POSITIONING AND ORIENTATION OF ADHERENT CELLS

IN A MICROFLUIDIC CHIP USING THE MICRO PATTERNING

OF A PARYLENE-C FILM

Claire Dalmay, Jun-Jung Lai, Laurent Griscom, Olivier Français, Bruno Le Pioufle

CNRS SATIE, IFR d’Alembert, ENS Cachan, Cachan, France

Frédéric Subra, Patrick Tauc

CNRS LBPA, IFR d’Alembert, ENS Cachan, Cachan, France

Joseph Lautru

IFR d’Alembert, ENS Cachan, Cachan, France

Keywords: Parylene-C patterning, Cell patterning, Cell orientation, Cell migration.

Abstract: A new method for the positioning and orientation of adherent cells on a culture substrate is presented. We

demonstrate the ability of a micro patterned parylene-C film deposited on a fused silica substrate to position,

isolate and/or orientate cells. Such features are crucial for the development of future biodevices for the

analysis and treatment of single-cell or organized cell tissues. In particular, our method is advantageous for

controlling the orientation of the cells within an organized tissue while being exposed to an electrical field.

The developed method does not require any chemical treatment of the cells or any additional surface

modification and is suitable for integration into a microfluidic system.

1 INTRODUCTION

This paper reports a novel method, based on

parylene-C patterning, for on-chip cell positioning.

This new approach finds various applications such

as i) the orientation of cells on biodevices ii) the

study of cell motility.

Classically, cell positioning can be achieved

thanks to different methods. Different works report

on the use of specific (as Fibronectin) or non-

specific (as poly-L-lysine) attachment biomolecules

(Ruiz, 2009 and Vogt, 2003). These biomolecules

are commonly patterned on the culture substrate by

microcontact printing process. Another solution

consists of using a high magnetic field (up to 10 T)

value during cell growth. In these conditions, cell

orientation is aligned in the same direction as

magnetic field (Umero, 2001). Nevertheless, the

efficiency of this kind of method for adherent cells

requires (i) the application of a strong magnetic field

and (ii) long exposure times (Hiroko, 2000).

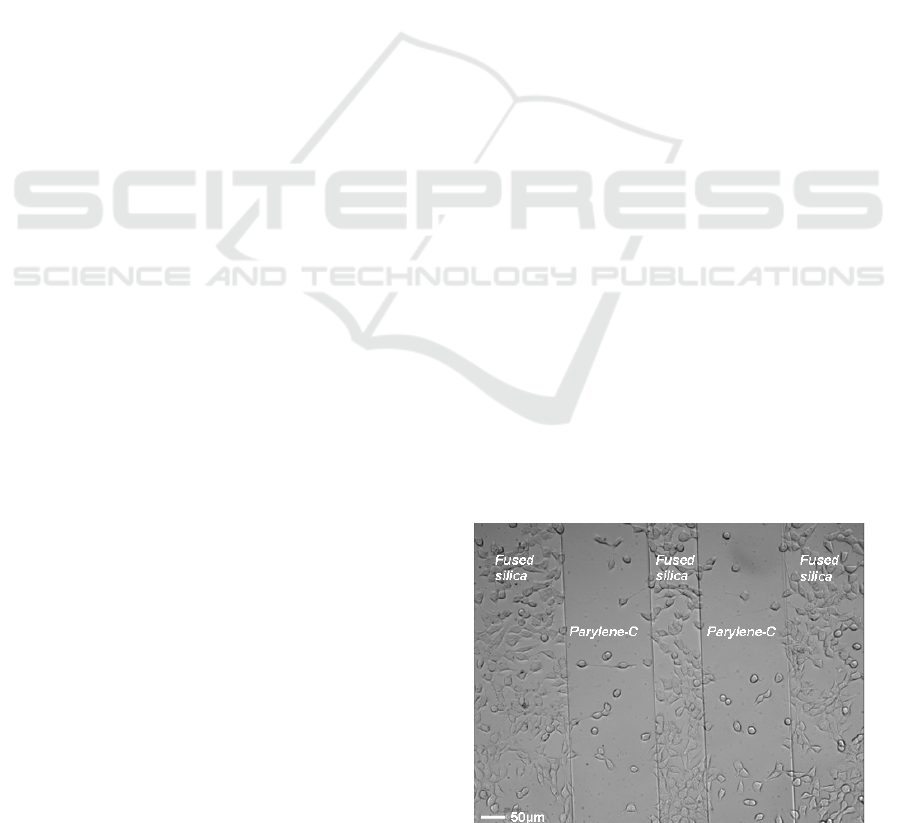

Figure 1: Photograph of NIH-3T3 EWS/fli fibroblasts

cultured on a substrate of fused silica covered with two

repulsive lines of parylene-C.

In parallel, the use of parylene-C polymer in

biodevices has encountered an increasing interest

due to its biocompatibility, transparency, conformity

properties and long term stability (Shin, 2003 and

212

Dalmay C., Lai J., Griscom L., Français O., Le Pioufle B., Subra F., Tauc P. and Lautru J..

POSITIONING AND ORIENTATION OF ADHERENT CELLS IN A MICROFLUIDIC CHIP USING THE MICRO PATTERNING OF A PARYLENE-C FILM.

DOI: 10.5220/0003156702120215

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 212-215

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Osaki, 2009). Some current cell-patterning

approaches use parylene-C as a stencil to achieve

patterns of cells (Wright, 2007 and Tan, 2009). In

these cases, the parylene-C film is peeled-off after

the cells have grown on the substrate in area

delimited by etched windows. This method is also

used to pattern proteins on a glass substrate, with

various high resolution shapes (Atsuta, 2007).

Nevertheless, these approaches are not directly

compatible with integration in a functional

microfluidic chip as (i) the peeling of the parylene

film inside a fluidic chamber or channel is not

permitted (ii) the adherent cells progressively spread

out from the initial patterns once the parylene stencil

is removed.

Consequently, alternative methods are required

to reach cell patterning techniques well adapted to

the use in biodevices including microfluidic systems.

We show in this paper that differences in surface

properties of parylene-C versus fused silica,

combined with the use of specific nanosized or

microsized patterns is capable of inducing precise

cell patterns, as well as the orientation of cells

towards specified directions. Our protocol does not

require the removal of the parylene-C film after the

cell culture, as the micro-patterned parylene-C film

functionalizes the biochip surface on which cells are

directly grown. The method benefits from several

parylene properties like biocompatility, biostability,

chemical inertness and hydrophobic nature.

Previous works have already demonstrated that

the nature of the substrate, as rigidity for example,

influences the cell movement (Lo, 2000). Here, we

show that the difference in cell adhesion affinity

between parylene-C and a fused-silica substrate

provoques cell migration towards fused silica

surfaces and induces their adhesion on the silica

surface (Figure 1). The paper highlights that the cells

are repulsed from small parylene structures, both in

the case of dots or micro-holes as long as the size of

the patterns is an order of magnitude lower than the

cell size.

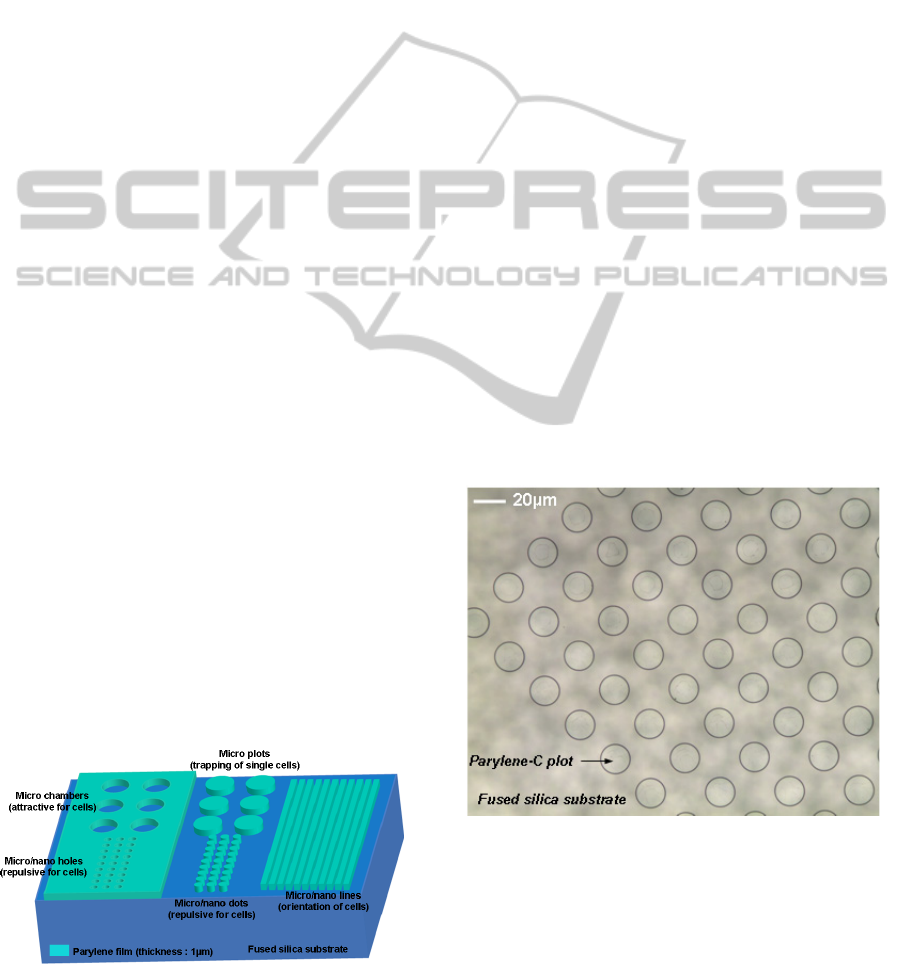

Figure 2: Schema of the patterned parylene film onto the

fused silica substrate (arbitrary scale).

Moreover, the patterning of different shapes -lines or

plots - within the parylene film (Figure 2), leads to a

preferential orientation of cells on the substrate

(typical result on figure 8).

2 EXPERIMENTAL SETUP

2.1 Fabrication Process

The chip is fabricated using classical

photolithography process for micropatterning the

parylene-C. In case of thin film Parylene-C layer

(1μm), we used Shipley S1818 photoresin as a

masking layer. So first, a uniform layer of parylene-

C, 1µm thick is deposited on a 2-inch diameter fused

silica substrate using a Specialties Coating Systems

Labcoater. The deposition is made by Chemical

Vapor Deposition (CVD) after a silanization step,

which ensures a good adhesion of the film. Patterns

defined by a standard photolithographic process

using Shipley S1818 positive photoresin and are

subsequently etched through the parylene-C layer by

oxygen plasma Reactive Ion Etching (Figure 3). For

thicker parylene layers (above 3μm), aluminum

layer (200nm) is used as interlayer mask since

S1818 is etched proportionally to parylene. To

finish, the biochip is sterilized under UV light to

ensure that no contamination appears during the cell

culture.

Figure 3: Photograph of a 1µm thick parylene-C film after

patterning.

2.2 Material and Methods

Biological tests have been performed using NIH-

3T3 EWS/fli fibroblasts which present a high

motility (Figure 4). These cells have been specially

POSITIONING AND ORIENTATION OF ADHERENT CELLS IN A MICROFLUIDIC CHIP USING THE MICRO

PATTERNING OF A PARYLENE-C FILM

213

chosen for their good properties of adherence and

migration.

First, cells are grown in standard culture wells

using Minimum Essential Medium supplemented

with 10% fetal bovine serum and 10% streptomycin

at 37°C in a humidified 5% CO

2

- 95% air incubator.

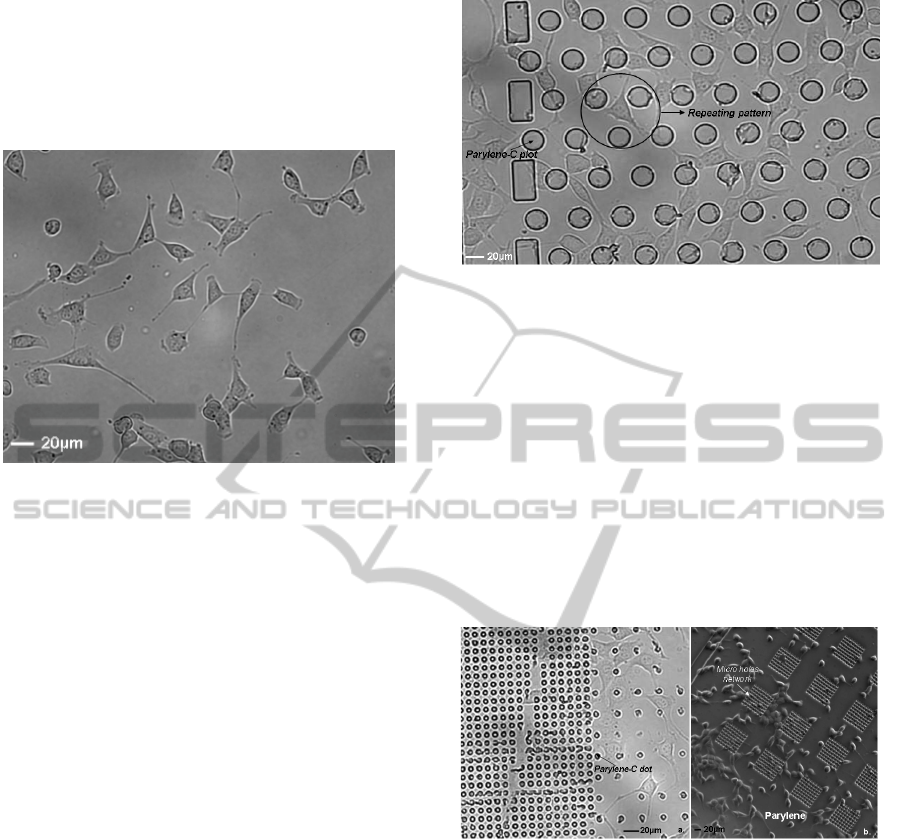

Figure 4: Photograph of a classical NIH-3T3 EWS/fli

fibroblast culture.

Then, cells are collected and counted in order to

be cultured within the biochip with the convenient

concentration.

The chip is firstly placed into a Petri dish and

immersed in the culture media. Then, approximately

200 000 cells are added into the media on the

surface of the chip. A few hours are necessary to

achieve cell adhesion. Cell behaviors such as

migration, adhesion and orientation are then

monitored during several days, using time-lapse

microscopy, for further analysis of the impact of the

micro patterned surface on their behavior.

3 BIOLOGICAL RESULTS

Biological experimentations led on these types of

micro patterns pointed out several phenomena,

which could be used advantageously for cell

positioning or orientation once integrated in

biodevices.

First, we show that it is possible to trap cells in

specific areas of the biochip as shown in Figure 5 (to

compare to the control experiment figure 4), thanks

to the migration and preferential adhesion of cells

towards fused silica surfaces versus parylene-C

areas.

Figure 5: 20µm Diameter dots made of parylene arrayed

with a 20µm step on a fused silica substrate. Photograph

of cell patterning after 82 hours in culture.

Plots arrayed with a distance comparable to the

cell diameter induce single cell patterning (which is

the case on Figure 5).

Secondly, we demonstrate that cells are strongly

repulsed from the areas covered with micro-dots

made of parylene arrayed on fused silica substrate

(figure 6.a.). In the same way, arrays of micro-holes

etched in the parylene film, down to the fused silica

substrate, induce the repulsion of cells (Figure 6.b).

These assumptions are verified as soon as patterns

characteristic sizes are equal or less than 5 μm.

Figure 6: Cells are repulsed from arrays of micro-dots or

micro-holes (a) 5µm diameter dots made of parylene,

arrayed with a 5µm step on a fused silica substrate. Cell

patterning after 82 hours in culture (b) 5µm diameter

micro-hole etched in the parylene film down to the fused

silica substrate, arrayed with a 5µm step. This network

(8x8 holes) is itself arrayed with a 75µm step. Phase

contrast image of cells patterning after 88 hours in culture.

Thirdly, we realized time-lapse imaging of cells

cultured on the micro patterned substrate for 15

hours. This experiment allowed us to observe the

migration of cells towards the fused silica and away

from the parylene surfaces (as shown in Figure 7).

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

214

Figure 7: Images of cell division and migration over a

span of 1h40min – cells are kept in sterile conditions

under 5% C0

2

at 37°C – Migrating cells are dark circled.

After 10 minutes dark circled cells divided. Then divided

cells started to send their pseudopods towards fused silica

areas where they finally migrate.

Finally, we show that the micro-patterning of

parylene induces the orientation of cells on the

substrate, as demonstrated on figure 8 where an

array of thin lines (typical width between 1 to 3μm,

spaced every 2μm) of parylene-C is performed on a

fused silica substrate. As shown on Figure 8, cells

orient themselves in parallel to the lines and grow

along the parylene lines (phase contrast image,

compared to a cell culture made on a non-patterned

substrate shown in Figure 4).

Figure 8: Phase contrast image of cells after 38 hours in

culture. On the left side the cells orient themselves along

2µm spaced network of 2µm width parylene lines. On the

right side of the images the cells cultured on a plain silica

surface display a random orientation.

4 CONCLUSIONS

These results demonstrate the high capability of

micro-patterned parylene film on fused silica

substrate to position and orientate adherent cells.

The developed technique can be easily adapted for

use inside a microfluidic system making it very

attractive in the biodevice field. It might be used

advantageously in cell biochips where a physical,

chemical, or electrical solicitation is applied to

cultured cells, as these activations may be sensitive

to the cell orientation (like electroporation chip for

instance). In addition, the possibility to isolate cells

may be very promising in the development of

biodevices for single-cell analysis.

REFERENCES

Atsuta, K., Suzuki, H., Takeuchi, S., 2007. A parylene lift-

off process with microfluidic channels for selective

protein patterning. J. Micromech. Microeng., 17, 496.

Hiroko, K., Masakazu, I., Shogo, U., 2000. Orientation of

adherent cells under magnetic fields and medical

applications. Papers of technical meeting on

magnetics, IEE Japan, 86, 19.

Lo, C.M., Wang, H.B., Dembo, M., Wang, Y.L., 2000.

Cell movement is guided by the rigidity of the

substrate. Biophysical Journal, 79, 144.

Osaki, T., Suzuki, H., Pioufle, B. L., and Takeuchi, S.

(2009). Multichannel simultaneous measurements of

single-molecule translocation in ˂-hemolysin

nanopore array. Analytical Chemistry 81.

Ruiz, A., et al., 2009. Single stem cell positioning on

polylysine and fibronectin microarrays. Micro and

nanosystems, 1, 50.

Shin, Y. S., et al., 2003. PDMS-based micro PCR chip

with Parylene coating. J. Micromech. Microeng., 13,

768.

Tan, C. P., Ri Seo, B., Brooks, D. J., Chandler, E. M.,

Craigheadb, H. G., Fischbach, C., 2009. Parylene peel-

off arrays to probe the role of cell–cell interactions in

tumour angiogenesis. Integr. Biol., 1, 587.

Umeno, A., Kotani, H., Iwasaka, M., Ueno, S., 2001.

Quantification of adherent cell orientation and

morphology under strong magnetic fields. IEEE

Transactions on Magnetics, 37(4), 2909.

Vogt, A. K., Lauer, L., Knoll, W., Offenhäusser, A., 2003.

Micropatterned substrates for the growth of functional

neuronal networks of defined geometry.

Biotechnology progress, 19(5), 1562.

Wright, D., Rajalingam, B., Selvarasah, S., Dokmecid, M.

R., Khademhosseini, A., 2007. Generation of static

and dynamic patterned co-cultures using

microfabricated parylene-C stencils. Lab Chip, 7,

1272.

POSITIONING AND ORIENTATION OF ADHERENT CELLS IN A MICROFLUIDIC CHIP USING THE MICRO

PATTERNING OF A PARYLENE-C FILM

215