AN RFID-BASED DRUG MANAGEMENT SYSTEM

A case in Medical Organization

S. L. Ting, S. K. Kwok, Albert H. C. Tsang and W. B. Lee

Department of Industrial and Systems Engineering, The Hong Kong Polytechnic University, Hung Hom, Hong Kong, China

Keywords: Case Study, Radio Frequency Identification (RFID), Drug Management System.

Abstract: Drug safety has attracted considerable public concern and press attention in recent years. Many precautions

have been suggested to ensure the accuracy of drug distribution to patients but the results are not yet fully

satisfactory. Enhancement of drug management is undoubtedly a trend to ensure no medication error happen

in the healthcare industry, but there is still plenty of room for improvement in this situation. Drug

Management System (DMS) is proposed as a platform for the hospital and clinics to explore the drug safety

and patient safety. This paper will present the details about DMS for assisting the medical workers in drug

replenishing and dispensing process. Also, problems existing in drug safety and benefits bring from DMS

are presented.

1 INTRODUCTION

Medicine is regarded as a tool to heal people with

sickness, but it is a weapon that can kill people. If

humans take in wrong medicine, they will have side

effects or eventually die. To avoid such mishaps,

effective drug management is very important to

healthcare industry.

Drug management involves two processes,

namely Drug Quality and Replenishing Process

(DQRP), and Drug Dispensing Process (DDP). To

enhance safety in these two processes, improving

human inspection is one of the common methods

applied in medical organizations. Despite

enhancements of inspection and quality of standards,

numerous poor drug management incidents have

been reported frequently in recent years. This

situation is particularly much more serious in clinics

compared with hospitals. This can be attributed to

the lack of monitoring system in drug management

adopted at clinics. As a result, medication errors

happened inevitably. In 2008, the Department of

Health reported that misidentifying medicines is a

common mistake (Department of Health, 2008).

Four clinics in Hong Kong have 442 medication

error events in two months with an average of seven

events a day. 260 medication error events were

related to wrong packaging (Tam et al., 2008). Some

medication errors brought serious impact to humans.

For example, in 2006, the clinic of a private general

practitioner in Hong Knog mistakenly mixed up the

syrup medicine for treating running nose with

Isopropyl alcohol in which it involves poison that is

normally used for wood processing. Another

example happened in last year: wrong drugs in packs

of medicine were found by mixing up diabetes

tablets with drugs for controlling high blood

pressure. About 60 patients were affected and they

were nearly killed because of drug allergy.

These medication error incidents have a common

characteristic – all the mistakes occurred and were

detected in the drug management processes, i.e.

DQRP and DDP. These processes involve the

knowledge of pharmacy. Drugs with similar shapes

and colors may have very different properties. For

example, Gasteel and Isodil, shown in Figure 1, have

similar shapes and colors but they are different on

the back side. The current practice of drug

identification mainly relies on visual inspection

performed by humans to determine the drugs. Unlike

the case in hospitals, clinics usually do not have

resident pharmacists. Instead, nurses usually play an

important role in the drug management processes.

With lesser medicinal knowledge and experience

compared with pharmacists, nurses are easier to

make mistakes in the drug management processes.

In short, if such processes contain errors, adverse

drug incidents will continue to happen even though

correct medications have been prescribed to patients.

In response to the above mentioned issue, a new

99

L. Ting S., K. Kwok S., H. C. Tsang A. and B. Lee W. (2010).

AN RFID-BASED DRUG MANAGEMENT SYSTEM - A case in Medical Organization.

In Proceedings of the Multi-Conference on Innovative Developments in ICT, pages 99-107

DOI: 10.5220/0003037700990107

Copyright

c

SciTePress

Drug Management System (DMS) is designed to

deal with the problems of medication errors. This

needs to modify the clinic operation by

implementing an RFID-based solution (Huang and

Ku, 2009; Ting et al., 2009; Fanberg, 2004). With

the automatic identification capability enabled by

RFID technology, the processes of drug

identification, drug distribution and drug processing

will be greatly improved. Moreover, the proposed

system can even detect whether the drugs are put in

the correct place or container, check the

compatibility of drugs for adverse interaction, and

deliver real time expiry date alert automatically.

In order to study the feasibility of our proposed

DMS, a Hong Kong medical organization is chosen

as case study. It specializes in providing health care

for ambulatory patients treated by several general

practitioners and medical professionals. Same as

many clinics around Hong Kong, its drug

management is a major challenge in its daily

operation. It would like to seek an effective and

accurate method to prevent medication errors.

Figure 1: Gasteel and Isodil – drugs that look alike at one

side.

2 MOTIVATION

AND OBJECTIVES

Four critical issues and challenges encountered in

current drug management practices are attempted to

address in this project:

Mixing Up of Drugs

In typical medical organizations, doctors and

nurses have to differentiate the drugs

frequently. It is because they need to replenish

the drugs when they are below the safety stock

level and dispensing drugs to patient when

electronic report is received. However,

concerning the shapes and colours of drugs are

similar (i.e. an example is shown in Figure 1);

it increases the challenges to distinguish the

drugs for human. Most of the errors occurred

because one drug is mixed up with another

drug. With the eyes and perception, the

mistakes of mixing up in the drugs

management cannot be tackled easily.

Therefore, it is necessary to apply technology

to facilitate the medical staff in drug

identification.

No Checking Expiry Date

As shown in Figure 2, the expiry date of drugs

is often printed on the original package of

drugs. After the packages of the drugs are

opened, the drugs of expiry date cannot be

tracked easily. Syrup will be found easily if the

drugs are deteriorated due to expired date. This

is because there are turbidities in syrup.

However, tablets will not have any appearance

changes after expiry date. Therefore, there is no

way to enhance the expiry date management

for the drugs.

Figure 2: Original Package of Drug with Expiry Date

Shown.

Lack of Drug-Drug Interaction

Some drugs cannot be prescribed to patients at

the same time as they will interact with each

other. In addition to the clinical knowledge and

experiences of physicians, a proper prescription

is also relied on the physicians’ understanding

of medicine properties, functions and

ingredients. With more and more new drugs are

available in the marketplace, medicine relation

becomes more complex. In this sense, doctors

may find difficult to recognize all these

relations and thus drug-drug interaction may

easily occur. In order to confront drugs adverse

interaction, technology can be used to facilitate

the physicians.

Based on the problem statements, the three major

objectives are:

INNOV 2010 - International Multi-Conference on Innovative Developments in ICT

100

To develop an effective and trusted drug

processing method to avoid the drugs mixing

up problems;

To provide a dynamic and evaluation platform

to assist the medical workers to check the

expiry date and drugs interaction of drugs; and

To facilitate collaborative and interactive drugs

replenishing and dispensing processes between

medical workers and patient.

3 ARCHITECTURAL

FRAMEWORK, STANDARDS

AND FUNCTIONS

OF THE RFID-BASED DRUG

MANAGEMENT SYSTEM

(DMS)

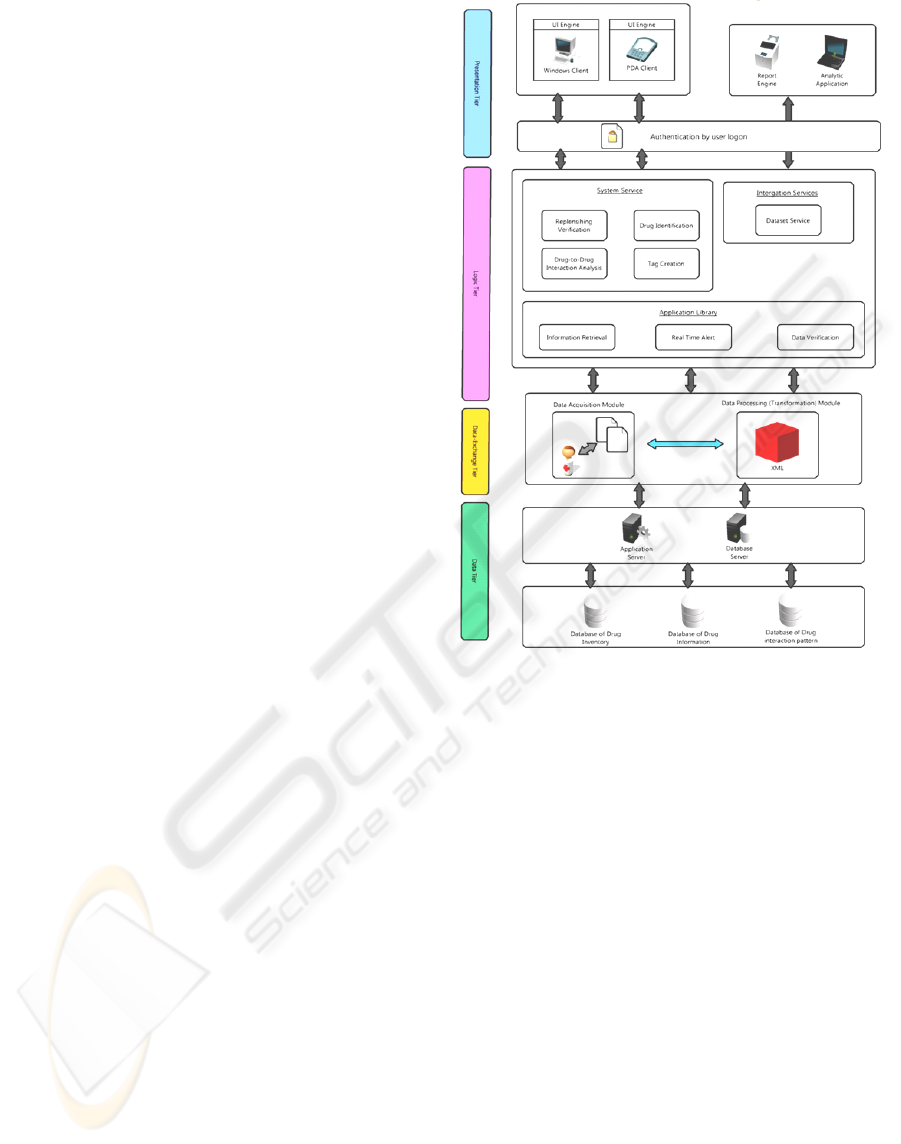

Figure 3 shows the system architecture of DMS.

Simply stated, the system is divided into 4-tiers

namely: Presentation Tier, Logic Tier, Data

Exchange Tier and Data Tier. The Presentation Tier

is used to deliver the response to the users; while the

Logic Tier processes and fuses the information

scanned by the RFID reader; then the collected raw

data is transforming into standard information by the

Data Exchange Tier and the Data Tier stores the

processed information (RFID tag information) for

further analysis.

3.1 Details of the System Architecture

The Presentation Tier represents the communication

media that enable users to receive essential

information in appropriate form, and to acquire

information based on the various authorities.

Generally, it includes input or output devices such as

UI Engine (like Personal Computers (PC) and

Personal Digital Assistants (PDA)) and Report

Engine (like Printer). Through a secure

authentication by user logon with Logic Tier, users

can enquire the system and obtain the information

like drug information, expiry date, and so on.

The Logic Tier is the brain of the whole system

since most of the work is performed here. It consists

of three major applications: Information Retrieval,

Real Time Alert and Data Verification. These

applications are useful in recording and retrieving

data in an intelligent and logical way. So that the

system can send out alert for enquiries after any

successful match between Logic Tier and Data Tier.

Moreover, these applications support difference

Figure 3: System Architecture of Drug Management

System (DMS).

services and can be classified into two categories:

System Service and Integration Service. The details

of the services are demonstrated as follow:

System Service

The System Service consists of 4 modules

which are Replenishing Verification, Drug

Identification, Drug-to-Drug Interaction

Analysis and Tag Creation. The Replenishing

Verification module responds for ensuring the

correctness between the two replenished

package and container; while the Drug

Identification module responds for retrieving

all the information of particular drug from drug

database; and the Drug-to-Drug Interaction

Analysis module responds for checking the

interaction; and finally, the Tag Creation

module responds for creating the tag once

drugs are received from manufacturers.

Integration Service

The Integration Service is mainly responsible

for report generation. That means useful

information can be extracted from suitable

database(s) by the Dataset Service module and

AN RFID-BASED DRUG MANAGEMENT SYSTEM - A CASE IN MEDICAL ORGANIZATION

101

they will be presented by the Report Engine in

the Presentation Tier.

After the information processed by the Logic

Tier, it will then be transferred to the Data Exchange

Tier which is responsible for collecting raw data and

transforming them into standard information. The

Data Exchange Tier is constituted of 2 modules:

Data Acquisition Module and Data Processing

(Transforming) Module. For Data Acquisition

Module, it acquires raw data to the system. Each

RFID tag, on the package of drugs, containing tag

ID and drug information will be used to represent

each category of drug. When we use RFID reader to

detect them and once the reader received the

returned signal, the tag can be read. For Data

Processing Module, those collected data will be

transformed and normalize into a common format –

eXtensible Markup Language (XML). XML is a

common information format which can be used on

the Internet, Intranets and elsewhere. Upon the

completion of transformation process, the standard

information will be transferred to the Data Tier to

store the information.

The Data Tier consists of several databases

include Drug Inventory, Drug Information and Drug

Interaction Pattern that contain all the information of

the system. When a raw data is captured, it will be

first under processing in Logic Tier. Then it will be

converted to meaningful information and pass

through the Application Server or the Database

Server. Finally, the information will be stored in a

suitable database in Data Tier. When any enquiry is

made, the information will be selected from the

related database in Data Tier. The Data Tier is acting

as an information repository of the system.

3.2 RFID Technology Standards

In normal practice of medical organizations, there

are mainly eight types of medicine, including

capsules, tab, syrup, power, lozenges, gel, cream and

drops or lotion.

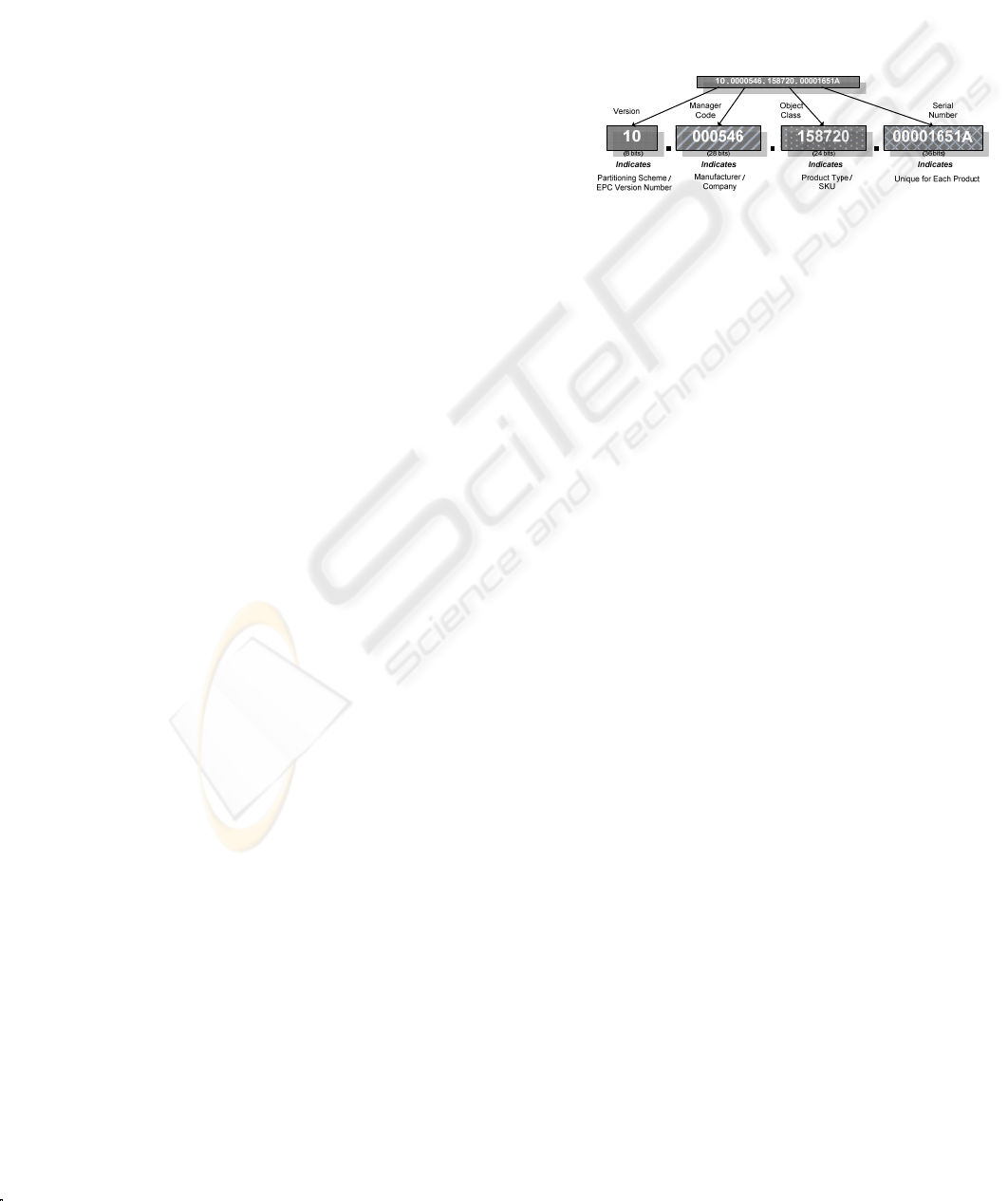

To standardize the numbering schema in the

DMS, Electronic Product Code (EPC) is adopted

(Kwok et al., 2008). EPC is a global unique serial

number that identifies products in item level

(EPCglobal Inc., 2005). As shown in Figure 4, EPC

consists of four components. Generally, it enables

users to store 96-bit data, which categories into

version, manager code, object class and serial

number. In order to store detail information of

medicine and enable medical staff to identify drugs

in item level, some critical information will be given

specific number as differentiation. The schema is

described as follow:

Version Section

It stores a 2-digit figure which can indicate

types of medicine from 01-08 (i.e. the typical

eight categories).

Manager Code and Object Class

They store 7-digit and 6 digit code

respectively. They record the other relevant

information like types of package and

manufacturing company for identification.

Serial Number

It stores a 9-digit code that represents the

assigned unique number for item identification.

Figure 4: Format of EPC Number (96-bit version).

There are various package combinations of

different types of medicines such as boxes or bottles.

If the exact volume can be identified, large packages

of drugs can be stored systematically. By assigning

an EPC numbering system in the clinic, exact

package or bottle of drugs can be easily identified or

found. Once the RFID reader detects an RFID tags,

the DMS can efficiently show related information

such as drugs’ name and quantity to the medical

staff.

3.3 System Functions

The proposed system performs 5 functions: Tag

Creation Function, Drug Identification Function,

Replenishing Verification Function, Expiry Date

Alerting Function and Drug-to-drug Interaction

Checking Function, they are described as Table 1.

4 CASE STUDY: APPLICATION

OF DMS IN A HONG KONG

MEDICAL ORGANIZATION

In order to study the feasibility of our proposed Drug

Management System, a Hong Kong medical

organization is chosen as case study. Traditional

workflow analysis is discussed first to illustrate the

problems encountered in drug management in the

organization, and hence the second part

demonstrates how the proposed methodology can

enhance the current situation and challenges.

INNOV 2010 - International Multi-Conference on Innovative Developments in ICT

102

Table 1: System Functions of RFID-based DMS.

Function Description

Tag Creation To create the tags and input

relevant

drugs information

Drug Identification To review the drug details

Replenishing Verification To confirm the drugs being

replenished correctly

Expiry Date Alerting To determines whether the

drug is expired or not

Drug-to-drug Interaction

Checking

To determine whether the

medicines dispensed to

the patient have interaction or

not

4.1 Traditional Workflow Analysis

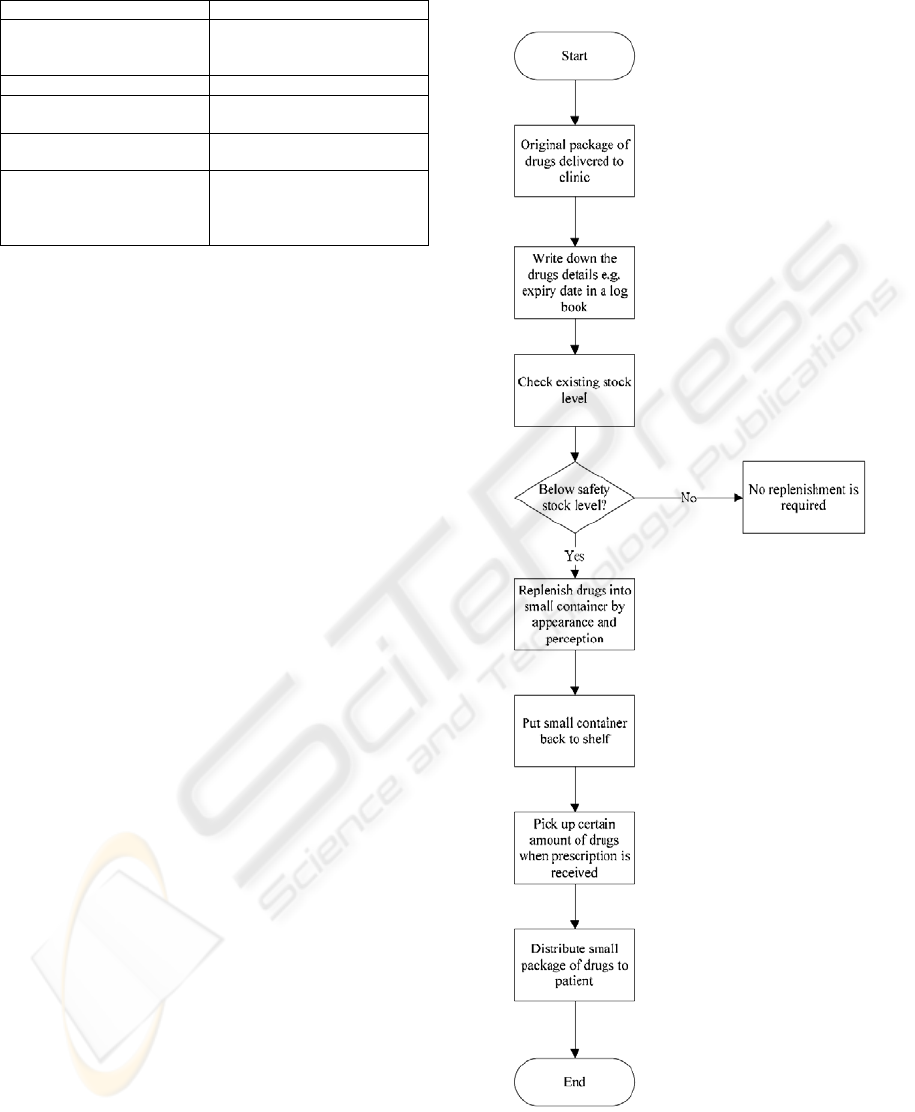

Figure 5 shows the existing working process of drug

management. Generally, drug management can be

divided into two processes, Drug Quality and

Replenishment Process (DQRP) and Drug

Dispensing Process (DDP).

When several large packages of drugs have been

first delivered to the clinic, medical workers (i.e.

usually nurses may take this role) may record the

relevant drugs information such as expiry date and

quantity in a logbook. In usual practice, large

packages of drugs are replenished into small

containers for stocking. After checking the existing

stock level of drugs, if the existing stock level is

lower than the safety stock level, large packages of

drugs are refilled into small containers. While

refilling drugs, nurses are required to match drugs

and small containers largely based on drugs’

appearance and their experiences. In a large extent,

human errors are made since there is not much

difference between drugs’ appearance and medical

staff may mistake small container and transfer pills

to an incorrect small container. Moreover, some

relevant information like expiry date of drugs needs

large human involvement to check from the

logbook. With the demanding services of clinic, it is

time consuming to realize the date first before any

replenishment is conducted. Once the refilling

process completed, the containers are stored back to

the shelf.

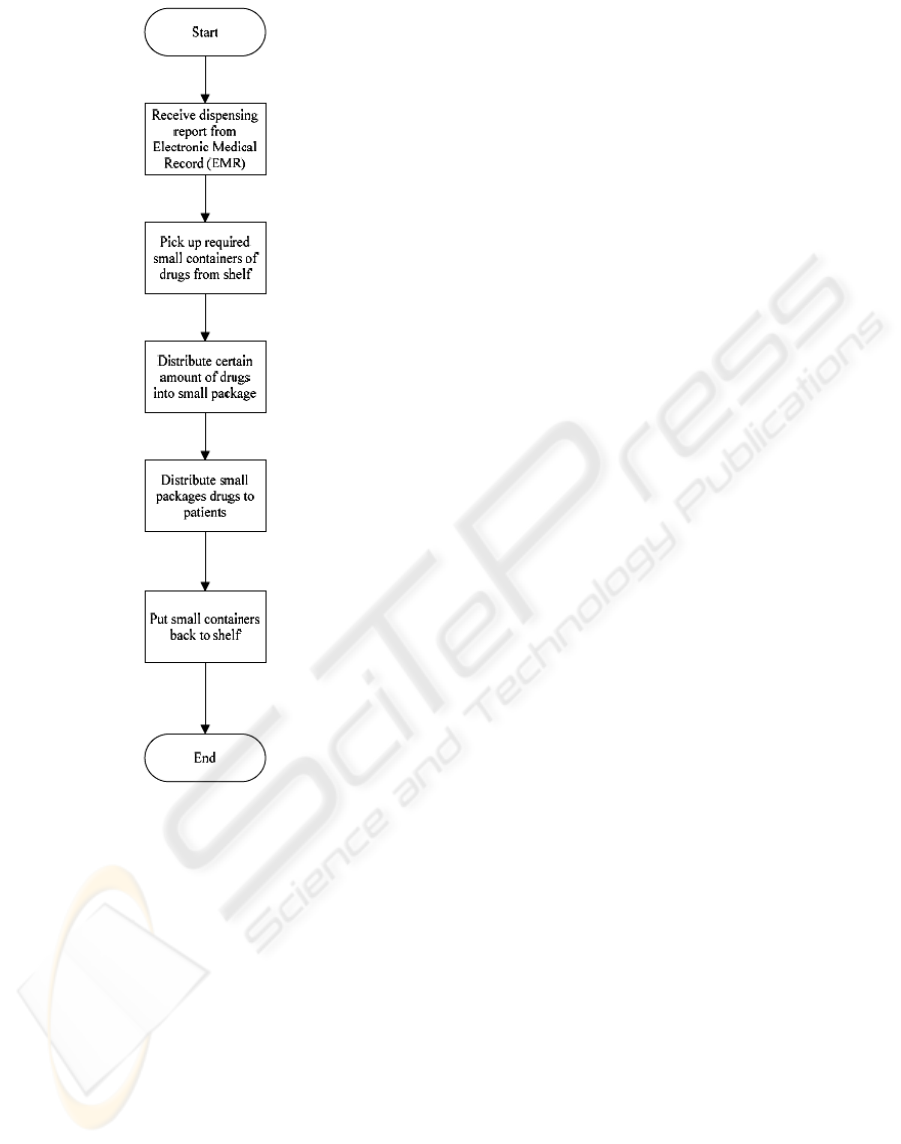

Another process is about drug dispensing which

regulates the procedure of dispensing drugs to

patients. Figure 6 shows the workflow of DDP. In

existing clinic operation, an Electronic Medical

Record (EMR) system is used to notice staff that

specific kinds of medicines should be distributed to

an exact patient (McInnes et al., 2006). After

receiving the record, nurses may pick up particular

small containers of drugs from the shelf and

distribute certain amount of drugs into small

package and finally distribute to patient.

Figure 5: Existing Workflow of DQRP.

AN RFID-BASED DRUG MANAGEMENT SYSTEM - A CASE IN MEDICAL ORGANIZATION

103

Figure 6: Existing Workflow of DDP.

4.2 Proposed Methodology

In order to tackle the problems that involved in the

DQRP, a DMS is introduced to the company. It is an

RFID-enabled system to manage the flow of drugs

throughout the chain. As large packages of drugs

have been delivered to the clinic, each package of

drugs is given a RFID tag with relevant information

stored in EPC standard. Since drugs are split into

different categories, the categories indicator is stored

as a part of identity according to EPC standard. By

then, after creating a unique RFID identity to each

package of drugs, drugs are refilled into small

containers if the existing stock level is lower than

the safety stock level. In order to ensure a correct

small container is picked, nurses are required to

place both large package of drug and small container

on an RFID reader for authentication. This is an

important step to make sure the right medicine will

be replenished into the right small bottle. Prior to

DMS, human errors are happened frequently since

the authentication process is highly depends on

worker’s perception and identification of drugs’

appearance.

If package of drugs can match with a small

container, nurses can start to replenish medicine into

small bottles. After refilling all medicines, small

containers are placed back to shelf.

For the proposed working procedure of DDP,

after receiving drugs dispensing report from EMR

system, nurses pick the right small containers from

shelf and place onto an RFID reader to ensure the

right bottles are selected. Meanwhile, expiry date

can be double examined and to prevent from

distributing expire medicine to patients. If drugs are

expired, they should be disposed immediately.

Moreover, the DMS enables users to detect whether

there is drugs interaction. If drugs are not interacted,

they can be distributed to patients.

4.3 System Functions

The proposed system performs 5 functions: Tag

Creation Function, Drug Identification Function,

Replenishing Verification Function, Expiry Date

Alerting Function and Drug-to-drug Interaction

Checking Function, they are described as follow:

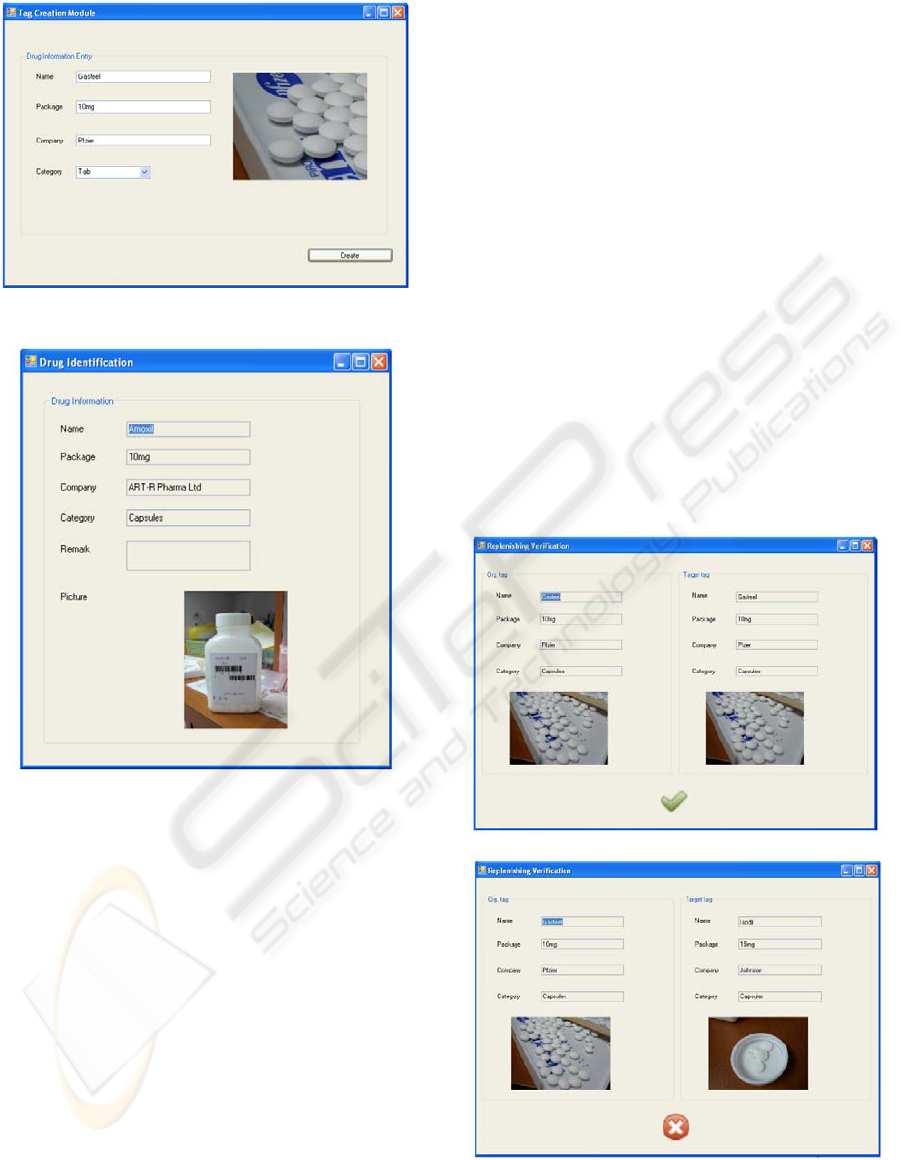

Tag Creation Function

As shown in Figure 7, this function is in charge

of creating the tags and input relevant drugs

information once drugs received from

manufacturers.

Drug Identification Function

As shown in Figure 8, this function retrieves all

relevant information of particular drug from

databases so that the medical workers can

review the drug details and make sure the

replenished and dispensed drugs are correct.

Replenishing Verification Function

This function deals with confirming relevant

drugs mainly. It examines the tags on two

packages of drugs first, and then come to use

replenishing verification function. If the two

RFID tags are matched, a Green Tick will be

shown (Figure 9a); otherwise, a Red Cross will

be shown (Figure 9b). After the steps

completed, the medical workers are admitted to

transfer the drugs from one package to the

other.

INNOV 2010 - International Multi-Conference on Innovative Developments in ICT

104

Figure 7: Screen Capture of Tag Creation Function.

Figure 8: Screen Capture of Drug Identification Function.

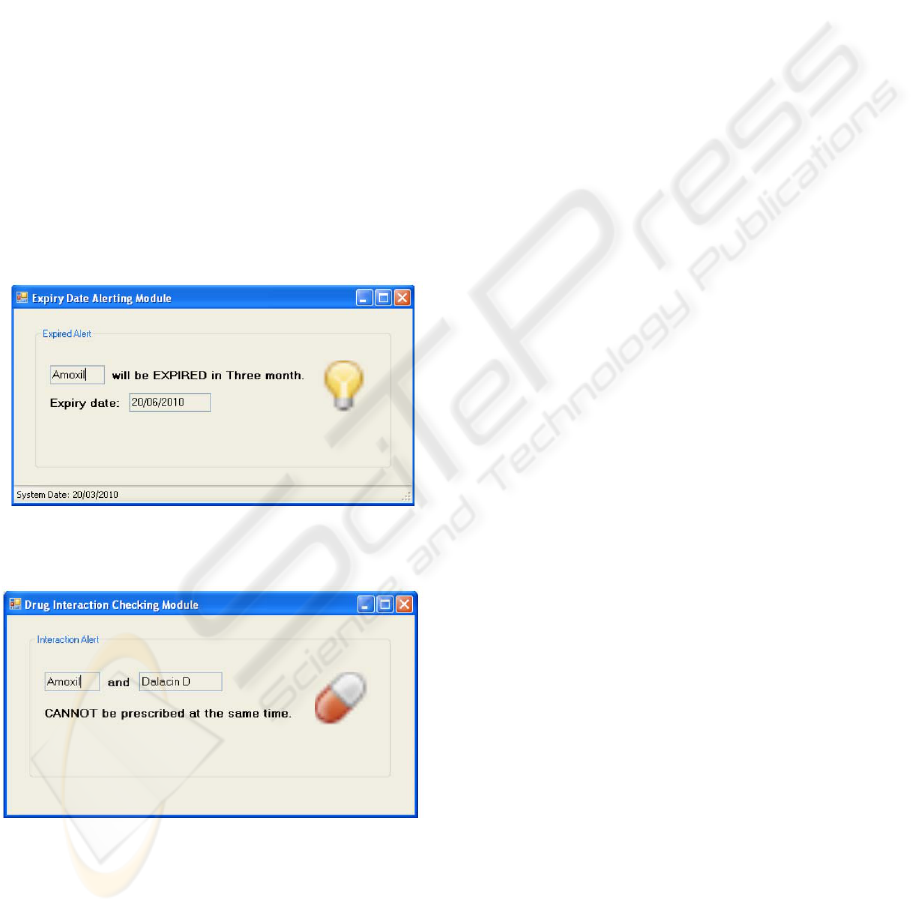

Expiry Date Alerting Function

As shown in Figure 10, this function

determines whether the drug is expired or not.

A large pop up alert message box is generated

to warn the medical workers about the expiry

date.

Drug-to-drug Interaction Checking Function

As shown in Figure 11, this function

determines whether the medicines dispensed to

the patient have interaction or not. Similar to

the Expiry Date Alerting Function, a large pop

up alert message box is generated to warn the

medical workers when interaction exists.

5 DISCUSSION

AND CONCLUSIONS

DMS can enrich, enliven and add variety to

traditional drug replenishing and dispensing

processes by using RFID technology. The following

are some of the significant impacts of DMS.

Originality, uniqueness and innovativeness

DMS is path breaking. Although some research

projects have investigated the feasibility of

implementing RFID in the dispensing process

(Lehmann and Kim, 2005), they overlook the

importance of drugs replenishing process.

Since the drugs replenishment process is the

initial stage to process the incoming drugs, if

mistakes are made in that process, medication

errors will eventually take place even though

the dispensing operation is correctly

performed. Moreover, in order to enhance the

innovativeness of DMS, special features like

drug images and interaction alert are added to

the DMS.

(a)

(b)

Figure 9: Screen Capture of Replenishing Verification

Function with (a) Matched tags (b) Unmatched tags.

AN RFID-BASED DRUG MANAGEMENT SYSTEM - A CASE IN MEDICAL ORGANIZATION

105

Practicality, User-friendliness, Extensibility &

Scalability

DMS provides users with information about

drugs immediately. By using DMS, they can

easily determine whether the drug has reached

its expiry date and it will interact with other

drugs. A real time alert (or pop up window) is

used to warn the users of abnormalities and

thus bring their awareness to the problematic

medicines. Furthermore, with the user-friendly

interface of DMS, users can easily distinguish

between drugs that look alike by the checking

system to avoid medication error. Furthermore,

the DMS applies an international standard and

a global unique serial number (i.e. EPC) to

identify drugs at item level that can be adopted

by different clinics or hospitals. When more

and more clinics and hospitals adopt the DMS,

it can be extended to pharmaceutical

manufacturers so that the whole drug supply

chain can be traced and tracked easily (ITU,

2005).

Figure 10: Screen Capture of Expiry Date Alerting

Function.

Figure 11: Screen Capture of Drug-Drug Interaction

Checking Function.

Social Responsibility

Traditionally, inspections are carried out only

when patients are found to be sick after taking

wrong medicine. However, with the help of

RFID, DMS improves the efficiency and

effectiveness of drug management. All the

problematic cases can be brought to the

attention of the operator (such as the nurse) in

real time. By adopting DMS, clinics can

adequately address social and environmental

concerns in their business operations. The

proposed system will assure drug safety

consistently. Thus, patient safety is enhanced

by reducing medication errors. In addition,

DMS speeds up the drug replenishing and

dispensing processes that help to reduce

operation expenses. This can drive the

stakeholders to scale up change throughout

their clinics.

ACKNOWLEDGEMENTS

The authors would also like to express their sincere

thanks to the Research Committee of the Hong Kong

Polytechnic University for providing the financial

support for this research work.

REFERENCES

Department of Health, 2008. Health Statistics , available

at: http://www.dh.gov.hk/. Accessed from 20 March

2010 14:03:40.

EPCglobal Inc., 2005. The EPCglobal Architecture

Framework, EPCglobal Final.

Fanberg, H., 2004. The RFID Revolution, Marketing

Health Services, Vol. 24, No. 3, pp. 43-44.

Huang, H. H., Ku, C. Y., 2009. A RFID Grouping Proof

Protocol for Medication Safety of Inpatient, Journal of

Medical Systems, Vol. 33, No. 6, pp. 467-474.

International Telecommunication Union (ITU), 2005. The

Internet of Things, ITU internet reports.

Kwok, S. K., Tsang, A. H. C., Ting, J. S. L., Lee, W. B.,

Cheung, B.C.F., 2008. An Intelligent RFID-based

Electronic Anti-Counterfeit System (InRECS) for the

Manufacturing Industry, In: Proceedings of the 17th

International Federation of Automatic Control (IFAC)

World Congress 2008, Seoul, Korea, July 6-11, 2008,

pp. 5482-5487.

Lehmann, C. U., Kim, G.R., 2005. Prevention of

Medication Errors, Clinics in Perinatology, Vol. 32,

No. 1, pp. 107-123.

McInnes, D. K., Saltman, D. C., and Kidd, M. R., 2006.

General practitioners’ use of computers for prescribing

and electronic health records: results from a national

survey, The Medical Journal of Australia, Vol. 185,

pp. 88–91.

Tam, K. W. T., Kwok, H. K., Fan. Y. M. C., Tsui, K. B.,

Ng, K. K., Ho, K. Y. A., Lau, K. T., Chan, Y. C., Tse,

C. W. C., Lau, C. M., 2008. Detection and prevention

INNOV 2010 - International Multi-Conference on Innovative Developments in ICT

106

of medication misadventures in general practice,

International Journal for Quality in Health Care, Vol.

20, No. 3, pp. 192-199.

Ting, S. L., Kwok, S. K., Tsang, A. H. C., Lee, W. B.,

2009. Critical Elements and Lessons Learnt from the

Implementation of an RFID-enabled Healthcare

Management System in a Medical Organization,

Journal of Medical Systems, DOI: 10.1007/s10916-

009-9403-5.

AN RFID-BASED DRUG MANAGEMENT SYSTEM - A CASE IN MEDICAL ORGANIZATION

107