A Particle Swarm Optimization Algorithm

for the Grasp Planning Problem

Chiraz Walha, Hala Bezine and Adel M. Alimi

REGIM: Research Group on Intelligent Machines, University of Sfax, National Engineering School of Sfax (ENIS),

BP 1173, 3038, Sfax, Tunisia

Keywords: Grasp Planning, Robotic Hand, Particle Swarm Optimization (PSO).

Abstract: Computing a set of contact points between a robotic hand and an object in order to fulfill some criteria is the

main problem of the grasp planning. An automatic grasp planning can produce a set of joint angles defining

a configuration of the robotic hand. The huge number of solutions that satisfy a good grasp is the main

difficulty of such a planner. In this paper, we represent the grasp planning problem as an optimization

problem and we propose a new algorithm based on a Particle Swarm Optimization (PSO) technique. To

generate the positions of the fingertips, the kinematic of the hand is modeled. Therefore, a simple PSO

algorithm is described to optimize the workspace of the operating hand based on a quality of measure of the

grasp. The simulation results support the effectiveness of our approach.

1 INTRODUCTION

The most complicated task that a robot is asked to

achieve is to take an object and bring it to another

place. Many configurations of the hand can be found

considering the high dimension of the wrench space,

the huge number of possible contact points in the

surface of the object and the many degrees of

freedom of the robotic hand. However, finding the

positions of the fingertips on the object can be really

competitive since some criteria had to be taken into

account like the stability of the grip, minimization of

the friction, etc. Therefore, grasp planning problem

is considered as an optimization problem.

To grasp an object, some information is needed,

like the position and the shape of the object

(Infantino et al., 2003), its material, the actual

localization of the robotic hand (Chesi and Hung,

2007) (Chesi, 2009) and its kinematic model

(Boughdiri et al., 2011), etc. All this information

should be considered during the grasping process.

Some can be collected using camera devise or

sensor, and others, like the material and the weight

of the object, should be defined by the user. This

information serves as input to the grasp planner. The

output is the position of the fingertips on the object

or the configuration of the posture of the hand (the

joints angles of the fingers and wrist associated with

the position of the hand).

In this paper, we propose a novel grasp planner

based on Particle Swarm Optimization algorithm.

The main purpose of the method is to explore the

dexterous manipulation space of a multi-fingered

robot hand and to find the best configuration of the

fingers that enables the grasp as fast as possible.

For a successful gripping of the object, several

grasp planners have been developed (Shimoga,

1996), (Coelho and Grupen, 1996), (Morales et al.,

2006). Zhixing et al., (2009) have classified these

planners on forward and backward direction. The

forward direction follows these steps:

close the fingers on the object

extract the joint angles using the kinematic

model of the hand

detect the positions of the fingertips at

collision, using the collision detection

technique

evaluate the grasp quality

This methodology is evaluated in the simulator

(Miller and Allen, 1999), (Miller and

Allen, 2004), which have been used for analyzing

and visualizing the grasps of a variety of different

hands and objects. This grasp planner includes two

phases, the first one is to generate a configuration of

the hand using shape primitives (Miller et al., 2003),

and the second one, is to evaluate the quality of

these grasps. The backward direction is object-

centred solution and is presented as follow:

130

Walha C., Bezine H. and Alimi A..

A Particle Swarm Optimization Algorithm for the Grasp Planning Problem.

DOI: 10.5220/0003996501300135

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 130-135

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

contact points are randomly or analytically

located on the object surface

evaluate the grasp quality

find the corresponding feasible finger joint

position using an inverse kinematic algorithm

Fuentes, Marengoni and Nelson (1994) have

presented a grasp planner based on genetic algorithm.

They posed the grasp planning problem as a search

problem. Borst et al., (1999) used a heuristic

approach to plan a precision grasp for a 3D objects.

Pelossof et al., (2004) presented an SVM approach

involving a combination of numerical methods to

recover parts of the grasp quality surface with any

Pollard (2005) presented a matching algorithm to

select appropriate grasps from a database based on the

shape of the object.

2 MODEL OF THE HAND

2.1 Presentation of the Degrees of

Freedom of the Modeled Hand

Our hand is a five-fingered human hand. Eventually,

the human hand has 27 degrees of freedom (Elkoura

and Singh, 2003) deployed like this:

6 at the wrist : 3 rotations and 3 translations,

4 for each finger : 1 DOF for flexion/extension

at each of the three joints and 1 DOF for the

abduction/adduction (Agur and Lee, 1999)

the thumb has 5 DOF (Buchholz and

Armstong, 1992), the carpo-metacarpal joint

has 3 degrees of freedom: abduction /

adduction, flexion / extension and a pseudo-

rotation due to incongruity between the carpal

bones and the base of the thumb metacarpal

and the relaxation of the ligaments connecting

them and 1 for each of the two joints.

The human hand interacts under static and

dynamic constraints (Wagner, 1988). The static

constraints explain the limits of joint angles and the

dynamic constraints describe the interconnection

between the degrees of freedom of the finger joints.

Amongst these biomechanical constraints, we are

interested in the relationship between the distal and

proximal phalanges and which can be translated by

the following equation:

(1)

Therefore and to model the hand, we opted for an

optimization of the DOF by coupling the distal and

proximal joints. This allows us to simplify the model

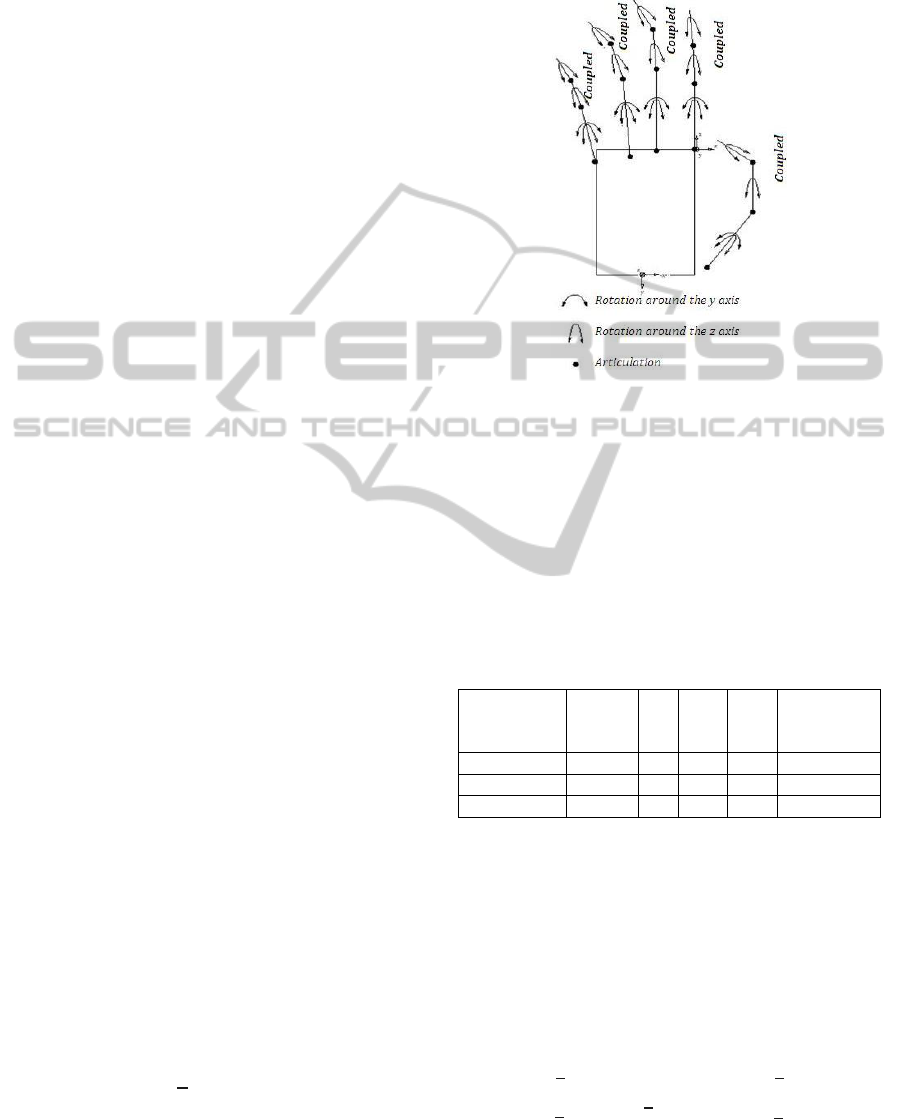

to 21 DOF (Figure 1): 3 DOF for each of the fingers

and 6 DOF for the wrist.

Figure 1: Distribution of the 21 degrees of freedom of the

modeled hand.

2.2 Kinematics of the Hand

The kinematic of the modeled hand is used to

determine the positions and velocity of articulations in

space relative to the robot base coordinator. The

Denavit-Hartenberg parameters (Denavit and

Hartenberg, 1955) are given in this table:

Table 1: The Denavit-Hartenberg parameters of the finger

with 3 DOF.

Articulation

ij

d

ij

a

ij

ij

Variable

of the

articulation

1

θ

i1

0

l

i1

0

θ

i1

2

3/2*θ

i1

0

l

i2

0

θ

i1

3

θ

i2

0

l

i3

θ

i3

θ

i2,

θ

i3

i1

i2

i3

represent the angles of the

articulations of the finger i and l

i1

, l

i2

and l

i3

represent the length of each phalange of the finger i.

Therefore, the transformation matrix from the

coordinator 0 to 3 of the finger i is given by:

(2)

(3)

A Particle Swarm Optimization Algorithm for the Grasp Planning Problem

131

(4)

(5)

We assume that,

The forward kinematic model is as follow:

(6)

Where represents the position and orientation

of the joint, is the configuration system and is the

Jacobian matrix.

3 PSO ALGORITHM

PSO (particle swarm optimization) (Kennedy and

Eberhart, 1995) is a population based on a search

algorithm and is initialized with a population of

random solutions, called particles. Not like other

computational techniques, each particle in PSO is

also associated with a velocity. The particles fly into

space with velocities which are dynamically

adjusted based on their historical behavior. This

technique has received more and more attention

because of its simplicity and success.

Inspired by this, we propose a particle swarm

optimization based algorithm for grasp planning

problem in which each of the joints of the hand is

viewed as a particle and we integrated this algorithm

in our grasp planner.

t of the joints.

Finger

Distal

Intermediate

Proximal

Pivot

Thumb

Index

Middle

Ring

Little

finger

The final purpose of the grasp planner is to find

the best location of contact points in the surface of

the object satisfying some criteria. Assuming

the particles represented by a

configuration of the hand. It contains the values of

the limitations of Table 2 (Brand and Hollister,

1999), (Buchholz et al., 1992). The velocity

associated to

is

with the

number of particles.

For each iteration, the velocity

and the particle

are

updated. According to the fitness values of the

updated individuals, the personal best angle

of each particle and the

global best position

among all

the particles are updated. For the update of the

velocities in PSO, a particle

is influenced by its

personal best position

and the global best

position

. Hence, the PSO searches the global

optimum solution by adjusting the trajectory of each

particle toward its personal best position and the

global best position. According to the above

description about the PSO, the procedure of the PSO

is described as following:

Step 1. Initialize the PSO with

m, the number of particles

, the number of iterations

Generate randomly initial configurations

, in the population taking

into consideration the limitations of Table II.

If an illegal collision is detected (case where a

finger enter the object perimeter), we generate

another values for the corresponding finger.

Generate randomly initial velocity vectors

Step 2. Calculate the fitness value of each particle

and set initial

,

and initial

for the initial population.

Set

where

represents the fitness value of the

particle

Set

and

Find the index I of the particle with best

fitness value by

Set

and

Set

Step 3. Update

and

.

Calculate

then set

and

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

132

then set

Step 4. Update the velocity vector

and the vector

of each particle.

- Update

where is a function returning a random value

between 0 and 1.

.

Set

Step 5. , if

then go to Step 6, else go to Step 3

Step 6. The desired solution is the global best

with the best fitness value

.

We assume that the position of the object is

reachable by the hand and the localization of the

object is known. Furthermore, we will restrict our

search of solution to a precise grasp which allows

only contact with the fingertips.

Although, we have 21 DOF, the six DOF of the

wrist is computed apart. It represents the position

and orientation of the hand.

We used HandGrasp (Walha et al., 2010) to

simulate the trajectories of the fingers in space.

HandGrasp is an environment used for hand

developed under a modular architecture (Walha et

al., 2011).

In our grasp strategy, the fitness function is based

on a quality measure ( et al.,

2006) associated with the position of the contact

points. It takes into account the object properties as

the shape, the weight, the size and the location. Park

and Starr (1992) have proven that the contact points

are distributed in a uniform way on the object

surface, this improves the grasp stability. The quality

of the grasp under this criterion, called the stability

grasp index (Kim et al., 2001), is given by:

(7)

Where:

is the quality measure,

is the number of fingers in contact with object,

the internal angle at vertex i of the contact

polygon,

is the average internal angle of the

corresponding regular polygon (in degrees) :

(in degrees),

is the sum of the internal angles when the polygon

has the poorest conditioned shape.

Each position of the fingertips is computed using

the kinematic of the hand and in each of the iteration,

the algorithm check if a contact is detected. The force

of the fingers is computed using the equation:

(8)

Where is the mass of the hand.

4 EXPERIMENTATION

The experiment is computed in HandGrasp. Given a

sphere with a diameter 5 cm, we run our grasp

planner in order to grip this object with our simulated

hand (Figure 2). The results of this simulation are

shown in figure 3.

Figure 2: Simulated hand.

After 50 iterations and with 100 particles, we

remark that the fingers are not all in contact with the

sphere since it is not a condition in our grasp planner.

In less than one second (Pentium Dual CPU, T3400

2.16 GHz * 2.16 GHz, 3 GB of RAM), the algorithm

has generated the desired grasp. The second test is

applied to a cube with 7 cm length (Figure 4) and the

third test is for the object barrel (Figure 5).

Iteration=5 Iteration=20 Iteration=35 Iteration=50

Figure 3: Simulation results for the object sphere.

Iteration=5 Iteration=20 Iteration=35 Iteration=50

Figure 4: Simulation results for the object cube.

A Particle Swarm Optimization Algorithm for the Grasp Planning Problem

133

Iteration=5 Iteration=20 Iteration=35 Iteration=50

Figure 5: Simulation results for the object Barrell.

5 CONCLUSIONS

In this paper, a grasp planner based on a particle

swarm optimization is proposed to find optimum

positions of fingertips in the object, ensuring a

stability of the grip. In order to guaranty a good

grasp, a quality of measure function is computed.

Furthermore, we restricted the limits of value for

each particle so that the algorithm can generate a

faster solution. Our system performs very well with

simple objects.

In future works, we will adopt a multi-object

particle swarm optimization (MOPSO) (Reyes-Sierra

and Coello, 2006) to build a list of leaders to save the

chosen based on variety of a quality of measure

functions like quality based on the margin of

uncertainty in the finger positions or Max-Normal-

Grasping-Force quality (Liu et al., 2004).

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

support of this work by grants from General

Direction of Scientific Research (DGRST), Tunisia,

under the ARUB program.

REFERENCES

Agur, A. M. R. and Lee, M. J. (1999). Grant's Atlas of

Anatomy. Lippincott Williams and Wilkins, 10th

Edition.

Bicchi, A. (2000). Hands for dexterous manipulation and

robust grasping: A difficult road towards simplicity.

IEEE Trans. Robotics and Automation 16(6), 652662.

Borst, C.; Fischer, M. and Hirzinger, G. (1999). A fast and

robust grasp planner for arbitrary 3D objects. In

ICRA’1999, Proc. IEEE Intl. Conf. on Robotics and

Automation, pages 1890 - 1896, Detroit, Michigan,

USA.

Boughdiri, R.; Bezine, H.;

and Alimi, A. M. (2011). Dynamic modeling of a

multi-fingered robot hand in free motion.

International Multi-Conference on Systems, Signals &

Devices SSD’11, Sousse Tunisia.

Brand, P. W. and Hollister, A. M. (1999). Clinical

Mechanics of the Hand. Mosby, Inc. Third edition.

Buchholz, B. and Armstong, T. J. (1992). A kinematic

model of the human hand to evaluate its prehensile

J. Biomecanics, 25 : 2, pp. 149-162.

Buchholz, B.; Armstrong, T. and Goldstein, S. (1992).

Anthropometric data for describing the kinematics of

the human hand. Ergonomics, 35(3):261273.

Chesi G. and Hung Y.S. (2007). Global path-planning for

constrained and optimal visual servoing, IEEE Trans.

on Robotics, vol. 23, no. 5, pp. 1050-1060.

Chesi G. (2009). Visual servoing path-planning via

homogeneous forms and LMI optimizations. IEEE

Trans. on Robotics, vol. 25, no. 2, pp. 281-291.

Chinellato, E.; Morales, A.; Fisher, R. B.; and del Pobil,

A. P. (2005). Visual quality measures for

characterizing planar robot grasps. IEEE Trans.

Systems, Man and Cybernetics - Part C: Applications

and Reviews, 35(1), 3041.

Coelho, J. A. Jr. and Grupen, R. A. (1996). Online grasp

synthesis. IEEE Int. Conf. on Robotics and

Automation.

Denavit, J. and Hartenberg, R. S. (1955). A kinematic

notation for lower-pair mechanisms based on matrices.

Trans ASME J. Appl. Mech, 23:215221.

Elkoura, G. and Singh, K. (2003). Handrix - animating the

human hand. Proceedings of the 2003 ACM

SIGGRAPH/Eurographics Symposium on Computer

Animation pp. 110-119.

Fuentes, O.; Marengoni, H. F. and Nelson, R. C. (1994).

Vision-based planning and execution of precision

grasps. TR546, Computer Science Dept., U.Rochester.

Infantino, I.; Chella, A.; Dzindo, H. and Macaluso, I.

(2003). Visual control of a robotic hand. In

IROS’2003, IEEE/RSJ International Conference on

Intelligent Robots and Systems, vol.2, no., pp. 1266-

1271 vol.2, 27-31.

Kennedy, J. and Eberhart, R. C. (1995). Particle swarm

optimization. Proceedings of IEEE International

Conference on Neural Networks, Piscataway, pp.

1942-1948.

Kim B., Oh S., Yi B. and Suh I. H. (2001). Optimal

grasping based on non-dimensionalized performance

indices. Proc. IEEE IROS 2001, pp. 949956.

Li, Y. and Pollard, N. S. (2005). A shape matching

algorithm for synthesizing humanlike enveloping

grasps. Humanoids’2005, IEEE-RAS International

Conference on Humanoid Robots, Tsukuba, Japan, pp

442-449.

Liu, G.; Xu, J.; Wang, X. and Li, Z. (2004). On quality

functions for grasp synthesis, fixture planning and

coordinated manipulation. IEEE Trans. Automation

Science and Engineering, 1(2), 146162.

Miller A. T. and Allen, P. K. (1999). Examples of 3D

grasp quality computations. In Proceedings IEEE

International Conference on Robotics and

Automation, Detroit, MI, pp. 1240-1246.

Miller, A. T. and Allen, P. K. (2004). Graspit!: a versatile

simulator for robotic grasping. IEEE Robotics and

Automation Magazine, vol. 11, no. 4, pp. 110-122.

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

134

Miller, A. T.; Knoop, S.; Christensen, H. I. and Allen, P.

K. (2003). Automatic grasp planning using shape

primitives. In Proceedings of the IEEE International

Conference on Robotics and Automation, pp. 1824-

1829.

Morales, A.; Asfour, T. and Azad, P. (2006). Integrated

grasp planning and visual object localization for a

humanoid robot with five-fingered hands. IEEE/RSJ

Int. Conf. on Intelligent Robots and Systems.

Park Y. C. and Starr G. P. (1992). Grasp synthesis of

polygonal objects using a three-fingered robotic hand.

Int. J. Robotics Research 11(3), 163184.

Pelossof, R.; Miller, A. T.; Allen, P. K. and Jebara, T.

(2004). An SVM learning approach to robotic

grasping. IEEE Int. Conf. on Robotics and

Automation, New Orleans, pp. 3512-3518.

Reyes-Sierra, M. and Coello, C. A. C. (2006). Multi-

Objective Particle Swarm Optimizers: A Survey of the

State-of-the-Art. International Journal of

Computational Intelligence Research, Vol. 2, No. 3.

287-308.

Shimoga, K. B. (1996). Robot grasp synthesis: a survey.

Int. J. of Robotics Research, Vol.5, No.3.

). Grasp quality

measures. Technical University of Catalonia, Tech. Rep.

Wagner, C. (1988). The pianist's hand: anthropometry and

biomechanics. Ergonomics 31: 1, pp. 97-131.

; Naamane, A. and

Alimi, A. M. (2011). HandGrasp: a new simulator for

human grasping. Workshop on Autonomous Grasping

at ICRA’2011, IEEE International Conference on

Robotics and Automation, Shanghai Chine.

Alimi, A. M. (2010). Contribution to the development

of a theory of generation of grasping movements.

WIMTA'2010, The 17th Workshop Intelligent

Machines : Theory and Applications, Mahdia, Tunisia.

Zhixing, X.; Stadie, U.; Zoellner, J. M. and Dillmann, R.

(2009). An efficient grasp planning system using

impulse-based dynamic simulation. Multybody

Dynamics, Warsaw, Poland.

A Particle Swarm Optimization Algorithm for the Grasp Planning Problem

135