EXPERIENCES OF ERP USE IN SMALL ENTERPRISES

Paivi Iskanius

RaaheUnit, University of Oulu, Rantakatu 5,Raahe, Finland

Raija Halonen

CISC, National University of Ireland, Galway, Ireland

Department of Information Processing Science, University of Oulu, Finland

Matti Mottonen

Department of Industrial Engineering and Management, University of Oulu, Oulu, Finland

Keywords: Enterprise resource planning, ERP, Small enterprises, SME.

Abstract: This paper investigates the role of Enterprise Resource Planning (ERP) systems in the context of small and

medium size enterprises (SMEs). The paper reports on research findings from a case study that has been

conducted in 14 SMEs, operating in steel manufacturing and woodworking. By dividing the enterprises into

three different groups; medium-sized, small, and micro enterprises, this study provides a richer

understanding of enterprise size related issues in motivations, risks and challenges of ERP adoption.

1 INTRODUCTION

This paper investigates the role of enterprise

resource planning (ERP) systems in the context of

small and medium enterprises (SMEs). ERP systems

are enterprise-wide software packages that provide

fully integrated business processes with shared data

and visibility, and thereby hold the potential of

greatly enhancing organizational performance and

establishing competitive advantage (Davenport,

1998).

This case study is carried out in 14 SMEs

operating in steel manufacturing and woodworking.

By dividing enterprises into three different groups;

medium-sized, small, and micro enterprises, the

study provides a richer understanding of enterprise

size related issues in motivations, risks and

challenges of ERP adoption. According to European

Commission, medium-sized enterprises employ less

than 250 persons and an annual turnover is not

exceeding 50 M€, and/or an annual balance sheet

total is not exceeding 43 M€; small enterprises

employ less than 50 persons and an annual turnover

and/or an annual balance sheet total is less than 10

M€; and micro enterprises employ less than 10

persons and an annual turnover and/or an annual

balance sheet total is less than 2 M€.

Most of large enterprises (LEs) worldwide have

already adopted ERP systems and SMEs are

increasingly following the suit (Bernroider and

Koch, 2001). In 1998, 27 % of European midsize

enterprises across all counties and industries had

installed ERP software in one or more functional

areas, and the ERP software penetration was

estimated to rise to 56 % by the year 2000. The

expected penetration rates were especially high in

Northern European countries, as in Finland, where

the rate was estimated to be about 70 % (Van

Everdingen et al., 2000).

There are some reasons for this trend, including

a saturation of the LE market, increasing

possibilities and need for the integration of systems

between organizations, and the availability of

relatively inexpensive hardware (Gable and Stewart,

1999). However, SMEs use ERP systems mainly for

the finance/accounting functions and many advanced

features, such as production planning and

scheduling, typically have not been explored

(Muscatello et al., 2003).

The ERP research has so far concentrated on

LEs and the findings cannot easily be extended to

5

Iskanius P., Halonen R. and Mottonen M. (2009).

EXPERIENCES OF ERP USE IN SMALL ENTERPRISES.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Databases and Information Systems Integration, pages 5-10

DOI: 10.5220/0001856600050010

Copyright

c

SciTePress

SMEs because of their particular characteristics

(Laukkanen et al., 2007). The needs, operating

requirements, logistics fulfillment and financial

capabilities of SMEs are vastly different from that of

LEs (Huin, 2004). Recently, the ERP research on

SMEs has received more attention (e.g. Gable and

Stewart, 1999, Van Everdingen, et al., 2000;

Bernroider and Leseure, 2005, Raymond &

Uwizeyemungu, 2007). Also this study contributes

to the ERP research in the context of SMEs and

provides insights that may have been overlooked in

previous research.

2 LITERATURE REVIEW

ERP systems, when successfully assimilated into an

enterprise, can provide both operational and strategic

benefits, and enforce a discipline of best practice and

consultancy. ERP systems can significantly improve

information flow, streamline processes and hence

develop the enterprise’s efficiency and its

competitive advantage. (Van Everdingen, et al.,

2000; Bernroider and Leseure, 2005, Raymond &

Uwizeyemungu, 2007).

The main motivations for ERP use are seen as

the production of real-time data shared across the

organisation and consequently the integration and

automation of business processes (Gupta, 2000).

According to Botta-Geboulaz and Millet (2005),

technology motivations (system not Y2K compliant,

disparate systems, poor quality/visibility of

information, business process or system not

integrated, difficult to integrate acquisitions ad

inability to support growth) and operational

motivations (poor or uncompetitive business

performance, cost structure too high, not responsive

enough to customers or suppliers, complex,

ineffective business processes, inability to support

new business strategies, business becoming global,

and inconsistent business processes) motivates

enterprises towards ERP use. Overall, improving

productivity, competitive advantage, and customer

demands are the top three business drivers for

companies with ERPs (Scott and Shepherd, 2002).

Especially SMEs adopt ERP systems with the

goal of replacing inefficient standalone legacy

systems, increasing communications between

business functions, increasing information

processing efficiencies, improving customer

relations, and improving overall decision making

(Cereola, 2008).

Laukkanen et al. (2007) indicate that significant

differences exist between SMEs (medium-size,

small, micro enterprises) and LEs in ERP adoption.

Specifically, the findings suggest that SMEs

experience more knowledge constraints than LEs in

ERP adoption. Also, SMEs differ from LEs in

important ways affecting their information-seeking

practices that impact information and technology

(IT) adoption. These differences include lack of

information systems management, concentration of

information-gathering responsibilities to a small

number of individuals, lower levels of resources

available for information-gathering, and in the

quantity and quality of available environmental

information (Buonanno et al., 2005). Thus, SMEs

need different characteristics from ERP systems.

Today, some ERP vendors have taken up the

gauntlet and have been moving their attention

toward SMEs (Gable and Stewart, 1999) by offering

simplified and cheaper solutions from both the

organizational and technological points of view, pre-

configured systems based on best-practices at a

fraction of the cost originally required and promising

short implementation times.

Poba-Nzaou et al. (2008) identifies six main

dimensions of risk in ERP implementation, namely,

organizational, business-related, technological,

entrepreneurial, contractual and financial risks.

Organizational risk derives from the environment in

which the system is adopted. Business-related risk

derives from the enterprise’s post-implementation

models, artefacts, and processes with respect to their

internal and external consistency. Technological risk

is related to the information processing technologies

required to operate the ERP system – for example

the operating system, database management system,

client/server technology and network.

Entrepreneurial or managerial risk is related to the

attitude of the owner-manager or management team,

while contractual risk derives from relations with

partners and financial risk from cash-flow

difficulties, resulting in an inability to pay license

fees or upgrading costs, for example. (Poba-Nzaou

et al., 2008)

Also individuals’ knowledge and skills may turn

out problematic. When exploring change and

uncertainty in SME environments with ERP, Koh

and Simpson (2005) discover lack of knowledge and

expertise in how modification, feedback and

management should be made and organized to

enable ERP systems to support production planning

and control.

To minimize the risk of implementing ERP

systems, Markus and Tanis (2000) have

recommended the application of a risk management

plan at the implementation stage. Consequently,

Bernroider and Leseure (2005) suggest that major

mistakes are made in the early stages of the ERP,

ICEIS 2009 - International Conference on Enterprise Information Systems

6

even prior to the implementation process. Kliem

(2000), however, emphasizes the efficiency of risk

management when it is introduced at the earliest

possible opportunity in the life cycle of the system in

question, when planning issues are most important

and the criteria for system selection are determined.

3 ANALYSIS

3.1

Research Setting

This case study was carried out in the SMEs

operating in steel manufacturing and woodworking

in the Raahe region, Finland during 6/2007–8/2008.

A specific web questionnaire was designed to find

out the current state of ERP use in SMEs. The

survey was executed through the Webropol software

(www.webropol.com). Besides the basic company

information, the survey included questions related to

organisational performance and business processes;

problems in electronic data transfer; experiences of

ERP use and challenges/risks to implement them. In

addition, the survey included questions of change

management and IT knowledge of the personnel. In

this paper, the results of survey are divided into four

theme areas of Motivation, Problems, Risks, and

Challenges.

The return rate was 27.5%, in total, 14

enterprises responded out of 51 industrial SMEs.

The number of employees in the case enterprises

varied from 5–9 to over 100, and the annual turnover

between € 0.6–15 million. Four (28,5%) of the case

enterprises were medium-size, four (28,5%) were

small, and six (43%) were micro enterprises.

Totally, ten (72%) case enterprises had an ERP

system in function, half of which were off-the-shelf

software packages and half company-specific,

tailored systems. However, only one of these

enterprises had a fully functioning system and five

informed that they have serious difficulties in ERP

use. All medium-size enterprises had either an ERP

system in function or an ERP development project

ongoing. Two small enterprises had an ERP system

in function; however, with problems. One small

enterprise had an ongoing ERP development project.

Other small enterprises aim to start an ERP

development project within two years. Two micro

enterprises had an ERP system; however, one of

them had problems with the implementation. One

micro enterprise aimed to start an ERP development

project within two years. Three micro enterprises

stated that acquiring ERP is not a current issue or

that they do not need one at all. These enterprises

were all small companies with 5–9 employees, and

they saw that compared to the costs, the benefits of

the system would remain small.

All case enterprises were subcontractors. Also,

almost all of them had their own subcontractors.

Typically, SMEs had outsourced distribution

(including transport), production, marketing,

maintenance, and repair and support operations.

Also, financial management and accounting services

were often purchased or leased.

All case enterprises worked in the global

markets, directly or through the focal company’s

value chain. Over 75% of case enterprises had large

customers, also international customers. Over 60%

of enterprises had SMEs customers, also

international customers.

3.2 Motivation for ERP use

In the questionnaire, the enterprises were expected

to choose out of 19 alternatives the most significant

factors they require from ERP systems. They were

also asked what motivations for change and

expectations and development targets they had for

ERP systems. The alternatives were assessed on the

scale ‘insignificant’, ‘some significance’,

‘significant’ and ‘very significant’. Based on the

replies, there were six alternatives to which ten

companies answered ‘significant’ or ‘very

significant’. Of these alternatives, integrating

operations, eliminating unproductive work and

enhancing process monitoring are related to

increasing cost-effectiveness.

Factors related to quality and quality

improvement was considered as the primary

development target. Process monitoring, and

sourcing and sharing information were also raised as

significant development targets of ERP.

Insignificant factors as regards the development of

ERP were change and improving change

management, reducing the time-to-market, reducing

the number of terms, expanding the product range,

and reducing the costs of product development.

The enterprises were also asked, what central

development operations they were going to execute

in the near future (1-2 years) or later. In the near

future, all of the enterprises were planning to

execute development operations to improve

production quality. They expected ERP systems to

provide assistance in their quality improvement

processes. Another important development target for

the near future was to improve machinery and tools.

According to most of the respondents, management

development projects would take place later.

EXPERIENCES OF ERP USE IN SMALL ENTERPRISES

7

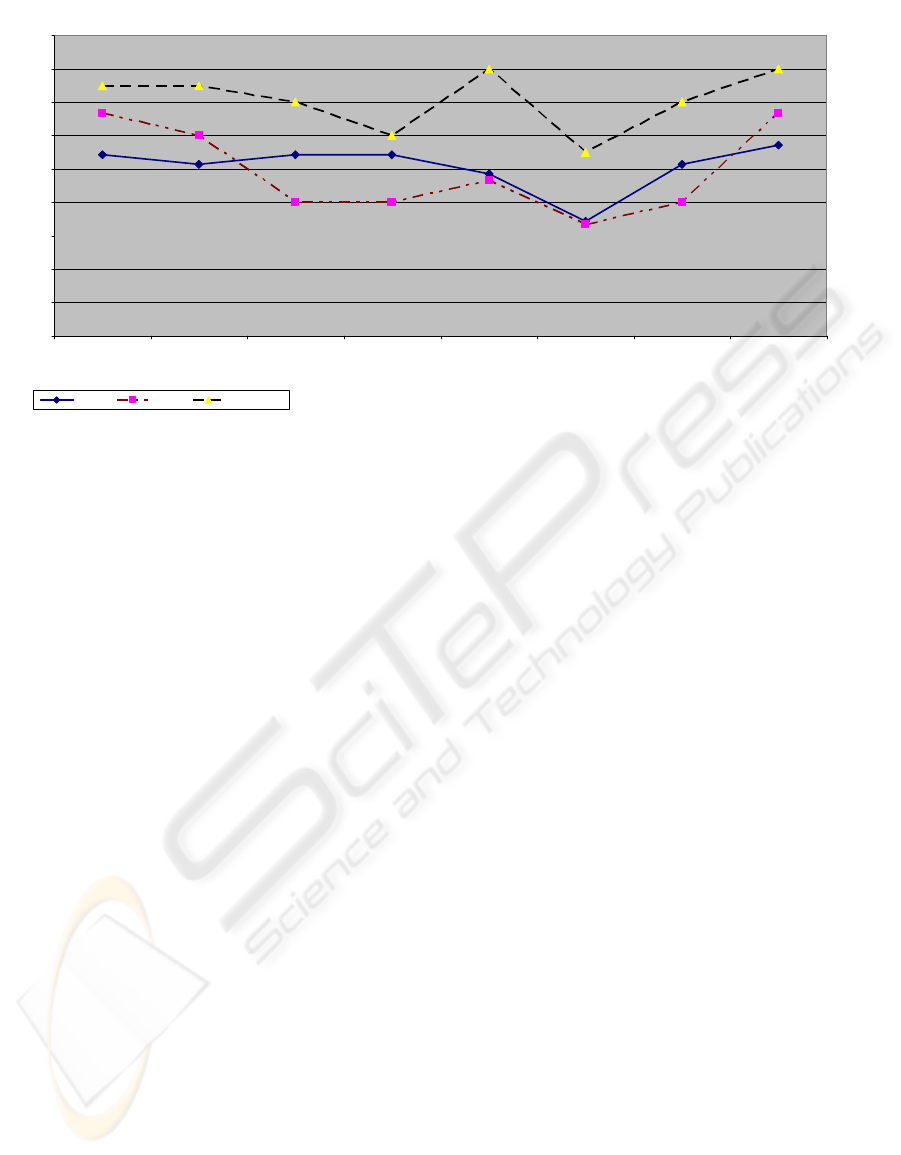

Motivation for ERP use in the different size enterpirses

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

Finding and sharing

information

Standardising

operational

processes

Improving planning

procedures

Increasing

possibilities for

customer-specific

tailoring

Digitisation of

doc ume nts

Reducing time-to-

market

Improvement the

change management

processes

Eliminating

unproductive work

Mi cr o Small Me dium-s i z e

Figure 1: Motivation for ERP use.

The respondents viewed customer relationship

management important, and ten of them considered

it as a near-future development target. When

comparing the near-future development targets of

different-sized companies, it could be noted that the

small enterprises had stronger pressures for product

development than the larger ones. This could also be

seen in the enterprises’ motivation to improve

planning procedures and customer-specific

flexibility. The medium-size enterprises were more

interested in goals and strategies as well as internal

information flow. Organizing production and staff

cooperation were development targets in the near

future for most of the enterprises. Several companies

also mentioned staff competence as one of their

development targets.

The survey revealed that motivation for ERPs

are about the same regardless of the size of the

enterprise. Figure 1 illustrates responses to eight

issues related with pressures and expectations for

EPRs, namely, 1) Finding and sharing information in

a dispersed environment; 2) Standardizing

operational processes; 3) Improving planning

procedures; 4) Increasing customer-based tailoring;

5) Digitalization of documents; 6) Reducing the

time-to-market; 7) Managing and decreasing costs of

change processes; and 8) Eliminating unproductive

work. The highest line displays motivation of

medium-size enterprises, and, respectively, the two

crossing lines show responses from small and micro

enterprises. The lines expose that the larger the

enterprise is, the more significant motivation for

ERP use is.

Digitalising documents was perceived important

in medium-size enterprises whereas the smaller

enterprises did not value it much. Moreover,

eliminating unproductive work was found significant

in all enterprises.

3.3 Risks of ERP use

The case enterprises had several different and

different-aged IT systems in function. New ERP

systems were often expensive, and enterprises

wanted to receive all possible benefits that even a

poor system could produce. New IT/ERP systems

were usually acquired as off-the-shelf software

packages, which were often purchased from

different suppliers, that meant that they included

multiple, overlapping system modules that

performed the same tasks.

This could be clearly seen also in the answers of

the surveyed enterprises. Utilising same information

and same database in different IT systems could

successfully be done only in two case enterprises.

The other enterprises could not utilise the

information in different systems at all, or that they

could do it only partially. Different IT/ERP systems

or modules had similar properties, and they partly

overlapped in 45.5% of enterprises. None of the case

enterprises had automatic information exchange

between them and their subcontractors’ or clients’

systems, and only one enterprise had partial

exchange.

The greatest problems of current operational

mode and information processing aroused from data

transfer. In 33.3% of enterprises, the necessary

information was not transferred between various

IT/ERP systems. In addition, the enterprises reported

ICEIS 2009 - International Conference on Enterprise Information Systems

8

the lack of the users’ knowledge/education.

Maintaining the various systems was also seen as a

reasonable problem in nine (64%) case enterprises.

The main problems of ERP use were as follows:

the lack of adequate planning information,

ineffective project steering systems, piled-up work,

up-to-date load information, material-related

operations, the lack of a functioning ERP system,

material resource planning, up-to-date information

exchange/relevance between planning and

production, changes in delivery times made by

customers, and availability of material resources.

The enterprises were asked to assess the level of

risks produced by ERP solutions to their business

processes on the scale ‘great’, ‘reasonable’ and

‘small’. Ten (71%) of case enterprises considered

the impacts of system breakdowns and malfunctions

on their customers as the greatest risks. Six (43%)

enterprises considered operation failures resulting

from technical difficulties as a great risk.

The enterprises viewed as small risks chaining of

production, dependence on other enterprises, and

losing a contract because they had a wrong kind of a

IT system or they did not have one at all. The

aforementioned risks as well as other risks resulting

from cooperation relationships were typical in

subcontracting enterprises.

Another risk factor was the lack of IT

competence. Often, users and developers did not

have time or competence to implement an ERP

system. This risk was actualized in one of the

respondent enterprises. Resistance to change was

also a risk factor. The existence of change resistance

was acknowledged in the case enterprises and could

clearly be seen in the survey.

3.4 Challenges of ERP use

The enterprises chose out of six alternatives the

greatest challenges that ERP systems caused for

their business processes. The alternatives were

assessed on the scale ‘small’, ‘reasonable’, ‘great’.

Seven (50%) enterprises viewed as their greatest

challenge in implementing an ERP system the

change it induced in their operational practices. Six

(43%) enterprises considered the staff’s readiness

and willingness to learn new things challenging as

regards implementing an ERP system. In addition,

enterprises found actualizing and measuring the

benefits of an ERP project challenging. Three

enterprises saw them as great and one enterprise as

reasonable challenges.

Increase in the interdependence between

different operations and difficulties in pinpointing

the problem areas were considered as reasonable

challenges. However, the small companies with less

than 20 employees considered them greater

challenges than the companies with over 20

employees did. The large companies were more

challenged by changes in operational practices than

the companies with less than 20 employees were.

From the surveyed enterprises, seven (50%)

enterprises considered the lack of skills in using

ERP systems as the most significant problem as

regards electric data transfer. Four (28,5%)

enterprises saw development of the systems and lack

of experience related to it as problematic. Lack of

standards, however, was not brought up in any

enterprises. Some enterprises were unsure of the

system’s usefulness and their own IT competence.

Most problems in the data transfer between interest

groups, customers, subcontractors, prime

contractors, and network partners resulted from

incompatibility of different systems. In addition, the

companies saw the problems in the connection speed

and connection breaks as problematic. Furthermore,

the staff’s willingness and readiness to adopt new

systems and resistance to change related to it were

also strongly emphasized.

The benefits of electric data transfer were most

visible in a dispersed environment where the produc-

ers and the users of product information were phys-

ically far apart each other. Six case enterprises

operated under one roof, which meant that in almost

half of the respondents’ cases, the knowledge

producers and users were physically close to each

other. In the rest eight case enterprises, different

operations were physically in different places: in

different departments, buildings, industrial areas,

geographical locations, and even countries.

4 CONCLUSIONS

In this study, the focus was to investigate the role of

ERP systems in (SMEs. To correspond to the focus,

a case study of 14 SMEs was carried out.

The findings of the study response to the

suggestion by Laukkanen et al. (2007) about not

considering small and medium-sized enterprises as

one homogenous group, but acknowledging the

differences between these two groups of companies

in future research. This study showed that among

SMEs, smaller enterprises valued more product

development than medium-size enterprises did in

relation to ERP systems. Further, small and micro

enterprises were more motivated to improve

planning procedures and customer-specific

flexibility whereas medium-size companies were

EXPERIENCES OF ERP USE IN SMALL ENTERPRISES

9

more interested in goals and strategies as well as

internal information flow.

Regarding to the size of enterprises, some

differences were found in the motivations and

expectations for ERPs, too. In overall, medium-size

enterprises perceived the measures more significant

than the smaller ones. Especially digitalising

documents was perceived more important in

medium-size enterprises compared to the smaller

ones.

Differing from prior research (e.g. Davenport,

1998; Scott & Shepherd, 2003; Botta-Geboulaz &

Miller, 2005), the respondents in the study assessed

factors related to quality and quality improvement as

the primary development targets. An interesting

finding was the importance of IT competence, and

especially communication skills of the system

vendor’s expert when choosing a new ERP system,

while the maintenance price that forms more than

half of the total cost of the system was not

considered a decision factor at all. On the other

hand, the enterprises tried to stick with old systems

and receive all the possible benefits that even a poor

system could produce. When purchased, the new

ERP system was usually an off-the-self software

package without any tailoring and often from

different suppliers, thus causing overlapping system

modules and producing problems with information

relevancy between different systems.

Lack of knowledge was perceived problematic in

all but one case enterprise. This verifies findings of

Koh and Simpson (2005), which highlighted

problems with scarce knowledge especially in

SMEs.

In all, one can conclude that the need of ERP

systems is understood in SMEs but ERP adoption is

not yet as penetrated as it is in LEs. Furthermore, to

noticing differences between SMEs and LEs, the

research highlighted differences also in the SMEs .

As such, the current study offered interesting

new knowledge concerning current status of

utilisation of ERP in SMEs. While this empirical

study also showed existing differences in the group

of SME, it serves as a prior study for future research

on later ERP penetration in SMEs.

REFERENCES

Bernroider, E. and Koch, S., 2001. ERP selection process

in midsize and large organizations, Business Process

Management Journal, Vol. 7, No. 3, pp. 251-257

Bernroider Leseure (2005)

Botta-Genoulaz, V. and Millet, P-A., 2005. An investi-

gation into the use of ERP systems in the service

sector, International Journal of Production

Economics, Vol. 99, pp.202–221

Buonanno, G., Faverio, P., Pigni, F., Ravarini, A., Sciuto

D. and Tagliavini, M., 2005. Factors affecting ERP

system adoption. A comparative analysis between

SMEs and large companies, Journal of Enterprise

Information Management, Vol. 18, No. 4, pp. 384-426

Cereola, S., 2008. The performance effects of latent

factors on assimilation of commercial open-source

ERP software on small-medium enterprises, Virginia

Commonwealth University Richmond, Virginia, USA

Gable, G.G. and Stewart, G., 1999. SAP R/3

Implementation Issues for Small to Medium

Enterprises. Americas Conference on Information

Systems, August 13-15, Milwaukee, WI

Gupta, A., 2000. Enterprise resource planning: the

emerging organizational value systems, Industrial

Management & Data Systems, Vil. 100, No. 3, pp.

114-118.

Davenport, T.H., 1998. Putting the enterprise into the

enterprise system, Harvard Business Review, Vol. 76,

No.4, pp.121-31

Huin, S. F., 2004. Managing deployment of ERP systems

in SMEs using multi-agents, International Journal of

Project Management,Vol. 22, pp. 511-517.

Kliem, R.L., 2000. Risk management for business process

reengineering project, Information Systems

Management, Vol. 17, No. 4, pp.71-3

Koh, S.C.L. and Simpson, M., 2005. Change and

uncertainty in SME manufacturing environments using

ERP, Journal of Manufacturing Technology

Management, Vol. 16, No. 6, pp. 629-653

Laukkanen, S., Sarpola, S. and Hallikainen, P., 2007.

Enterprise size matters: objectives and constraints of

ERP adoption. Journal of Enterprise Information

Management, Vol. 20, No. 3, pp.319-334

Markus, M.L. and Tanis, C., 2000. The enterprise system

experience – from adoption to success”, in Price, M.F.

(Ed.), Framing the Domains of IT Management:

Projecting the Future through the Past, Pinnaflex

Educational Resources, Cincinnati, OH, pp. 173-207

Muscatello, J.R., Small, M.H., Chen, I.J., 2003.

Implementing ERP in small and midsize

manufacturing firms, International Journal of

Operations and Production Management, Vol. 23, No.

8, pp.850–871

Poba-Nzao, P., Raymond, L., Fabi, B., 2008. Adoption

and risk of ERP systems in manufacturing SMEs: a

positivist case study, Business Process Management

Journal, Vol. 9l. 14, No. 4, pp. 530-550

Raymond, L. and Uwizeyemungu, S., 2007. A profile of

ERP adoption in manufacturing SMEs. Journal of

Enterprise Information Management, Vol. 20, No.4,

pp. 487-502

Scott, F. and Shepherd, J., 2002. The steady stream of

ERP investments. AMR Research Alert, August 26

Van Everdingen, Y., Van Hillegersberg, J. and Waarts, E.,

2000. ERP adoption by European mid-size companies,

Communications of ACM, Vol. 43 No. 4, pp. 27-31.

ICEIS 2009 - International Conference on Enterprise Information Systems

10