IMPEDANCE MATCHING CONTROLLER FOR AN INDUCTIVELY

COUPLED PLASMA CHAMBER

L-type Matching Network Automatic Controller

Giorgio Bacelli, John V. Ringwood and Petar Iordanov

Department of Electronic Engineering, National University of Ireland, Maynooth, Ireland

Keywords:

Automatic Impedance Matching, Matching Network, Impedance Sensor, Inductively Coupled Plasma.

Abstract:

Plasma processing is used in a variety of industrial systems, including semiconductor manufacture (deposition

and etching) and accurate control of the impedance matching network is vital if repeatable quality is to be

achieved at the manufacturing process output. Typically, impedance matching networks employ series (tune)

and parallel (load) capacitors to drive the reflection coefficient on the load side of the network to zero. The

reflection coefficient is normally represented by real and imaginary parts, giving two variables to be controlled

using the load and tune capacitors. The resulting problem is therefore a nonlinear, multivariable control prob-

lem. Current industrial impedance matching units employ simple single-loop proportional controllers, which

take no account of interaction between individual channels and, in many cases, may fail to tune altogether, if

the starting point is far away from the matching point. A hierarchical feedback controller is developed which,

at the upper level, performs a single-loop tuning, but with the important addition of a variable sign feedback

gain. When convergence to a region in the neighbourhood of the matching point is achieved, a dual single-loop

controller takes over, which gives fine tuning of the matching network.

1 INTRODUCTION

The BAsic Radio frequency Inductive System

(BARIS) is an experimental inductively coupled

plasma chamber used to study the closed-loop con-

trol of plasma states. Inductively coupled plasma is

ignited by an electromagnetic field irradiated from

an antenna connected to a Radio Frequency (RF)

power supply. An Impedance Matching Unit (IMU)

is used to match the impedance of the antenna to the

impedance of the generator, in order to deliver the

maximum power to the plasma. The IMU is com-

posed of a matching network, a Phase and Magni-

tude Detector (PMD) and a controller that automat-

ically tunes the matching network using the informa-

tion supplied by the PMD. Each time plasma param-

eters or plasma state set-points are changed (i.e. RF

power, pressure, gas mixture), the plasma impedance

also changes. In addition, when the controller is tun-

ing the matching network, the reflection coefficient

is decreasing, therefore the power delivered to the

plasma is increasing causing a variation of the plasma

states and, as a consequence, a variation of plasma

impedance. The main issue regarding the existing

driver circuitry associated with the original controller

is the global convergence (Mazza, 1970), that is, if the

initial conditions of the system are far away from the

matching point, the controller may not be able to tune

the matching network.

The automatic impedance matching problem has been

solved using neural networks (Vai and Prasad, 1993),

genetic algorithms (Thompson and Fidler, 2000) (Sun

and J.K., 1997) (Sun and J.K., 1999), deterministic

tuning algorithms with look-up tables (Moritz and

Sun, 2001) and using adaptive systems (Parro and

Pait, 2003) (Ida et al., 2004c) (Ida et al., 2004a)

(De Mingo et al., 2004) (Ida et al., 2004b); nonlinear

control systems have been also considered (Cottee,

2003). In all of the above mentioned cases, the load

impedance is not affected by the matching conditions

while, in the case studied (inductively coupled plasma

discharges), the load impedance is varying during the

matching process. In this paper a hierarchal struc-

ture controller has been designed; it is composed of

202

Bacelli G., V. Ringwood J. and Iordanov P. (2007).

IMPEDANCE MATCHING CONTROLLER FOR AN INDUCTIVELY COUPLED PLASMA CHAMBER - L-type Matching Network Automatic Controller.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 202-207

DOI: 10.5220/0001648802020207

Copyright

c

SciTePress

a higher level coarse controller that drives the sys-

tem close to the matching point, and lower level feed-

back controller for the fine tuning. An impedance

sensor has been also designed to supply more reliable

measurements of the reflection coefficient to the con-

troller.

2 BARIS IMPEDANCE

MATCHING

The BARIS is an experimental plasma chamber, used

to study plasma phenomenon for applications in semi-

conductor manufacturing, and generates an argon and

oxygen plasma that is ignited by a 13.56MHz mag-

netic field irradiated from an antenna. The main parts

that compose this device are the plasma discharge

chamber, the RF power supply, the matching unit and

the real time monitoring and control of the system.

Match

network

Plasma

Antenna

Ar O2

Vacuum

pump

Gate

valve

Discharge chamber

PMD

RF

power

supply

Mass flow

controllers

Impedance

matching

controller

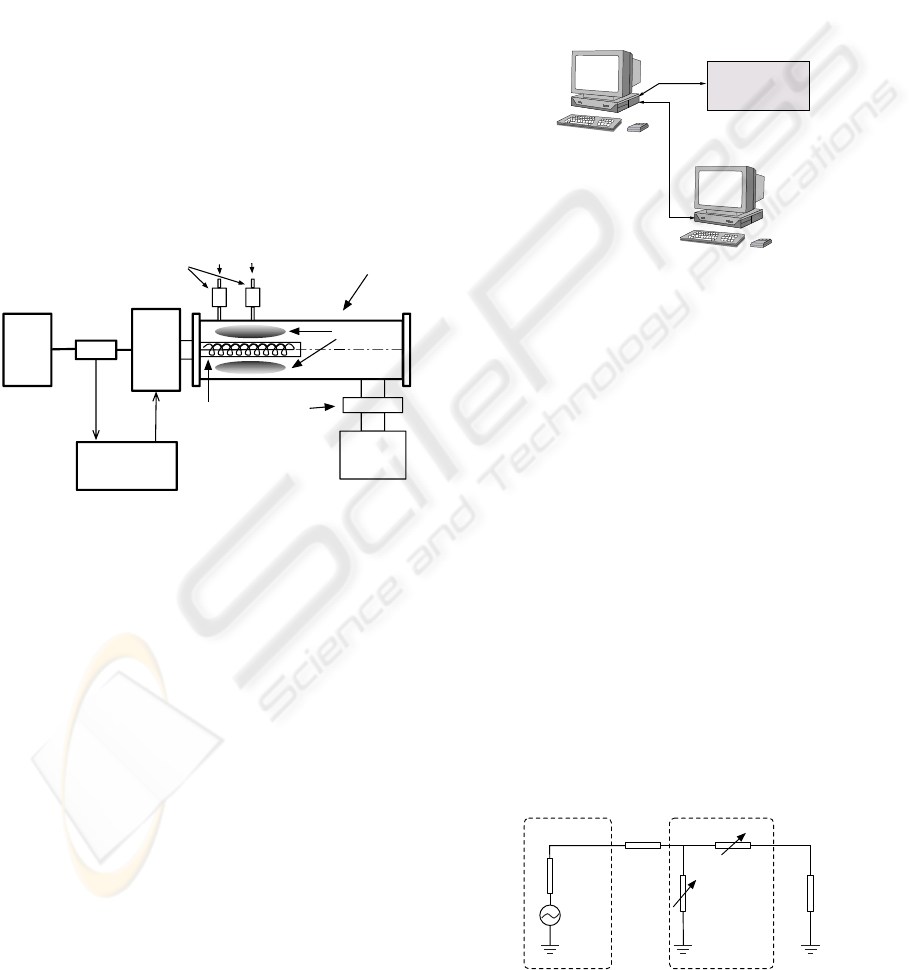

Figure 1: BARIS block diagram.

2.1 Plasma Discharge Chamber

The plasma discharge chamber is a stainless steel

cylindrical vacuum chamber of internal diameter

200mm and length 900mm (Fig.1). The helical an-

tenna is placed along the axis of the chamber, inside

a sealed 50mm diameter quartz tube, in order to keep

it outside of the vacuum region. The gasses are in-

jected into the chamber by the mass flow controllers

and are evacuated through the gate valve using a vac-

uum pump. The pressure at which the plasma is ig-

nited is usually between 10mTorr and 100mTorr, and

it is regulated by adjusting the position of the gate

valve and the gas flows.

2.2 RF Power Supply

The RF power generator is the ACG-10B made by

MKS Instruments, which can deliver a maximum of

1000W at a frequency of 13.56 MHz into a 50Ω load.

2.3 Plasma Process Monitoring and

Control

The control of the plasma process is achieved using

the Matlab xPC Target anvironment. This system

is composed of two PCs, one running Windows XP

(Host PC) and the other one running the real time xPC

Target operative system (Target PC) as in Fig.2. The

RS232 (TCP/IP)

Analog & Digital

Host PC

BARIS Plasma System

Interfaces

Target PC

Figure 2: Matching network schematic.

Target PC is equipped with analog and digital inter-

faces in order to read data from sensors and control

actuators and other devices. The role of the Host PC

is to upload the software to be executed in real time by

the Target PC, to start it, stop it and to monitor it while

running using the RS-232 interface. This kind of con-

figuration gives a considerable amount of computa-

tional power, allowing the implementation of com-

plex control algorithm for the plasma process (Ior-

danov et al., 2006).

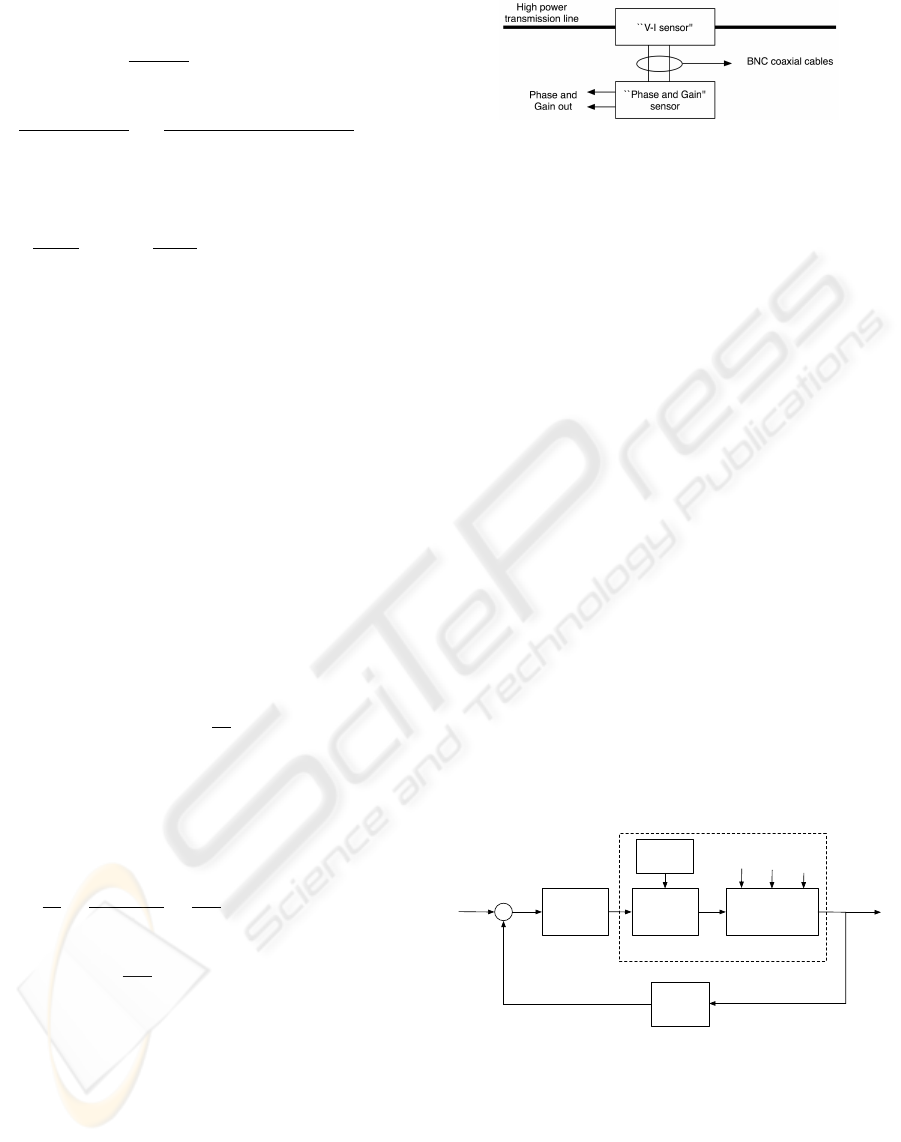

2.4 Matching Network

The matching network transforms the plasma load

impedance (Z

PL

) into the Z

0

= 50Ω characteristic

impedance of the transmission line. It is a basic

“L” configuration (Fig.3) characterized by eq.(1) and

composed of “Load” (C

L

) and “Tune”(C

T

) variable

capacitors , both driven by servomotors.

Z

0

Z

L

Z

T

Z

PL

Z

Int

Z

0

=

RF Generator Matching Network

Figure 3: Matching network schematic.

IMPEDANCE MATCHING CONTROLLER FOR AN INDUCTIVELY COUPLED PLASMA CHAMBER - L-type

Matching Network Automatic Controller

203

Z

PL

=

Z

0

Z

L

Z

0

+ Z

L

+ Z

T

∗

=

Z

0

(1+ ω

2

Z

2

0

C

2

L

)

+ j

(1+ ω

2

Z

2

0

C

L

(C

L

+C

T

))

ωC

T

(1+ ω

2

Z

2

0

C

2

L

)

∗

(1)

with:

Z

T

=

1

jωC

T

, Z

L

=

1

jωC

L

, ω = 2π13.56·10

6

rad/s

where [...]

∗

denotes complex conjugation and ω is the

circular frequency.

3 SENSOR

The impedance sensor is based on the Analog Devices

AD8302 phase and gain detector, which gives infor-

mation about the amplitude ratio and the phase differ-

ence between two signals. The inputs of the circuit

are two sinusoidal signals proportional to the volt-

age and the current waves in the power line respec-

tively. By measuring the ratio between voltage and

current and their phase difference, it is possible to cal-

culate the impedance or the reflection coefficient. The

impedance of a load connected in a transmission line

is defined as (2),

Z

L

=

V

0

I

0

(2)

where V

0

and I

0

are the vectors of voltage and cur-

rent respectively measured on the load and Z

L

the load

impedance. The last expression can be written using

the vectors in the exponential form as in (3):

Z

L

=

V

0

I

0

=

|V

0

| · e

jθ

V

|I

0

| · e

jθ

I

=

|V

0

|

|I

0

|

·e

j(θ

V

−θ

I

)

= G· e

∆θ

(3)

G =

|V

0

|

|I

0

|

∆θ = (θ

V

− θ

I

)

where G is the ratio between the voltage and the

current magnitudes and ∆θ is the phase difference be-

tween voltage and current waves. The impedance sen-

sor provides two analog signals that are proportional

to G and ∆θ. This device is divided in two parts,

the “V-I Sensor” and the “Phase and Gain Sensor”,

each one enclosed in a shielded aluminum box in or-

der to attenuate the effect of radio frequency distur-

bances (Fig.4). The former is connected along the

high power transmission line, and supplies two sig-

nals proportional to the voltage and the current of the

Figure 4: Block schematic of the impedance sensor.

main line. The “Phase and Gain Sensor” takes the

output signals of the “V-I Sensor” and provides their

phase difference and amplitude ratio. At the inputs of

the AD8302 there are two integrated low pass filters

(MINI-CIRCUITS SCLF-10.7) in order to remove the

harmonics components.

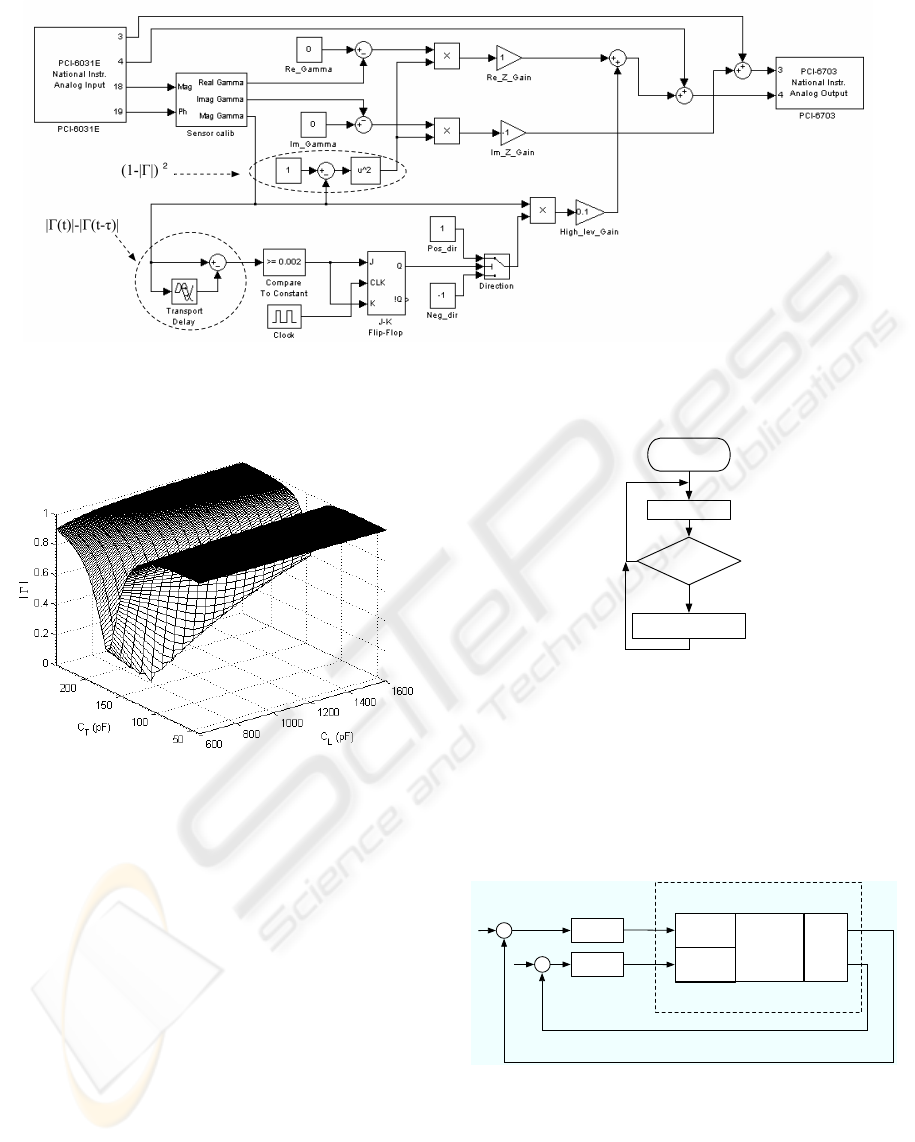

4 CONTROLLER

The main property required of the controller is global

convergence, that is the ability to drive the capaci-

tors to the matching point from any starting condition.

A model of the plasma impedance has been studied

(Keville et al., 2006), but it is quite complicated, not

suitable for the problem of the impedance matching

because it is computationally demanding. The dy-

namics of the plasma process are stable and time in-

variant, in addition the part related to the RF power

delivered P

D

(Fig.5) is much faster than the dynamic

of the matching unit, therefore it has been decided to

consider the variation of the plasma impedance during

the matching as a static disturbance. In this case the

only dynamics terms considered in the system are due

to the servomotors described by G(s). Considering

Controller

Matchbox

G(s)

Imp

sensor

+

-

RF

generator

Plasma

Ar

flow

O2

flow

Gate

Valve

BARIS

PD

Figure 5: Block schematic of the BARIS.

the magnitude of the reflection coefficient |Γ| as a

function of the capacitorsC

L

andC

T

, for a given value

of the load impedance (Z

PL

), using (1) is possible to

plot the graph in Fig.6. The main characteristic of this

function is that there is only one critical point corre-

sponding to the global minimum, that is the matching

point (|Γ| = 0). In this situation, the control problem

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

204

Figure 8: Simulink implementation of the hierarchical controller.

Figure 6: |Γ| as function of (C

L

,C

T

).

can be considered as a function minimization prob-

lem. A first possible approach can be to drive the

capacitors in the opposite direction of the gradient

of |Γ|, but the plasma impedance is variable and its

value it is unknown, therefore it is not possible to cal-

culate this vector. From Fig.6 is possible to see that

|Γ| is significantly more sensitive respect to C

T

than

C

L

. We have decided to use a hierarchical structure

composed of two parts: a coarse and a fine tune con-

troller. The coarse controller brings the system close

to the matching point, where the fine tune controller

takes over and drives the capacitors to the final po-

sition. The coarse controller is based on an iterative

minimization algorithm for |Γ| respect toC

T

, as in the

flow chart in fig.7. At regular intervals of time δ it

checks if the reflection coefficient and if it is increas-

ing, it inverts the direction of movement ofC

T

. When

Start

Wait !c

|!(t)|>|!(t-")|

Change CT direction

YES

NO

Figure 7: Iterative minimum search algorithm flow chart.

the system is approaching to the matching point there

is a smooth transition between the coarse controller

and the fine tune controller. The fine tune controller

is a dual SISO proportional controller (Fig.9) in which

C

L

is driven by Im[Γ] and C

T

is driven by Re[Γ].

BARIS

Load Cap

Imp.

sensor

Tune Cap

MatchBox

0

0

+

+

-

-

Re[

Γ]

Im[

Γ]

Plasma

SISO

SISO

Figure 9: Block schematic of the fine tune controller.

4.1 Implementation

Fig.8 illustrates the Simulink implementation of the

controller. The AD converter provides measurements

IMPEDANCE MATCHING CONTROLLER FOR AN INDUCTIVELY COUPLED PLASMA CHAMBER - L-type

Matching Network Automatic Controller

205

of G and ∆θ at a sampling period of δ

f

= 20mS,

which is also the sampling rate used by the fine tune

controller. The coarse controller uses a sampling pe-

riod of δ

c

= 100mS. |Γ| is determined via eq (4) by

the fine tune controller, allowing the delayed value of

|Γ(t − τ)| to be available at the δ

c

sampling instants

(τ = 4δ

f

).

Γ =

Z

L

− Z

0

Z

L

+ Z

0

(4)

The coarse controller checks the variation of the re-

flection coefficient |Γ(t)| − |Γ(t − τ)|. If it is increas-

ing, the J-K flip-flop inverts the direction of move-

ment of C

T

. Since the speed of C

T

is proportional to

|Γ|, the controller can be considered as a proportional

controller. The gains of the fine tune SISO controllers

are multiplied by (1− |Γ|)

2

in order to reduce its ef-

fect in the non-convergence region, in which it tends

to drive the capacitors in the wrong direction. In this

way, when approaching to impedance matching con-

dition, |Γ| is decreasing and (1 − |Γ|)

2

is increasing,

and there is a smooth transition from the coarse to the

fine tune controller.

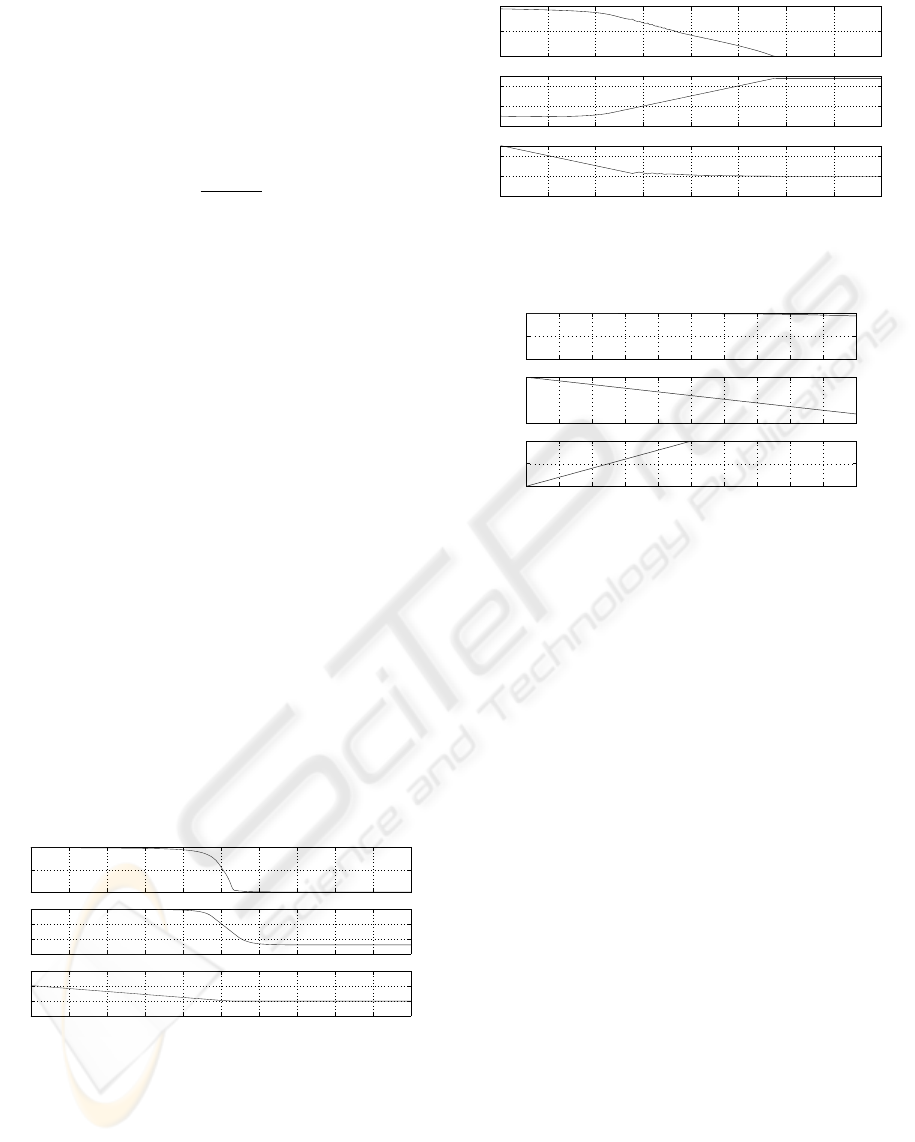

5 RESULTS

The controller has been tested both in simulation and

in the BARIS chamber. The simulation has been

performed using constant loads, and giving different

starting positions for the capacitors. Figs.10 and 11

show that the system converges both when the ini-

tial conditions are close and far away to the match-

ing point, that is the controller drives the capacitors in

the right direction in order to minimize |Γ|. Fig.12

0 1 2 3 4 5 6 7 8 9 10

0

0.5

1

| Γ |

0 1 2 3 4 5 6 7 8 9 10

4.7

4.8

4.9

Load pos (V)

0 1 2 3 4 5 6 7 8 9 10

1

2

3

4

Time (s)

Tune pos (V)

Figure 10: Simulation results with starting conditions close

to the matching point.

shows the behavior of the system when the fine tune

controller’s gains are not multiplied by (1 − |Γ|)

2

;

for a starting condition far away from the matching

point there is no convergence. In this case the coarse

controller can’t take over and the fine tune controller

drives the capacitors in the wrong direction.

0 5 10 15 20 25 30 35 40

0

0.5

1

|Γ|

0 5 10 15 20 25 30 35 40

0

2

4

Load pos (V)

0 5 10 15 20 25 30 35 40

0

2

4

Time (s)

Tune pos (V)

Figure 11: Hierarchal controller with starting conditions far

away from the matching point.

0 2 4 6 8 10 12 14 16 18 20

0

0.5

1

| Γ |

0 2 4 6 8 10 12 14 16 18 20

0

5

Load pos (V)

0 2 4 6 8 10 12 14 16 18 20

3

4

5

Time (s)

Tune pos (V)

Figure 12: Hierarchical controller, with no fine tune con-

troller gain attenuation.

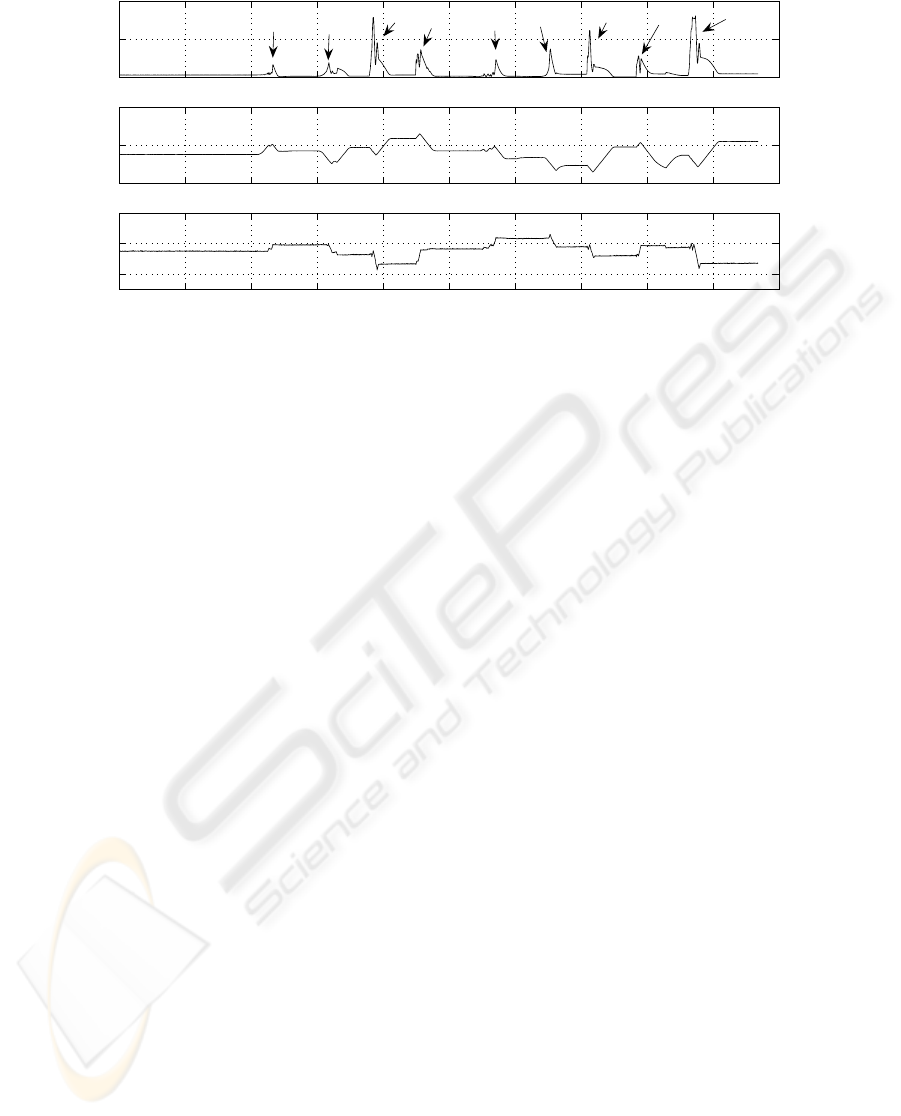

The controller has been tested also in the BARIS sys-

tem; this test has been performed using step func-

tions for the plasma variables (RF power, pressure, A

r

and O

2

flows). From the results of this test (Fig.13)

it is possible to see that each time the plasma state

changes, the controller tunes the matching network,

minimizing the magnitude of the reflection coefficient

|Γ|. In particular, mark A denotes a step in RF power,

mark B denotes a step in the gate valve position, mark

C denotes a step in O

2

flow and mark D denotes a step

in A

r

flow.

6 CONCLUSION

The hierarchical controller shows good performances

regarding the convergence. Besides, it is computa-

tionally not demanding, giving the possibility to be

implemented using a simple micro-controller. A mul-

tivariable controller, which observes the dependance

of Im[Z

PL

] on both C

L

and C

T

was also designed, but

requires an extensive look-up table and matrix inver-

sion, which is in stark contrast to the attractive sim-

plicity of the final controller presented above. The

underlying principle of the controller is based only

on the matching network structure, therefore it can be

implemented also in other applications using a similar

“L-type” matching network.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

206

0 10 20 30 40 50 60 70 80 90 100

0

0.5

1

|Γ|

0 10 20 30 40 50 60 70 80 90 100

1

2

3

Load pos (V)

0 10 20 30 40 50 60 70 80 90 100

3.6

3.8

4

Time (s)

Tune pos (V)

A

A

A

B

B

C

C

D

D

Figure 13: Experimental measurements in the BARIS.

ACKNOWLEDGEMENTS

The authors are grateful for the financial support of

the Irish Research Council for Science Engineering

and Technology (IRCSET) and INTEL Ireland Ltd.

REFERENCES

Cottee, C.J.; Duncan, S. (2003). Design of matching circuit

controllers for radio-frequency heating. IEEE Trans-

actions on Control Systems Technology, 11(1):91–

100.

De Mingo, J., Valdovinos, A., Crespo, A., Navarro, D., and

Garcia, P. (2004). An RF electronically controlled

impedance tuning network design and its application

to an antenna input impedance automatic matching

system. IEEE Transactions on Microwave Theory and

Techniques, 52(2):489–497.

Ida, I., Takada, J., Toda, T., and Oishi, Y. (2004a). An

adaptive impedance matching system and considera-

tions for a better performance. IEEE 5th International

Symposium on Multi-Dimensional Mobile Communi-

cations Proceedings, 2:563–567.

Ida, I., Takada, J., Toda, T., and Oishi, Y. (2004b). An adap-

tive impedance matching system and its application to

mobile antennas. IEEE Region 10 Conference, 3:543–

546.

Ida, I., Takada, J., Toda, T., and Oishi, Y. (2004c). An adap-

tive impedance matching system for mobile commu-

nication antennas. IEEE Antennas and Propagation

Society International Symposium, 3:3203–3206.

Iordanov, P., Keville, B., Ringwood, J., and Doherty, S.

(2006). On the closed-loop control of an argon plasma

process,. Irish Signals and Systems Conference.

Keville, B., Iordanov, P., Ringwood, J., Doherty, S.,

Faulkner, R., Soberon, F., and McCarter, A. (2006).

On the modeling and closed loop control of an induc-

tively coupled plasma chamber. IFAC Workshop on

Advanced Process Control for Semiconductor Manu-

facturing.

Mazza, N. (1970). Automatic impedance matching system

for RF sputtering. IBM Journal of Research and De-

velopment, 14(2).

Moritz, J. and Sun, Y. (2001). Frequency agile antenna tun-

ing and matching. IEE Eighth International Confer-

ence on HF Radio Systems and Techniques, 148:177–

182.

Parro, V. and Pait, F. (2003). Design of an automatic

impedance matching system for industrial continuous

microwave ovens. Sociedade Brasileira de Microon-

das Optoeletronica/IEEE Microwave and Optoelec-

tronics Conference, 2:20–23.

Sun, Y. and J.K., F. (1997). Component values ranges of

tunable impedance matching networks in rf commu-

nications systems. IEE HF Radio Systems and Tech-

niques, 441.

Sun, Y. and J.K., F. (1999). Antenna impedance matching

using genetic algorithms. IEE National Conference on

Antennas and Propagation, 441:31–36.

Thompson, M. and Fidler, J. (2000). Application of

the genetic algorithm and simulated annealing to LC

filter tuning. IEE Circuits, Devices and Systems,

474(2):169–174.

Vai, M. and Prasad, S. (1993). Automatic impedance

matching with a neural network. IEEE Microwave and

Guided Wave Letters, 3(10).

IMPEDANCE MATCHING CONTROLLER FOR AN INDUCTIVELY COUPLED PLASMA CHAMBER - L-type

Matching Network Automatic Controller

207