 56 firms directly

supplied by company “cp58” are located (12 states).

The solution computed by the DLV solver for this

traceability problem includes 877 atoms of type

“bktrace”. Similarly to (51)-(54), (55)-(58) count the

number of firms and states in the contamination path

backward in the supply chain to firm “cp58”.

all_ftrace_firms(N) :- (51)

#count{C:fwtrace(_,_,_,C,_)}=N.

dir_ftrace_firms(N) :- (52)

recall(_,C),

#count{F:fwtrace(C,_,_,F,_)}=N.

all_ftrace_states(N) :- (53)

#count{S:fwtrace(_,_,_,_,S)}=N.

dir_ftrace_states(N) :- (54)

recall(_,C),

#count{S:fwtrace(C,_,_,_,S)}=N.

all_btrace_firms(N) :- (55)

#count{F:bktrace(F,_,_,_,_)}=N.

dir_btrace_firms(N) :- (56)

recall(_,C),

#count{F:bktrace(F,_,_,C,_)}=N.

all_btrace_states(N) :- (57)

#count{S: bktrace(_,S,_,_,_)}=N.

dir_btrace_states(N) :- (58)

recall(_,C),

#count{S:bktrace(_,S,_,C,_)}=N.

In supply chains with multiple products, firms may

have more than one role. Thus, the intersection of

firms computed by (51)-(52) and (55)-(56) may be

greater than zero. For this reason, we must eliminate

duplicates as computed by rules (59)-(62). Similar

rules compute the number of firms directly linked to

“cp58” upstream and downstream in the supply

chain. In fact, 98 unique firms in 25 states are

SupplyChainTracingofMultipleProductsunderUncertaintyandIncompleteInformation-AnApplicationofAnswerSet

Programming

403

affected by this recall since 32 firms in 5 states

belong to the intersection.

total_aff_firms(T) :- (59)

#count{A:fwtrace(_,_,_,A,_)}=M,

#count{C:bktrace(C,_,_,_,_)}=N,

firms_intersect(I),U=M+N,T=U-I.

firms_intersect(I) :- (60)

#count{A:fwtrace(_,_,_,A,_),

bktrace(A,_,_,_,_)}=I.

total_aff_states(T) :- (61)

#count{LA:fwtrace(_,_,_,_,LA)}=M,

#count{LC:bktrace(_,LC,_,_,_)}=N,

states_intersect(I),U=M+N,T=U-I.

states_intersect(I) :- (62)

#count{L:fwtrace(_,_,_,_,L),

bktrace(_,L,_,_,_)}=I.

4.2 Geographically Targeted Tracing

Regional and state public health officials are tasked

with the coordination of recall efforts occurring in

the geographical area within their jurisdictions.

Hence, it is important to obtain specific information

about affected companies located within the

boundaries of such areas. For this reason, our ASP

program encodes four U.S. regions, atoms (63)-(66),

and 50 states plus the District of Columbia, with 51

(ground) atoms of type (67). A more complete

geographic ontology was developed in (Nogueira

and Greis, 2011). Regions of interest are indicated

to the program by adding (ground) atoms of type

(68). Rules (69)-(70) make it possible to generate a

list of all potentially affected firms in a given region

of the country to assist the efforts of its regional

recall coordinators. Identifying firms downstream

from the point of recall, i.e. forward tracing, is

performed by (69), and upstream, or backward,

tracing by (70).

The number of states affected by a recall within

the trace region (68) is computed by (71), and those

belonging to the intersection by (72). The recall of

fresh tomatoes issued by “cp58” can potentially

affect 7 (out of 17) states in the South, 5 (out of 9)

states in the Northeast, 6 (out of 12) in the Midwest,

and 7 (out of 13) in the West; or 25 states total.

Similarly, (73)-(74) compute the number of firms

affected by the recall within the specified region.

From all 98 unique firms affected, the program

returns 16 firms located in the Northeast, 21 in the

South, 25 in the Midwest, and 36 in the West. A

complete list of supplier and customer firms sharing

a contamination path, and located within the same

region, is generated by (75)-(76). For this recall, 21

such firms are in the South, 36 in the West, 15 in the

Northeast, and 22 in the Midwest, i.e. 94 in total.

us_region(northeast). (63)

us_region(midwest). (64)

us_region(south).

(65)

us_region(west). (66)

us_state(State,Region). (67)

geotrace(Region). (68)

ftrace_firms(R,A,LA) :- (69)

geotrace(R),us_state(LA,R),

fwtrace(C,LC,F,A,LA).

btrace_firms(R,C,LC) :- (70)

geotrace(R),us_state(LC,R),

bktrace(C,LC,F,A,LA).

reg_states_aff(R,T) :- (71)

#count{LA:ftrace_firms(R,_,LA)}=M,

#count{LB:btrace_firms(R,_,LB)}=N,

reg_states_intersect(R,I),

U=M+N,T=U-I.

reg_states_intersect(R,N) :- (72)

geotrace(R),

#count{L:ftrace_firms(R,_,L),

btrace_firms(R,_,L)}=N.

reg_firms_aff(R,T) :- (73)

#count{A:ftrace_firms(R,A,_)}=M,

#count{B:btrace_firms(R,B,_)}=N,

reg_firms_intersect(R,I),

U=M+N,T=U-I.

reg_firms_intersect(R,N) :- (74)

geotrace(R),

#count{A:ftrace_firms(R,A,_),

btrace_firms(R,A,_)}=N.

in_region(R,A,LA) :- (75)

geotrace(R),fwtrace(C,LC,F,A,LA),

us_state(LA,R),us_state(LC,R).

in_region(R,C,LC) :- (76)

geotrace(R),bktrace(C,LC,F,A,LA),

us_state(LA,R),us_state(LC,R).

5 TRACK-TRACE OF MULTIPLE

CONTAMINATED PRODUCTS

There are always multiple on-going cases of food

contamination and associated food recalls being

investigated in a country or region. Hence, any

proposed solutions must be able to track and trace

multiple tainted products in the supply chain. Public

health officials often seek information regarding

several outbreaks at the same time. We examine two

KEOD2013-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

404

common situations involving multiple recalls next.

5.1 Tracing Concurrently Recalled

Products

To demonstrate that this ASP program can be used

to trace multiple products, let us assume that recalls

have been issued for the two main products involved

in the 2008 tomatoes and jalapeño peppers outbreak,

and that the supply chains of these products closely

resemble that illustrated by Figure 1. Without loss of

generality we assume that the peppers supply chain

follows the linear structure captured by rules of type

(7) or (8) corresponding to the top portion of Figure

1. To complete this description we need only to

ensure that the food ontology employed by the ASP

program contains: a) facts (17)-(46) describing the

production hierarchy for tomato and pepper

products, and b) recall (77) of peppers issued by the

grower/processor/exporter firm “cp951”. ASP

programs that require only small changes to

accommodate new circumstances, as this one does,

are called “elaboration tolerant”. Programs

exhibiting such property are highly preferred

because they require less time and effort to be

modified to solve larger, more complex problems.

The new, augmented ASP program will now take

into account both supply chains when computing the

firms affected by these recalls. Public health

officials may be especially interested in firms that

produce both products being recalled. A quick, albeit

naive, way to list these firms can be achieved with

(78). The number of firms that produce both

products, as well as the number of states where these

firms are located, can be calculated by (79). DLV

results found 72 companies in 19 states potentially

affected by the contamination of both products.

recall(ppfresh,cp941). (77)

dir_aff_firms(C,L) :- (78)

firm(C,_,_,L),

recall(P1,_),prod_supplied(C,P1),

recall(P2,_),prod_supplied(C,P2).

recall_eff_totals(C,S) :- (79)

#count{A:dir_aff_firms(A,_)}=C,

#count{L:dir_aff_firms(_,L)}=S.

5.2 Tracing Products Suspected of

Contamination before Confirmation

An equally important but different situation faced by

health officials concerns tracing several products

suspected of contamination before clinical test

results or epistemological studies provide definite

confirmation of the tainted product. When there is a

lack of evidence due to uncertainty and incomplete

information, public safety must be ensured and

provisory warnings must alert the population to

avoid consumption of suspected products. In these

cases, a software tool that allows scenario-based

reasoning can help identify possible contamination

paths through all the supply chains involved. Thus,

we introduce disjunctive rules to our program as an

effective construct to simulate what-if scenarios—

each corresponding to a stable model of the ASP

program—and show how to interpret such models.

Assume that during an on-going contamination

outbreak, a number of patients reported consuming

both fresh tomatoes and peppers weeks before the

onset of their illness. Hence, officials may suspect

that one of these foods is the cause of the outbreak

and, until tests can prove which one, those firms

producing both products must be investigated. The

traceability problem is thus reduced to identifying

the firms that produce the suspected products. A rule

of type (80), e.g. (81), expresses the suspicion that

one of two products is tainted and specifies what

type of firms may be part of the contamination.

Since no recall has been issued, we retract any rules

of the form (5) and, to keep using the existing ASP

program, we redefine predicates “recall” and

“supply_chain” in terms of new predicates

“recalled(P,C)” and “suspect(P,T)” with (82)-(85).

Consequently, whenever a food recall is issued facts

of type “recalled(P,C)” are added to the program.

suspect(A,T1) v suspect(B,T2). (80)

suspect(ttfresh,processor) v (81)

suspect(ppfresh,grower).

recall(P,C) :- recalled(P,C). (82)

recall(P,C) :- (83)

firm(C,_,_,L),type_firm(C,T),

suspect(P,T),prod_supplied(C,P),

us_state(L,R),geotrace(R).

supply_chain(S) :- (84)

recalled(P,_),is_of(P,S).

supply_chain(S) :- (85)

suspect(P,_),is_of(P,S).

The DLV solver derives two solutions, i.e. stable

models, for this program corresponding to the two

possible contamination scenarios. The meaning of

atoms “recall(P,C)” in the solutions below is that

firm C, located in the tracing geographic area(s),

produces suspected product P. For space reasons, we

omit the complete solution of affected firms traced

SupplyChainTracingofMultipleProductsunderUncertaintyandIncompleteInformation-AnApplicationofAnswerSet

Programming

405

in the supply chain encompassing all four U.S.

regions. Lastly, the forward and backward traces are

done in two separate program runs to avoid the

combinatorial explosion that occurs when searching

for all affected firms without starting from a single

point of recall.

{suspect(ttfresh,processor),

supply_chain(tomatoes),

recall_eff_totals(39,8),

recall(ttfresh,cp174),

recall(ttfresh,cp431),…}

{suspect(ppfresh,grower),

supply_chain(peppers),

recall_eff_totals(48,17),

recall(ppfresh,cp239),

recall(ppfresh,cp753),…}

6 CONCLUSIONS

This paper demonstrates the utility of answer set

programming in identifying the contamination

source(s) in complex food chains characterized by

multiple products flowing through intersecting

supply chains. Using rules and aggregate functions,

we compute the effects of recalls on targeted

geographic areas to identify the affected companies

located within. Disjunctive rules are used to simulate

possible scenarios in the face of uncertainty and

incomplete information. We use the example of the

2008 food contamination event involving tomatoes

and jalapeños to show the value of this approach to

state agencies charged with managing product

recalls in the event of a foodborne disease outbreak.

Two future avenues of research include: 1)

moving to a risk-based approach by adding

knowledge extracted from publicly available data on

reported foodborne illness such as the likelihood that

a particular food has a high potential risk for

contamination, or the degree of severity of illness

attributed to a particular food; and 2) incorporating

supply chain data on international food businesses.

REFERENCES

Calimeri, F; Dell’Armi, T; Eiter, T; Faber, W; Gottlob, G;

Ianni, G; Ielpa, G; Koch, C; Leone, N; Perri, S;

Pfeifer, G; Polleres, A; 2002. “The dlv system.” In

Flesca, S; Ianni, G; eds., JELIA’02, pp. 537–540.

CDC, 2013. “Surveillance for Foodborne Disease Out-

breaks—U.S., 2009–10,” MMWR 2013, 62:3, pp.41-

47.

CDC, 2008. “Outbreak of Salmonella Serotype Saint-paul

Infections Associated with Multiple Raw Produce

Items—U.S.,” MMWR 2008, 57:34, pp. 929-934.

Dell'Armi, T; Faber, W; Ielpa, G; Leone, N; Pfeifer, G;

2003. “Aggregate Functions in DLV.” In Answer Set

Programming: Adv. in Theory and Implementation,

vol. 78, CEUR Workshop Proceedings, pp. 274–288.

Fritz, M; Schiefer, G; 2008. “Tracking and tracing in food

networks.” In IAALD AFITA WCCA’08, Tokyo

University of Agriculture, pp. 967–972.

Fritz, M; Schiefer, G; 2009. “Tracking, tracing and

business process interests in food commodities: A

multi-level decision complexity.” International

Journal Production Economics, 117:2, pp. 317–329.

Gelfond, M; Lifschitz, V; 1988. “The stable model

semantics for logic programming.” In Kowalski, R;

Bowen, K; eds., International Logic Programming

Conf. and Symp., pp. 1070–1080. MIT Press.

Gelfond, M; Lifschitz, V; 1991. “Classical negation in

logic programs and disjunctive databases.” New

Generation Computing, 9, pp. 365–385.

GS1, 2010. “Business Process and System Requirements

for Full Supply Chain Traceability.” GS1 Global

Traceability Standard, Issue 1.2.2.

Kher, SV; Frewer, LJ; Jonge, JD; Wentholt, M; Davies,

OH; Luijckx, NBL; Cnossen, HJ; 2010. “Experts’

perspectives on the implementation of traceability in

Europe,” British Food Journal, 112:3, pp. 261-274.

Emerald Group Publishing Limited.

Marek, VW; Truszczynski, M; 1999. The Logic Program-

ming Paradigm: a 25-Year Perspective, chap. “Stable

models and an alternative logic programming

paradigm,” pp. 375–398. Springer Verlag, Berlin.

McEntire, J; Bhatt, T; 2012. “Pilot Projects for Improving

Product Tracing along the Food Supply System–Final

Report.” Institute of Food Technologists.

Nogueira, ML; Greis, NP; 2011. “Rule-Based Complex

Event Processing for Food Safety and Public Health.”

In Bassiliades, N; Governatori, G; Paschke, A; eds.,

RuleML-Europe’11. LNCS 6826, pp. 376–383.

Springer.

Nogueira, ML; Greis, NP; 2012. “Recall-driven Product

Tracing and Supply Chain Tracking using Answer Set

Programming.” In Filipe, J; Dietz, JLG; eds.,

KEOD’12, pp.125–133. SCITEPRESS.

Nogueira, ML; Greis, NP; 2013. “An Answer Set

Programming Solution for Supply Chain

Traceability.” In Filipe, J; Dietz, JLG; eds., KEOD’12.

Springer.

Regattieri, A; Gamberi, M; Manzini, R; 2007. “Trace-

ability of food products: general framework and

experimental evidence.” J Food Eng, 81, pp. 347–356.

Scallan, E; Hoekstra, RM; Angulo, FJ; Tauxe, RV;

Widdowson, M-A; Roy, SL; Jones, JL; Griffin, PM;

2011. “Foodborne Illness Acquired in the United

States.” Emerging Infectious Disease, 17:1, pp. 7–15.

Thakur, M; Sørensen, C-F; Bjørnson, FO; Forås, E;

Hurburgh, CR; 2011. “Managing food traceability

information using EPCIS framework.” Journal of

Food Engineering, 103:4, pp. 417–433.

KEOD2013-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

406