Neuro-fuzzy Sliding Mode Control for a Two Link Flexible Robot

Khedoudja Kherraz

1

, Mustapha Hamerlain

2

and Nouara Achour

1

1

Electronic Department, University of Sciences and Technology U.S.T.H.B, Bab-Ezzouar-Algiers, Algeria

2

Center of Development of Advanced Technologies (CDTA), Baba Hacen-Algiers, Algeria

Keywords: Robot Manipulator, Flexible Link, Sliding Mode, Neuro Fuzzy, Vibration Control, Chattering, Trajectory

Control, Hybrid Control, Super Twisting Algorithm.

Abstract: In most robotic applications, trajectory tracking control and vibration suppression in flexible link

manipulator is a recurring problem, due to the unknown nonlinearities and strong coupling often caused by

the presence of flexibility in the links. In order to solve this problem, a new sliding mode controller using

neural networks and fuzzy logic is presented in this paper. The stability of the proposed controller is proved

with the Lyapunov function method. The neural network is used to compensate the highly nonlinear system

uncertainties. The fuzzy logic is used to eliminate the chattering effect caused by the robust conventional

sliding mode control. The effectiveness of this control system will be compared to the performance obtained

with a second order sliding mode control which is the super twisting algorithm. Comparative simulations

show the superiority of the proposed controller regarding the second order sliding mode controller and

confirm its robustness with bounded disturbance and its ability to suppress the flexible link manipulator

vibrations.

1 INTRODUCTION

In the last few years, the dynamic proprieties and

control techniques for flexible link manipulators are

being intensively studied (Sanz and Etxebarria,

2006). They exhibit many advantages with respect to

the rigid manipulators, such as payload-to-arm ratio,

operation speed and energy consumption. But the

use of structurally flexible robotic manipulators

requires the inclusion of deformation effects due to

the flexibility in the dynamic equations which

complicates the analysis and the control design.

In a robot system, there are many uncertainties,

such as dynamic parameters, dynamic effects and

unmodeled dynamics. These uncertainties should be

taken into consideration in the control algorithm. So,

the controller of flexible manipulator must achieve

the same motion objectives as a rigid manipulator,

and it must also stabilize the vibrations. A large

number of reports have been presented, employing

the hybrid control scheme (Ho Lee and Won Lee,

2002), the radial basis function network (Tang and

Sun, 2005), the impedance control (Hui Jiang,

2005), inversion techniques (De Luca et al., 1989),

adaptive control (Yang et al., 1997) (Lin and Yeh,

1996), and VSC (variable structure control) (Fung

and Lee, 1999) (Singh and Nathan, 1991). Sliding

modes are the primary form of VSSs. The sliding

mode control is a well known approach to the

control of uncertain systems. It has received much

attention due to its ability to reject disturbances

while tracking a desired trajectory. However,

standard sliding modes are caracterized by a high-

frequncy switching of control, wich causes problems

in practical applications (so-called chattering effect).

To avoid this drawback, higher order sliding mode

(HOSM) can be used. The HOSM concept emerged

in 1980s with the motivation of tackling the

chattering phenomenon. HOSM controllers have the

capability of stabilizing around zero in finite time

not only the sliding variable, but also a number of its

time derivatives. A lot of HOSM approaches have

been studied in (Kunusch et al., 2009) (Khan et al.,

2003) (Boiko and Fridman, 2005) (Levant and

Alelishvili, 2004) (Levant, 2000) (Jimenez, 2004).

In order to reduce the chattering, other methods can

be applied such as boundary layer approach (Yeung

and Chen, 1988), fuzzy sliding mode control (Wang,

2009) and neural network sliding mode control

(Peng et al., 2006).

This paper presents the design of neuro fuzzy

sliding mode controller for flexible robotic trajectory

189

Kherraz K., Hamerlain M. and Achour N..

Neuro-fuzzy Sliding Mode Control for a Two Link Flexible Robot.

DOI: 10.5220/0004032001890195

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 189-195

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

and vib

r

the mer

i

network

s

dynami

c

robustn

e

super t

w

sliding

m

analyse

d

Stability

Simulati

effectiv

e

p

ropose

d

robustn

e

to distur

b

2 D

Y

We con

s

of n flex

obtain t

h

introduc

e

the ma

n

links.

Let

θ

the link

that the

r

its joint

s

end-effe

c

dimensi

o

among

P

P = f(θ,

The

r

is linear

Where

matrices

as J

=

By t

a

we have

robo

t

flexible

Element

The

manipul

a

r

ation suppre

s

i

ts slinding

m

s

, in order

t

c

s, eliminate

e

ss. This co

n

w

isting algor

i

m

ode contro

l

d

for syste

m

y

of the c

ons are car

r

e

ness and

h

d

control me

t

e

ss to parame

t

b

ances.

Y

NAMIC

s

ider a flexib

l

x

ible links dri

v

h

e dynamic

m

e

of a conve

n

n

ipulator, inc

l

θ

∈ R

b

e th

e

flexible dis

p

r

obot has no

r

s

, and defin

e

c

tor positio

n

o

n workspac

e

P

, θ and δ is

n

δ).

r

elationship

a

and can be a

n

P

=

J

J

ϵR

an

d

of f with res

p

and J

=

a

king derivat

i

th en

d

-effect

o

P

=J

θ

+

J

t

We derive

d

using Lagra

n

Method).

physical

m

a

tor is shown

s

sion. The co

n

m

ode, fuzzy

t

o compensat

e

the chatteri

n

n

troller is co

m

i

th

m

, wich i

s

l

. It has bee

n

m

s with rela

t

ontrol syste

m

r

ied out to

h

igher perf

o

t

hod which i

s

t

er variations

MODEL

I

l

e robot mani

p

v

en by n rigid

m

odel, it bec

o

n

ient kinema

t

l

uding the d

e

e

joint variab

l

p

lacement ve

r

edundant deg

e

vector PϵR

n

and orien

t

e

. The kinem

a

n

onlinear, an

d

a

mong the vel

o

n

alyzed as fol

l

J

θ

+J

δ

d

J

ϵR

a

p

ect to θ and

i

on of P

wit

h

o

rs’ accelerat

i

J

δ

+J

θ

+J

d

the dyna

m

n

ge approach

m

odel of t

w

in Figure 1

n

troller integ

r

logic and n

e

e

for unmo

d

n

g and save

m

pared with

s

a second

o

n

developed

t

ive degree

m

is anal

y

demonstrate

o

rmance of

characterize

d

and insensit

i

NG

p

ulator consi

s

joints. In ord

e

o

mes necessa

r

t

ic descriptio

n

e

formation o

f

l

e vector, δϵ

R

c

tor. We ass

r

ee of freedo

m

to describe

t

ation in th

e

a

tical relatio

n

d

can be give

n

o

cities θ

, δ

a

n

l

ows:

a

re the Jaco

δ that are de

f

h

respect to t

i

on

δ

m

ic model o

f

and FEM (F

i

w

o-link fle

x

r

ates

e

ural

d

eled

the

the

o

rder

and

one.

y

zed.

the

the

d

by

i

vity

s

ting

er to

r

y to

n of

f

the

R

be

s

ume

m

on

e

the

e

n-

n

ship

n

as:

n

d P

(1)

o

bian

f

ined

t

ime,

(2)

f

the

inite

x

ible

rob

Le

M

o

M

wh

e

an

d

ce

n

se

m

ter

m

dia

g

fle

x

mo

d

ve

c

dis

p

τ

=

rot

o

W

e

ref

e

ele

m

fle

x

ma

n

att

e

so

m

3

Tr

a

Figure 1:

A

The dynami

c

otic manipul

a

Vey, 2004)

o

rris, 2002) ca

n

M

(

θ,δ

)

θ

δ

F

(

θ,δ

)

=

τ

0

e

re M is the

d

positive de

f

n

trifugal forc

e

m

i definite li

n

m

s and ext

e

g

onal stiffne

s

x

ible modes

.

d

eled very ac

c

c

tor consists

o

p

lacements (δ

=

τ

τ

are t

h

or

-2 respectiv

e

e

take

D

The param

e

e

rence (De L

u

The control

o

m

ents bears

t

x

ibilities. Th

e

n

ipulator w

i

e

nuating the

m

e of its com

p

SLIDIN

G

a

cking error is

A

two-link flex

i

c

equation

o

a

tor with rigi

d

(

Talebi et al.

n

be given as:

+

C

θ,θ

,δ,

τ

0

=u

inertia matri

x

f

inite, C is

e

e

s, D is the

n

k damping

e

rnal disturb

a

s

s matrix th

a

Although,

c

urately. The

o

f link positi

o

11

, δ

12

, δ

21

, δ

2

2

e torques a

p

e

ly.

0

δ

+

K

δ

e

ter matrice

s

u

ca and Sicili

a

o

f a manipul

a

t

he study of

e

control obj

e

i

thin a sp

e

v

ibrations d

u

p

onents.

G

MODE

defined as:

x

ible manipulat

o

o

f a two-lin

k

d

joints (Beno

.

, 2002) (Su

b

:

δ

+

0

D

δ

+

x

, which is s

y

effect of co

r

diagonal an

d

matrix, F

i

s

a

nces and

K

a

t only affec

F

(

θ,δ

)

c

a

generalized

c

o

ns (θ

1

, θ

2

) a

n

2

).

p

plied by ro

t

=H

s

are intro

d

a

no, 1991).

a

tor formed b

y

the robot’s

e

ctive is to

m

e

cific trajec

t

u

e to the el

a

CONTR

O

o

r.

k

flexible

s

man and

b

udhi and

+

K

δ

+

(3)

y

mmetric

r

iolis and

d

positive

s

friction

K

is the

ts to the

a

nnot be

oordinate

n

d modal

t

o

r

-1 and

(4)

d

uced in

y

flexible

structural

m

ove the

t

ory but

sticity of

O

L

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

190

e=

θ

−

θ

(5)

Where θ

d

is desired joint trajectory vector.

The sliding surface variable is defined by:

s=e +

λ

e

(6)

Where λ = diag[λ

,λ

,….λ

] in wich λ

is a

positive constant for i= 1, 2….n.

The control goal is to guarantee the state

trajectories convergence to sliding surface s=0, and

keep them on the sliding surface, that is s =0.

4 SUPER TWISTING

ALGORITHM

The super twisting algorithm is one of the popular

algorithms among the second order sliding mode

algorithms (Boiko et al., 2008), (Kunusch et al,

2009). The super twisting algorithm defines the

control law u(t) as a combination of two terms

(Khan et al., 2003). The first is defined in terms of

discontinuous time derivative u

1

(t), while the second

is a continuous function of the sliding variable u

2

(t).

The super twisting algorithm is defined as follows:

u

(

t

)

=u

(

t

)

+u

(t)

(7)

where

u

={−u,

|

u

|

≻1

(8)

u

=−ωsign

(

s

)

,

|

u

|

≤1

(9)

u

|

s

|

sign

(

s

)

,

|

s

|

>s

(10)

u

=−

λ

|

s

|

sign

(

s

)

,

|

s

|

≤s

(11)

And sufficient conditions for finite time

convergence are:

ω>

Ф

Γ

≻0

(12)

λ

=

4ФΓ

(ω + Ф)

Γ

(ω − Ф)

(13)

where , λ and ρ are variable controller parameters,

∅ is positive norm bound on the smooth uncertain Ф,

Γ

and Γ

are lower and upper positive bounds on

the smooth uncertain function, γ. The choice of

ρ=0.5 assures that sliding order 2 is achieved

(Levant, 1993).

The super twisting algorithm in equation (7) can

be simplified as follows:

u

(

t

)

=−

λ

|

s

|

sign

(

s

)

+u

(14)

u

=−ωsign

(

s

)

(15)

This control algorithm does not need any

information on the time derivatives of the sliding

variable nor any explicit knowledge of other system

parameters.

5 DESIGN OF NEURO FUZZY

SLIDING MODE CONTROL

We define a Lyapunov function:

V=

1

2

s

Ms

(16)

V

=s

Ms +

1

2

s

M

s

(17)

Since s

M

−2Cs=0

(18)

Then

V

=s

(

Ms +Cs

)

= s

[(u − M

(

q

−λe

)

−C

(

q

−λe

)

−H−F

]

=s

(u +

(

Mλe +Cλe

)

−F

−Mq

−Cq

− H) (19)

u is chosen as:u= −μ − k

sign(s)

(20)

where

μ=M

λ

e +C

λ

e

(21)

B=Mq

+Cq

+H)

(22)

Then

V

=s

(−F

−B−k

sign

(

s

)

)

(23)

The sliding condition V

<0 can be satisfied if k

is

selected such that:

k

>

|

F

+B

|

(24)

In order to guarantee that the system tracking

error is quickly convergent k

should be chosen

sufficiently large.

When s>0,

s

(−F

−B−k

sign

(

s

)

)<0

(25)

When s<0,²

s

−F

−B−k

sign

(

s

)

<0

(25)

Thus

V

=s

−F

−B−k

sign

(

s

)

<0

(27)

This guarantees that hitting condition is satisfied.

Neuro-fuzzySlidingModeControlforaTwoLinkFlexibleRobot

191

In this paper, a neuro-fuzzy is used to

compensate the uncertainty F

in the robot system

reel-time. A five layer neuro-fuzzy structure is

applied. It can be described in detail as below:

Where x=(x

,x

) is the input of the neuro-fuzzy.

y=(y

,y

) is the output of the neuro-fuzzy.

Layer 1:

The nodes in this layer represent membership

functions.

O

=μ

(x), for i=1. ...3, j=1……3.

(28)

O

=μ

(x), for i=4. ...6, j=1……3.

(29)

Where:

and

are triangular fuzzy sets.

Layer 2:

O

= μ

(

x

)

μ

(

x

)

=W

,j=1……9.

(30)

Layer 3:

O

=

W

∑

W

=V

(31)

Layer 4:

O

=

1−e

1+e

=Z

(32)

Layer 5:

O

=

∑

T

O

(33)

k=1…2

T

is the connection weight

T=

T

T

…….. T

T

T

…….. T

(34)

The output of the five layer neuro fuzzy can be

rewritten as follows:

Y

=TZ

(35)

The system uncertainty F

can be described as

follows:

F

=TZ+ε

(36)

ε is the approximation error.

If the neuro fuzzy algorithm satisfies:

T

=−

γ

sZ

(37)

Where γ>0.

The output of the controller is designed as:

u=−s−μ+

(

1+

γ

)

TZ − B − k

sign(s)

(38)

But k

can cause chattering due to the sign function.

In order to eliminate the chattering, we replace the

control k

sign(s) by a fuzzy gain k

. Then,

V

=s

(−F

−B−k

)

(39)

In order to make V

<0 and guarantee the sliding

mode condition, the fuzzy rules can be decided as

follows:

IF s is NB THEN k

is NB

IF s is N THEN k

is N

IF s is Z THEN k

is Z

IF s is P THEN k

is P

IF s is PB THEN k

is PB

Then

u=−s−μ+

(

1+

γ

)

TZ − B + k

(40)

6 SIMULATION RESULTS

In order to demonstrate the superior performance of

the two methods, a simulation example of a two–link

flexible robotic manipulator is also considered. The

function of the desired trajectories can be expressed

as:

θ

(

t

)

=

θ

+

(

)

(

−sin

)

(41)

Where θ(t) is the desired tracking curve. θ

is the

initial value of θ(t).

We assume the disturbance as:

d

(

t

)

=w

(

t

)

sin (2 πt)

(42)

Where w(t) is a Gaussian distributed randon signal

with mean zero and standard deviation σ.

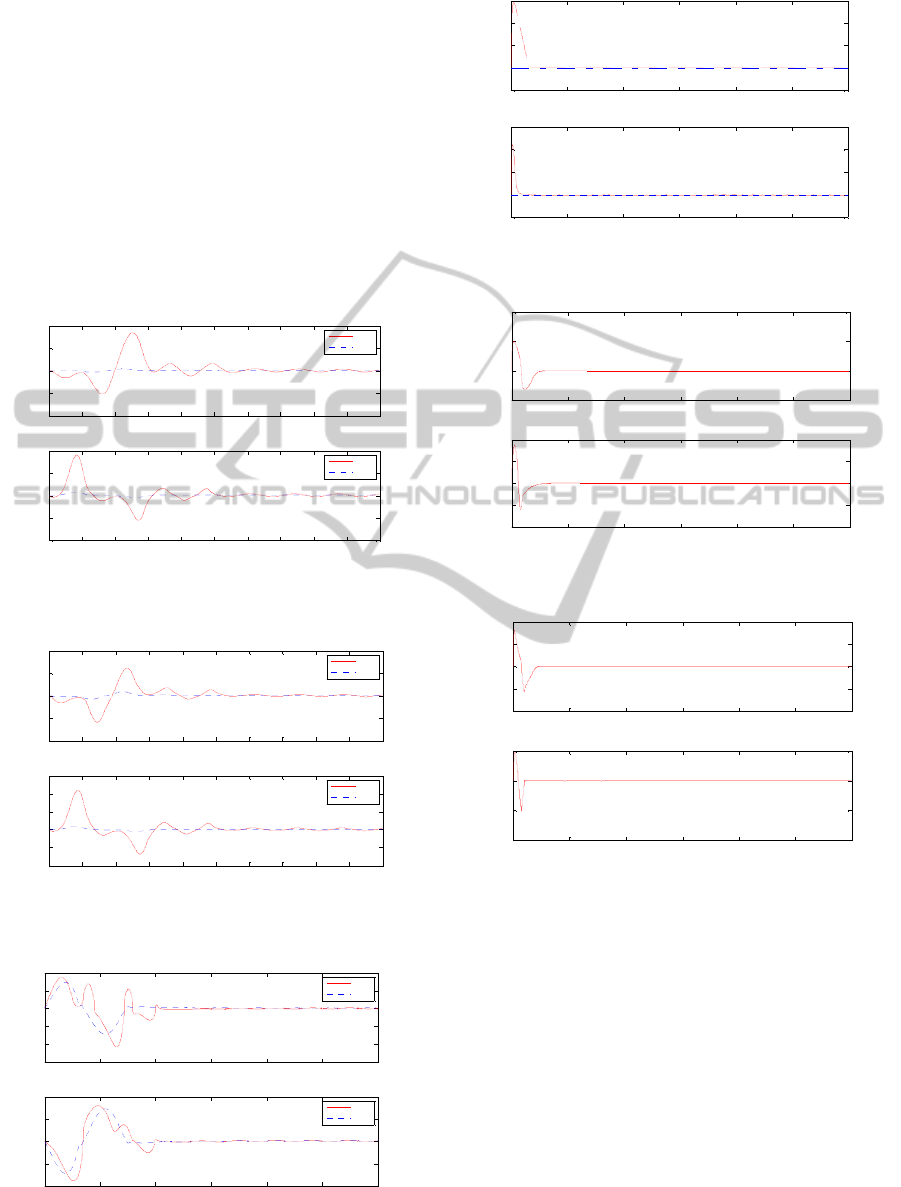

The figures compare the results obtained with the

super twisting algorithm and neuro fuzzy sliding

mode control for tip position control when the

flexible manipulator was commanded to move from

an initial position of 0 rad to a target tip position of

0.5 rad. From the tip deflection trajectories shown in

figures (2) and (3), it can be seen that deflection is

less with the neuro fuzzy sliding mode control than

Super Twisting algorithm. The first and second

mode of vibration has smaller amplitude with the

neuro fuzzy sliding mode compared to the super

twisting. Even more important, it should be noted

that the oscillations of elastic modes are attenuated

quickly with the neuro fuzzy sliding mode control.

Control profiles of the controllers are shown in

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

192

figure (4). Initially, the control torque rises to a

maximum of 0.6 and 0.8 respectively, and in all

cases, the control torque eventually becomes zero

when the desired tip displacement is achieved and

the vibration is completely damped out.

Figure (5) shows the position error for the two

methods. The tip position trajectory with the method

of Super Twisting algorithm has a law rise time but

overshoots more than the method of neuro fuzzy

sliding mode control.

Figures (6) and (7) show the velocity error for

the two methods. It can be seen that the tracking of

the desired velocity is better with the neuro fuzzy

sliding mode control.

Figure 2: First mode and second mode deflection

trajectories (link 1).

Figure 3: First mode and second mode deflection

trajectories (link 2).

Figure 4: Control torque.

Figure 5: Position error σ=0.

Figure 6: Velocity error with Super Twisting algorithm.

Figure 7: Velocity error with neuro fuzzy sliding mode

control.

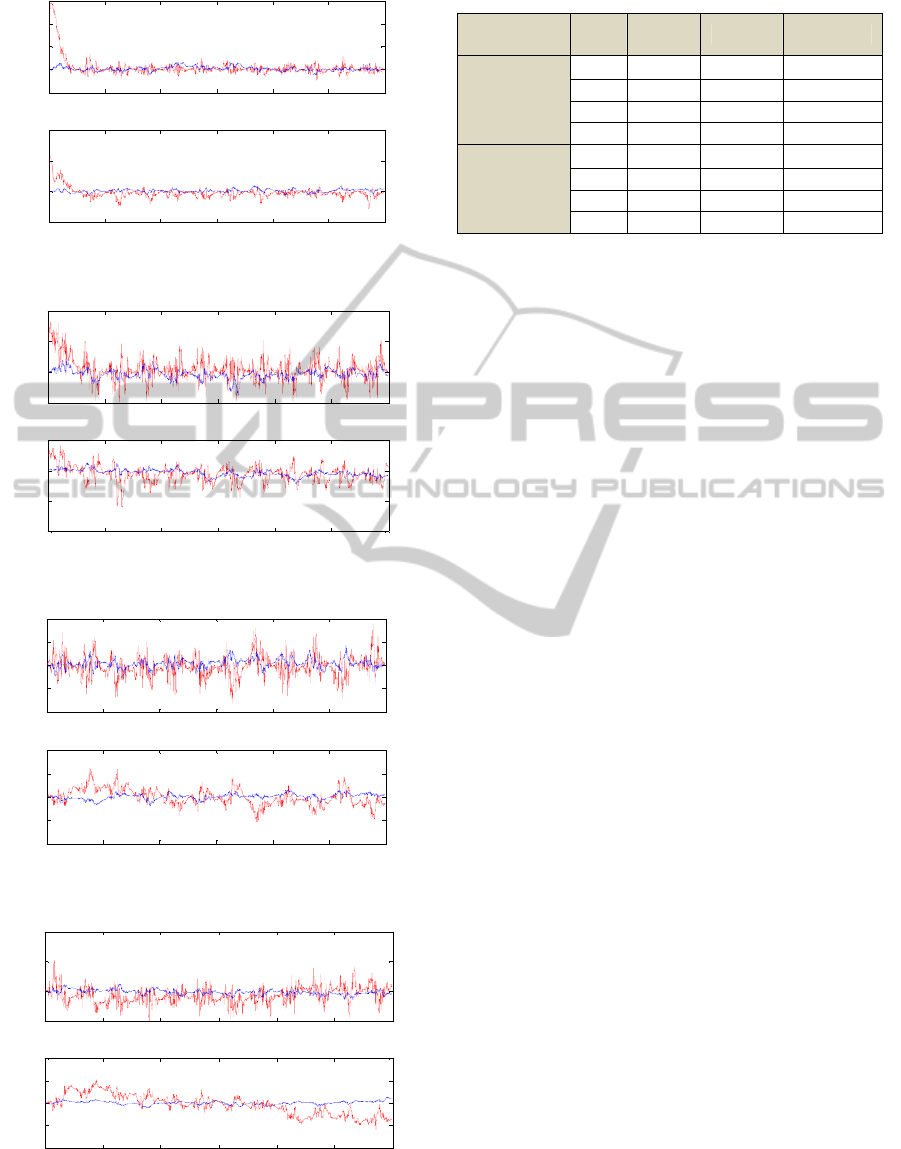

Figures (8) to (11) show the position error for the

two controllers with the variation of the

perturbation. The neuro fuzzy sliding mode is more

robust than Super Twisting algorithm. It can be seen

that the tip position exhibits better tracking of the

desired trajectory with the neuro fuzzy sliding mode

control. For σ = 0.1 to 100, the error position is

acceptable with the two methods. But since

= 120, the desired trajectory with Super Twisting

algorithm is completely divergent. For σ = 180, the

error position with the neuro fuzzy sliding mode

control start to be high.

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

-0.04

-0.02

0

0.02

0.04

Temps (sec)

First mode deflection art(1)

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

-0.02

-0.01

0

0.01

0.02

Temps (sec)

Second mode deflection art(1), (m)

ST

MNF

ST

MNF

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

-0.01

-0.005

0

0.005

0.01

Temps (sec)

First mode deflection art(2)

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

-0.02

-0.01

0

0.01

0.02

0.03

Temps (sec)

Second mode deflection art(2), (m)

ST

MNF

ST

MNF

0 1 2 3 4 5 6

-1.5

-1

-0.5

0

0.5

1

Temps (s ec)

Control torque art(1), (N.m)

0 1 2 3 4 5 6

-1

-0.5

0

0.5

1

Temps (s ec)

Control torque art(2), (N.m)

ST

MNF

ST

MNF

0 1 2 3 4 5 6

-5

0

5

10

15

x 10

-3

Temps (sec)

Erreur art(1)

0 1 2 3 4 5 6

-5

0

5

10

15

x 10

-3

Temps (sec)

erreur art(2), (rad)

0 1 2 3 4 5 6

-5

0

5

10

x 10

-6

Temps (sec)

Link 1:Velocity error(rad/s)

0 1 2 3 4 5 6

-2

-1

0

1

2

x 10

-5

Temps (sec)

Link 2:Velocity error(rad/s)

0 1 2 3 4 5 6

-4

-2

0

2

4

x 10

-6

Temps (sec)

Link 1:Velocity error(rad/s)

0 1 2 3 4 5 6

-2

-1

0

1

x 10

-5

Temps (sec)

Link 2:Velocity error(rad/s)

Neuro-fuzzySlidingModeControlforaTwoLinkFlexibleRobot

193

Figure 8: Position error σ= 6.

Figure 9: Position error σ= 20.

Figure 10: Position error σ= 120.

Figure 11: Position error σ= 180.

Table 1: Comparaison between the two controllers.

Control

σ

Rise

time

Precision Robustness

Super

Twisting

algorithm

6 0.1 0.015 Good

20 0.5 0.02 Good

120 Bad 0.6 Bad

180 Bad Bad Very bad

Neuro Fuzzy

Sliding Mode

Control

6 0.1 10

-7

Very good

20 0.2 10

-5

Very good

120 0.5 0.1 Good

180 0.6 0.2 Good

7 CONCLUSIONS

Due to nonlinearities and uncertainties, the dynamic

characteristics of flexible-link manipulator are very

difficult to obtain precisely. In order to achieve high

precision position control and suppress the

vibrations, a combined control strategy based on the

concept of sliding mode control, neural network and

fuzzy logic is proposed in this paper. Neural network

is employed to mimic an equivalent control law in

the sliding mode control and approximate the

uncertainties and disturbances; fuzzy logic is

developed to eliminate the chattering phenomenon.

This controller is compared with the super twisting

algorithm. The simulation results show that the two

methods can eliminate the phenomenon chattering

greatly, and confirm that the proposed controller

achieves efficient positioning and vibration

suppression performances. The neuro fuzzy sliding

mode controller is more robust than Super Twisting

algorithm.

REFERENCES

Sanz A., Etxebarria V., 2006. Experimental Control of a

Two-Dof Flexible Robot Manipulator by Optimal and

Sliding Methods. Intell Robot Syst.

Ho Lee S., Won Lee C., 2002. Hybrid control Scheme for

robust tracking of two-link-Fexible manipulator.

Journal of intelligent and robotic system.

Tang Y., Sun F., Sun Z., 2005. Tip tracking of a Flexible-

link manipulator with radial basis Function and fuzzy

system. Springer- Verlag Berlin Aeidlberg.

Hui Jiang Z., 2005. Impedance control of flexible Robot

arm with parametric uncertainties. Journal of

intelligent and robotic system.

De Luca, A., Lucibello, P., and Ulivi, G., 1989, Inversion

techniques for trajectory control of flexible robot arms.

J. Robotic Systems 6(4), 325–344.

0 1 2 3 4 5 6

-5

0

5

10

15

x 10

-3

Temps (sec)

Link 1:Position error, (rad)

0 1 2 3 4 5 6

-0.01

0

0.01

0.02

Temps (sec)

Link 2:Position error, (rad)

0 1 2 3 4 5 6

-0.01

0

0.01

0.02

Temps (sec)

Link 1:Position error, (rad)

0 1 2 3 4 5 6

-0.04

-0.02

0

0.02

Temps (sec)

Link 2:Position error, (rad)

0 1 2 3 4 5 6

-0.4

-0.2

0

0.2

0.4

Temps (sec)

Link 1:Position error, (rad)

0 1 2 3 4 5 6

-1

-0.5

0

0.5

1

Temps (sec)

Link 2:Position error, (rad)

0 1 2 3 4 5 6

-0.5

0

0.5

1

Temps (sec)

Link 1:Position error, (rad)

0 1 2 3 4 5 6

-2

-1

0

1

2

Temps (sec)

Link 2:Position error, (rad)

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

194

Yang, J. H., Lian, F. L., and Fu L. C., 1997. Nonlinear

adaptive control for flexible-link manipulators, IEEE

Trans. Robotics Automat. 13(1), 140–148.

Lin, L. C. and Yeh, S. L., 1996. A composite adaptive

control with flexible quantity feedback for flexible-

link manipulators, J. Robotic Systems 13(5), 289–302.

Fung E. H. K., Lee C. K. M., 1999. Variable structure

tracking control of a single-link flexible arm using

time-varying sliding surface, J. Robotic Systems

16(12), 715–726.

Singh S. N. and Nathan, P. J., 1991. Sliding mode control

and elastic mode stabilization of a robotic arm with

flexible links, ASME J. Dyn. Systems Meas. Control

113, 669–676.

Kunusch C., Puleston P. F., Mayosky M. A., and Riera J.,

2009. Sliding Mode Strategy for PEM Fuel Cells

Stacks Breathing Control Using a Super-Twisting

Algorithm. IEEE Transactions on Control Systems

Technology, VOL. 17, NO. 1.

Khan M. K., Goh K. B., and Spurgeon S. K., 2003.

Second Order Sliding Mode Control of a Diesel

Engine. Asian Journal of Control, Vol. 5, No. 4, pp.

614-619.

Boiko I. and Fridman L., 2005. Analysis of Chattering in

Continuous Sliding-Mode Controllers. IEEE

Transactions on Automatic Control, VOL. 50, NO. 9.

Levant A. and Alelishvili L., 2004. Transient adjustment

of high-order sliding modes. in Proc. of the 7th

Scientific Workshop “Variable Structure Systems

VSS'2004”, Vilanova, Spain, September 6-8.

Levant A., Pridor A., Gitizadeh R., Yaesh I., and Ben-

Asher J. Z., 2000. Aircraft Pitch Control Via Second

Order Sliding Technique. AIAA Journal of Guidance,

Control and Dynamics, 23(4), 586-594.

Jimenez T. S., 2004. Diving control a torpedo

Autonomous Underwater Vehicle. Doctorate thesis,

LIRMM - University of Montpellier II.

Yeung K. S. and Chen Y. P., 1988. A new Controller

design for manipulators using the theory of variable

structure systems. [J]. IEEE Trans.Automat. Control.

Wang W., 2009. Adaptive Fuzzy Sliding Mode Control

for Inverted Pendulum. Proceedings of the Second

Symposium International Computer Science and

Computational Technology (ISCSCT ’09).

Peng J., Wang Y., Wei S. and Liu Y., 2006. A neural

network sliding mode controller with application to

robotic manipulator. Proceedings of the 6th world

congress on intelligent control and automation, June

21- 23, Dalian, China.

Benosman M. and Le Vey G., 2004. Control of flexible

manipulators: A survey. Robotica (2004) volume 22,

pp. 533–545. Cambridge University Press

Talebi H. A., Khorasani K. and Patel R. V., 2002.

Tracking control of a flexible-link Manipulator using

neural networks: experimental results. Robotica (2002)

volume 20, pp. 417–427. Cambridge University Press.

Subudhi B., Morris A. S., 2002. Dynamic modelling,

simulation and control of a manipulator with flexible

links and joints. Robotics and Autonomous Systems 41,

257–270.

De Luca A. and Siciliano B., 1991. Closed- form dynamic

model of planar multilink lightweight robots. IEEE

Transactions on systems, MAN, and cybernetics, vol

21, NO, 4.

Boiko I., Castellanos I. and Fridman L., 2008. Analysis of

response of second-order sliding mode controllers to

external inputs in frequency domain. Int. J. Robust

Nonlinear Control.

Levant, A., 1993. Sliding order and sliding Accuracy in

sliding model control, International Journal of

Control, vol.58, no.6, pp.1247-1263.

Neuro-fuzzySlidingModeControlforaTwoLinkFlexibleRobot

195