Recall-driven Product Tracing and Supply Chain Tracking using

Answer Set Programming

Monica L. Nogueira and Noel P. Greis

Center for Logistics and Digital Strategy, The University of North Carolina at Chapel Hill, Chapel Hill, U.S.A.

Keywords: Answer Set Programming, Track-and-Trace, Supply Chain, Food Recall Process.

Abstract: Incomplete information and the inability to trace the movement of contaminated products across the food

chain has hindered our ability to locate and remove contaminated products once a food recall has been

announced. The FDA Food Safety Modernization Act (FSMA) that was signed into law in 2011, however,

supports traceability by both expanding the registration requirements for companies that are involved in

food production and, in the event of a food recall, requiring companies to provide information about their

immediate suppliers and customers—what is referred to as “one step forward” and “one step backward”

traceability. In this paper we implement the logic-based approach called answer set programming that uses

inference rules to determine the set of all companies that may be linked to a contaminated product. Unlike

other approaches, we do not depend on the availability of common standards or unique identifiers. Rather,

the proposed approach utilizes information about the company’s primary suppliers and customers along

with their products—consistent with the “one step forward” and “one step backward” required under FMSA

as noted above. We demonstrate this approach using the example of a food recall involving pork products.

1 INTRODUCTION

Food safety is a challenging problem that has been

growing worldwide due to the globalization of the

food supply chain, internationalization of trade, and

customer new eating habits, among other factors.

The lack of a consistent, unified, and standardized

tracking and tracing system for food manufactured,

produced, processed, packed, held, distributed, and

sold in the United States is a major pain point of the

American food safety system, but this is a problem

that affects most countries, if not all. The food

supply chain consists of many entities from

producer/grower and processor to distributor and

retailer. Each of these entities is linked to one

another through the food chain. Contamination can

enter the food chain at any point due to a range of

causes from improper processing or handling to

intentional contamination.

In the U.S. once public health officials have

determined that a foodborne disease event has

occurred and identified the offending product and its

manufacturer, a product recall may be issued by the

U.S. Food and Drug Administration (FDA) agency.

This recall signals the launch of a series of actions

by state food safety departments to remove any

contaminated products from retail shelves within

their states. State agencies must quickly determine

whether any recalled products are being sold by

retail enterprises or whether the contaminated

products have been used as ingredients in any of the

products being sold. At the point of recall, state

agencies are required to piece together information

from enterprises across the food chain in an

environment where there is not a uniform system for

linking this information, nor accepted standards for

identifying products, nor any central place where

this information is stored and accessible.

The difficulty of the task is complicated by (1)

the complexity of the food chain where a single food

product can be made of hundreds of ingredients

which each may be supplied by multiple suppliers;

(2) the fact that uniform standards for data collection

in the food industry do not exist, making it difficult

to re-create the food chain for contaminated

products; and (3) the fact that companies are often

reluctant to make public proprietary information

about their supply chain suppliers and customers.

Further, traceability across enterprise boundaries

requires agreements and coordination among

suppliers and customers that can be difficult to

achieve.

125

L. Nogueira M. and P. Greis N..

Recall-driven Product Tracing and Supply Chain Tracking using Answer Set Programming.

DOI: 10.5220/0004146201250133

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2012), pages 125-133

ISBN: 978-989-8565-30-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2 MOTIVATION

The lack of track-and-trace capability has received

considerable attention recently due to several high-

profile and costly incidents of foodborne disease in

the United States (c.f. peanut butter, spinach,

jalapenos peppers) and abroad (c.f. milk, pork,

sprouts). New studies from the U.S. Centers for

Disease Control and Prevention (CDC) estimate the

total effect of contaminated food consumed in the

United Sates as follows: 47.8 million illnesses,

127,839 hospitalizations and 3,037 deaths per year

(Scallan et al., 2011a and 2011b). The total cost of

food contamination in the U.S. was recently

estimated to be $152 billion a year including health

and human welfare costs, as well as economic

damage to companies and entire industries (Scharff,

2010). In 2009, the Peanut Corporation of America

(PCA) peanut butter contamination alone sickened

more than 700 people in 44 states and was

associated with nine deaths—and also resulted in the

largest dollar-valued food recall in U.S. history.

More than 3,000 products were recalled. Early

estimates of the costs to the peanut butter industry

due to lost peanut butter and peanut sales were more

than $1 billion.

The PCA peanut contamination also illustrates

the problems of determining both the source and the

location of contaminated foods in the food chain.

Difficulties are complicated when the contamination

is ingredient-driven, that is when the contaminated

product is an ingredient in a large number of

different products that are sold in many different

channels.

Traceability refers broadly to the ability, for any

product at any stage within the food chain, to

identify the initial source (backward tracing) and,

eventually, its final destination (forward tracing)

(Fritz and Schiefer, 2009). Tracking refers to the

ability to identify, for any product, its actual location

at any given time. Together these two capabilities

provide the functionality of a “track-and-trace”

system for the food supply chain.

A 2009 traceability exercise conducted by the

U.S. Department of Health and Human Services

(DHHS) illustrated the gaps in the current system.

Investigators purchased 40 different products and

attempted to trace each through the supply chain

back to the farm or the border, in the event of an

imported food. Of the 40 products, only five could

be traced back completely to the point of origin.

Thirty-one of the products could be traced back

partially; four of the products could not be traced

back at all (DHHS, 2009).

3 BACKGROUND

The FDA Food Safety Modernization Act (FSMA)

that was passed by both houses of the U.S. Congress

in late 2010 and signed into law by President Obama

in January 2011 is the first major overhaul of food

safety law in the U.S. in decades. It sets the stage for

a new era in food safety regulation that moves FDA

towards new risk based approaches.

FSMA includes several key provisions that

position the FDA to improve its ability to respond to

a food recall. First, the FDA now has the authority to

issue a mandatory recall when it has been

determined that there is a reasonable probability that

a food poses a threat to human health. Previously,

FDA could only request a voluntary recall.

FSMA also requires that the FDA, in

consultation with the U.S. Department of

Agriculture (USDA), establish, as appropriate,

within the FDA “ a product tracing system to receive

information that improves the capacity of the

Secretary to effectively and rapidly track and trace

food that is in the United States or offered for import

into the United States” (FSMA, 2011). FSMA does

not specify the details of such a traceability system

or the technology to be used, but directs the FDA to

conduct at least two pilot projects to evaluate

methods for improving traceability. On September

2011, the FDA announced that the Institute of Food

Technologists (IFT) will “carry out two new pilot

projects at the direction of FDA to explore and

demonstrate methods for rapid and effective tracking

and tracing of food, including types of data that are

useful for tracing, ways to connect the various points

in the supply chain and how quickly data can be

made available to FDA” (FDA, 2011).

In addition, FSMA expands the registration

requirements established by the U.S. Congress in the

2002 Bioterrorism Act that required all facilities that

manufacture, process or pack food to register with

the FDA, but exempted farms and retail food

establishments, by limiting that exemption only to

family and smaller growers.

Finally, in support of traceability, FSMA

requires companies to provide for all food products

“one step forward” and “one step backward”

traceability. Food facilities are not required to

provide full traceability for their products “from

farm to fork” but only from/to their immediate

suppliers and immediate customers. If every food

facility maintains such records it should be possible

to trace the entire food chain. The law does not

require tracking to the case level nor the retention of

records for more than two years.

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

126

4 SOLUTION APPROACH

The ability to reduce the costs, both human and

financial, in the event of a food recall event depends

directly on the ability to locate, or trace,

contaminated food products across the food chain.

Our solution approach addresses the need by food

safety personnel in the event of a food product recall

to quickly identify companies within their

jurisdiction that have a high likelihood of possessing

contaminated products. The efficiency and

effectiveness of a traceability system depends on the

ability to collect, transmit, and analyze information

about the handling of food products across all stages

of the food chain.

A wide range of traceability schemes are

currently in use by food system stakeholders (Buhr,

2003; Raschke et al., 2006; Regattieri et al., 2007;

Bulut and Lawrence, 2008; Shanahan et al., 2009;

Souza-Monteiro and Caswell, 2009). These systems

range from paper-based records to bioactive

labelling technology to an array of IT-based

solutions from bar codes and radio-frequency

identification (RFID) technologies supported by

software systems to database management systems.

Across the food chain, companies use a variety of

these systems which may not be interoperable. An

efficient traceability system should be able to link all

these different monitoring techniques into an

integrated, unified and consistent system.

A necessary requirement to accomplish this

integration is the availability of a common standard

identification system that is recognized across all

stakeholders, or a system to create these translations.

Thus, when a contaminated product is confirmed, it

would be possible to trace the unique identifier

(RFID) or product code (bar code) for that product

with all of the companies that were involved in the

creation of that food product. In the case of RFID,

the tag on the contaminated product would contain

the entire history/pedigree for that product. The

Global Traceability Standard, a full supply chain

traceability solution proposed by the universal

standard committee GS1 (General Standard One),

recommends the use of Global Location Numbers

(GLN), a universal trade unit identification scheme

based on the Global Trade Item Number (GTIN),

and Electronic Product Codes (EPC) to enable the

use of RFID tags to trace products (Fritz and

Schiefer, 2008; GS1, 2010). A methodology for

modelling traceability information using the

Electronic Product Code Information Service

(EPCIS) framework and statecharts in the Unified

Modelling Language (UML) to define states and

transitions in food product has recently been

proposed (Thakur et al., 2011). While progress has

been made in achieving this integration, mostly

within large vertically integrated multi-nationals, the

difficulties of achieving such a system based on

standard codes have been noted above.

In this paper, we explore a different logic-based

approach that uses inference rules to determine the

set of all companies that may be linked to a

contaminated product. Our approach does not

depend on the availability of a common standard or

unique identifier. Rather, the proposed approach

utilizes information about the primary suppliers and

customers for all food companies, along with their

products — consistent with the “one step forward”

and “one step backward” required under FMSA as

noted above. In the event of a recall for Product A

manufactured by Company X, we use logic

programming to compute the set of all companies

that are linked to the dyadic unit food-company

across the entire supply chain. Using rules, we can

trace backward to the set of likely companies that

are the possible source of the contamination and can

trace forward to identify the destination and location

of similarly contaminated products. A detailed

example is presented in the next section.

5 ASP PROGRAM ENCODING

In this work, we use a form of declarative

programming – Answer Set Programming (ASP)

(Marek and Truszczynski, 1999), to represent the

rule-based complex event processing of the food

safety domain and to track-and-trace recalled

products and other information of interest to public

health officials. ASP has been applied to industrial

problems, but to the best of our knowledge it has not

been used in food supply chain applications before.

The ASP paradigm is based on the stable models/

answer sets semantics of logic programs (Gelfond

and Lifschitz, 1988; Gelfond and Lifschitz, 1991)

and has been shown to be a powerful methodology

for knowledge representation, including the

representation of defaults, inheritance reasoning, and

multiple interesting aspects of reasoning about

actions and their effects, as well as being particularly

useful to solve difficult search problems. In the ASP

methodology, search problems are reduced to the

computation of the stable models of the problem.

Several ASP solvers – programs that generate the

stable models of a given problem encoded in the

ASP formalism – have been implemented, e.g.

ASSAT, clasp, Cmodels, DLV, GnT, nomore++,

Recall-drivenProductTracingandSupplyChainTrackingusingAnswerSetProgramming

127

Pbmodels, Smodels, etc. In what follows we provide

the basic syntactic constructs and the intuitive

semantics of the ASP language used in this work. A

complete formal specification of the syntax and

semantics of the language can be found at (Gelfond

and Lifschitz, 1991; Niemela and Simons, 2000).

A signature Σ of the language contains constants,

predicates, and function symbols. Terms and atoms

are formed as is customary in first-order logic. A

literal is either an atom (also called a positive literal)

or an atom preceded by classical or strong

negation), a negative literal. Literals l and l are

called contrary. Ground literals and terms are those

not containing variables. A consistent set of literals

does not contain contrary literals. The set of all

ground literals is denoted by lit(Σ). A rule is a

statement of the form:

h

1

... h

k

l

1

, ..., l

m

, not l

m+1

, ..., not l

n

.

(1)

where h

i

’s and l

i

’s are ground literals, not is a logical

connective called negation as failure or default

negation, and symbol corresponds to the

disjunction operator. The head of the rule is the part

of the statement to the left of symbol , while the

body of the rule is the part on its right side.

Intuitively, the rule meaning is that if a reasoner

believes {l

1

, … , l

m

} and has no reason to believe

{l

m+1

, …, l

n

}, then it must believe one of the h

i

’s. If

the head of the rule is substituted by the falsity

symbol then the rule is called a constraint. The

intuitive meaning of a constraint is that its body

must not be satisfied. Rules with variables are used

as a short hand for the sets of their ground

instantiations. Variables are denoted by capital

letters. An ASP program is a pair of Σ, Π, where Σ

is a signature and Π is a set of rules over Σ, but

usually the signature is defined implicitly and

programs are only denoted by Π. A stable model (or

answer set) of a program Π is one of the possible

sets of literals of its logical consequences under the

stable model/answer set semantics.

Our encoding – the set of rules of program Π –

contains roughly 25 rules, while event records (in

ASP, rules with an empty body, also called “facts”)

and the ontologies describing facts, utilized for

experiments, are in the thousands. We use the DLV

system (Calimeri et al., 2002) as our ASP solver.

Advantages of applying the ASP formalism to

the food supply chain traceability problem include:

(1) ASP can easily encode many forms of domain

knowledge, including hierarchical ontologies and

heuristics. As shown by some previous works

(Nogueira and Greis, 2011a and 2011b), ASP allows

generating ontologies for different types of

information relevant to this domain, e.g. food,

geographical, disease, etc. Encoding of heuristics

make it possible to prune the search space and

increase the efficiency of tracking and tracing a

contaminated product in the supply chain; (2) ASP is

well suited to represent action and change. A food

supply chain is an intrinsically dynamic enviroment

where food products move from one node, or food

operator, to the next node in the chain, and the track-

and-trace of contaminated products posing risk to

human lives should be highly efficient to curb a

contamination event that may spread very rapidly;

and (3) ASP is well suited to deal with incomplete

information – an inherent problem of this domain as

food enterprises are avert to sharing information

about their supplier and customer bases which

constitutes competitive advantage to their business.

5.1 Domain Representation

Given the proprietary nature of supplier/customer

base information and the difficulty to obtain this

data directly from private sector companies, we

turned to data publicly available on the World Wide

Web and using web scrapping techniques

downloaded and assembled a database of suppliers

of food and agricultural products. This database

contains more than 6,000 American companies

located in all 50 states, the District of Columbia and

Puerto Rico, with firms encompassing the whole

food supply chain, including: grower, manufacturer,

processor, packer, distributor, wholesaler, retailer,

etc. Each firm is classified as at least one of these

types, but a firm may have more than one role in the

supply chain, e.g. it may be a processor and also a

wholesaler of its products. Besides the standard

information about a firm, i.e. name, address, the

database contains a list of the products’ categories,

e.g. salad dressing, juice mixed, peanut butter, the

firm commercializes.

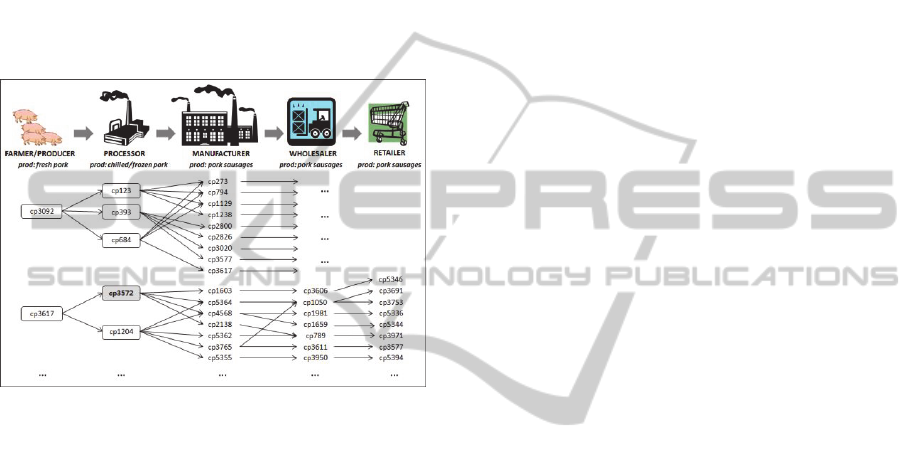

We demonstrate the power of using ASP to solve

the traceability problem by showing an example

involving pork products. For simplicity sake, in this

example we assume that the supply chain for pork

sausages, shown on Figure 1, encompasses: (a)

farmers supplying fresh pork meat to (b) processors

supplying chilled or frozen pork to (c) manufacturers

of pork sausages supplying (d) wholesalers of pork

sausages supplying (e) retailers who sell pork

sausages to consumers. A small number of

companies that populate this supply chain, as

identified in our assembled supplier database, are

also shown in Figure 1 in the form of a directed

graph. In this graph, each node corresponds to a

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

128

company identified by an id code, and an edge

originating from a company/node A and connecting

it to a company/node B expresses a supplier-

customer relationship where A supplies certain food

product to B. In addition, each type of company/

node aligns vertically with its role or category in the

pork supply chain represented at the top of Figure 1.

For example, company “cp3092” corresponds to a

farmer who supplies fresh pork meat to three

processors identified by codes “cp123”, “cp393”,

and “cp684”; processor “cp123” supplies chilled or

frozen pork meat to four manufacturers, e.g.

“cp273”; and so forth.

Figure 1: Illustrative Supply Chain for Pork Sausages.

In the ASP knowledge base, each company is

modelled by three types of “facts,” rules (2)-(4).

company(Idcode,Name,State). (2)

type_company(Idcode,Type). (3)

prod_supplied(Idcode,Product). (4)

In our model, for the purpose of this example,

each company is represented by a single rule (2),

which identifies it by an id code, its name, and the

state where the company is located. For

simplification, we assume that each company has a

single facility and this is the state where the supplied

product originates and is shipped to others. Rules of

type (3) indicate the role each company exerts in the

supply chain. As mentioned before, it is not

uncommon that a given company may have more

than one role, e.g. a wholesaler may also be a retailer

who sells directly to consumers. Thus, such

company will have at least two rules of type (3), one

to indicate that the company is of type “wholesaler”

and the other that the company is a “retailer”. It is

very common for a given company to supply several

products, and thus, our knowledge base contains a

rule of type (4) for each of these products.

Once a recall of a food product commercialized

by a certain company is issued, this information is

added to the knowledge base in the form of rule (5),

with the company being identified by its id code.

recall(Product,Idcode). (5)

The expected course of action at this point is that the

contaminated product, and its derivative products,

are taken out of the market and destroyed. But given

that only limited information is made available to

food safety officials about which companies may be

affected – those who received the tainted product or

supplied a related contaminated product – this can

delay the recall process and put in risk human lives.

Our approach works to reduce these latencies by

generating all possible paths this product may have

travelled through the supply chain graph. This is

done by generating each complete path – from

farmer to retailer – for the product in question, as

described in the next section.

First, assume that wholesaler company “cp1050”

recalls their “porksausage” product. Our knowledge

base contains a simple ontology which models the

main stages of a food product as it evolves from raw,

unprocessed food at the farmer/ grower level of the

supply chain, to a processed food ready for

consumption at the retail point-of-sale. At each stage

of the supply chain the product supplied from a

company A becomes an ingredient to the company B

to which it has been supplied. In the case of pork

sausages, the ontology contains facts (6) to (11)

which express the production process sequence for

pork products illustrated on Figure 1.

is_ingr(porkfresh,porkchilled). (6)

is_ingr(porkchilled,porkfrozen). (7)

is_ingr(porkchilled,porksausage).(8)

is_ingr(porkfresh,porkfrozen). (9)

is_ingr(porkfrozen,porksausage).(10)

is_ingr(porksausage,porksausage)

.

(11)

5.2 Generating Supply Chain Paths

We use a two-step approach to solve the problem of

identifying companies affected by a food recall

when incomplete information may hinder the

process and create delays. In the first step, we

generate all supply chain paths for pork products

with rules of type (12) to (17), where the supplied

pork product at each level of the supply chain is

used to prune the search among all other possible

combinations of food products represented in our

knowledge base.

Recall-drivenProductTracingandSupplyChainTrackingusingAnswerSetProgramming

129

Intuitively, rule (12) means that a five-tuple

supply_chain(G,P,M,W,R) represents the complete

path of production of a given final product, e.g. pork

sausages, from grower/producer to processor to

manufacturer to wholesaler to retailer. Rules (13) to

(17) compute the individual supplier-client relations,

or edges of the supply chain graph.

supply_chain(G,P,M,W,R) :- (12)

produces(G,porkfresh),

processes(P,porkchilled),

manufactures(M,porksausage),

wholesells(W,porksausage),

sells(R,porksausage).

produces(C,F) :- (13)

company(C,_,_),

type_company(C,grower),

prod_supplied(C,F),

F == porkfresh.

processes(C,F) :- (14)

company(C,_,_),

type_company(C,processor),

prod_supplied(C,F),

F == porkchilled.

manufactures(C,F) :- (15)

company(C,_,_),

type_company(C manufacturer),

prod_supplied(C,F),

F == porksausage.

wholesells(C,F) :- (16)

company(C,_,_),

type_company(C,wholesaler),

prod_supplied(C,F),

F == porksausage.

sells(C,F) :- (17)

company(C,_,_),

type_company(C,retailer),

prod_supplied(C,F),

F == porksausage.

In the second step, each such supply chain path is

broken down and expressed as individual supplier-

client relations by rules (18) to (21). The reason for

converting the supply chain back to these relations is

to improve the efficiency of the computation during

the tracing stage.

Rule (18), and similarly rules (19) to (21),

intuitively expresses that a grower/producer

company G supplies fresh pork to a processor

company P which utilizes this product as the main

ingredient to produce and supply chilled pork to its

clients. Rule (18), as well as rules (19)-(21), also

enforces that companies G and P are not the same to

ensure that the supply chain graph is cycle free.

supplies(G,porkfresh,P) :- (18)

supply_chain(G,P,M,W,R),

company(G,_,_),

type_company(G,grower),

prod_supplied(G,porkfresh),

company(P,_,_),

type_company(P,processor),

prod_supplied(P,porkchilled),

G != P.

supplies(P,porkchilled,M) :- (19)

supply_chain(G,P,M,W,R),

company(P,_,_),

type_company(P,processor),

prod_supplied(P,porkchilled),

company(M,_,_),

type_company(M,manufacturer),

prod_supplied(M,porksausage),

P != M.

supplies(M,porksausage,W) :- (20)

supply_chain(G,P,M,W,R),

company(M,_,_),

type_company(M,manufacturer),

prod_supplied(M,porksausage),

company(W,_,_),

type_company(W,wholesaler),

prod_supplied(W,porksausage),

M != W.

supplies(W,porksausage,R) :- (21)

supply_chain(G,P,M,W,R),

company(W,_,_),

type_company(W,wholesaler),

prod_supplied(W,porksausage),

company(R,_,_),

type_company(R,retailer),

prod_supplied(R,porksausage),

W != R.

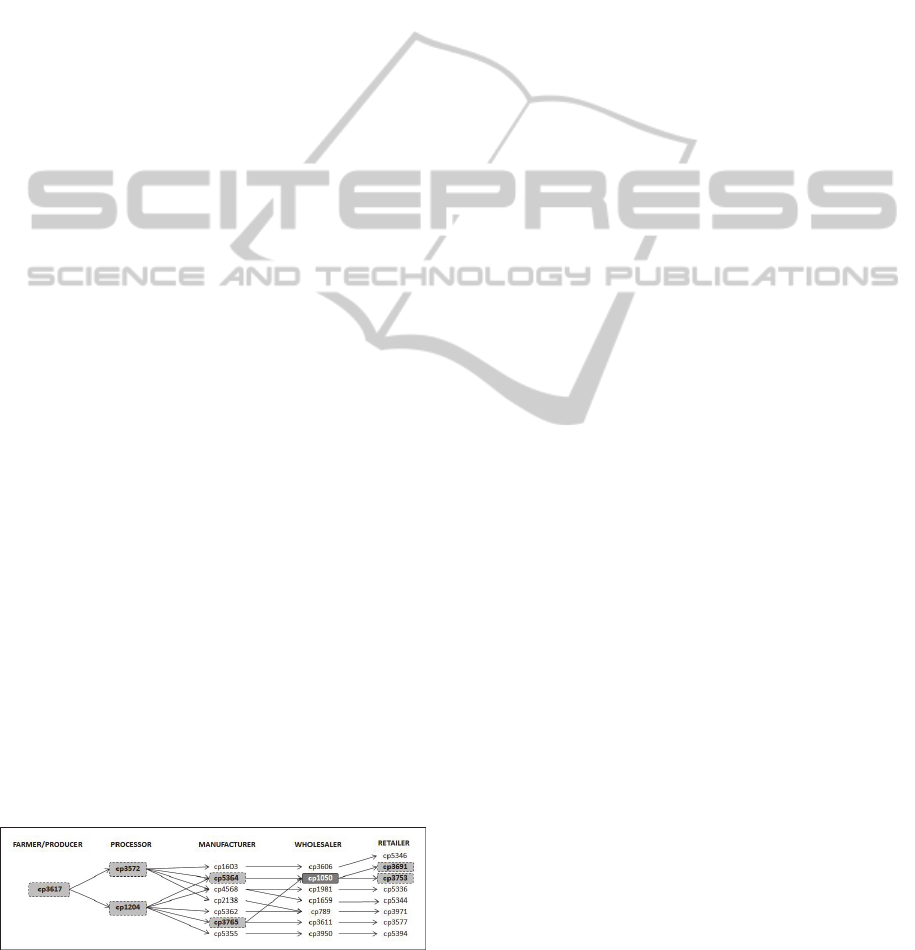

5.3 Tracing Contaminated Products

The goal of tracing the contamination forward in the

supply chain from the point of recall, e.g. wholesaler

“cp1050,” is achieved by rules (22) and (23). Rule

(22) says that if recalling company C, located in

state LC, supplies its recalled food product F to

company A, located in state LA, then LA may be

affected by the recall and is part of the

contamination. Thus, company A must be inspected

by food safety officials to verify that its entire

contaminated product is taken out of the market.

Rule (23) propagates this trace to the next forward

stage of the supply chain. Figure 2 shows an

example of companies affected by a recall after

tracing back and forward in the supply chain such

product.

forward_trace(C,LC,F,A,LA) :- (22)

recall(F,C),

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

130

supplies(C,F,A),

company(C,_,LC),

company(A,_,LA),

C != A.

forward_trace(B,LB,F1,A,LA) :- (23)

company(B,_,LB),

company(A,_,LA),

supplies(B,F1,A),

is_ingr(F,F1),

company(C,NC,LC),

forward_trace(C,LC,F,B,LB),

B != C, B != A, A != C.

Similarly, rules (24) and (25) trace back the

contaminated product through the supply chain.

backward_trace(A,LA,F1,C,LC) :- (24)

recall(F,C),

is_ingr(F1,F),

supplies(A,F1,C),

company(C,_,LC),

company(A,_,LA), C !=

A.

backward_trace(B,LB,F1,C,LC) :- (25)

company(C,NC,LC),

supplies(B,F1,C),

is_ingr(F1,F),

backward_trace(C,LC,F,A,LA),

company(B,_,LB),

company(A,_,LA),

B != C, B != A, A != C.

Finally, when these rules are submitted to the

answer set solver DLV, we obtained the following

list of atoms which correspond to the solution to the

traceability problem illustrated in Figure 2. In

addition to the rules listed above a couple of other

rules are used to retrieve the name of the recalling

company and of those companies to whom this

company has supplied the contaminated product

directly and their clients forward in the supply chain.

These companies are named in atoms of the type

“affected_comp(Idcode, Name, State)”. Company

names and codes appearing in this example are for

illustrative purposes only and do not correspond to

real company names in the knowledge base. Note

that using ASP we can further focus the search, and

obtain a list of affected companies on a given state

of interest.

Figure 2: Tracing Contaminated Pork Sausages in the

Supply Chain.

recalling_comp(cp1050,atrading,ca),

forward_trace(cp1050,ca,

porksausage,cp3691,il),

forward_trace(cp1050,ca,

porksausage,cp3753,il),

affected_comp(cp3691,gustopack,il),

affected_comp(cp3753,apacking,il),

backward_trace(cp3617,il,

porkfresh,cp3572,il),

backward_trace(cp3617,il,

porkfresh,cp1204,ca),

backward_trace(cp3572,il,

porkchilled,cp5364,il),

backward_trace(cp1204,ca,

porkchilled,cp3765,il),

backward_trace(cp5364,il,

porksausage,cp1050,ca),

backward_trace(cp3765,il,

porksausage,cp1050,ca).

Assume now that processor company “cp3572”

is recalling its chilled pork product. To find a

solution to this new contamination problem one

needs only to substitute the recall fact, i.e. rule (5),

by the new rule (26) below:

recall(cp3572,porkchilled). (26)

The solution can then be computed by DLV and

consists of the following list of atoms.

recalling_comp(cp3572,ainc,il),

forward_trace(cp3572,il,

porkchilled,cp5364,il),

forward_trace(cp3572,il,

porkchilled,cp4568,la),

forward_trace(cp3572,il,

porkchilled,cp2138,wi),

forward_trace(cp3572,il,

porkchilled,cp1603,ok),

forward_trace(cp5364,il,

porksausage,cp1050,ca),

forward_trace(cp4568,la,

porksausage,cp1981,wi),

forward_trace(cp4568,la,

porksausage,cp1659,co),

forward_trace(cp2138,wi,

porksausage,cp789,fl),

forward_trace(cp1603,ok,

porksausage,cp3606,il),

forward_trace(cp1050,ca,

porksausage,cp3691,il),

forward_trace(cp1050,ca,

porksausage,cp3753,il),

forward_trace(cp1981,wi,

porksausage,cp5336,ca),

forward_trace(cp789,fl,

porksausage,cp3971,il),

forward_trace(cp3606,il,

porksausage,cp5346,ga).

forward_trace(cp1659,co,

porksausage,cp5344,ny),

Recall-drivenProductTracingandSupplyChainTrackingusingAnswerSetProgramming

131

affected_comp(cp5364,alivestock,il),

affected_comp(cp4568,acreolfood,la),

affected_comp(cp2138,agourmet,wi),

affected_comp(cp1603,afoods,ok),

affected_comp(cp1050,atrading,ca),

affected_comp(cp3691,gustopack,il),

affected_comp(cp1981,aservice,wi),

affected_comp(cp5336,ainttrade,ca),

affected_comp(cp789,afoodsusa,fl),

affected_comp(cp3971,asausage,il),

affected_comp(cp3606,afarms,il),

affected_comp(cp5346,agrove,ga),

affected_comp(cp3753,apacking,il),

affected_comp(cp1659,aprocessor,co),

affected_comp(cp5344,aglobe,ny),

backward_trace(cp3617,il,

porkfresh,cp3572,il).

6 CONCLUSIONS

Using the case of a food recall involving pork

products, this paper demonstrates the utility of

answer set programming in identifying not only the

source of a food contamination but also the location

of contaminated products across the food chain. We

represent all possible paths of a contaminated

product across the supply chain as a sequence of

stages by which a food product evolves from raw,

unprocessed food at the farmer/grower level of the

supply chain, to a processed food ready for

consumption at the retail point-of-sale. Using rules

of inference, we then reduce the set of all possible

pathways of contamination based on information

contained in the recall. We are also able to capture

the process by which contaminated products become

ingredients in other products during sequential

stages of production. The logic-based approach

developed herein is well-suited to be used by

state

agencies charged with inspecting food production,

distribution and retail facilities in the event of a

national recall. The approach is particularly useful

for ingredient-driven contaminations in which the

contaminated product is used as an ingredient in a

broad set of secondary products.

REFERENCES

Buhr, B. L. 2003. “Traceability and information

technology in the meat supply chain: implications for

firm organization and market structure.” Journal of

Food Distribution Research, 34 (3), pp. 13–26.

Bulut, H., and Lawrence, J. D. Apr. 2008. “Meat Slaughter

and Processing Plants’ Traceability Levels: Evidence

From Iowa.” Working Paper # 08015, Working Paper

Series, Department of Economics, Iowa State

University.

Calimeri, F.; Dell’Armi, T.; Eiter, T.; Faber, W.; Gottlob,

G.; Ianni, G.; Ielpa, G.; Koch, C.; Leone, N.; Perri, S.;

Pfeifer, G.; and Polleres, A. 2002. “The dlv system.”

In Flesca, S., and Ianni, G., eds., Proceedings of the

8th European Conference on Artificial Intelligence

(JELIA 2002), pp. 537–540.

FDA Food Safety Modernization Act of 2010, S. 510,

111

th

Congress, 2

nd

Session. Signed into law by

President Barack Obama on 4 Jan. 2011.

Fritz, M., and Schiefer, G. Feb. 2009. “Tracking, tracing

and business process interests in food commodities: A

multi-level decision complexity.” International

Journal of Production Economics, 117(2), pp. 317–

329.

Fritz, M., and Schiefer, G. 2008. “Tracking and tracing in

food networks.” World Conference on Agricultural

Information and IT (IAALD AFITA WCCA 2008),

Tokyo University of Agriculture, Tokyo, Japan, 24–27

August 2008, pp. 967–972.

Gelfond, M., and Lifschitz, V. 1988. “The stable model

semantics for logic programming.” In Kowalski, R.,

and Bowen, K., eds., International Logic

Programming Conference and Symposium, pp. 1070–

1080. MIT Press.

Gelfond, M., and Lifschitz, V. 1991. “Classical negation

in logic programs and disjunctive databases.” New

Generation Computing, 9, pp. 365–385.

GS1. Mar. 2010. “Business Process and System

Requirements for Full Supply Chain Traceability.”

GS1 Global Traceability Standard, Issue 1.2.2.

Marek, V. W., and Truszczynski, M. 1999. The Logic

Programming Paradigm: a 25-Year Perspective, chap.

“Stable models and an alternative logic programming

paradigm,” pp. 375–398. Springer Verlag, Berlin.

Niemela, I., and Simons, P. 2000. Logic-Based Artificial

Intelligence, chap. “Extending the Smodels System

with Cardinality and Weight Constraints,” pp. 491–

521. Kluwer Academic Publishers.

Nogueira, M. L., and Greis, N. P. 2011. “Rule-Based

Complex Event Processing for Food Safety and Public

Health.” In Bassiliades, N., Governatori, G., and

Paschke, A., eds., Proceedings of the 5

th

International

Symposium of Rule-Based Reasoning, Programming,

and Applications (RuleML Europe 2011), Barcelona,

Spain, July 19–21, 2011. Lecture Notes in Computer

Science 6826, pp. 376–383. Springer.

Nogueira, M. L., and Greis, N. P. 2011. “Application of

Answer Set Programming for Public Health Data

Integration and Analysis.” A Min Tjoa, A. M.;

Quirchmayr, G., You, I., and Xu, L., eds., Proceedings

of the 6

th

International Availability, Reliability and

Security for Business, Enterprise and Health

Information Systems (ARES 2011), IFIP WG 8.4/8.9

Cross Domain Conference and Workshop, Vienna,

Austria, August 22–26, 2011. Lecture Notes in

Computer Science 6908, pp. 118–134. Springer.

Raschke, A.; Strich, S.; Huppke, S.; Neugebauer, M.;

Geuther, E.; Bertling, W.; Walders, B.; Reiser, C.; and

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

132

Hess, J. Jan. 2006. “Induction and detection of long-

lasting peptide-specific antibody responses in pigs and

beef cattle: A powerful technology for tracing meat

processing chains from stock farmers to sales

counters.” Food Control, 17(1), pp. 65–74.

Regattieri, A.; Gamberi, M.; and Manzini, R. 2007.

“Traceability of food products: general framework and

experimental evidence.” Journal of Food Engineering,

81, pp. 347–356.

Scallan, E.; Hoekstra, R. M.; Angulo, F. J.; Tauxe, R. V.;

Widdowson, M-A.; Roy, S. L.; Jones, J. L.; and

Griffin, P. M. Jan. 2011. “Foodborne Illness Acquired

in the United States—Major Pathogens.” Emerging

Infectious Diseases, 17(1), pp. 7–15. Web. 10 Feb.

2011.

Scallan, E.; Griffin, P. M; Angulo, F. J.; Tauxe, R. V.; and

Hoekstra, R. M. Jan. 2011. “Foodborne Illness

Acquired in the United States—Unspecified Agents.”

Emerging Infectious Diseases, 17(1), pp. 16–22.

Scharff, R. L. 2010. “Health-Related Costs From

Foodborne Illness in the United States.” The Produce

Food Safety Project at Georgetown University.

Shanahan, C.; Kernan, B.; Ayalew, G.; McDonnell, K.;

Butler, F.; and Ward, S. 2009. “A framework for beef

traceability from farm to slaughter using global

standards: an Irish perspective.” Computers and

Electronics in Agriculture, 66(1), pp. 62–69.

Souza-Monteiro, D. M. and Caswell, J. A. Feb. 2009.

“Traceability adoption at the farm level: An empirical

analysis of the Portuguese pear industry.” Food

Policy, Elsevier, 34(1), pages 94–101.

Thakur, M.; Sørensen, C-F., Bjørnson, F. O.; Forås, E.;

and Hurburgh, C. R. Apr. 2011. “Managing food

traceability information using EPCIS framework.”

Journal of Food Engineering, 103(4), pp. 417–433.

Web. 16 Nov. 2010.

U.S. Department of Health and Human Services: Office of

Inspector General. March 2009. “Traceability in the

Food Supply Chain,” Report OEI-02-06-00210.

U.S. Food and Drug Administration. Sep. 2011. “Pilot

Projects for Improving Product Tracing along the

Food Supply System.” Web. 7 Sep. 2011. www.fda.

gov/Food/FoodSafety/FSMA/ucm270851.htm

Recall-drivenProductTracingandSupplyChainTrackingusingAnswerSetProgramming

133