Constrained Predictive Control of MIMO System

Application to a Two Link Manipulator

Joanna Zietkiewicz

Institute of Control and Information Engineering, Poznan University of Technology, Poznań, Poland

Keywords: Predictive Control, Constraints, MIMO Systems, LQ Control.

Abstract: In the paper application of constrained predictive control to multi input, multi output system is presented.

The method is based on feedback linearization and LQ control. Constraints of the system are implemented

by interpolation of reference trajectory. Finding solution is a compromise between the unconstrained LQ

control and a constrained feasible control and is executed by minimization of one variable. The application

of the method to a two link manipulator is used to present advantages and limitations of the algorithm.

1 INTRODUCTION

Feedback linearization is a powerful technique that

allows to obtain linear model with exact dynamics

(Isidori, 1985), (Slotine and Li, 1991). Linear

quadratic control is well known optimal control

method and with its dynamic programming

properties can be also easily calculated (Anderson &

Moore, 1990). The combination of feedback

linearization and LQ control has been used in many

algorithms in Model Predictive Control applications

for many years and it is used also in present papers

(He De-Feng et al., 2011), (Margellos and Lygeros,

2010). Another problem apart from finding the

optimal solution on a given horizon (finite or

infinite) is the constrained control. A method which

use the advantages of feedback linearization, LQ

control and applying signals constraints was

proposed in (Poulsen et al., 2001). It rely in every

step on interpolation between the LQ optimal control

and a feasible solution – the solution that fulfils

given constraints. A feasible solution is obtain by

taking calculated from LQ method optimal gain for a

perturbed reference signal. The compromise

between the feasible and optimal solution is

calculating by minimization of one variable – the

number of degrees of freedom in prediction is

reduced to one variable.

2 THE TWO LINK

MANIPULATOR SYSTEM

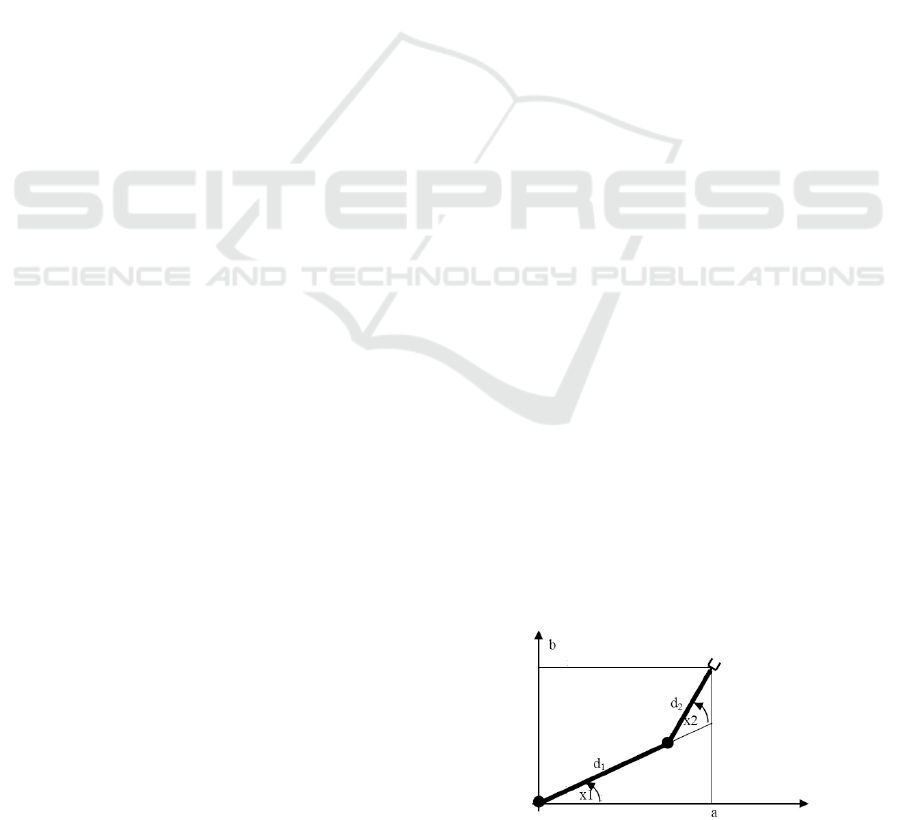

The considered system is the two link manipulator

(fig.1). It consists of two rigid links and two one

degree-of-freedom wrists, whose motion is in the

vertical axis. The objective of control is to move the

clutch of the manipulator from one position in two

dimensional space to the other. The output variables

are the two angles y

1

=x

1

and y

2

=x

2

. The coordinates

of the clutch can be obtained from kinematics

equations (1)

(1)

Figure 1: The two link manipulator system.

The dynamics of the system is represented by below

equations (2)

(2)

293

Zietkiewicz J..

Constrained Predictive Control of MIMO System - Application to a Two Link Manipulator.

DOI: 10.5220/0004122002930298

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 293-298

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

where x

1

and x

2

are the angles, variables x

3

and x

4

are

the respective angular velocities, d

1

, d

2

are the

lengths of the links. The input variables u

1

and u

2

are

the moments of force in the wrists. Furthermore

(3)

represents Coriolis and centrifugal forces and

(4)

are the friction forces approximated by smooth

functions. The approximation is used to fulfil

conditions of feedback linearization method.

Masses and inertial forces are represented by M

matrix, where

(5)

The values of coefficients which appeared in

equations (3-5) are listed in tab.1.

Table 1: Coefficients of manipulator system.

link 1

link 2

I

i

[kg*m

2

]

1

1

m

i

[kg]

10

5

d

i

[m]

1

0.7

x

ci

[m]

0.5

0.35

y

ci

[m]

0

0

s

i

[Nm]

0.1

0.1

f

i

[kg*m

2

/s]

0.01

0.01

In considered system input variables u

1

and u

2

are

constrained by -1 and 1 Nm

(6)

2 CONTROL ALGORITHM

2.1 Feedback Linearization

Nonlinear equations of manipulator system are

smooth and the system has full relative degree. The

system has the same number of inputs and outputs.

Feedback linearization of the system can be

accomplished with diffeomorphism

(7)

and the new input variables

(8)

The inputs of the nonlinear system (2) are nonlinear

functions of v

1

, v

2

and the state x obtained from (8)

(9)

Consequently we obtain two identical linear systems

(10)

for which the theory of linear control can be applied.

2.2 Linear Quadratic Control

Each of the two linear systems is discretized with

sampling interval T

s

. In order to track the change of

set point the state is augmented by new variable with

included reference signal w

t

and each system is

described in form

tt

d

t

d

d

t

wv

1

0

0

1

0

1

B

z

C

A

z

tdt

y zC 0

(11)

The linear quadratic cost function can be written as

tk

kk

T

kt

RvJ ,

2

Qzz

(12)

and the solution

,

ttyt

wLv Lz

(13)

where L is the optimal gain obtained from Riccati

equation and

.0

T

dy

L CL

2.3 Constrained Predictive Control

The system equation (11) can be used as model

prediction equation to calculate the state for the

samples t+1=(k,…,k+H-1), on horizon H in the time

instant k. Constraints will be included into control

law by interpolation method in every predicted step.

It rely on using perturbed reference trajectory

(14)

In place of reference trajectory in equations (11 and

13). Then the prediction equation:

ktkktkt

d

kt

d

d

kt

pwv

|||||1

1

0

1

0

ˆ

0

ˆ

1

0

ˆ

B

z

C

A

z

(15)

And the control predicted values:

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

294

,

ˆˆ

|||| ktktyktykt

pLwv zLL

(16)

Variable α

k

is calculated in instant k and is the same

for every predicted states and inputs on H, p

t|k

for

t=k,…,k+H-1 forms a vector p

H|k

. α

k

can adopt

values from 0 to 1 and p

H|k

is chosen in that manner

so the perturbed reference trajectory with α

t

=1

provides feasible, satisfying constraints solution for

the considered system. Whereas α

t

=0 corresponds

with unconstrained control. The aim is to minimize

variable α

t

on the horizon with respect to system

equations (15,16) and constraints (6). Since the two

systems (11) are considered, constrained values are

the functions of two variables α

k

I

and α

k

II

through

nonlinear equations (9) and (7) (linear in this

example, but nonlinear in general).

2.4 Feasible Trajectory

The perturbation vector p

H|k

providing feasible

solution can be obtain from previous k-1 step by

.1|1|

kHkkH

pp

(17)

With calculated α

t

for the n=3 dimensional system

(11) we can express the prediction equation from

(15) with used (16) in form:

),(

ˆˆ

|||1 ktkkttkt

pw

ΓzΦz

(18)

where

,

1

321

d

ddd

LLL

C

BBA

Φ

.

1

yd

LB

Γ

The initial perturbation p

H|i

for i at the beginning

of control application is calculated by using zero as

the reference signal and the initial state

corresponding to the step of original reference

signal. The method presented in (Poulsen et al.,

2001) of obtaining initial feasible perturbation

provided too large absolute values of control v at the

beginning of the predicted vector. The alternative

method is used in the paper with minimization of v

t

as a function of p

t

in (20).

For the state equation

ttt

pz ΓΦz

1

(19)

and initial z

0

=-(z

f

– z

k

),where z

f

– final stable state z

for w

k+1

, z

k

– initial state for control system,

additional cost function is used

tk

kpkp

T

kt

vRJ

2

zQz

(20)

where

tytt

pLv Lz

(21)

then the cost function has form

tk

kj

T

kkpkj

T

kt

pNzpRzQzJ 2

2

(22)

with

,RLLQQ

T

pj

,

yyj

RLLR

1

RLLN

T

j

(23)

The optimal gain K obtained by minimization (22) is

used to calculate initial perturbations p

t|i

, t=1,...H-1

.

|| itit

p Kz

(24)

Now we can describe the predicted variable z

k+l

and

predicted control law v

k+l

as a functions of initial and

final state, reference trajectory and one variable α

k

.

In equations k=i+1 is used:

)(

)(

)(

)(

ˆ

1

1

0

1

1

| kf

l

k

lk

k

k

k

l

klk

w

w

w

zz

ΓΦK

ΓΦK

ΓΦK

ΛΛzΦz

(25)

where

ΓΦΓΓΦΛ

1

l

)(

)(

)(

)(

0

0

ˆ

1

0

1

|

kf

l

d

k

lk

k

k

d

k

l

klk

w

w

w

v

zz

ΓΦK

ΓΦK

ΓΦK

C

ΛL

C

ΛLzLΦ

(26)

The linearized system of manipulator example (2)

consists of two linear equations (10) therefore in the

algorithm two prediction equations (25) and law

equations (26) are used. To avoid problems with

multivariable minimization it is assumed that α

k

is

equal to both subsystems, α

k

I

=α

k

II

.

3 PERFORMANCE OF THE

ALGORITHM

3.1 Simulations

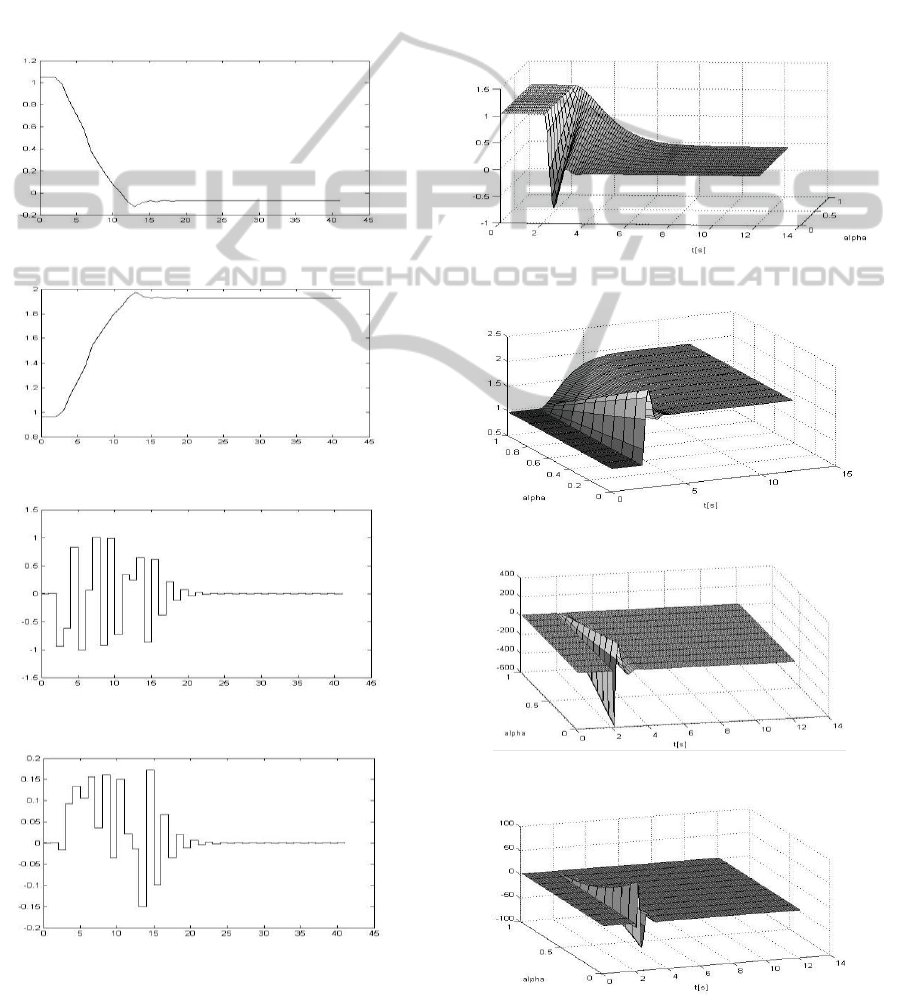

Simulations was performed for the change of output

y

1

from 1.0489 to -0.0716 [rad] and y

2

from 0.9626

to 1.9284 [rad]. This is equivalent to the change of

Constrained Predictive Control of MIMO System - Application to a Two Link Manipulator

295

coordinates (a,b) from (0.2,1.5) to (0.8,0.6). The

weight matrices in cost function (12) for both

subsystems was chosen as Q=[0 0 0; 0 0 0; 0 0 1],

R=0.001 hence the emphasize in the minimization of

the difference between the set point and the output.

Remaining variables of the vector z are weighted

with 0, since constraints are coped while

minimization of α. R has to be positive define hence

the small value was chosen. The resulted trajectories

satisfied constraints, variables are changing fast and

without significant overshoot. Oscillations on inputs

charts are the effect of small R.

Figure 2: Output variable y

1

.

Figure 3: Output variable y

2

.

Figure 4: Input variable u

1

.

Figure 5: Input variable u

2

.

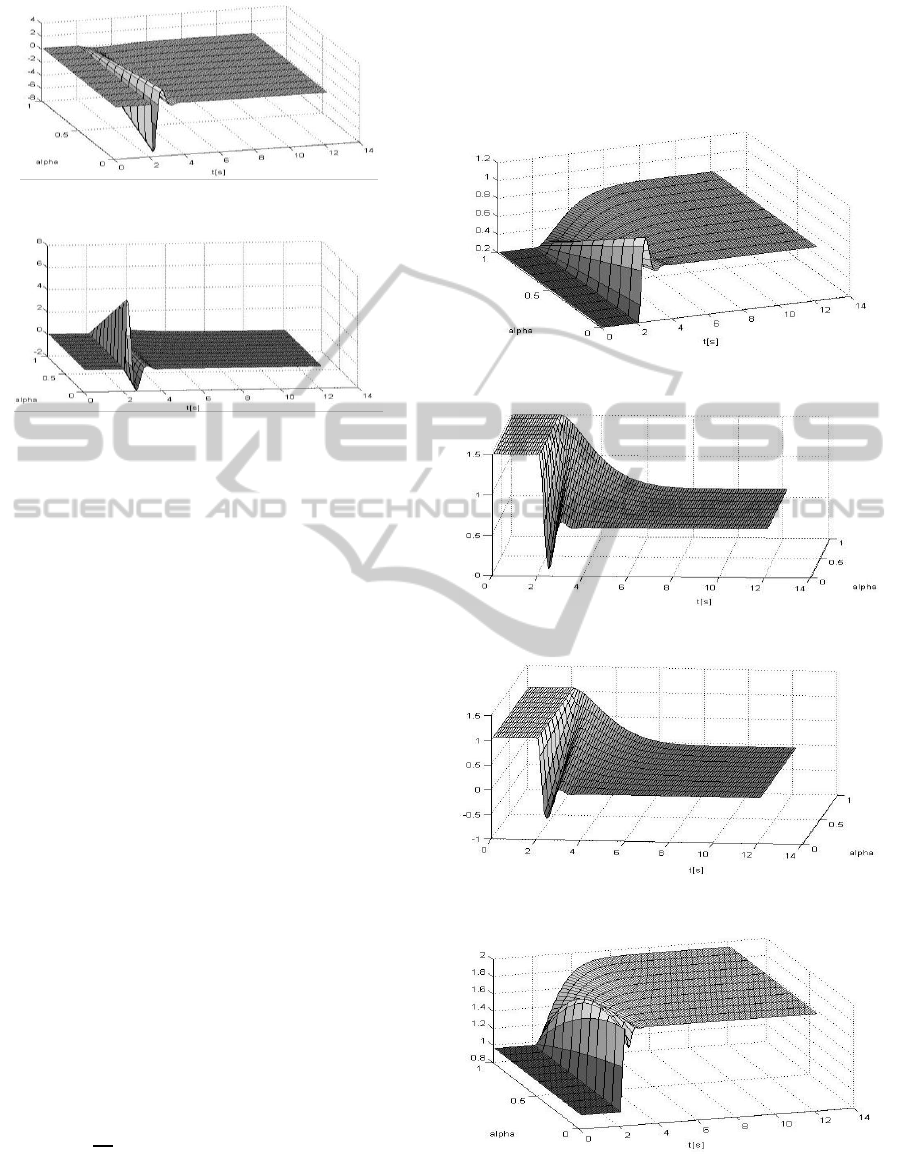

3.2 Variables as Functions of

In simulations only constraints of the two inputs

values was considered. In this section it can be seen

that for the remaining variables (the variables of

state x) can be considered constraints. The idea of

the algorithm is that by decreasing α the absolute

variables of inputs and consequently variables of

state are higher, the possibility of violating

constraints is greater. On figures (6-11) this

dependence of state variables and input on α is

presented.

Figure 6: Output variable y

1

in dependence on α.

Figure 7: Output variable y

2

in dependence on α.

Figure 8: Input variable u

1

in dependence on α.

Figure 9: Output variable u

2

in dependence on α.

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

296

Figure 10: State variable x

3

in dependence on α.

Figure 11: State variable x

4

in dependence on α.

3.3 System with Coordinates as

Outputs

In order to present that the algorithm is not valid for

every feedback linearizable system of smooth

function the implementation of manipulator system

with different outputs was prepared. In this section

the outputs represents coordinates of the system that

is y

1

=a, y

2

=b. Then the system equations

(27)

The feedback linearization will be accomplished by

diffeomorphism

(28)

And new inputs

,

.

Two linear systems are obtained as in (10). The

system (21) has relative degree r=4, therefore there

are 4 variables the linear system and two additional

variables [z

5

z

6

]

T

=T

i

(x) has to be chosen. They have

to satisfy (Isidori, 1985), (Slotine & Li, 1991) equation

(29)

One of the possible choice is

(30)

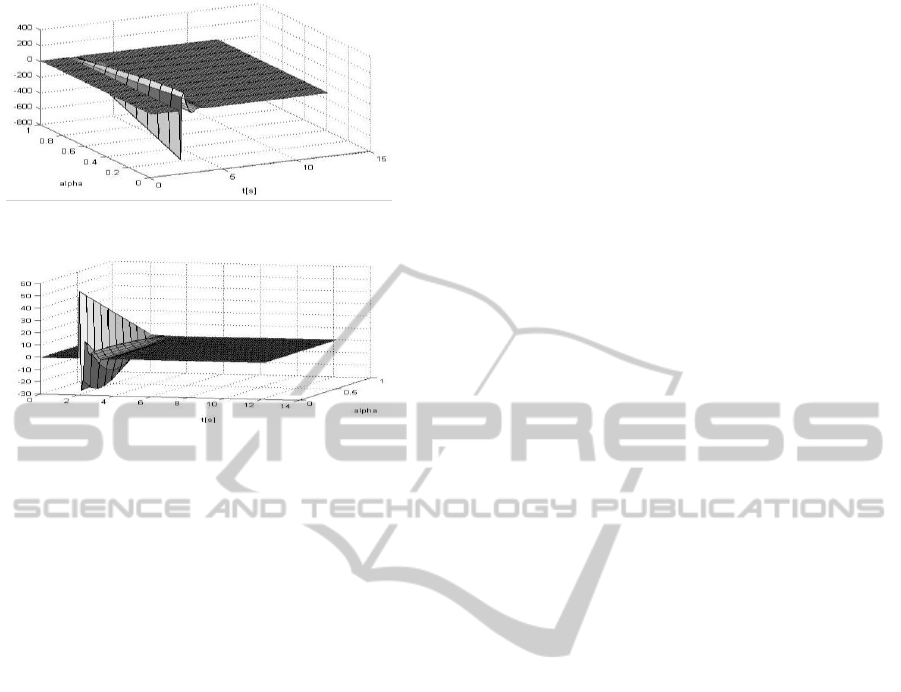

The system (21) with performed linearization (22-

24) and used presented algorithm is not working

properly. The reason for this is that the dependence

of some variables on α is not monotonic as can be

seen on figures (12-17).

Figure 12: Output variable y

1

in dependence on α.

Figure 13: Output variable y

2

in dependence on α.

Figure 14: The variable x

1

in dependence on α.

Figure 15: The variable x

2

in dependence on α.

Constrained Predictive Control of MIMO System - Application to a Two Link Manipulator

297

Figure 16: Input variable u

1

in dependence on α.

Figure 17: Input variable u

1

in dependence on α.

In this case variables x

2

and u

1

changes in the

undesirable manner as α increases. The main reasons

for this result is the chosen variable z

6

=x

1

+x

2

and

that nonlinear functions described inputs (9) are

fractions with nonlinear denominator dependent on

α.

REFERENCES

Slotine, J. E.; Li W. (1991). Applied Nonlinear Control,

Prentice-Hall, ISBN 0-13-040049-1, New Jersey,

USA

Poulsen, N. K.; Kouvaritakis, B.; Cannon, M. (2001).

Constrained predictive control and its application to a

coupled-tanks apparatus, International Journal of

Control, pp. 74:6, 552-564, ISSN 1366-5820

Isidori A. (1985). Lecture Notes in Control and

Information Sciences, Springer-Verlag, ISBN 3-540-

15595-3, ISBN 0-387-15595-3, Berlin, Germany

Margellos, K.; Lygeros, J. (2010), Proceedings of 49th

IEEE Conference on Decision and Control, ISBN

978-1-4244-7745-6, Atlanta, GA

He De-Feng, Song Xiu-Lan, Yang Ma-Ying, (2011),

Proceedings of 30th Chinese Control Conference,

ISBN: 978-1-4577-0677-6, pp. 3368 – 3371, Yantai,

China

Anderson, B. D. O.; Moore J. B. Optimal control. Linear

quadratic methods (1990), Prentice-Hall, ISBN 0-13-

638560-5, New Jersey, USA

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

298