Modelling of a Grasping and Manipulation Controller

Pavel Dzitac and Abdul Md Mazid

School of Engineering and Built Environment, Central Queensland University, Rockhampton, Australia

Keywords: Grasping, Slippage, Grasp Control, Tactile Sensor.

Abstract: This paper presents the development of a robot grasping and manipulation control system, including the

modelling approach for the control functions, and the criteria used for functional module design in order to

achieve the required functionality and allow its integration into the overall control model. This work is an

example of a practical implementation of a robotic grasping and manipulation controller and may be

relevant to researchers looking for an example of a practical controller design “from scratch”.

1 INTRODUCTION

This paper presents the detailed architecture

modelling of a controller for a robotic object

manipulator, as part of a project that aims to develop

reliable and safe object manipulation as its main

attributes. The controller architecture is designed to

use tactile, force, position and vision sensing. It also

makes use of sensor fusion and learning concepts to

improve controller performance through robust

feedback and “intelligent” decisions.

The concept of instinctive control, for the

purpose of fast reactions to unexpected events such

as collisions or unexpected object slippage, is also

included in the controller architecture.

2 LITERATURE REVIEW

Significant amount of work has already been done

by researcher to develop robot control strategies that

would maximise the capability of individual sensing

technologies through their strategic integration.

(Namiki and Ishikawa, 1996), (Allen et al., 1999),

(Boshra and Zhang, 2000), and (Prats et al., 2009)

used sensor fusion strategies to integrate vision and

tactile sensing to improve grasping. Pelossof et al

(2004) used simulation based on SVM (Support

Vector Machine) method to find optimum grasps for

complex shape objects. Khalil and Payeur (2007)

proposed a control strategy specifically aimed at

grasping deformable objects.

A brief description of the proposed control

architecture in this paper was given by Dzitac and

Mazid (2011). This control architecture is presented

here in detail.

3 MODEL DEVELOPMENT

3.1 The Choice of Control Model

The minimum necessary controller functionality is

based on the minimum project requirements which

are as follows:

1. Find an egg cup that matches the colour of

the target egg (chosen by user), and orientate

the egg cup correctly.

2. Find an egg that matches the colour of the

egg cup and place the egg safely in it.

3. Find a metal bushing and a matching shaft,

and insert the shaft into the bushing.

4. Find a thin-walled plastic drink bottle and

move it safely to a location designated by the

user. The amount water in the bottle not

known to the controller.

The first requirement tests the manipulation

dexterity of the controller because the egg cup could

be sitting upside-down.

The second requirement tests the ability to apply

only the absolutely minimum grasping forces to a

rigid but fragile object that will fail catastrophically

if the allowable grasping force is exceeded.

The third requirement tests the ability to orientate

parts correctly and assemble parts with reasonable

199

Dzitac P. and Mazid A..

Modelling of a Grasping and Manipulation Controller.

DOI: 10.5220/0003992801990204

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 199-204

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

dexterity.

The fourth requirement tests the ability to

maintain grasp control of a deformable object

without prior knowledge of object characteristics.

3.2 Robot Capabilities

The robot must be able to locate the target objects

and potential obstacles in the area and therefore the

robot must have the following capabilities:

1. Detect known objects

2. Estimate object location and orientation

3. Estimate object shape

4. Estimate object size

5. Discriminate objects by colour

For reasonable dexterity the robot must also have:

1. Velocity and acceleration control for fingers,

hand and arm

2. Position control for fingers, hand and arm

3. Tactile sensing for sensitive touch detection

4. Grip force control for heavier grasp

5. Object slippage detection

6. Sufficient degrees of freedom

3.3 Manipulation Controller Design

The specified object manipulation capability

requires a controller with several modules, each with

specialized functions to facilitate grasping and

slippage control. The block diagram in Figure 1

shows the controller functional modules and their

interactions.

The sensors selected for robot’s tactile, force,

position and vision capabilities are considered to be

the minimum number of sensors required for

successful grasping and manipulation.

The tactile, force and position sensors output an

analog voltage of 0 to 5VDC, which is proportional

to the sensing range of the respective sensors.

The term “tactile sensor” is used to represent

sensitive force sensors with a small sensing range.

These sensors are used to detect the instant at which

an object is touched and for manipulating small,

fragile objects. The term “force sensors” is used to

represent sensors with a large force sensing range

and lower sensitivity, such as those in the robot arm.

The Sensing Processor module is based on a

combination of mathematical and logic control

models, depending on the specific requirements of

each function. The Sensing Processor is designed:

1. To filter the digitized analog sensor signals

using digital filters.

2. Use sensor fusion to improve sensor feedback

reliability.

3. Convert the sensor feedback into useful

information for other controller modules.

Figure 1: The grasp and manipulation controller.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

200

In order to achieve confident manipulation, grasping

force control and slip detection it is important to

have quality feedback signals, which translate into

two specific requirements:

1. The grasping hardware must be capable of

controlling the grasping forces with adequate

mechanical resolution and speed.

2. The feedback system must provide accurate

information, in real time, to the relevant

modules that control the grasping hardware.

Sensor fusion acts as a filter to help produce

reliable information. A voting scheme is used. For

example the controller must know the position of the

robot arm, hand and fingers to determine whether

the slippage sensed by the tactile sensors is real.

The Instinctive Controller module was designed to:

1. Bypass the slow, planned control flow to

generate fast, instinct-like reactions.

2. React to touch, collision and sensory overload

3. Request fast, local reaction from the robot

drives.

4. Provide feedback to the Decision-Making

module and the robot safety controller.

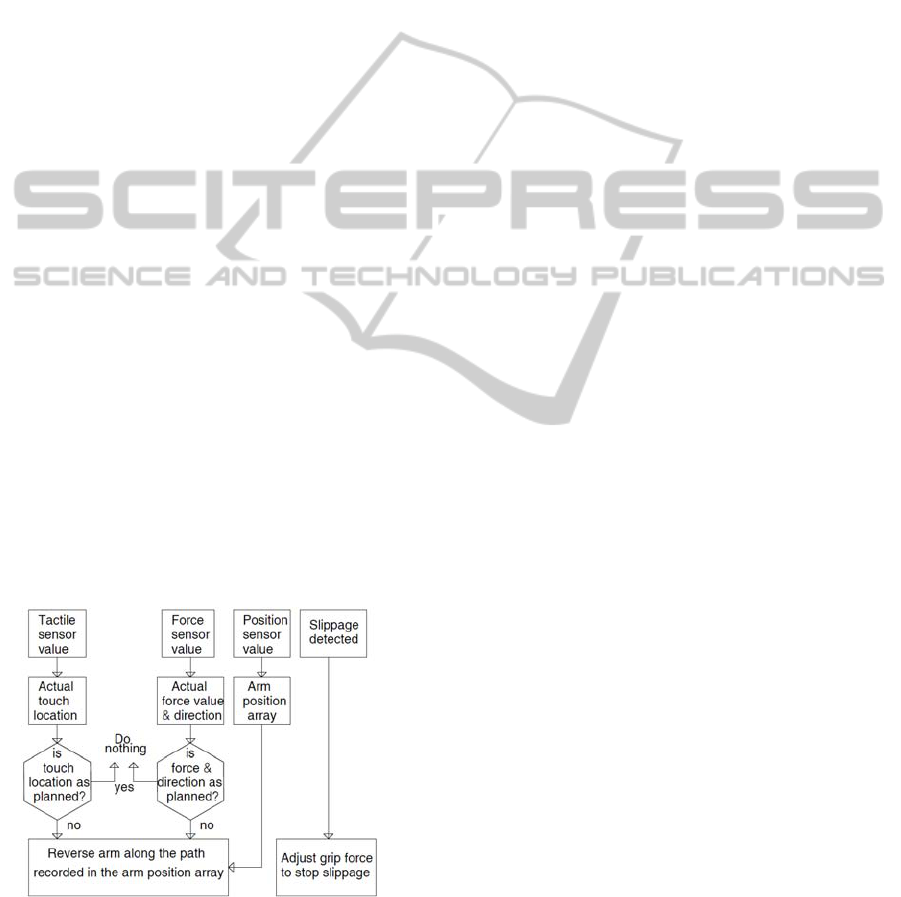

The basic structure of the Instinctive Controller’s

logic decision engine is shown in Figure 2. The

Instinctive Controller is based on logic control that

determines whether the touch and forces sensed by

the robot arm are as planned by the Motion Planning

module or are abnormal. The instinctive motion

controller does not compute a new motion path: it

keeps a record of the current motion path, and in

case of an abnormal event it reverses the robot arm

along the same path for a short distance.

Figure 2: Logic control block diagram of Instinctive

Controller.

In order to prevent loss of control, the Instinctive

Controller reacts fast to slippage events that were

determined by the Sensing Processor and passed to

the Instinctive Controller.

The Decision-Making module was designed to

determine the actions to be taken based on

objectives set by the user, sensory information and

performance feedback from the learning module. It

performs two main tasks: decides whether the object

can be grasped, as shown in Figure 3, and whether

the object can be moved, as shown in Figure 4.

The grasping function uses feedback from the

Sensing Processor that provides information about

the target object and all other objects around the

target object including:

1. Object size

2. Object shape

3. Object location

4. Object orientation

The Decision-Making module monitors the

following information provided by the Sensing

Processor during grasping:

1. Tactile info (touch location/area)

2. Force info (force at finger joints)

3. Arm/hand/finger position info

Before initiating a grasping attempt, the Decision-

Making module searches for obstacles that would

prevent object grasping. An obstacle is any object

located around the target object that prevents

grasping the target object. If grasp is possible it will

forward the following grasp information to the

Motion Planning module:

1. Target object info (size / shape / location /

orientation)

2. Obstacle info (size / shape / location /

orientation)

3. Tactile info

4. Force info

5. Arm / hand / finger position info

This information will be continuously updated

during grasping and forwarded to the Motion

Planning module until grasping is complete. If an

abnormal event takes place, such as an unexpected

collision, the Decision-Making module will abort the

grasping attempt. The grasp abortion criteria are the

same as that used by the Instinctive Controller. The

recovery sequence retracts the robot arm to a safe

position and then tries again.

The Learning function will “remember” which

constraint was violated and why, and will provide

this information to the Decision-Making module

during the next grasping attempt to help prevent the

same estimation error.

ModellingofaGraspingandManipulationController

201

Figure 3: Object grasping algorithm structure.

The object move (relocation) function uses

feedback from the Sensing Processor that provides

the following information during object move:

1. Target object info

2. Tactile info

3. Force at fingers, hand and arm joints

4. Arm/hand/finger position info

5. Object slippage info

The object move function also uses information

compiled by the Decision-Making module which

includes:

1. Local obstacle info

2. Remote location info (where object will be

placed)

3. Remote obstacle info

The Decision-Making module determines whether

there are obstacles that would prevent moving the

object to its new destination. If there is sufficient

distance between the obstacle and the target object

to allow the object to be moved, the Decision-

Making module will decide that the move is possible

and will forward the following object move

information to the Motion Planning module:

1. Target object info

2. Remote location info

3. Local and remote obstacle info

4. Tactile info

5. Force at fingers, hand and arm joints

6. Arm/hand/finger position info

7. Object slippage info

This information will be continuously updated

during object move and forwarded to the Motion

Planning module until object move is complete. If an

abnormal event takes place, such as unexpected

collision, the Decision-Making module will abort the

move attempt. The object move abortion criteria are

the same as that used by the Instinctive Controller.

The recovery sequence retracts the robot arm to a

safe position and then tries again.

Figure 4: Object moving algorithm structure.

The Learning function will “remember” which

constraint was violated and why. It will provide this

information to the Decision-Making module during

the next object move attempt to help prevent the

same estimation error.

The Motion Planning module was designed to

plan the grasping and the motion of the robot arm

based on action requests received from the Decision-

Making module. This module uses rule-based grasp

planning as shown in Figure 5.

Figure 5: Grasp rule for cylindrical objects.

The Planned Motion Controller (planned motion

trajectory generator) was designed to execute the

motion plan generated by the Motion Planning

module. It generates a sequence of motion path

points based on the motion path generated by the

Motion Planning module and velocity constraints,

and feeds these points at the correct time to the robot

drives that perform the actual position control of the

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

202

servo motors.

The Robot hand and arm controller module

consists of the hardware and firmware that executes

robot hand and arm actions, and responds to

instructions received from the motion controllers.

3.4 The Vision System

Figure 6: Simplified block diagram of vision system.

To be capable of finding, grasping and

manipulating objects the robot must be equipped

with a vision system that can perform the vision

tasks mentioned in section 3.1. The vision system is

not the main research objective in this project, but it

is indispensable for an autonomous object grasping

and manipulation system.

At this stage the vision system detects simple

objects, such as cylinders, eggs and drinks bottles,

and estimates their location, orientation and size.

4 IMPLEMENTATION AND

RESULTS

An average egg weighs around 50g (~500mN).

Experimentation shows that to hold an egg in

vertical orientation with a two-finger gripper the

grasping mechanism would have to apply a grasp

force of about 1N. To achieve reasonable force

control during egg grasping the force sensing and

control resolution of the grasping mechanism must

be capable of a minimum resolution of 1 in 100 (i.e.

at least 1N / 100 = 10mN). This is in the sensitivity

range of the tactile force sensors. For this prototype,

the maximum tactile grasping force range of the

grasping mechanism has been limited to 5N.

Assuming that the grasping mechanism has

sufficient mechanical control resolution, the force

sensor signal must be discriminated to 10mN or less.

A 9 bit A/D converter would provide 5N / 511 =

9.8mN, which is sufficient resolution for ideal signal

quality. However the least significant bit (LSB) of

the digitized signal is corrupted by noise, so a better

choice is a 12Bit converter because it provides a

higher signal resolution (5N / 4095 = 1.2mN), which

facilitates noise filtering and signal reconstruction.

The signal reconstruction resolution is dependent

on the A/D converter resolution, sampling frequency

and the number of samples used per sampling

period. The fidelity of the reconstructed signal must

be sufficient to provide a good representation of the

actual sensor signal, minus the random noise.

A digital signal analyser was used to determine

the type of noise in the analog signals coming from

sensors. It was determined that the noise was mostly

random noise.

The Sensing Processor performs digital signal

filtering on the tactile, position and force feedback

signals. The model used for digital filtering is based

on the recursive moving average filter, which is

optimum for eliminating random noise. The filter

used is based on a running average (Smith, 1999) of

20 values and its output y is given by

y[n] = (y [n-1] + x[nm+1] - x[nm - (m-1)]) / 2 (1)

where y[n] is the current point being calculated, y[n-

1] is the previous calculated point, x[nm+1] is the

latest sample, x[nm-(m-1) is the oldest sample, n is

the current sample number and m is the number of

samples in the moving average. Note that y[0] must

be initialise by getting m number of samples and

calculating the average before equation (1) can be

used (Smith, 1999).

The control system uses an FPGA, which is

interfaced with a 12 bit A/D converter that has a

parallel data bus. Each of the 12 bits of the A/D

converter is connected in parallel to the FPGA

inputs, which allows the digital filters to use higher

signal sampling rates if necessary. The 12 bit A/D

provides a resolution of 5V / 4095 = 1.22mV.

The tactile sensor outputs 0-5V when it is

compressed 1mm. The grasping mechanism can

move with a maximum linear velocity of 100mm/s,

ModellingofaGraspingandManipulationController

203

therefore it takes the sensor output 10ms to change

from the minimum of 0V to the maximum of 5V

from the point of contact with the object. The sensor

DC signal is reconstructed at 100ksps samples.

This gives 100ksps * 0.01s = 1000 signal

reconstruction points during the 10ms when the

sensor signal changes from 0 to 5V. This is

equivalent to 5N / 1000 = 5mN tactile grasping force

resolution. Note that during the fastest sensor signal

change rate, the control system can only distinguish

the grasping force at a resolution of 5mN despite the

fact that the A/D converter can provide a resolution

of 1.2mN.

To allow the prototype to manipulate heavier

objects, such as the plastic drink bottle described

earlier, the “bulk” grasping force sensing was

designed for a maximum of 20N.

The same analysis as for the 0-5N range tactile

sensor is applicable to the 0-20N range force sensor.

A 12 bit converter was selected, which provides a

signal conversion resolution of 20N / 4095 = 4.9mN.

The force sensor outputs 0-5V when the finger is

deflected 4mm at the tip (finger has compliant

joints). The grasping mechanism can move with a

maximum linear velocity of 100mm/s, therefore it

takes the sensor output 40ms to change from the

minimum of 0V to the maximum of 5V from the

point of contact with the object. The sensor DC

signal is reconstructed at 100ksps, which gives

100ksps * 0.01s = 1000 signal reconstruction points

during the 40ms when the sensor signal changes

from 0 to 5V. This is equivalent to 20N / 1000 =

20mN grasping force resolution. During the fastest

sensor signal change rate, the control system can

only distinguish the grasping force at a resolution of

20mN despite the fact that the A/D converter can

provide a resolution of 4.9mN.

The position sensors output 0 to 5V per 90

degrees of rotation. Using a 12 bit A/D converter

gives a resolution of 90 deg / 4095 = 0.022 degrees.

If a resolution of 0.03 degrees is used, the resolution

at the end of a robot arm with two links of 300mm

each is 1mm, which is adequate for reliable arm,

hand and finger positioning during object

manipulation.

Object handling experimentation shows that the

choice of sensor signal feedback resolution and

update frequency is adequate for reliable control of

fragile object grasping and safe manipulation.

5 CONCLUSIONS

The main objective in this project is to develop

object grasping and manipulation with collision

detection and slippage control to allow the robot to

manipulate objects safely with useful dexterity. The

most challenging part in the project is to achieve

useful feedback information from sensors.

Currently the experimental tactile slippage

sensing approach is based on a parallel-jaw gripper

that provides acceptable slippage detection but only

in one axis (object rotation in the gripper is only

detected by vision). Further work is needed to

develop a robust slippage sensing strategy that

would provide reliable slippage status feedback to

help detect and prevent slippage in all axes.

Further work is needed to add advanced

functionality to the sensor fusion module. The

learning module also needs further work to improve

its usefulness.

REFERENCES

Namiki, A., Ishikawa, M., 1996, Optimal Grasping using

Visual and Tactile Feedback, Proceedings of the

IEEE/SICS/RSJ International Conference on

Multisensor Fusion and Integration for Intelligent

Systems, Washington DC, USA, December.

Allen, P. K., Miller, A., Oh, P. Y., Leibowitz, B., 1999,

Integration of vision, force and tactile sensing for

grasping, International Journal of Intelligent

Machines, 4(1):129-149.

Boshra, M., Zhang, H., March 2000, Localizing a

polyhedral object in a robot hand by integrating visual

and tactile data, PR(33), No. 3, pp. 483-501.

Pelossof, R., Miller, A., Allen, P., Jebara, T., 2004, An

SVM Learning Approach to Robotic Grasping,

Proceedings of International Conference on Robotics

and Automation (ICRA’04), vol. 4, pp. 3512 -3518.

Khalil, F. F., Payeur, P., 2007, Robotic Interaction with

Deformable Objects under Vision and Tactile

Guidance - a Review, International Workshop on

Robotic and Sensors Environments, pp.1-6, 12-13 Oct.

Prats, M., Sanz, P. J., del Pobil, P. A., May 2009, Vision-

tactile-force integration and robot physical interaction,

Conference on Robotics and Automation, 2009. ICRA

'09. IEEE International, pp.3975-3980.

Dzitac, P., Mazid, M. A., 2011, An Innovative Approach

for Grasping Force Estimation Using Tactile and

Vision Sensors, 15th International Conference on

Mechatronics Technology (ICMT). November 30 to

December 2, Melbourne, Australia.

Smith, S., 1999, The Scientist and Engineer's Guide to

Digital Signal Processing 2nd Ed., California

Technical Publishing, San Diego, California.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

204