A QUADRATIC PROGRAMMING APPROACH TO THE

MINIMUM ENERGY PROBLEM OF A MOBILE ROBOT

Alain Segundo Potts*, José Jaime da Cruz* and Reinaldo Bernardi**

*Department of Telecommunications and Control, São Paulo University, São Paulo, Brazil

**Genius Institute of Technology, São Paulo, Dept. of Telecommunications and Control, São Paulo University, Brazil

Keywords: Mobile robots, quadratic programming, minimum energy, optimal control.

Abstract: As a consequence of physical constraints and of dynamical nonlinearities, optimal control problems

involving mobile robots are generally difficult ones. Many algorithms have been developed to solve such

problems, the more common being related to trajectory planning, minimum-time control or any specific

performance index. Nevertheless optimal control problems associated to mobile robots have not been

reported. Minimum energy problems subject to both equality and inequality constraints are generally

intricate ones to be solved using classical methods. In this paper we present an algorithm to solve it using a

Quadratic Programming approach. In order to illustrate the application of the algorithm, one practical

problem was solved.

1 INTRODUCTION

1.1 Preliminaries

Mobile robotics is an important research area and for

its study many researchers have dedicated a lot of

time to it. There are many problems in mobile robots

that are not present in industrial robots. Problems

with posture maintenance, localization, equilibrium

and energy consumption are common both at design

and operation times. Limbed robots can be

considered an important engineering conquest due to

the fact that they have larger mobility, flexibility and

freedom of movements than any other automatic

machine (Dudek, 2000). Research in this area

requires strong knowledge of mechanics, electronics,

computation, and eventually biomechanics. Limbed

robots are capable of walking and climbing and have

been developed around the world. (Armada et al.,

2003; Virk, 2005). Some of them have been used to

inspect bridges (Abderrahim et al., 1999) and

pipelines (Galves; Santos; Pfeiffer, 2001).

Presently the literature reports just two robots with

the ability of tree climbing. The first one was

developed at the Waseda University, Japan, and the

second one is the RiSE robots (Robots in Scansorial

Enviroments) (Saundersa et al., 2006) developed at

the United States. The RiSE robot is a member of a

new class of climbing robots whose design is based

on animals. For all of them, the energy consumption

is a big problem. Generally the battery is their

heaviest part since a considerable amount of energy

is necessary to drive the legs’motors.

Typically a leg has the form of a serial mechanism

with a highly nonlinear dynamics. This is one of the

reasons that make to find an optimal control law a

difficult problem. A second reason is the presence of

both equality and inequality constraints imposed on

the system – e.g., the actuator of each joint is subject

to saturation (Spont et al., 1989).

Many authors have worked in the optimization of

robots operation in the context of trajectory

planning. (Lin et al., 1983; Garg et al., 2002; Luo et

al., 2004). The problems considered in general

aimed to minimize the time or some quadratic

performance index. Nevertheless in the majority of

them both the Coriolis and Centrifugal terms were

omitted.

Optimal trajectory control systems usually can be

built by solving two associated sub-problems: i) the

optimal trajectory planning (OTP); ii) the trajectory

tracking control (TTC). Since there are many

complex constraints conditions concerning robot

kinematics and dynamics, the corresponding

245

Segundo Potts A., Jaime da Cruz J. and Bernardi R. (2008).

A QUADRATIC PROGRAMMING APPROACH TO THE MINIMUM ENERGY PROBLEM OF A MOBILE ROBOT.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 245-251

DOI: 10.5220/0001499102450251

Copyright

c

SciTePress

algorithms for solving the OTP problem have been

improved in recent years (Luo et al., 2004). Even

though good results have been obtained with the

OTP problem for both manipulators and industrial

robots, this is not the case for mobile robots.

A minimum energy formulation may be an

interesting approach for mobile robots, particularly

in applications where the battery weight is a critical

issue. Minimum energy problems may be difficult to

solve by classical methods since they involve both

the nonlinear dynamics of the robot and a set of

constraints.

In this paper a Quadratic Programming approach to

the minimum energy problem of a mobile robot is

proposed. The method is based on the discretization

of the problem. Numerical tests were performed for

Kamanbaré

1

, a robot currently under development at

the Automation and Control Laboratory (LAC),

University of São Paulo.

1.2 The Robotic Platform

Kamambaré is a biomimetic robotic platform, i.e., a

robotic platform inspired in nature, with the purpose

of climbing trees for environmental research

applications (see Fig. 1). More specifically the

platform locomotion is inspired in the form lizards

climb trees. The main characteristics sought in the

definition of the Kamanbaré platform were:

locomotion in irregular environments

(unpredictability of the branch complexity that

compose a tree), surmounting obstacles (nodes and

small twigs), tree climbing and descending without

risking stability, and keeping low structural weight

(mechanics + electronics + batteries). (Bernardi et

al., 2006)

Figure 1: Robot Kamanbaré.

1

Kamanbaré is the word in the Tupi indian language for

chameleon.

The prototype of the Kamanbaré platform presented

in this work was developed considering certain

capabilities (abilities), such as: locomotion in

irregular environments (unpredictability of the

branch complexity that compose a tree),

surmounting obstacles (nodes and small twigs), tree

climbing and descent without risking stability, and

keeping low structural weight (mechanics +

electronics + batteries). (Bernardi et al., 2006)

Each leg has three rigid links connected by two

rotational joints with one degree-of-freedom (d.o.f.)

each. The first link is connected to the platform by a

two d.o.f. rotational joint (Fig. 2).

Figure 2: Limb of the Kamanbaré Platform.

All joins are controlled by DC motors. The control

problem for mobile robot is the problem of

determining the time history of join required to

cause the end-effectors (the gripper) executed a

commanded motion.

There are many control techniques and

methodologies that can be applied to the control of

limbed robots. The particular control method chosen

as well as the manner in which it is implemented can

have a significant impact on the performance of the

robot and consequently on the range of its possible

applications. Optimal control of energy can be an

interesting policy when the robot must operate

autonomously for a long time. The control problem

for the tree climbing robot considered here is to

determine the time history of each limb joint

required to cause the leg to move from an initial

angle to a final one in such a way that the energy

loss in the motors is minimal.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

246

2 FORMULATION AND

SOLUTION OF THE OPTIMAL

CONTROL PROBLEM

2.1 The State Space Model

This work consider the control strategy named

independent joint control. In this type of control

each axis of the limb is controlled as a single input

/single output system. Any coupling effects due to

the motion of the others links is either ignored or

treated as a disturbance. (Spont et al., 1989)

The space state model that describes the dynamics of

the DC motor located at the i-th joint (

ni

≤

≤1 ) of

the leg can be expressed by the equations:

BuAxx

+

=

(1)

τ

EDuCxy ++=

(2)

where

⎥

⎦

⎤

⎢

⎣

⎡

−

=

Jb

A

/0

10

,

(3)

⎥

⎦

⎤

⎢

⎣

⎡

=

JK

B

m

/

0

,

(4)

[]

ab

RKC /0 −= ,

(5)

a

RD /1= ,

(6)

()

ma

KRrE /= ,

(7)

and

m

m

x

θ

θ

⎡⎤

=

⎢⎥

⎣⎦

,

(8)

m

r

uV

K

τ

=−

.

(9)

J

is the moment of inertia of the rotor,

b

is the

viscous damping coefficient of the mechanical

system,

V is the armature voltage (control variable),

a

R

is the armature resistance,

a

iY = is the

armature current,

m

K

is the torque coefficient of the

motor,

b

K

is the counter-electromotive coefficient,

τ

is the load torque, 1

<

r

is the gear reduction

factor,

m

θ

is the angular position of the rotor and

m

θ

is the angular speed of the rotor. Notice that the

input variable

u depends on both the control

variable

V

and the load torque

τ

, which also

depends on

V through

m

θ

and

m

θ

.

The load torque

τ

, which depends on the robot

dynamics, is given by : (Spong, 1989)

(

)

(

)

[

]

(

)

(

)

2

iz

M

qq Bq qq Cq q Gq

τ

⎡⎤

=+ + +

⎣⎦

(10)

where

(

)

M

q

is the leg inertia matrix,

(

)

Bq

is the

Coriolis torque matrix,

(

)

Cq

is the centrifugal

torque matrix,

(

)

Gq

is the gravitational torque

vector,

[

]

[

]

12 13 1

T

iz n n

qq qq qq q q

−

=

…

,

:1 ,1iz in zn

∀

≠<<<<

222 2

12

⎡

⎤⎡ ⎤

=

⎣

⎦⎣ ⎦

…

T

n

qqq q

and

[

]

T

n

qqqq …

21

=

,

where

i

q , ni

≤

≤

1 , is the generalized coordinate

of joint

i and n is the number of joints of the leg.

Some dynamical effects like friction were not

included in (10) although they may be significant for

some limbs. In addition, a more detailed model of

the leg dynamics could include various sources of

flexibility, defection of the links under load and

vibrations (Borrow et al., 2004). Nevertheless, this

model is sufficiently accurate for our purposes since

these effects are not significant for the leg under

consideration.

One of the characteristics of the independent joint

model is that

τ

is multiplied by the gear

reduction

r . Thus effect of the gear ratio is to

reducing the coupling nonlinearities presents in

dynamics of the limbs.

The solution to equation (1) is given by:

() ( )

()

()

0

0

t

At

At

x

tex e Bu d

ς

ς

ς

−

=+

∫

(11)

2.2 The Optimal Control Problem

In this section it is assumed that

τ

(t) is known for all

t in the interval [0 t

f

]. The performance index

adopted is the Joule loss in the armature resistance

of each motor during the motion:

A QUADRATIC PROGRAMMING APPROACH TO THE MINIMUM ENERGY PROBLEM OF A MOBILE ROBOT

247

∫

=

f

t

dtP

0

min

ε

(12)

where

f

t

is the time required to move the joint from

the initial to the final position, and

P is the power

dissipated:

where

Y was defined in (2).

The optimal control problem is subject to the

following constraints:

() () ()

2

1

b

m

aaam

K

r

x

tut tI

RRRK

τ

−++ ≤

,

(14)

() () ()

2

1

b

m

aaam

K

r

I

xt ut t

RRRK

τ

−≤− + +

,

(15)

(

)

mm

VutV−≤ ≤

,

(16)

()

1

f

f

x

tqr=

,

(17)

(

)

2

0

f

xt =

,

(18)

where

m

I and

m

V are, respectively, the maximum

armature current and maximum armature voltage of

the motor and

0

f

tt

⎡⎤

∈

⎣⎦

. With no loss of

generality we take

1

(0) 0x =

. Considering the motor

initially at rest,

2

(0) 0x =

.

This type of problem is hard to solve and generally

involve a great computational effort (Kirk, 1998).

Mobile robots require a quick solution and to solve it

in real-time is practically impossible. These are

among the reasons for which we decided to look for

another kind of solution.

2.3 Discretization

Let us to define the time-step as:

1

f

kk

t

ttt

N

−

Δ= = −

(1 )kN<≤

(19)

where

N can be chosen sufficiently large to

discretize

f

t . Then it is assumed that

(

)

ut

is a

stepwise constant function and

k

u is used to denote

the value of

(

)

ut

for all t in the k -th time interval

1

[,)

kk

tt

−

.

Taking into account equations (11), (12), (13) and

(19), the functional

ε

can be rewritten as:

2

11

min

NN

kaa

kk

P

tRit

ε

==

=

Δ= Δ

∑∑

(20)

and the solution of system (1) as:

(

)

k

At

kk

x

teIU=Γ

(21)

where,

12

1

00

N

N

t

tt

AA A

t

eBd eBd eBd

ςς ς

ς

ςς

−

−− −

Γ= + + +

∫∫ ∫

…

,

(22)

[

]

12

T

N

Uuu u= …

(23)

and

1

2

000

000

00 0

000

k

n

e

e

I

e

⎡

⎤

⎢

⎥

⎢

⎥

=

⎢

⎥

⎢

⎥

⎣

⎦

(24)

Where

i

e = 1 for 1 ik

≤

≤ and

i

e = 0 for

kiN

<

≤ .

Matrix

Γ

can be calculated offline since it depends

only on the motor parameters.

From equations (20) and (21) it is possible rewrite

(20) as:

where matrices

Q and K depend only on the motor

parameters and

σ

is a constant. The constraints for

the problem are:

2

1

k

b

mkkm

aaam

K

r

Ixu I

RRRK

τ

−

≤− + + ≤

(26)

mkm

VuV

−

≤≤

(27)

1

N

f

x

qr

=

(28)

2

0

N

x

=

(29)

where constraints (26) and (27) apply for all

k ,

.1 Nk

≤

≤

Since

σ

is a constant, it is not relevant for the

optimization.

[

]

[

]

22

'' '' ''

aa a a

P

Ri RY R xC u D E Cx Du E

τ

τ

== = ++ ++

(13)

()

1

min

2

TT

UUQUKU

ε

τσ

=

++

(25)

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

248

The problem given by equations (25)-(29) has thus

the form of a Quadratic Programming problem

which is certainly the kind of nonlinear

programming problem closest to linear programming

from analytical and computational point of view.

Solution for this kind of problem can be efficiently

found by numerical methods. (Avriel, 1976)

(Winston, 1995).

2.4 The Algorithm

An iterative algorithm to solve the minimum energy

problem based in equations (13) and (20) is

proposed in this section.

To start the algorithm it is assumed that

0:

0

≡=

kk

τ

τ

for all k , .1 Nk ≤≤ Then

Quadratic Programming problem of minimizing the

function (20) subject to constraints (26) to (29) is

solved. Denote by

0*

k

U the optimal solution for this

problem. Using equation (17) and recalling equation

(1), both the motor angular position

)(

0

k

m

θ

and

angular speed

)(

0

k

m

θ

can be evaluated for all k ,

.1 Nk ≤≤

The second step of the algorithm begins by using the

leg dynamical equations (10) to evaluate a new

torque time history

1

k

τ

for all

k

,

.1 Nk ≤≤

The

new Quadratic Programming problem is then solved

and

1*

k

U is obtained. )(

1

k

m

θ

and )(

1

k

m

θ

are

evaluated for all

k , .1 Nk

≤

≤

The process is repeated until

1jj

kk

τ

τ

τε

+

−< for a

given accuracy

τ

ε

and two consecutive steps j and

j+1. When convergence is attained the optimal

vector of armature voltages

*1+j

V

can be evaluated

using equation (9).

The algorithm is expected to converge since the gear

reduction ratio

r is generally small and the effect of

the torque on the motor dynamics is correspondingly

small too.

The algorithm may thus be summarized as:

Algorithm

0

0

1

k

j

τ

=

=

−

repeat

1

j

j

=

+

()

*

1

min

2

: (26) to (29)

001

0

TjT

k

jjj

kkk

m

UUQUKU

subject to constrains equations

xxU

K

b

J

J

ετ

⎧

=+

⎪

⎨

⎪

⎩

⎡⎤

⎡⎤

⎢⎥⎢⎥

=+

⎢⎥

⎢⎥

−

⎣⎦

⎣⎦

[][]

() ()

[]

() ()

12

TT

jj

kk

j

k

qqq rxxx

M

qq Bq qq Cq q Gq

τ

+

=

⎡⎤

=+ + +

⎣⎦

until

(

)

(

)

1

max

jj

kk

τ

τ

τε

+

−≤

3 SIMULATION RESULTS

This section presents the results obtained from the

application of the algorithm above to a leg similar to

that of the Kamanbaré platform.

The algorithm code was written in MatLab. The

following data were used:

2=

f

ts

,

10

=

N

,

11

10

−

=

τ

ε

and

012

0

4

NN N

T

T

mmm

π

θθθ π

⎡⎤

⎡⎤

=−

⎢⎥

⎣⎦

⎣⎦

Algorithm convergence occurred in 15 iterations.

Table 1 shows the algorithm steps until the optimal

solution is reached. The overall processing time was

quite small.

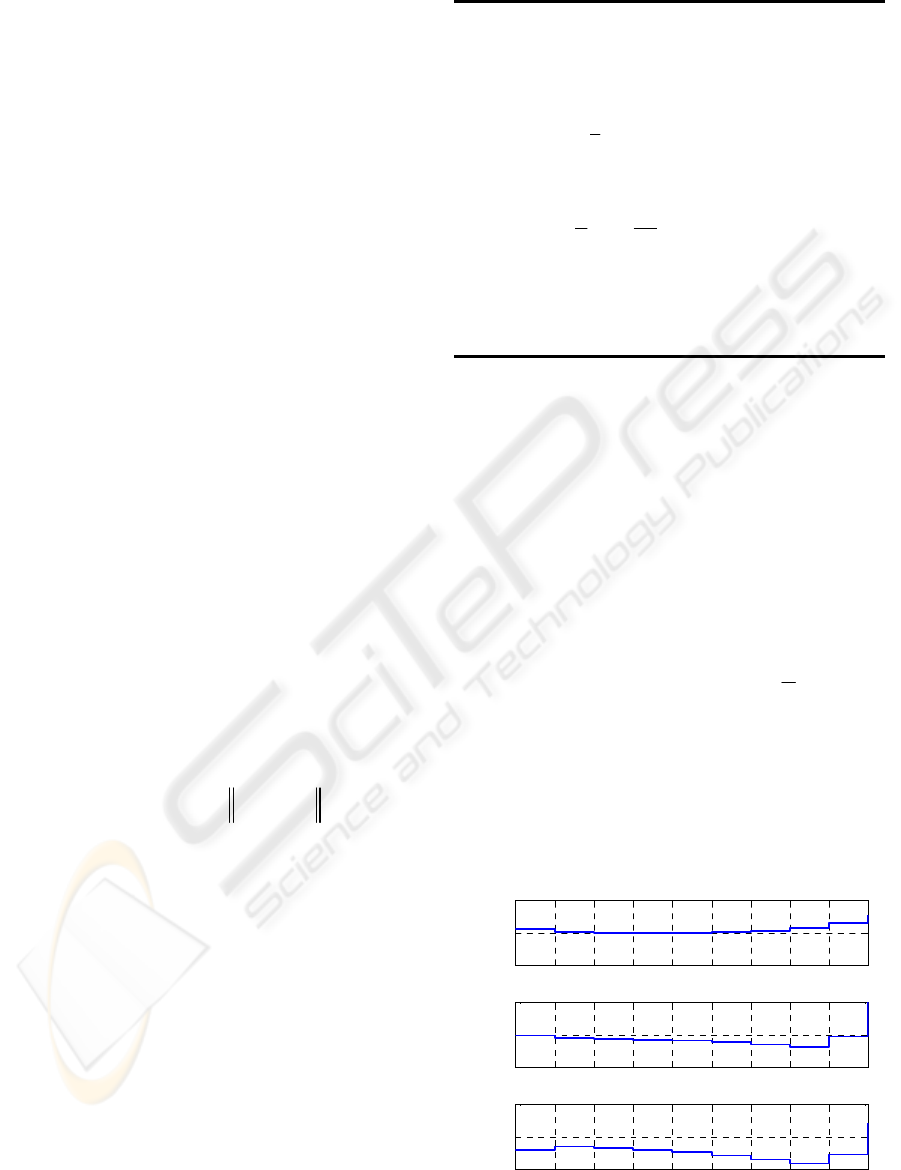

Figure 3 show the optimal solution

*

15

k

U

for each

motor.

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-0.5

0

0.5

Optimal Control

Voltage 1 [volts]

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-0.1

0

0.1

Optimal Control

Voltage 2 [volts]

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-0.1

0

0.1

Optimal Control

Voltage 3 [volts]

Time [s]

Figure 3: Optimal Solution.

A QUADRATIC PROGRAMMING APPROACH TO THE MINIMUM ENERGY PROBLEM OF A MOBILE ROBOT

249

Table 1: Minimum Energy Consumption.

Energy Consumption

1

N

k

k

Pt

ε

=

=

Δ

∑

[watts]

Iteration (j)

Joint 1 (Motor 1) Joint 2 (Motor 2) Joint 3 (Motor 3)

1 0.22583525809518 0 0.01411470363095

2 0.54691612008194 0.00249201214070 0.02563789026998

3 0.60424685648279 0.00151916407557 0.02084265484899

4 0.60913169232854 0.00162074115964 0.02201351589222

5 0.60878562782495 0.00159940182719 0.02201765824694

6 0.60878328339302 0.00160200730314 0.02202687314770

7 0.60877614492969 0.00160176202487 0.02202629388348

8 0.60877639908587 0.00160179288124 0.02202637161877

9 0.60877635993567 0.00160178879636 0.02202635576755

10 0.60877636906069 0.00160178928402 0.02202635725193

11 0.60877636847905 0.00160178921712 0.02202635705179

12 0.60877636859543 0.00160178922523 0.02202635707836

13 0.60877636858174 0.00160178922422 0.02202635707548

14 0.60877636858322 0.00160178922435 0.02202635707588

15 0.60877636858300 0.00160178922433 0.02202635707583

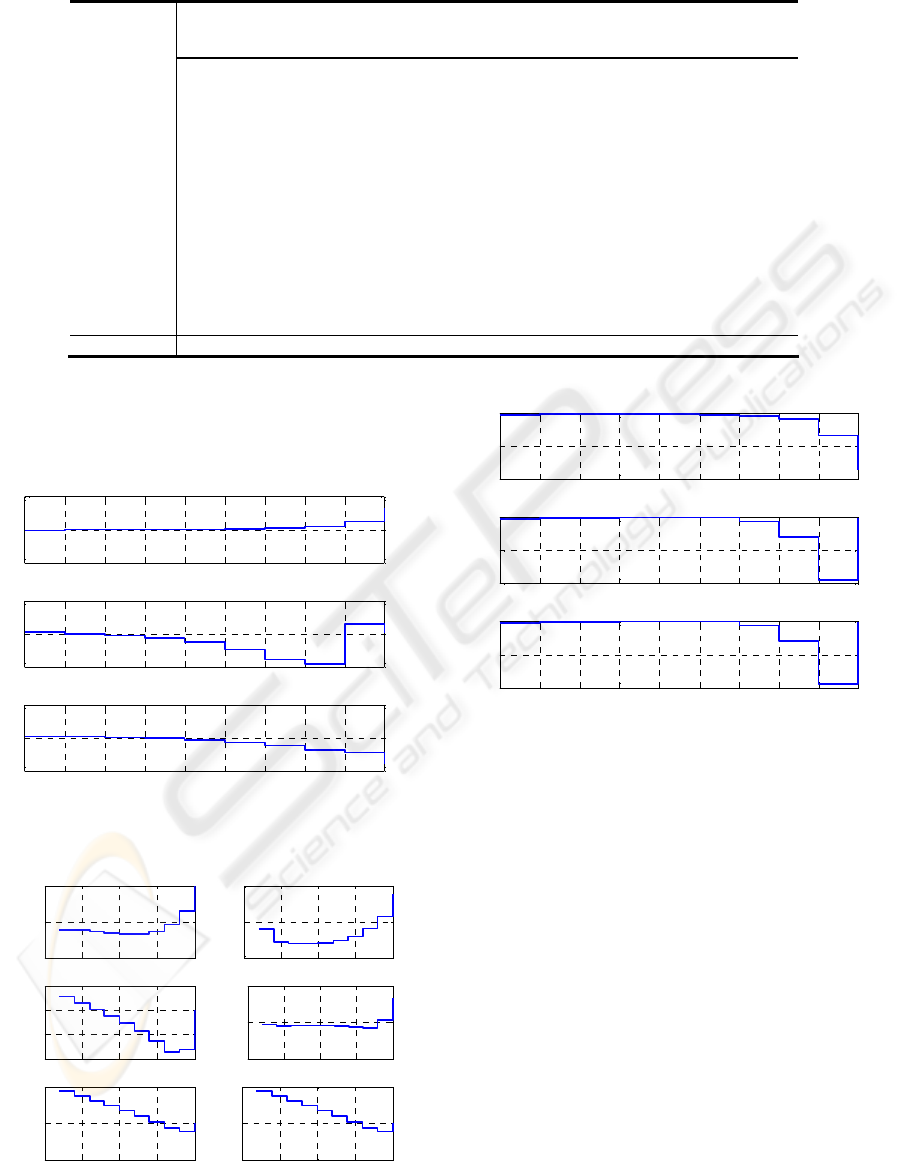

Figures 4 and 5 show kinematics of each joint; the

angular position and the speed and acceleration

achieved for the optimal control

*

15

k

U

.

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-5

0

5

rad

Join Position 1

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-0.1

0

0.1

rad

Join Position 2

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-1

0

1

rad

Join Position 3

Time [ s]

Figure 4: Joints Positions.

0 0.5 1 1.5 2

-0.1

-0.05

0

Angular Speed

[rad/s]

0 0.5 1 1.5 2

0

0.1

0.2

Angular Acceleration

[rad/s

2

]

0 0.5 1 1.5 2

-0.02

-0.01

0

0.01

[rad/s]

0 0.5 1 1.5 2

-0.1

0

0.1

[rad/s

2

]

0 0.5 1 1.5 2

-0.05

0

0.05

[rad/s]

Time [s]

0 0.5 1 1.5 2

-0.05

0

0.05

[rad/s

2

]

Time [ s ]

Figure 5: Speed’s Joints and Acceleration’s Joints.

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-10

0

10

τ

[n]

Torque 1

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-4

-2

0

τ

[n]

Torque 2

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-4

-2

0

Tim e[s]

τ

[n]

Torque 3

Figure 6: Torques for each motor.

In this particularly case the motor’s 2 and 3 have the

same torque.

4 CONCLUSIONS

This paper discussed the formulation and solution of

an important problem related to mobile robotics: the

minimum energy loss problem.

An optimal control problem was formulated to

represent this case. After discretization in time the

optimal control problem was rewritten in the form of

a Quadratic Programming problem whose solution

could be obtained efficiently. The algorithm was

tested for a leg similar to that of the Kamanbaré

platform.

Although the whole problem is nonlinear and quite

complex the algorithm converged quickly in all the

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

250

tests performed by now. It is thus expected that the it

can be used to operate in real-time.

REFERENCES

Abderrahim, M., Balaguer, C., Gimenez, A., Pastor, J. M.,

Padrón, V. M., 1999. ROMA: A Climbing Robot for

Inspection Operations. In, Proceedings of the IEEE

International Conference on Robotics and

Automattion, Vol 3, pp 10-15.

Armada, M., Santos, P. G. de, Jiménez, M. A., Prieto, M.

2003. Application of CLAWAR Machines. In, The

International Journal of Robotics Research. Vol. 22,

nº3–4, pp. 251-264.

Avriel, M, 1976. Nonlinear Programming. Analysis and

Methods. Prentice-Hall. New Jersey, 1

st

edition.

Bernardi, R., Cruz, J.J. 2006. KAMANBARÉ. A tree-

climbing biomimetic robotic platform for

environmental research. In, International Conference

on Informatics in Control, Automation and Robotics.

Bobrow, J.E., Park, F.C., Sideris, A. 2004. Recent

Advances on the Algorithmic Optimization of Robot

Motion. Departament of Mechanical and Aerospace

Engineering, University of California.

Dudek, G., Jenkin, M., 2000. Computational Principles of

mobile Robotics. Cambridge Press. 1

st

edition.

Galvez, J. A., Santos, P. G. de, Pfeiffer, F., 2001. Intrinsic

Tactile Sensing for the Optimization of Force

Distribution in a Pipe Crawling Robot. In,

IEEE/ASME Transactions on Mechatronics, Vol. 6,

n°1.

Garg, D. P., Kumar, M., 2002. Optimization Thecniques

applied to multiple manipulators for path planning

and torque minimization. In Eng. Applications Art,

Int., Vol 15, pp 241-252.

Kirk, D., 1998. Optimal Control Theory an Introduction.

Dover Publication, New York, 2

nd

edition.

Lin, Ch., Chang P., Luh, J.Y.S. 1983 Formulation and

Optimization of Cubic Polynomial Joint Trajectories

for Industrial Robots. In IEEE Transactions on

Automatic Control, Vol AC-28, No 12, December.

Luk, B., Cooke, D., Galt, S., Collie, A., Chen, S. 2005.

Intelligent legged climbing service robot for remote

Maintenance applications in hazardous environments.

In Robotics and Autonomous Systems. Accepted June

2005.

Luo, X., Fan, X., Zhang, H., Chen T., 2004. Integrated

Optimization of Trajectories Planning for Robots

Manipulators Based on Intensified Evolutionary

Programming. Proceedings of the 2004 IEEE,

International Conference on Robotics and

Biomimetics.

Saundersa, A., Goldmanb, D., Fullb,R., Buehlera, M.

2006. The RiSE Climbing Robot: Body and Leg

Design. In, Proceeding of SPIE, Vol. 6230, 623017.

Spong, M., Vidyasagar, M., 1989. Robot Dynamics and

Control. John Wiley & Sons, Canada, 1

st

edition.

Virk, G. S. 2005. The CLAWAR Project: Developments in

The Oldest Robotics Thematic Network. IEEE

Robotics & Automation Magazine, pp. 14-20.

Winston, W. 1995. Introduction to Mathematical

Programming. Applications and Algorithms. Duxbury

Press. California, 2

nd

edition.

A QUADRATIC PROGRAMMING APPROACH TO THE MINIMUM ENERGY PROBLEM OF A MOBILE ROBOT

251