Using Radio Frequency Identification Technology to Track

Individual Wine Bottles

Isabel Expósito, Iñigo Cuiñas and Paula Gómez

Dept. Teoría do Sinal e Comunicacións, Universidade de Vigo, r. Maxwell, s/n 36310 Vigo, Spain

Keywords: Radio Frequency Identification, Wine Traceability, Bottle Tracking, Tag Readability.

Abstract: Radio Frequency Identification (RFID) technology has been tested and it is now proposed to be used in

applications as food traceability, instead of the traditional barcode, as that could get advantages of its

inherent characteristics: automatic management and distance readability. Among food industries, wine

production represents an added value sector and so it would be a target to implement RFID. Wine bottles

present some problems to the radio propagation, as liquids are not electromagnetically friend materials.

Thus, a large radio electric measurement campaign has been performed in order to deal with the possible

mismatches in using this technology to trace wine bottles from the wine cellars to the final consumer. The

performance of different RFID tag models, as well as the effect of the wine content within the bottle, is

analysed along the paper, trying to identify the better technological solution. The tests indicate that the use

of RFID methods would be suitable to allow the consumer to obtain complete traceability information from

each wine bottle, and the producer to track its products. The proposal opens the door to new possibilities in

the relationship between consumer and producer, by demonstrating the possibility of using a new

technology in a traditional market.

1 INTRODUCTION

Some years ago, wine consumers hardly taste

products far away their own country, and even their

own region. In such circumstances, people were

confident of the product they bought. Perhaps they

personally met the producers, or some people

working at any production stage that could

significantly inform about the quality of the wine

they purchased. However, nowadays the market is

far from being local, and it has become global. This

fact is, indeed, an advantage. Thousands of different

wines are available at most of the markets in the

World, both traditional or on line. But that carries a

lack in the confidence, which only could be solved

by traceability technique proposals. Now, most of

the food industries have implemented traceability

procedures that assure the quality at the different

business steps. But the consumer hardly receives

such information. He only has access to the short

data on the label: the name of the wine, some origin

information, perhaps grape varietals, and sometimes

other nutritional figures.

The use of radio frequency identification (RFID)

technologies combined with transnational data bases

and, possibly, web services would be a technical

solution to both troubles; to allow a complete

traceability from producer to consumer, known as

“from farm to fork”, but also to make this

information available for the consumer. The final

proposal is to provide each bottle with a RFID tag

that univocally identifies it, and to use this tag to

trace the bottle from the winery to the consumer,

passing through the storage stage, transportation,

distribution, shopping,… controlling at each moment

its location and conservation conditions. A summary

of this information could be available for the

consumer by reading the RFID tag with his

smartphone and accessing the web service to read

the data in the own phone. This futuristic scenario is

technologically possible, as tested by European

Project RFID-F2F (RFID-F2F web page, 2011)

(Cuiñas et al., 2011); (Catarinucci et al., 2011), but

some electromagnetic restrictions could limit the

extension of the application.

The RFID technology (ISO/IEC 18000) is now

mature for large developments. The basic idea of

such systems could be paralleled to the bar codes.

Each product to be traced must be identified by a

RFID tag, which aspect is like a label that could

271

Expósito I., Cuiñas I. and Gómez P..

Using Radio Frequency Identification Technology to Track Individual Wine Bottles.

DOI: 10.5220/0004049902710276

In Proceedings of the International Conference on Signal Processing and Multimedia Applications and Wireless Information Networks and Systems

(WINSYS-2012), pages 271-276

ISBN: 978-989-8565-25-9

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

even be printed but it also contains a small electronic

circuit. The bar code reader would be replaced by a

RFID interrogator, which transmits radio frequency

signals that the tags identify as questions. Once a tag

receives a question, it transmits the identification

information it has previously recorded. The tags do

not need to be supplied by external power sources,

as they harvest the energy received with the question

to generate the transmitted answer.

However, there are some limitations that are

inherent to the radio propagation characteristics. The

liquids and metallic elements are not friend materials

for electromagnetic fields radiation (Zhang et al.,

2009); (Hasar, 2009); (Wang and Afsar, 2003). This

unfriendly environment represents a constraint in the

extension of RFID and other electromagnetism-

based technologies. In fact, the aim of this paper is

to analyse the use of RFID in tracking wine bottles,

and to study the technical viability of such

application, trying to overpass the constraints

induced by the elements we are managing.

UHF technology has been preferred to HF in

order to develop a RFID system EPCglobal

compliant. In addition recent works reveal that

passive UHF RFID systems provide many

advantages over HF ones (Uysal et al., 2008).

Something which affects the wine supply chain in

particular is the fact that some steps require far field

interrogation, where HF tags cannot be used as they

do not work properly (Cuiñas et al., 2011).

At item-level tagging, several UHF RFID

solutions have been proposed, some of them based

in the use of general purpose UHF far field (FF) tags

and other in near field (NF) ones (Catarinucci et al.,

2010). UHF NF RFID technology is used when

materials containing liquids and metals are involved,

as they allow mitigating performance degradation

due to the absorbance of RF energy. However, it

could be not suitable in steps where the distance

between the RFID tag and the antenna is large or

several RFID tags must be read simultaneously (De

Blasi et al, 2009). Moreover, recent experimental

studies have shown that FF passive UHF RFID tags

are able to provide higher performance in critical

conditions than NF ones also in an item-level

traceability system when using NF RFID antennas

(De Blasi et al., 2009) (Catarinucci et al., 2010).

In our approach we decided to use FF UHF

RFID tags. The intention is to find a tag that could

be used in the whole supply chain. Thus, a large

experimental research has been done.

2 TEST SET AND PROCEDURE

The study of the viability of the bottle tracking

system is proposed to be done by means of a large

experimental measurement campaign. The

description of the experiments is the objective of this

section.

2.1 Equipment and Materials

The main equipment used was a RFID interrogator

model ALR 9900 from Alien Corporation (Alien,

2012a). Although various researchers have proposed

specific antenna designs for readers (Fan et al.,

2007); (Mahmoud, 2010), the authors decided to

provide their reader with a cush-craft antenna Alien

ALR-8611-AC (Alien, 2009), as the equipment

would be directly implemented. The

transmitter/receiver system operates in the UHF

band, at 866 MHz.

During the tests, up to eight tag models were

involved, each one at a time, to avoid interference

problems (Lazaro et al., 2009). The objective was to

determine the design that best adapts the

electromagnetic behaviour of the bottle. This model

would be proposed as the most effective for the

application. The tested tags were manufactured by

UPM (UPM, 2010a); (UPM, 2010b); (UMP, 2010c);

(UPM 2008); or by Alien Corporation (Alien,

2012b); (Alien, 2012c); (Alien, 2012d); (Alien,

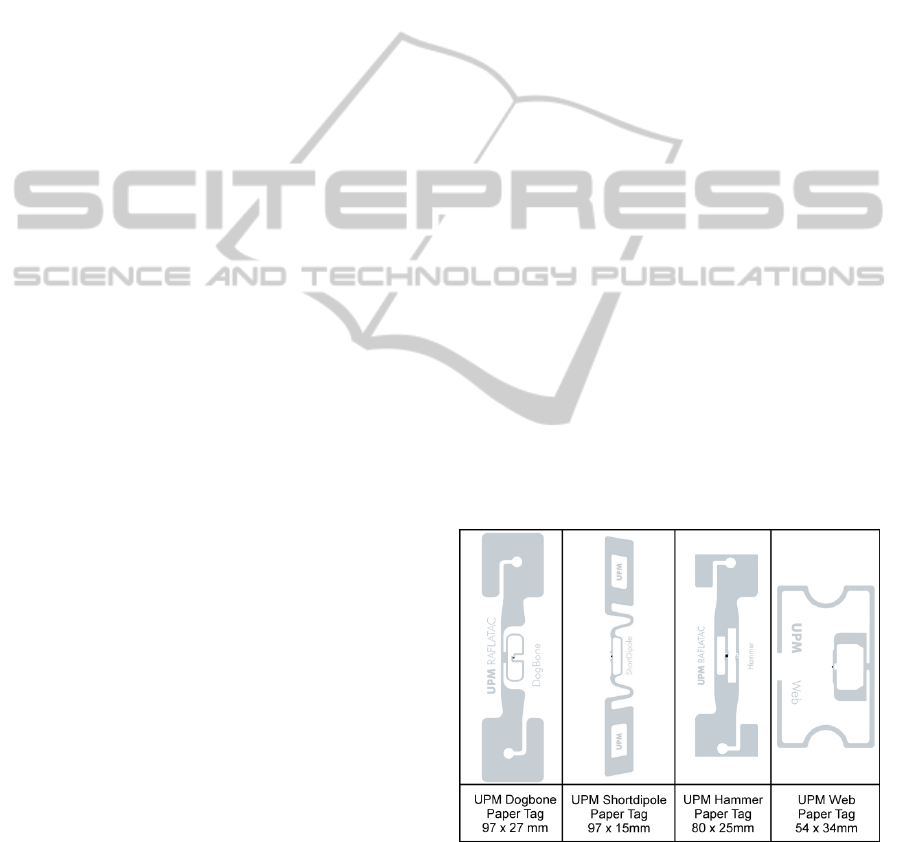

2012e) and their shapes are represented in figures 1

and 2, respectively.

Figure 1: RFID tags manufactured by UPM.

The tags were attached to the bottle with vertical

orientation in order to minimize performance loss

due to antenna curving. As we try to provide

information about a traceability system with massive

application, it would be out of scope the needing of a

WINSYS 2012 - International Conference on Wireless Information Networks and Systems

272

particular RFID tag design, as the individual cost of

these advanced models is unaffordable for wine

producers.

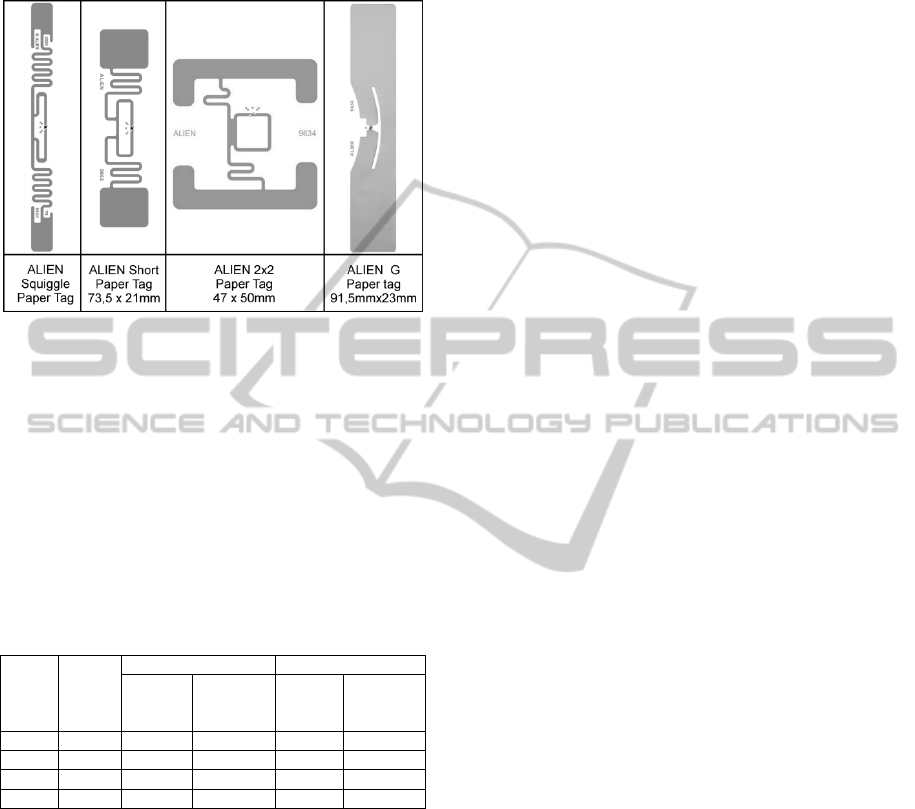

Figure 2: RFID tags manufactured by Alien Corporation.

The object to be tracked is, of course, also

important. And the variety of wine bottle designs,

with slight differences among them, is really large.

So, we have used four different 75 cl wine bottles.

And we tested two red wine bottles and two white

wines, all produced at well-known Spanish

denominations of origin. The bottles were labelled

from 1 to 4, and their dimensions are summarized in

table 1. All of them are Bordeaux shape design,

except number 1 that is like Burgundy shape.

Table 1: Bottle dimensions.

bottle

wine

complete bottle

neck

height

(cm)

base

diameter

(cm)

length

(cm)

diameter

(cm)

1

white

30.0

8.3

10.5

2.8

2

red

30.0

7.5

8.5

3.0

3

white

32.0

7.3

8.5

2.9

4

red

31.5

7.4

8.4

2.9

2.2 Procedure

The measurement campaign has been conducted

inside an anechoic chamber. Thus, when the RFID

interrogator reads the tag on the bottle, the received

signal comes surely from the tag, and not from

outside or after reflections on the room limits. Such

a facility guarantees the validity of the presented

results.

Each tagged bottle was placed in a fixed location

in the centre of the chamber, on a metallic platform,

as it would be placed in most of the industrial

processes. The RFID antenna, connected to the

interrogator, was moved around the bottle axis,

following a circular path. The distance from the

antenna to the rotation axis was 60 cm, and the

antenna was pointed to the bottle with an inclination

of 19º with respect to the vertical, to maintain the

main lobe of the antenna pointed to the tag. The

antenna displacement covered a 360 degree arc,

stopping each 1 degree, and asking the tag at each

stop. At each stop, the answer signal received from

the RFID tag on the bottle was analysed, checking if

an actual signal was received and, if so, the received

signal strength indicator (RSSI) was recorded. So,

we can determine the angles from which the tag

could be read, but also the quality of the radio link.

This procedure was applied to the four full

bottles, labelled successively with the different tags.

Besides that, the readability around similar shaped

empty bottles was tested, to be used as a reference

for the full bottles.

3 RESULTS

The outcomes of each 360 degree sweep around

each bottle can be combined into an individual chart,

in polar coordinates, representing what we called

readability pattern. Such graphs characterize the

received signal strength observed from any of the

360 antenna angular locations. These received signal

strength values have been normalized to the

maximum received signal strength. There could be

some observation angles with no received power,

which means that it was not possible to obtain a

response from the RFID tag on the bottle when the

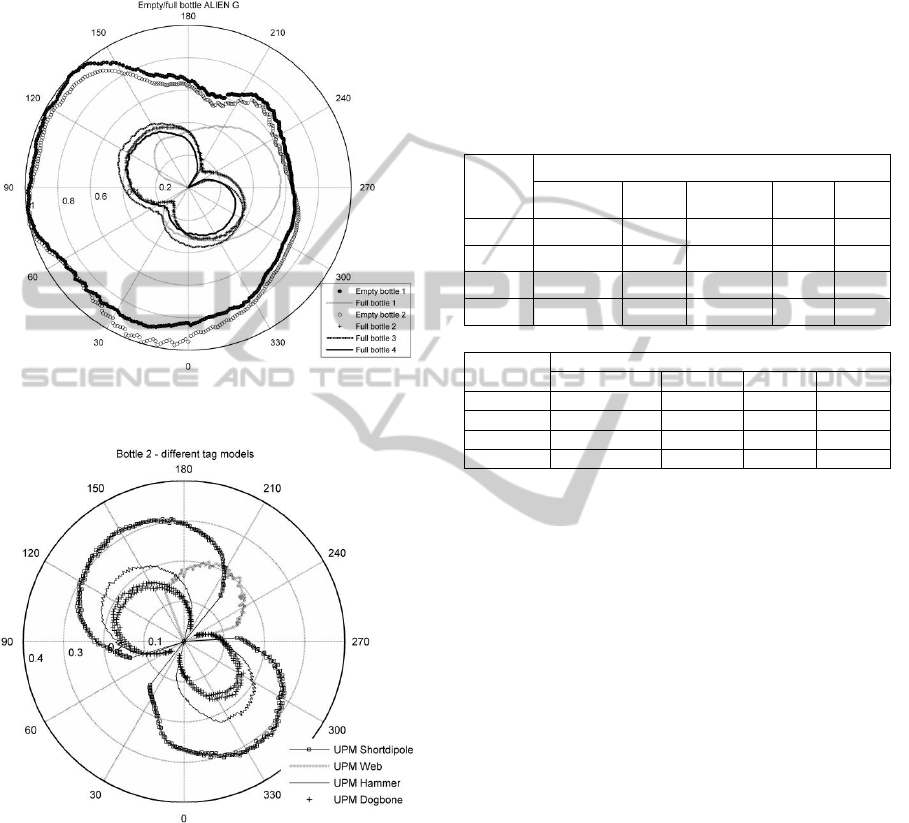

interrogator is pointed at those angles. An example

is showed in figure 3, where the readability patterns

around bottles are presented, by using the Alien G

model RFID tag on each bottle. The larger

readability capabilities are obtained when testing

empty bottles, number 1 (Burgundy shape) and

number 2 (Bordeaux). These are going to be used as

reference for full bottles number 1 (the Burgundy

one), and numbers 2 to 4 (the Bordeaux ones),

respectively. When the tested bottles are full, the arc

at which is possible to obtain a response is reduced

considerably, as could be observed in the figure 5.

This fact will be the most limitative situation if a

RFID-based traceability system must be installed to

track wine bottles in a store, during delivery, or at

the shop. Besides, the shape of the readability

pattern appears to be strongly modified when the

bottle is full of wine, which is obviously the status

we are interested in when tracking and traceability

systems are under deployment. These changes result

in huge differences in terms of readability,

Using Radio Frequency Identification Technology to Track Individual Wine Bottles

273

depending on the angle at which the tag is

interrogated. These effects are observed at figure 5

for one model of tag (Alien G), but they are general

trends using different tag models, but also gluing the

tag to different locations on the bottle surface.

Figure 3: Normalised RSSI, using Alien model G tags,

around the four bottles.

Figure 4: Normalised RSSI, using UPM tags, around the

bottle number 2.

Figure 4 shows the readability patterns around a

Bordeaux – type bottle (the labelled as number 2),

by using different RFID tag models. At the graphs,

the dependence on the RFID tag design appears to

be very strong, both in terms of shape and of

received signal strength as could be tested by

observing the scale of magnitudes. The power

transmitted by the tags is important to be

interrogated, of course, but the angular arc at which

a response is received is probably the crucial factor:

weak responses could be amplified or received with

more sensitive equipment, but silences have no

technical solutions. This means that the arc of

observation may be the key parameter to determine

the best tag model for the specific application. Table

2a-b contains the values of the readability arcs, i.e.

the angular arcs at which the RFID interrogator

receives a response from the tag on the bottle.

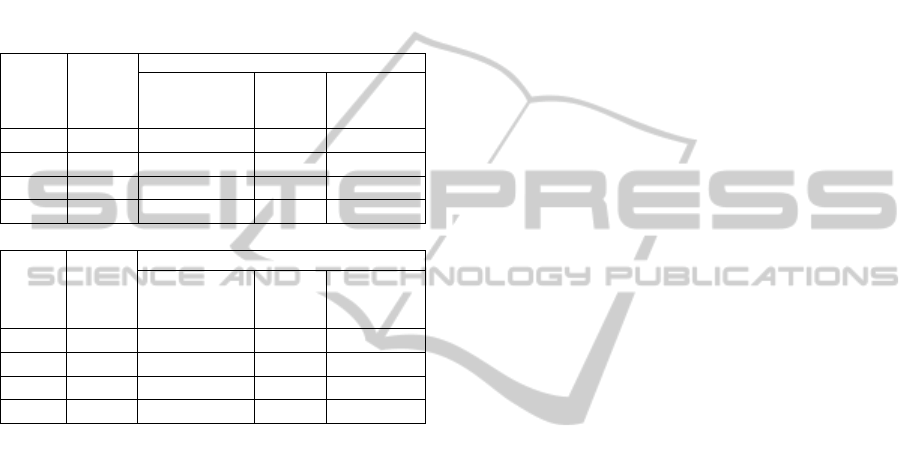

Table 2: Readability arcs in degree; with tags: (a) UPM;

(b) Alien.

bottles

UPM RFID tags

dogbone

short

d.

hammer

web,

H

web,

V

1

304

120

125

199

99

2

295

280

231

96

96

3

309

268

251

199

112

4

292

265

202

105

122

(a)

bottles

RFID Alien tags

squiggle

2x2

G

short

1

260

217

301

312

2

262

185

360

278

3

270

211

327

299

4

272

164

329

307

(b)

The first immediate observation on the results is

related to the shape of the readability pattern:

whereas the interrogation around an empty bottle

always obtains an answer from the RFID tag, this

changes when the bottle is full of wine. The

presence of wine, and probably any other liquid,

inside the bottle induces a strong modification in the

capability of exciting the circuits at the RFID tag

and, so, in the possibility of getting a response. It is

well known that liquids in general are not friendly

materials for radio electric wave propagation (Zhang

et al., 2009), and the results confirm this

asseveration, as could be detected in figures 3 and,

and in table 2. The measurements around empty

bottles indicate that it is possible to read the tag

independently of the interrogation angle. However,

when testing full bottles, the readable arc is reduced,

sometimes to less than 100 degree. Besides, the

RSSI values around empty bottles are always larger

than at full bottles.

The effect of gluing the tag on the bottle at

different heights is also interesting. The experiment,

this time, consisted in repeating the circular

movement of the antenna interrogating the tag when

this was glued on the bottle at different heights from

the bottom. The distance from the tag to the bottle

WINSYS 2012 - International Conference on Wireless Information Networks and Systems

274

bottom was measured from the centre of the tag,

which allows the comparison among different tag

models. Observing the results, it appears that

increasing the distance to the bottle bottom implies a

reduction in the received signal strength from the

tag, whereas the pattern maintains its shape. In

nearly all the cases the largest reading arc seems to

be obtained in the tag positions nearest to the bottom

of the bottle (between 7 and 8.5cm).

Table 3: Best tag position regarding reading arc; with tags:

(a) Alien G; (b) Alien Squiggle.

bottle

wine

ALIEN G tag

Best position

of tag’s centre

(cm)

Arc

width

(º)

Maximum

RSSI (a.u.)

1

white

8.5

314

10087

2

red

7 or 7.5

360

10497

3

white

8.5

345

9337.3

4

red

7.5

333

9849.8

(a)

bottle

wine

ALIEN Squiggle tag

Best position

of tag’s centre

(cm)

Arc

width

(º)

Maximum

RSSI (a.u.)

1

white

7

160

1262.5

2

red

8.5

247

1458.4

3

white

11.5

196

1298.5

4

red

7

246

1647.7

(b)

The results appear to show that the location of

the tags has low influence on the shape of the

readability pattern but it has large weight on the

power emitted by the RFID tag, and even in the

angles at which the tag is possible to be read. In

terms of reading arc the positions nearest to the

bottom of the bottle seem to be more convenient (see

table 3). At these tables, the maximum RSSI is

measured in arbitrary units, which represents the

value given by the handheld reader after

interrogating the tag. The success in selecting the

satisfactory location will lead to better performance

in the interrogation capacity.

The previously commented results will be useful

to select the most adequate tag model and bottle

location when implementing a RFID-based

traceability and tracking system for wine bottles as

proposed in RFID-F2F project. The use of such FF

tags would allow the control of bottle storage, and

combining with temperature sensors it would also

improve the conservation conditions tracking along

the distribution stage.

4 CONCLUSIONS

This paper presents a system to trace and track wine

bottles by means of radiofrequency techniques,

using the so-called RFID technology. Previously to

the implementation of such a system, some

experiments have been performed around different

wine bottles, by means of a complete collection of

commercial RFID tags. Up to four different bottles

and up to eight RFID tag models have been involved

in a large electromagnetic measurement campaign.

The results presented along the paper indicates

that the performance of the tracking system, in terms

of its capacity of effectively detect the RFID tags on

the bottles, depends on several factors, as the own

design of the tag, the location of the tag on the bottle

side, and the bottle shape.

Depending on the design of the tag, there are tags

that are able to be read from many angles of

observation, whereas there are others with small

visibility arcs. In any case, when the bottle is empty,

they could be read from all around, which means

that the presence of the wine affects in a different

way as a function of the design of the tag. Thus, a

good selection of tag design would be a key factor to

the success of the system.

Depending on the location of the tag on the

bottle side, the received signal strength at the RFID

interrogator varies and also the arc at with the

reading is possible, although the shape of the

readability pattern appears to be approximately the

same. This means that a precise selection of the

location would lead to better readability

performance of the system.

Although the measurements have been done in

controlled environments, the results are promising.

They seem to show that the proposed system could

be successfully implemented in actual wineries and

stores, being used to trace and track the bottles, as

well as in markets where final consumers could

access the data related to the product, increasing

their confidence on its process and quality.

ACKNOWLEDGEMENTS

This work has been supported by the European

Commission (CIP-Pilot Actions), under the project

“RFID from Farm to Fork”, grant agreement number

250444.

Authors would like to thank Ms Eva Sotos for

her help during the measurement campaigns.

Using Radio Frequency Identification Technology to Track Individual Wine Bottles

275

REFERENCES

Alien Technology Corp., ALR-9900+EMA, Enterprise

RFID Reader, 2012. Alien Technology, 18220

Butterfield Blvd., Morgan Hill CA 95037 USA.

Alien Technology Corp., ALN-9640 Squiggle Inlay, 2012.

Alien Technology, 18220 Butterfield Blvd., Morgan

Hill CA 95037 USA.

Alien Technology Corp., ALN-9662 Short Inlay, 2012

Alien Technology, 18220 Butterfield Blvd., Morgan

Hill CA 95037 USA.

Alien Technology Corp., ALN-9634 2x2 Inlay, 2012.

Alien Technology, 18220 Butterfield Blvd., Morgan

Hill CA 95037 USA.

Alien Technology Corp., ALN-9654 G Inlay, 2012. Alien

Technology, 18220 Butterfield Blvd., Morgan Hill CA

95037 USA.

Alien Technology Corp., ALR-8611-C, High Performance

RFID Antenna, 2009. Alien Technology, 18220

Butterfield Blvd., Morgan Hill CA 95037 USA.

Catarinucci L., Cuiñas I., Expósito I., Colella R., Gay-

Fernández J.A., Tarricone L., “RFID and WSNs for

traceability of agricultural goods from farm to fork:

electromagnetic and deployment aspects on wine test-

cases”, Proceedings of the 19th International

Conference on Software, Telecommunications and

Computer Networks, SoftCOM 2011, Split (Croatia),

2011.

Catarinucci L., Colella R., De Blasi M., Patrono L.,

Tarricone L., “Improving item-level tracing systems

through ad hoc UHF RFID tags”, Proceedings of the

IEEE Radio and Wireless Symposium (RWS’2010), pp.

160–163, New Orleans (USA), 2010.

Cuiñas I., Catarinucci L., Trebar M., “RFID from Farm to

Fork: traceability along the complete food chain”,

Progress In Electromagnetic Research Symposium,

PIERS 2011, Marrakesh (Morocco), 2011.

De Blasi M., Mighali V., Patrono L., Stefanizzi M. L.,

“Performance Evaluation of UHF RFID tags in the

Pharmaceutical Supply Chain”, Proceedings of 20th

Tyrrhenian International Workshop on Digital

Communications, Pula (Italy), 2009.

Fan Z. G., Qiao S., Huangfu J. T., Ran L. X., “A

miniaturized printed dipole antenna with V-shaped

ground for 2.45 Ghz RFID readers”, PIER, vol. 71, pp.

149-158, 2007.

Hasar U. C., “Thickness-independent automated

constitutive parameters extraction of thin solid and

liquid materials from waveguide measurements”,

Progress In Electromagnetics Research, PIER, vol.

92, pp. 17-32, 2009.

ISO/IEC 18000–Information Technology AIDC

Techniques– RFID for Item Management – Air

Interface , 18000-6 Part 6 – Parameters for Air

Interface Communications at 860 to 960 MHz, 2008.

Lazaro A., Girbau D., Villarino R., “Effects of

Interferences in UHF RFID Systems”, Progress In

Electromagnetics Research, PIER, vol. 98, pp. 425-

443, 2009.

Mahmoud K. R., “Design optimization of a bow-tie

antenna for 2.45Ghz RFID readers using a hybrid

BSO-NM algorithm”, Progress In Electromagnetics

Research, PIER, vol. 100, pp. 105-117, 2010.

RFID-F2F (RFID from Farm to Fork) project web page,

http://www.rfid-f2f.eu/.

UPM Raflatac, UPM Raflatac Dogbone, 05/2010 ENG

X006/3, 2010. UPM RFID, Myllyhaantie 6 C, 33960

Pirkkala, Finland.

UPM Raflatac, UPM Raflatac Shortdipolex, 05/2010 ENG

X003/3, 2010. UPM RFID, Myllyhaantie 6 C, 33960

Pirkkala, Finland.

UPM Raflatac, UPM Raflatac Webx, 05/2010 ENG

X002/2, 2010. UPM RFID, Myllyhaantie 6 C, 33960

Pirkkala, Finland.

UPM Raflatac, UPM Raflatac Hammer, 04/2008 ENG

X001, 2008. UPM RFID, Myllyhaantie 6 C, 33960

Pirkkala, Finland.

Uysal, D. D., Emond, J.-P., Engels, D. W., “Evaluation of

RFID Performance for a Pharmaceutical Distribution

Chain: HF vs. UHF”, Proceedings of the 2008 IEEE

International Conference on RFID, Las Vegas (USA),

2008.

Wang Y., Afsar M. N., “Measurement of complex

permittivity of liquids using waveguide techniques”,

Progress In Electromagnetics Research, PIER, vol.

42, pp. 131-142, 2003

Zhang Y., Yemelyanov K., Li X., Amin M. G., “Effect of

metallic objects and liquid supplies on RFID links”,

Proceedings of the IEEE Antennas and Propagation

Society International Symposium, IEEE AP-S 2009,

Charleston (USA), 2009.

WINSYS 2012 - International Conference on Wireless Information Networks and Systems

276