Preparation of a PLGA/Calcium Silicate Composite with Gradient

Pore Structure

Bong-Kyu Choi

1

, Suk Young Kim

2

and Sang-Hoon Rhee

3

1

Department of Oral Microbiology and Immunology, Dental Research Institute and BK21 HLS, School of Dentistry,

Seoul National University, Seoul, Korea

2

School of Materials Science & Engineering, Yeungnam University, Gyeongsan, Korea

3

Department of Dental Biomaterials Science, Dental Research Institute and BK21 HLS, School of Dentistry,

Seoul National University, Seoul, Korea

Keywords: Composite, PLGA, Calcium Silicate, Pore, Bioactivity.

Abstract: The PLGA/SiO

2

-CaO composite, which have a gradient pore structure, was newly prepared by the

expansion of carbon dioxide gas in the PLGA matrix. The bioactive SiO

2

-CaO particles were made by a sol-

gel method from tetraethyl orthosilicate and calcium nitrate tetrahydrate under acidic condition followed by

the heat treatment at 600

o

C for 2 h. The PLGA/SiO

2

-CaO composite was then prepared by a solvent casting

using chloroform as solvent. The composite was loaded into the high pressure chamber and then carbon

dioxide gas was introduced achieving a final pressure of 10 MPa. After 3 days, the gas was released quickly

and the gradient pore structure was developed. The samples were observed by FE-SEM and its bioactivity

was tested in simulated body fluid.

1 INTRODUCTION

The representative bone bonding materials are

calcium phosphates, bioactive-glasses, and –glass

ceramics. They are known to bond to bone directly

without intervening fibrous tissues. However, their

applications are only limited to non-load beading

sites because their fracture toughness are very low,

which results in low mechanical reliability.

Composites have been extensively studied as

alternations of a bioactive ceramic because a

polymer can give a ductility and flexibility while a

ceramic can give hardness, strength, and bioactivity.

One method to make a bioactive composite is just

mixing the ceramic particles and polymers

mechanically. Typical ones are thermal blending and

solvent casting methods. However, the drawback of

thermal blending method is that it is hard to increase

the ceramic portion in the composites as well as the

occurrence of phase separations due to the different

wettabilities between two materials. Ceramics show

hydrophilicity while most synthetic polymers have

hydrophobicity so they cannot mix together easily.

Solvent casting method is very simple way to make

ceramic/polymer composite but it also shows the

disadvantage when mixing two phases. After casting

the ceramic/polymer mixture, the sedimentation of

ceramic particles must occur due to the density

differences between solvent and ceramic particles.

Thus, thick polymer top layer generally forms. In

addition, phase separation between ceramic particles

and polymer matrix occurs after drying. Thus,

ceramic/polymer nano-composites are developed,

where the polymer is linked to ceramic precursor at

the molecular lever.

However, the reported process to make the

composite is hard to get porous structure. The bone

grafting materials must have porous structure

because it induces the growth of blood vessels into

the material.

The salt leaching method is generally used to make

porous structure when using the solvent casting

method to make ceramic/polymer composites.

However, this method is hard to make the

connections among the pores. In addition, it cannot

be applicable to the process for making nano-

composite because the calcium salt, which is

inevitable component to produce bioactivity in vivo,

is also leached out when washing out the salt after

the casting.

Mooney et al. (1996) reported the new method to

produce porous structure in PLGA scaffold by the

239

Choi B., Young Kim S. and Rhee S..

Preparation of a PLGA/Calcium Silicate Composite with Gradient Pore Structure.

DOI: 10.5220/0004200302390242

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 239-242

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

expansion of carbon dioxide gas in high pressure

chamber. The carbon dioxide has some solubility in

the PLGA. Thus, when the high pressure of carbon

dioxide is applied to the PLGA scaffold and then

released quickly, it becomes to expand in the PLGA

matrix. Resultantly, the pores are developed at the

places where the gas existed. However, the

disadvantage of this method is that it is also hard to

connect between the pores. Thus, the salt leaching

method is combined together to make porous

structure. However, there has been no reprot to

apply this method to make a porous bioactive

composite material, yet.

In this study, we prepare the PLGA/calcium

silicate composite by the solvent casting method and

then a gradient pore structure was introduced using

the expansion of carbon dioxide gas in a high

pressure chamber.

2 MATERIALS AND METHODS

2.1 Preparation of Calcium Silicate

Powders

The calcium silicate (SiO

2

-CaO) particles were

prepared with the starting composition of

70SiO

2

30CaO in molar ratio. The calcium silicate

particles were prepared by hydrolysis and

polycondensation of tetraethyl orthosilicate (TEOS,

Nacalai Tesque) in calcium nitrate tetrahydrate

(Nacalai Tesque) and polyethylene glycol (PEG,

Aldrich) in aqueous solution. The molecular weight

of PEG used in this experiment was about 10000.

PEG and calcium nitrate tetrahydrate were

dissolved in distilled water and then concentrated

nitric acid (60 wt%, Nacalai Tesque) was added.

TEOS was added to the above solution under

stirring. After 20 min, the solution was transferred to

a polystyrene box with its top sealed tightly, and

kept at 40C in a convection oven for gelation and

aging for 1 day. The obtained wet gel was immersed

in distilled water for 3 h with the distilled water

renewed every hour. After the wet gel was dried at

40C for 7 days, it was heated at 600C for 2 h and

then pulverized using a planetary ball mill.

2.2 Preparation of a PLGA/Calcium

Silicate Composite

The 90PLGA/10SiO

2

-CaO composite (in wt%) was

made by the solvent casting. PLGA powder

(90PLA10PGA, IV 0.55 ~ 0.75, Medisorb,

Alkemes) was dissolved in chloroform (4%) after

which SiO

2

-CaO particles were added to the

solution. After stirring vigorously for 1 h, the

mixture was poured into a Teflon mould and dried

under ambient conditions.

2.3 Preparation of a PLGA/Calcium

Silicate Composite with a Gradient

Pore Structure

The 90PLGA/10SiO

2

-CaO composite was loaded

into the high carbon dioxide pressure chamber and

then carbon dioxide gas was introduced into the

chamber achieving final pressure of 10 MPa. The

specimens were allowed to equilibrate and saturate

with the carbon dioxide gas for 3 days, forming a

single phase PLGA/CaO-SiO

2

/CO

2

gas solution at

room temperature. Subsequently, the carbon dioxide

gas was quickly released bringing the chamber to

ambient pressure. (Mooney et al., 1996)

2.4 Bioactivity Test

The bioactivity of the PLGA/CaO-SiO

2

composite

was assessed by evaluating its capability to form low

crystalline hydroxyl carbonate apatite on its surface

in simulated body fluid (SBF). (Kokubo et al., 1990)

The SBF was prepared by dissolving reagent grade

NaCl, NaHCO

3

, KCl, K

2

HPO

4

·3H

2

O, MgCl

2

·6H

2

O,

CaCl

2

, and Na

2

SO

4

in ion exchanged distilled water.

Their ionic concentrations were Na

+

142, K

+

5.0,

Mg

2+

1.5, Ca

2+

2.5, Cl

-

147.8, HCO

3

-

4.2, HPO

4

2-

1.0, SO

4

2-

0.5 (in mM). The solution was buffered at

pH 7.4 with tris(hydroxymethyl) aminomethane

((CH

2

OH)

3

CNH

2

) and 1 M hydrochloric acid (HCl)

at 36.5

o

C.

Specimen disks 12 mm in diameter by 4

mm in thickness were cut, sterilized under UV lamp

for 30 minutes, and then dried on a clean bench.

Subsequently, the specimens were incubated in 30

mL of the SBF at 36.5

o

C for 7 days. After

incubation, the PLGA/CaO-SiO

2

composite was

removed, gently rinsed with ion-exchanged distilled

water several times, and dried at room temperature.

2.5 Characterization

Microstructure was observed by a field emission

scanning electron microscopy (FE-SEM; S-4700,

Hitachi). The crystal phase of the specimens before

and after soaking in the SBF was evaluated by a thin

film X-ray diffractometry (TF-XRD; D8 Discover,

Bruker).

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

240

3 RESULTS AND DISCUSSION

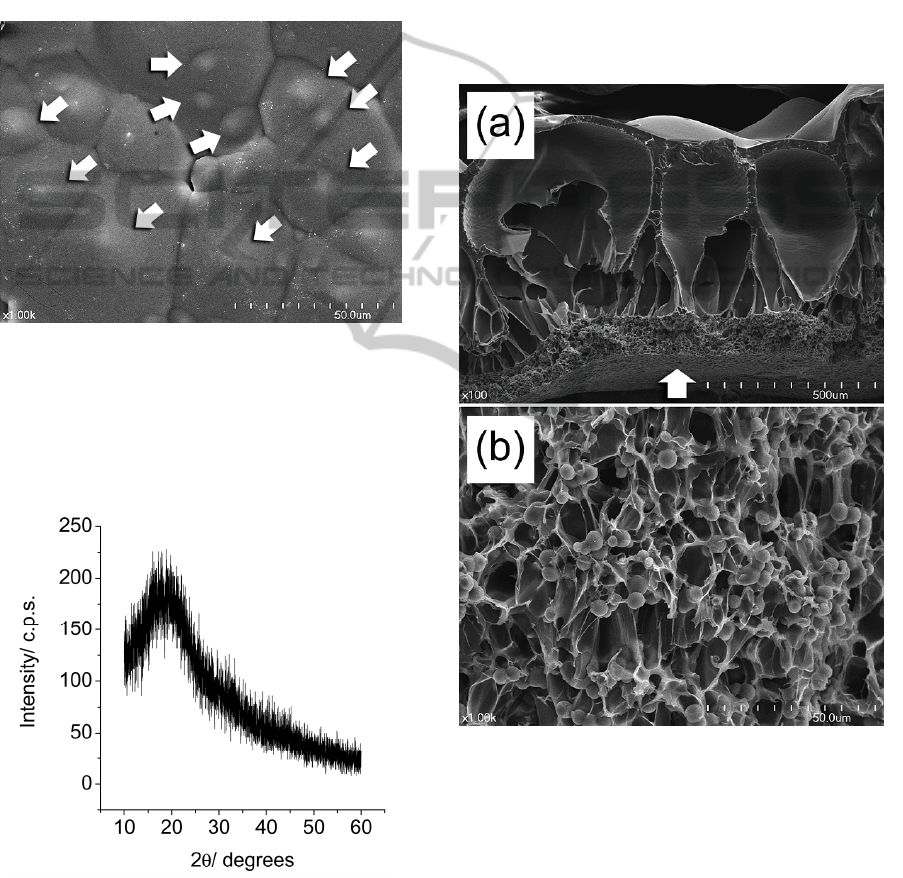

Figure 1 shows the FE-SEM photograph of the

PLGA/CaO-SiO

2

composite after the solvent casting.

A thick surface layer was the PLGA while the CaO-

SiO

2

particles were not observed at the surface.

However, the hemispherical convex surfaces

denoted as white arrows in Figure 1 must be the

CaO-SiO

2

particles, which placed under the thick

PLGA film.

Figure 1: FE-SEM photograph of the PLGA/CaO-SiO

2

composite after the solvent casting.

Figure 2 shows the XRD diffraction pattern of

the PLGA/CaO-SiO

2

composite after the solvent

casting. Only broad hallow peak was observed to

occur. It means there is no crystalline phase.

Figure 2: The XRD diffraction pattern of the PLGA/CaO-

SiO

2

composite after the solvent casting.

Figure 3 shows the (a) low and (b) high

magnification FE-SEM photographs of the fractured

PLGA/CaO-SiO

2

composite after the carbon dioxide

gas treatment. The thick PLGA surface layer was

inflated in large degree after the quick release of

carbon dioxide gas and resultantly it made large

pores at the surface of the composite (Figure 1(a)).

However, the PLGA/CaO-SiO

2

composite region,

which was previously placed under the thick PLGA

layer, was not inflated as much as the PLGA. Thus,

only small pores were produced (about 10 ~ 30 m

in size) (Figure 3(b)). The pore sizes were gradually

become larger from the bottom to top surface of the

specimen. The bottom layer of the composite

showed open pore structure (white arrow in Figure

3(a)).

Figure 3: (a) Low and (b) high magnification FE-SEM

photographs of the fractured PLGA/CaO-SiO

2

composite

after the carbon dioxide gas treatment.

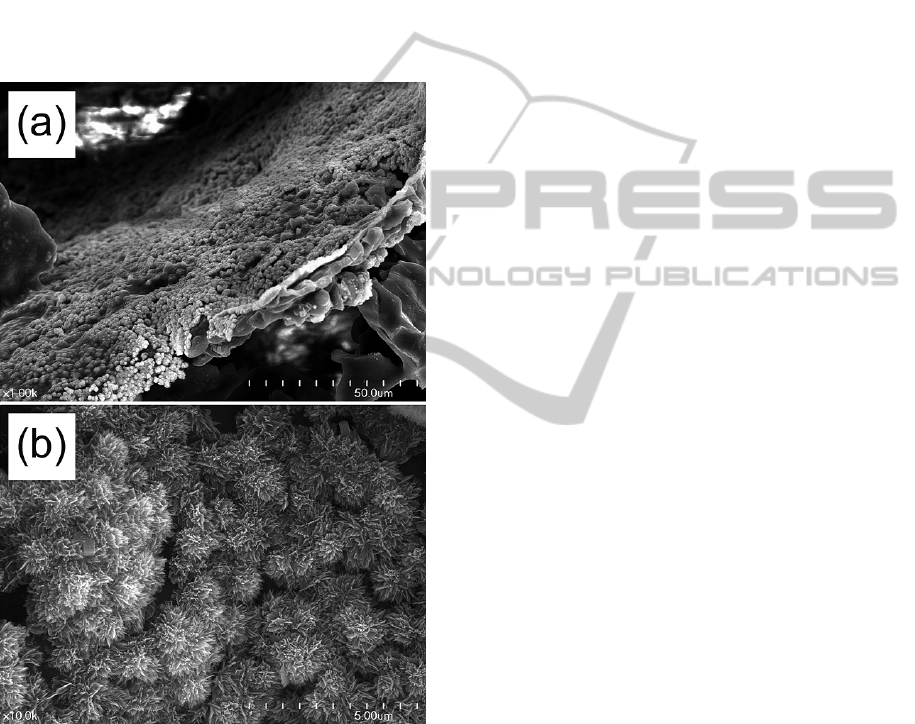

Figure 4 shows the (a) low and (b) high

magnification FE-SEM photographs of the

PLGA/CaO-SiO

2

composite after soaking in the SBF

for 1 week at 36.5

o

C. Small flake-like low

crystalline hydroxyl carbonate apatite crystals were

observed to occur on the surface of the PLGA/CaO-

SiO

2

composite. They started to occur from the

surface of the CaO-SiO

2

particles and then spread

PreparationofaPLGA/CalciumSilicateCompositewithGradientPoreStructure

241

out all the surface of the composite even on the

PLGA surface. It means this PLGA/CaO-SiO

2

composite has bioactivity and it also has a potential

to have a good osteoconductivity.

From the results, it can be summarized that the

PLGA-calcium silicate composite which had the

gradient pore structure was successfully made using

the expansion of carbon dioxide gas in the high

pressure carbon dioxide gas chamber. The practical

implication of this result is that this material can be

used as a bone grafting material or a scaffold

material for bone tissue engineering due to its high

porosity and apatite forming capacity in the SBF.

Figure 4: (a) Low and (b) high magnification FE-SEM

photographs of the PLGA/CaO-SiO

2

composite after

soaking in the SBF for 1 week at 36.5

o

C.

4 CONCLUSIONS

The PLGA/calcium silicate composite which had

gradient pore structure was newly developed. The

calcium silicate particles could be made by sol-gel

method while the PLGA/calcium silicate composite

could be made by solvent casting method. The thick

PLGA layer was formed during the casting process

due to the sedimentation of the calcium silicate

particles by the different densities between PLGA

and calcium silicate particles. After the treatment of

carbon dioxide gas, the gradient pore structure was

developed in the composite. This composite showed

the bioactivity in the SBF and it means it has a high

potential to be used as a bone grafting material or

the scaffold materials for bone tissue engineering.

ACKNOWLEDGEMENTS

This research was supported by the Bio & Medical

Technology Development Program of the National

Research Foundation funded by the Korean

government (MEST) (20110007746).

REFERENCES

Kokubo T, Kushitani H, Sakka S, Kitsugi T, Yamamuro T.,

1990. J. Biomed. Mater. Res., 24, 721-734.

Mooney, D. J., Baldwin, D. F., Suh, N. P., Vacanti, J. P.,

Langer, R., 1996. Biomaterials, 17, 1417-1422.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

242