Geometric Knowledge Analysis based in Part Functional Descriptions

João Carlos Linhares

1

and Altamir Dias

2

1

Graphic Expression Department, Federal University of Santa Catarina, Florianópolis, Brazil

2

Mechanical Engineering Department, Federal University of Santa Catarina, Florianópolis, Brazil

Keywords: Functional Modeling, Word Repetition Standard.

Abstract: Parts have associate elementary functions descriptions to each constructive detail. A first try to understand

this relationship is to look for, if exists a clear-cut syntactic standard to create the functions description.

After, it is necessary to establish some measure's method to evaluate how the functions are repeated in

several mechanical parts with some existent standards and how to associate it to one or more elementary

solid geometries, such as groove, hole, groove, round, chamfer, and others. This correlation may lead,

initially, to the likely feature operator in CAD system, which is used to create solid geometries that

accomplish the desired functions to the product. So, CAD 3D geometric modeling can be accomplished

from the functions description executed for the parts that integrate the products technical systems. When a

functions group with design meaning can be, in some way, associated to the solid geometry, it may realize a

new paradigm in the mechanical design: the product design from the function-form transformation. This

elementary functions description is closely to the geometric structure that gives the part's shapes. This

article shows the process to identify functions description and its phrasal structure applied to the mechanical

parts of an off-road Baja vehicle design.

1 INTRODUCTION

This article presents the current advances in the

research on the "shape function" mapping. At first, it

re-organizes the computational implementations

previously performed in Linhares (2005), and

explores a new approach, now, based in a technical

terminology which operates the relations between

the geometric details of parts and its functional

description areas. Also, it tries to look for patterns of

language that directs the choice basic geometry solid

in parts modeling.

Implementations carried out in Linhares (2005)

describe various correlations between functions

structures, functional areas, and solid features. The

implementation becomes possible to filter and

identify some languages patterns in terms of phrasal

components in functional descriptions and associate

them with design meaning and its functional areas,

and also, those that have link to the solid features

associated to the geometry model created in CAD

systems.

However, each time a certain type of solid

geometry or solid feature is required by the

functional description, based on design intent, it is

very likely, that it has the same verbs, nouns or other

phrasal components to describe the part functional

areas. To count the repetition of phrasal components

may be implemented computationally, and it can be

the first indicators that there is a way to associate

them to the part geometry description. Also, part

functional description in terms of functions has a

semantics composition, which if precisely identified

may lead to geometries alternative to design intent

It also was noted that these repetition patterns can

be help to find preliminary solution principles during

the design when all description are linked to

terminological similarities verification. In several

design processes designers use phrases to describe and

communicate intentions and solutions contain verbs

nouns and qualifiers (VNQ). Those descriptions, here

considered as a phrasal structure, belong to the part

preliminary solution principles chain.

Designers must study advance the “behavior in

use” of parts in the mechanical system or sub system

in order to get knowledge about their functions and

theirs preliminary solutions principles (Pp’s). This

procedure of learning becomes easy to the designer

to find geometric solutions, to identify physical

region or detail in a part.

When the designer looks at several products’

307

Linhares J. and Dias A..

Geometric Knowledge Analysis based in Part Functional Descriptions.

DOI: 10.5220/0004179603070313

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2012), pages 307-313

ISBN: 978-989-8565-30-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

projects, he always is able to identify repeated

patterns among several parts, systems or sub-

systems that compose them, although it depends of

the type of product or application domain. If he

looks to the part details, the final geometries are

largely associated to specific design requirements

and pre-defined for the part in the assembly in

carrying out their functions. It can be seen, in some

study case, where the functions described by the

designers will lead to the same repeating patterns as

will be showed latter in the text. In this paper will be

emphasized functions descriptions made for an off-

road Baja vehicle.

2 RESEARCH BACKGROUND

Most of researches have showed that 2D and 3D parts

geometric modeling begins in the product conceptual

definition where primary definitions, based on

principle of solutions are going to give initial shape to

a part and after to the product as whole. So, most of

users and design requirements have to take in account

to produce the objects embodiment in accord of

solution principles chosen from functions they are

able to identify to the product.

This paper was written to readers that know

about design methodology researches. The transition

function-form is a design activity in the interface

between conceptual and preliminary design phases,

when using the Pahl/Beitz design methodology

process. In this interface, questions about

product/assembly/part shapes and functionalities

have been strong importance in the design process.

Roth (1985) apud Hundal (1990) shows that in

functional/conceptual design and preliminary design,

the product model description (PMD) can be

represented in the computer for product data

definition (PDD).

Hubka and Eder (1988) use the term "action

mode" and emphasize that the technical systems

components must be developed simultaneously and

indicate that before describing functions is necessary

to understand the design principles associated with

carrying out those functions.

Hundal (1990) has written about the systematic

design method proposed by Rodenacker (1984) and

Pahl and Beitz (1988). They appointed scientific

procedures to aid the new products and processes

development, based on principles (physical,

chemical, biological) rather than pre-conceived

solutions and existing products

Deng et al. (2000), warn the importance of the

functional deployment and constraints definition

between the product physical components

elementary functions. The authors use the design

model "Function-Environment-Behavior-Structure –

FEBS”, to represent the product functional inputs

and outputs. Case and Hounsell (2000) present a

methodology used to validate a representation based

on features that capture the designer intentions

related to the part geometry functional, relational

and volumetric aspects.

Roy et al., (2001) proposed a method to design

synthesis by part functional requirements mapping

which is done in a restrictions multi-stage

optimization during the design process stages. This

function-form mapping can replenish the product

design specification, modifying, and optimizing the

organizational structure from product level to part

level.

Pahl et al., (2005) propose preliminary design

guidelines. These guidelines can be considered as

parts preliminary design principles. They are:

thermal expansion, creep and relaxation, corrosion,

wear, form, manufacturing, maintainability,

recycling, safety factors and technical standards.

These requirements can compose a checklist for

the designer serving as a guide in parts functions

defining. Linhares and Dias (2001a, 2001b, 2003a,

2003b) have written several papers presenting an

approach to the development of a computational

framework for modeling part functions to achieving

a correlation model between the functional and

geometric domain in the product preliminary design

stage, following the Pahl and Beitz (1996)

methodology.

In the product development process, a reference

model (PDPMR) was proposed in Back et al. (2008)

and implemented by NeDIP research group, in

which, like Pahl and Beitz, the process may be is

broken down into several tasks with inputs and

outputs, and so, providing mechanisms to

accomplish each task in design of a product.

Users and designers have to transform design

requirements in function description and those in the

solid geometry modeling, building the details of each

parts, to the group of parts and finally to each details

of the product. One of these tasks is to establish the

functional defining basis in the product level.

Bouzeghoub (1997), points to the importance of

promoting the use of natural language as language

specification and query databases. Points out

important projects dedicated to language dictionaries

definition from the end of 80 years in many research

laboratories, but the result spread was limited to

specialized communities.

Formal languages, which are sets of words built

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

308

on an alphabet, are specific languages used in the

context grammars preparation. They have specifics

semantics and syntax fixed or standardized, there are

no ambiguities. However, attempts to translate

formal expressions into knowledge concepts or

cognitive, often result in failure.

3 MECHANICAL PART DESIGN

AND THE FUNCTIONAL

SPACE

The hierarchical model is widely used in several

fields and is much appropriated to classify elements

of the physical objects representation. Products

component and its corresponding meanings in terms

of functions have been used extensively in the

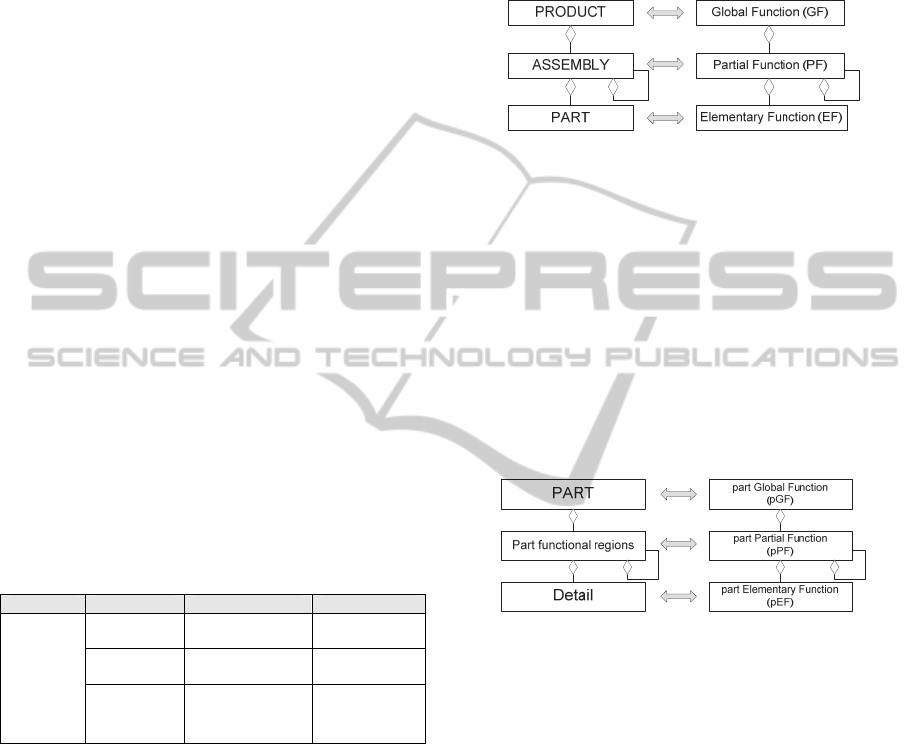

mechanical design. In Table (1) is showed how to

classify design functions applied to the product

design process.

This compilation is resulted from several

researches where various types of functions

classifications was been proposed by authors in the

literature Pahl and Beitz (1988), Back et al., (2008).

In the Table (1) an hierarchical product description

includes the product global function (GF), the partial

functions (PF) and the elementary functions (EF),

extended to assemblies, and to the parts in particular.

Table 1: Overview with various design functions

classifications collected the theoretical review.

Classification PRODUCT ASSEMBLY PART

Hierarchical

Global

Function (GF)

assembly Global

Function (aGF)

part Global

Function (pGF)

Partial

Function (PF)

assembly Partial

Function (aPF)

part Partial

Function (pPF)

Elementary

Function (EF)

assembly

Elementary

Function (aEF)

part Elementary

Function (pEF)

The prefix (a) and (p) indicates the role of the

component in the product hierarchy. The Figure 1

shows the corresponding UML representation of the

product physical and functional levels hierarchy.

The small diamond between representations frames

of each functional and physical level mean the

associated representation table aggregation. This

means that a PRODUCT is made up of ASSEMBLY

aggregations and consequently each ASSEMBLY

aggregations by PARTS aggregations. The frame on

the top right of Fig. (1) Represents the Global

Function level (GF).

The recursion symbol in the representative

framework of ASSEMBLY means that one new

ASSEMBLY can be formed by aggregations of the

several other assemblies (sub-assemblies), and

finally, the last level of representation is one

ASSEMBLY (sub-assembly) composed of the

PARTS aggregations. The physical representation

levels have their respective functional representation

levels.

Figure 1: Product physical and functional levels – a UML

representation.

The representation used for product can now be

extended to the physical areas and part functions

representation, as shown in Fig. (2). The Figure (2)

shows the UML representation of the part physically

as well as the functional levels. This representation

uses the same composition logic used for the

corresponding product physical levels

representation. The Global Function (pGF) adds

Partial Functions (pPF), which in turn adds

Elementary Functions (pEF), all related to the part

as a whole.

Figure 2: Part physical and functional levels - a UML

representation.

In the Table (2) is showed a set of design

functions in the design process of a product,

assembly, and parts. The term function can be

extended to specify different concept applied to the

parts, including "geometry form", part applications,

"manufacturing process", action mode, etc. In same

classification type it can have the same name in

different level of product hierarchy while to other it

can be more specialized for a specific level.

The classification types are important to

understand and to describe better the mapping and

representation process between design and

manufacturing, particularly in the CAD/CAM

systems.

Many authors has written and agreed to the fact

that the function based design is important in

geometry form to define product and parts layouts,

as discussed earlier. Also, they believe about the

GeometricKnowledgeAnalysisbasedinPartFunctionalDescriptions

309

Table 2: Extended design functions classifications in

design process review.

Classification PRODUCT ASSEMBLY PART

Geometric

form

rotational Function (rtF); prismatic Function (prF);

laminar Function (laF); mixed Function (ixF)

Part

application

mechanical Function (mcF); hydraulic Function (hdF);

pneumatic Function (pnF); electroelectronic Function

(eeF); computational or programming function (ifF)

Manufacturing

process

stamping Function (stF); sintering Function (siF);

machining Function (mcF); casting Function (ctF)

Complex level

Product

Functions (F

I

):

mechanical

systems

composed of

assemblies

and parts

Assembly

Funtions (F

II

):

simple

mechanical

systems that can

also carry a

larger functions

group.

Part Function

(F

III

): elementary

systems,

manufactured

without assembly

operations.

Qualification

Primary Function (PrF); Secondary Function (ScF);

Acessory Function (AcF); Derived Function (DeF):

Action mode

fastener Function (Fx); support Function (sF);

transmission Function (tF); transport Function (pF):

Descriptive

representation

Function described by verb (Fv); Function described by

verb and noun (Fs); Function described by verb, noun and

qualifier (Fq).

necessity to represent the product functions, either

through a graphical model, or computationally or yet

in a database resource. These techniques facilitate

understanding and verification of inter-functional

relationships, and providing a better use behaviors

visualization and anticipation. Part contains

geometric features essential to the performance in its

life cycle. It means, the part functional specificities,

in terms of the design process, have it geometric

shape closely related with the material, resistance,

dynamic requests, definitions, among other specific

requirements.

3.1 Functional Descriptions Model –

(VNQ)

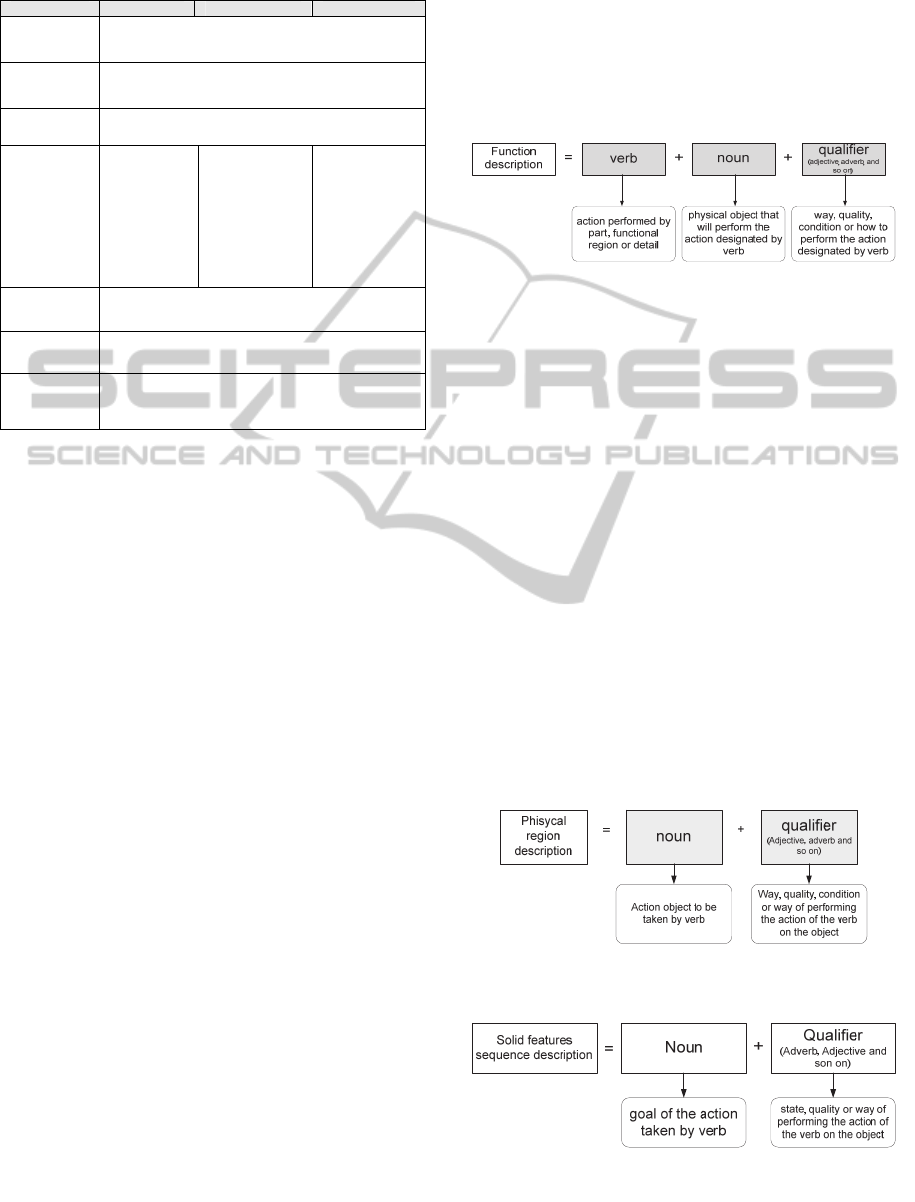

The phrasal descriptive structure provides a

grammatical components logically sequenced that

may include design intentions when is written on a

standard grammatical pattern.

Many authors suggest using only verbs to define

product functions in order to describe appropriated

solutions as design principle. However, to the part

function description is better to extend such

simplified description, including a phrasal sequence

composed by "verb + noun + qualifier", shortly

(VNQ), whose basic structure is showed in the

Figure (3).

The verb expresses the action that a part or some

part geometry is created for. The verb expresses is

related with the hierarchical level corresponding to

the physical model adopted. The noun is the object

upon which the verb action concerns and the

qualifier means a specialization of the designer

intention, because it embeds and specialize part

design requirements more precisely.

Thus, the format or grammatical sequence can

lead the designer to describe the functional needs,

and as it is inside a grammatical pattern help to

organize ways to find standard of functional

structure in part design.

Figure 3: Representation of the basic structure to part

function description.

Such pattern of functional structure may be

extended to describe physical areas, and CAD/CAM

features sequences used to compose geometrically a

part. In both cases, the functional structure are

simplified by using only the noun and the qualifier

in their descriptions, as showed in the Figures (4)

and (5), respectively.

In the physical region/area description is more

used colloquial patterns in design engineering

domain. Otherwise, the solid features description

begins with the grammar used in the CAD/CAM

system, according each user interface vendor. So,

the first description is characterized by expressing

the design intent, while the second structure is

described in the tree of features of the CAD/CAM

system, showing how the designer realizes the

geometric embodiment of the physical description.

Both are built on different linguistic corpora, but that

converge towards the same goals: the systematic

mechanical design.

Figure 4: Basic structure representation for part physical

region description composition.

Figure 5: Basic structure representation for the solid

features description.

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

310

Verbs design used in parts functional

descriptions, physical regions, and solid features can

be defined in the part design dictionary. In it, the

verbs contained in the technical language of a given

design scope, and can be, either added or removed or

even replaced for the design intended descriptions

composition, in terms of functions. The database

implementation contains the full of the verbs listed

in linguistic corpus implemented and can be dealt by

means of computer interfaces to aid the mechanical

designer to choose them to describe parts functions.

The Table (3) shows some examples of design verbs

used described actions necessary to parts

functionality.

Table 3: Design verb list.

absorb speed set housing balance

trigger add feed cushion pump

engage admit align enlarge capture

join compress connect control convert

cut lead derive untie download

Also, the Table (4) shows some design nouns

used in the physical regions descriptions and solid

features necessary theirs descriptions. Also, the

same database should have to contain the full set of

the nouns in the linguistic corpus implemented to aid

the mechanical designer to write the functional

description at each level.

Table 4: Design noun list.

lamp foundation ring arrangement base

finish food bulkhead washer stop

coupling relief support sprinkling rod

removal socket area actuator block

agitation damping rim tires balancing pump

The qualifiers database includes words like

horizontally, alternative, angular, angularity,

previous, horizontal, inclined, lower, assembled, etc.

Examples of grammatical elements or words classes

that are related to the mechanical design domain are

shown in Tab. (5).

Together with verbs, nouns and qualifiers there

are a set of terms, commonly called of technical

terms, which are largely used by designer to describe

the role of part belonging to an application domain

in product design. An additional database element

including technical terms may help technologists

and designers to project product and details based in

the functions description, as described in the Table

(6). It may lead to a standard set of word, and also

allow them to control and manage projects if they

have better familiarity with the technical terms used

within the design scope.

Table 5: Word class and qualifiers values used in

mechanical design.

N

o

word class possible value

01 adjective

perpendicular, axial, smooth,

straight, knurled, grooved,

02 adverb

perpendicular, axially, above, before,

in, out, horizontally

03 article the...

04 conjunction

and, or, what, as, since, though, as,

which, as…

05 numeral

one, two, thirteen, twelve hundred,

first, sixty, third, ,

06 preposition

since, between, until, against,

without, under, about, on, in,

07 pronoun

my, this, he, all, some, several, both,

any, much…

08 noun

coupling, gear, screw, rod, torque,

rotation, shaft, pulley,

09 verb

adjust, filter, position, retain,

transmit, pull, merge...

4 THE PRODUCT ANALYSIS

This research was applied to motor vehicle designed

for off-road competitions, organized annually by

SAE Brazil, called of the competition SAE Baja. It

geometric and functional requirements are

considered by designer as very singular.

The information registered on the design of the

vehicle was produced by student team. The team are

studying in the mechanical engineering program of

the Instituto Superior Tupy (IST) of the Educational

Society of Santa Catarina (Sociesc). The vehicle is a

minibaja TR-02 and the part nomenclature used was

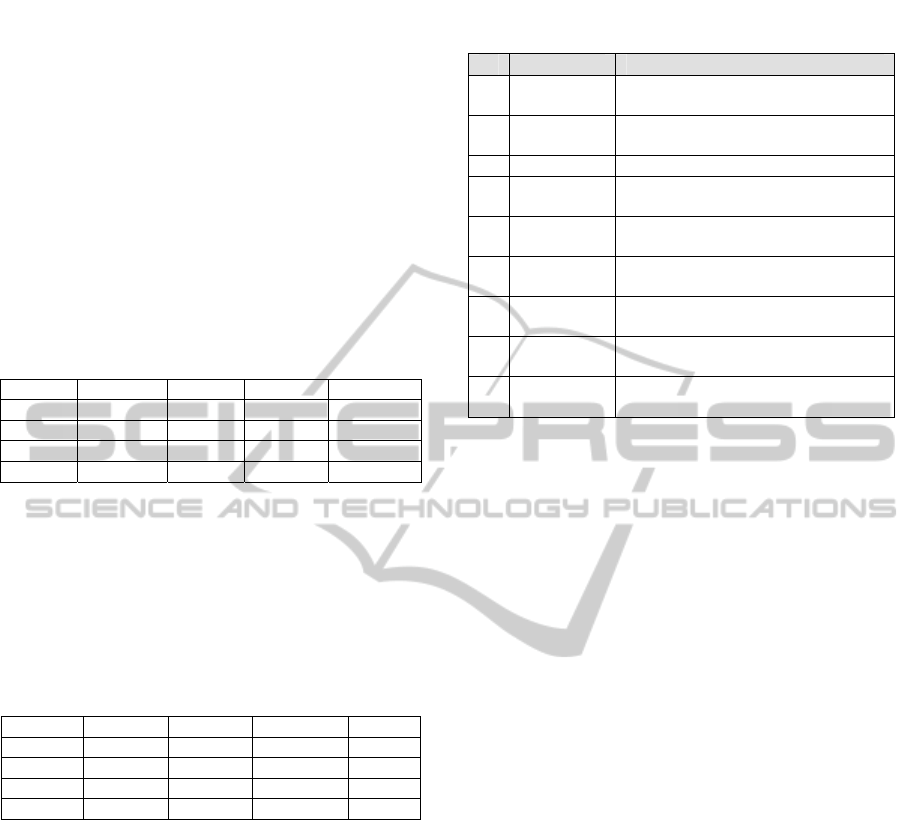

done, from design study project. In the Table (6) is

appointed the CAD/CAM features names used to

details geometrically components and parts of a

minibaja TR-02 studied. Also, the column Prof

indicates if the feature needs to be built by using a

2D profile or not, to produce the geometry. The

Table (7) shows the total of features in each

subsystem, as well as the part total number (in

units).

The part classification was done in terms of

global shapes, like rotational, prismatic or mixed

form. The phrasal structures description was created

by engineering academics team that acts in the

vehicle Baja design and manufacturing. The team

searched to identify which were the best phrasal

structures, types coordinate the system that was

more appropriated to use in CAD geometries

definitions, the “solid features”, to model each

vehicle part. So, the terminologies verification used

in the physical structures identification, the names

that are assigned for parts, the identification of its

GeometricKnowledgeAnalysisbasedinPartFunctionalDescriptions

311

Table 6: Technical terms list used to identify the solid

features details in CAD systems.

n

o

technical

terms

prof.

(*)

n

o

technical terms

prof.

(*)

01

cylindrical

trough hole

10

internal prismatic

round

02

cylindrical

blind hole

11

external prismatic

round

03

not cylindrical

hole

X 12

radial rotational

chuckhole

X

04

internal

rotational

chamfer

13

axial rotational

chuckhole

X

05

external

rotational

chamfer

14

prismatic

chuckhole

X

06

internal

prismatic

chamfer

15

conical chuckhole

07

external

prismatic

chamfer

16

radial rotational

rebound

X

08

internal

rotational round

17

axial rotational

rebound

X

09

external

rotational round

18

prismatic rebound

X

(*)

(prof. = profile)

Table 7: Mechanical Elements of the TR-02 Baja vehicle.

MS

code

Mechanical

System (MS)

Units

number

01 chassis 101

02 direction 25

03 transmission 11

04 front suspension 86

05 back suspension 12

Total 235

functional regions and details contribute for the

students to understand the design meanings study

involved in the mechanical design intentions and

helps them to systematize the part functional design

in the preliminary design phase. The units’

subdivision (quantity) and part types were very

important to understand the whole design process.

Later, in a second phase of this research, where the

statistics of the repetition standards occurrences was

measured, they learned more precisely the

descriptive structures phrasal meaning, how to

combine its composition elements in relation to the

best terms used in each case and how it was related

technical terms used in the solid features available in

system CADCAM.

5 CONCLUSIONS

This paper presents a model of functional

description that allows helping computational

implementations to discover patterns repetition in

functional structures, physical regions, terminologies

and solid geometries of mechanical parts.

The emphasis was to describe phrasal structures

to the functions, physical regions, technical

terminologies and solid features. To build the

database was used a Baja competition off-road

vehicle design, modeled in system CAD/CAM and

built physically by a student team of the Superior

Institute Tupy of the Educational Society of Santa

Catarina, hosted in the city of Joinville - SC.

The results lead to the conclusion that looks for

standards word repetition are important to give

background to the students in design and

manufacturing process. They understand better how

to map functional and geometric spaces of part

design. They learned, also, that the part final

geometry creation depends on the mechanical design

intentions.

These, in turn, depend on the knowledge about

involved variable in the product design as a whole,

but specifically, of the each part requirements and

preliminary design principles. Thus, the part final

geometries definition passes for a previous

organization of the tacit knowledge and goes for a

taking of decisions constant process concerning the

information correct guiding on the part adequate

behavior in the assembly.

Probably, the behavior used in the design

analysis is one of the most important factors to

describe the part functions because it has to take in

account several design information, like the part in

use, the work regimen, and how each geometry will

be playing its functions.

Therefore, in the future, this research have to

rework some aspects of the descriptive structures

computational implementation in the measure of the

database of verbs, nouns and qualifiers are going to

increase. Later, will be necessary to include in the

database more products and parts and how those

measures will behavior statistically.

REFERENCES

Back, N. et al., 2008, Projeto integrado de produtos:

planejamento, concepção e modelagem. Ed. Manole,

São Paulo.

Bertztiss, A. T., 1997, Natural-language-based

development of information systems, Data &

Knowledge Engineering, Vol 23;

Blanchard, B. S. & Fabrycky, W. J., 1990, Systems

Engineering and Analysis, Prentice-Hal;

Bouzeghoub, M., 1997, Natural language for data bases,

Data & Knowledge Engineering, Vol 21, pp. 109-110;

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

312

Hubka, V. & Eder, W. E., 1988, Theory Technical

Systems, A Total Concept Theory for Engineering

Design, Springer, New York;

Hundal, M. S. and Byrne, J. F., 1988, Computer-assisted

generation of function block diagrams in a methodical

design procedure, New York, ASME, pp 252-258;

Hundal, M. S., 1990, A systematic method for developing

function structures, solution and concept variants,

Mechanisms and Machines Theory, Vol 25, N0 3, pp

243-256;

Hundal, M. S., 1991, A methodical procedure for search of

solutions from function structures, ICED’91

proceedings, pp 9-16;

Linhares, J. C. e Dias, A., 2001, A new approach to

integrated mechanical part design, Proceedings of the

Flexible Automation & Intelligent Manufacturing -

FAIM’01, Dublin, Irlanda;

Linhares, J. C. e Dias, A., 2001, Integrated computational

interface in preliminary design applied to mechanical

part design, Proceedings of the International CIRP

Design Seminar - CIRP’01, pp. 283-288, Estocolmo,

Suécia;

Linhares, J. C. Dias, A., 2003, Part Design: Functional and

geometric Modeling Domain Relationship,

Proceedings of FAIM’03- Flexible Automation &

Intelligent Manufacturing - FAIM'2003, p. 519-529,

Tampa, Flórida;

Linhares, J. C. Dias, A., 2003, Functional and geometric

modeling domain relationship to part design. In:

Proceedings of CIRP’03 – 17th International

Conference on Production Research, Blacksburg,

Virginia;

Linhares, J. C. 2005, Uma Abordagem Computacional

Baseada na Descrição de Funções de Peças para

Projeto Preliminar de Produto. Tese de doutorado em

engenharia mecânica, Universidade Federal de Santa

Catarina, Florianópolis;

Pahl, G. & Beitz, W., 1988, Engineering Design – A

systematic approach, Springer Verlag, Berlin;

Pahl, G. & Beitz, W., 1996, Engineering Design – A

systematic approach, Springer Verlag, New York;

Pahl, G. et al., 2005, Projeto na engenharia: fundamentos

do desenvolvimento eficaz de produtos – métodos e

aplicações, 6

a

edição, Edgard Blücher, São Paulo;

RodenackerR, W. G., 1984, Methodisches Konstruieren,

Spring Verlag Berlin, New York;

Roth, K., 1985, Konstruieren mit Konstruktionskatalogen,

Spring Verlag, Berlin, New York;

Roy, U. et al., 2001, Function-to-form mapping: model,

representation and applications in design synthesis,

Computer-Aided Design 33, pp. 699-719, Elsevier.

GeometricKnowledgeAnalysisbasedinPartFunctionalDescriptions

313