A Complexity Theory Approach

to Evolvable Production Systems

Regina Frei

1

, José Barata

1

and Giovanna Di Marzo Serugendo

2

1

New University of Lisbon, Quinta da Torre, 2829-516 Caparica, Portugal

2

Birkbeck (University of London), Malet Street, London WC1E 7HX, United Kingdom

Abstract. Evolvable Production Systems differ from Reconfigurable and Holo-

nic Manufacturing Systems by implying ontology-based process-specific

modularity at fine granularity with local intelligence and a distributed control

solution based on the Multi-Agent paradigm. Understanding the dynamics of

such complex production systems is not feasible with traditional engineering.

For creating the manufacturing systems of the future, engineers need to dare a

leap in their ways of thinking. Complexity Theory and Artificial Intelligence

can be a valuable source of inspiration for manufacturing engineers. This article

illustrates how ideas from these scientific areas fit the problems and open ques-

tions of manufacturing. Some concepts, as Self-Organization and Emergence,

need adaptation to be applicable in production systems; others simply require

the right perspective. Finally, a vision of future EPS is outlined.

1 Introduction

Evolvable Production Systems, short EPS [1, 2], are a concrete solution to the re-

quirements from the market such as stated within the Agile, Reconfigurable and Dis-

tributed approaches: they include high responsiveness, low down-times, ability to

handle small series with many variants, and on-the-fly changeability. Together with

ontology-based process-specific modules at fine granularity, a distributed control

system using the Multi-Agent paradigm permits to quickly and cost-effectively adapt

to ever-changing production requirements. The inspiration from Artificial Intelli-

gence, Mobile Robots, Complexity Theory and Biology as well as other emerging

sciences, as detailed in this article, will help EPS to cope with the turbulent environ-

ment, many-to-many multi-directional relationships and incomplete data and knowl-

edge.

EPS have similarities with the Bionic, Fractal and Holonic approaches [3, 4], but

besides considering system morphology, EPS strongly link product, process and sys-

tem (see Fig. 1) by the means of detailed ontologies. As EPS, Emergent Synthesis, a

Biological Manufacturing Systems approach [5], also focuses on self-organization,

Barata J., Frei R. and Di Marzo Serugendo G. (2007).

A Complexity Theory Approach to Evolvable Production Systems.

In Proceedings of the 3rd International Workshop on Multi-Agent Robotic Systems, pages 44-53

Copyright

c

SciTePress

however lacks mechanisms usable for practical implementation and the product-

process background.

The purpose of this article is to show that Complexity Theory, Artificial Intelli-

gence and related domains can be a valuable source of inspiration for manufacturing

engineers, and to illustrate in which way many ideas found in these scientific areas fit

the problems and open questions of the manufacturing world. Section 2 briefly ex-

plains the concept of evolvability in manufacturing as well as the distributed control

approach required for Evolvable Production Systems (EPS). Section 3 illustrates the

main sources of inspiration for new way of thinking, and some suitable concepts

found in Complexity Theory and Artificial Intelligence are detailed. Among others,

Emergence and Self-Organization are fundamental for EPS. Section 4 explains in

which way they could be understood, and what their implications for production

systems are. With their help, systems with far more advanced capabilities can be

imagined, as outlined in section 5: the vision of future production systems. A brief

summary follows in the conclusion.

2 Evolvable Production Systems

Evolvable Production Systems take complex systems in nature a metaphor for their

own need to continuously adapt to an ever-changing environment. In this sense and in

the context of manufacturing, Evolvability means the ability of complex systems to

co-evolve with the continuously changing requirements, to undergo changes of dif-

ferent significance, from small adaptations on-the-fly to more important transforma-

tions. Ontology-based modularity at a fine granularity level, the modules’ plugability

as well as a powerful control approach based on the multi-agent paradigm are funda-

mental.

Evolvability is an enabler for tomorrow’s production systems. Using a concept

similar to LEGO together with local intelligence, they allow the user to build any

required system and to modify it at wish. Through their module re-usability and life-

cycle support, EPS considerably lower the system cost and enable the automation

even in case of low production volumes and small lot sizes with frequent changes.

Thanks to standardized, open interfaces, systems can gradually evolve through the

addition, removal or exchange of modules.

The EPS control approach, avoiding re-programming, is crucial to ensure the

modules’ rapid plugability. Distributed approaches have the important advantage of

low complexity in the individual control parts. They are modular and, by their nature,

Product

Process

System

Fig. 1. Strong relations.

45

show emergent robustness when facing disturbances, component failure or other

critical situations. Agent technology ideally matches distributed systems [6]. Co-

BASA [7] is an example of a Multi-Agent Shop-Floor Control System which focuses

on rapid system reconfiguration. Equipment resources are represented by agents and

form coalitions according to the current production requirements, given by order

agents. In the operation phase, product agents ask to be treated in the way specified

by their process plan. Agents exhibit both reactive and proactive attitudes and are

referred to as “intelligent” and having “social behavior” based on a corresponding

ontology.

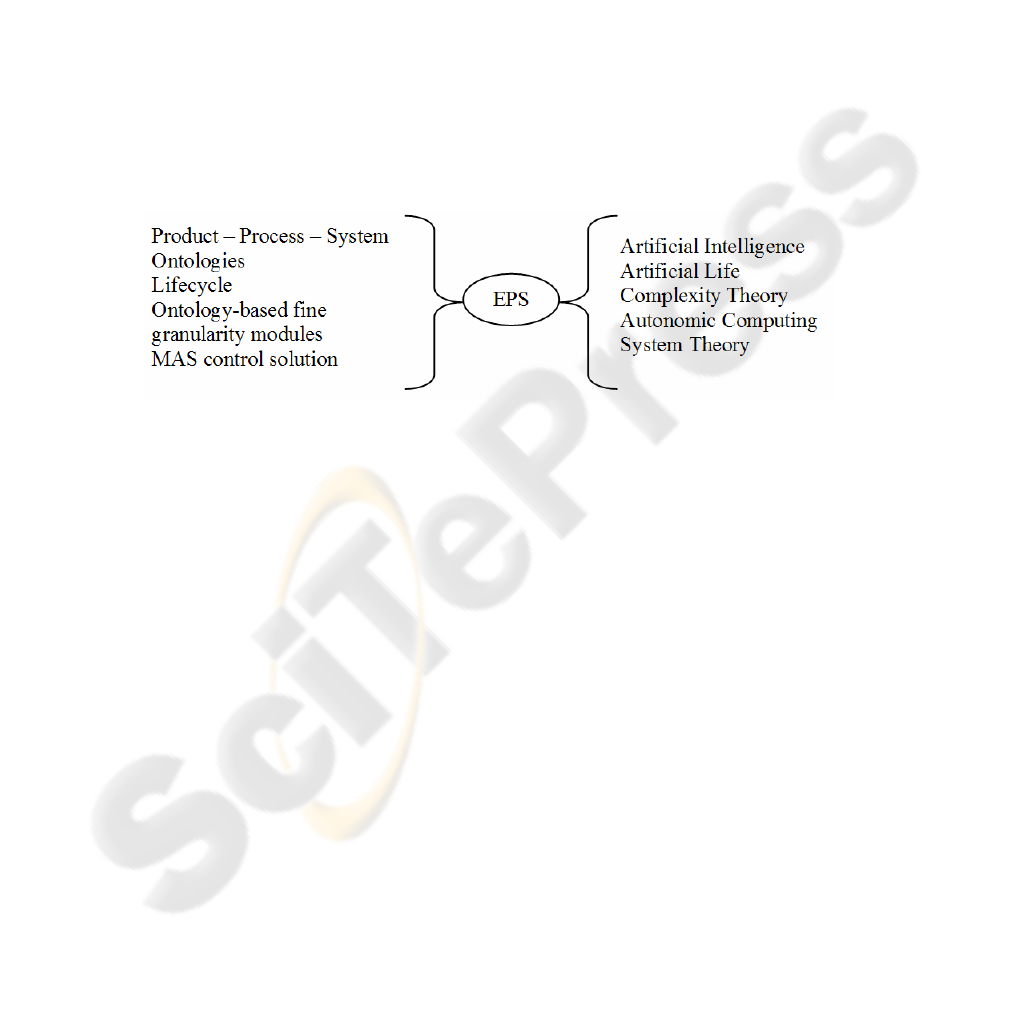

3 Sources of Inspiration and Relevant Concepts

Numerous scientific domains have emerged in the last few years, investigating phe-

nomena which EPS also exhibit. They can provide helpful tools and valuable theo-

retical background to cope with the complexity of manufacturing systems (see Fig. 2).

Fig. 2. Fundamental concepts and sources of inspiration for EPS.

3.1 Sources of Inspiration

In Artificial Intelligence the goal is often to create autonomous, intelligent behavior,

learning capabilities, and adaptation mechanisms in machines used for sophisticated

tasks. Typical examples are expert systems, which, in the case of EPS, provide sup-

port for human decision making. Machine learning can be helpful for improving

equipment calibration procedures or for the automatic creation of complex skills

based on simple skills in coalitions of equipment modules.

Complexity Theory looks for simple causes leading to complex behaviors [8].

Complex systems are spatially and/or temporally extended non-linear systems with

many strongly-coupled degrees of freedom and high non-linearity. They are com-

posed of numerous often simple elements and characterized by collective properties.

EPS consist of equipment modules which are connected to each other and have multi-

lateral interactions. Together, the modules form a system with the desired global

behavior.

Chaos Theory studies cases where future outcomes are arbitrarily sensitive to tiny

changes in present conditions [9]. The mathematical methods founded by Poincaré

and Lorentz try to find patterns in this seemingly chaotic situations. Manufacturing

46

systems often exhibit sensitivity to specific conditions and to disturbances. Certain

factors lead to system breakdown while others have no significant effect. It is difficult

to predict the critical circumstances and to cope with them.

A promising engineering approach based on Complexity Theory is described in

“Foundations of Complex System Theories” [10]: the Synthetic Microanalysis. Com-

bining the bottom-up and top-down views, it proposes an iterative journey from the

whole to its parts and back.

System Theory and Cybernetics. All systems, however complex they are, have

some kind of organization [11]. This structures or concepts, studied in System The-

ory, are often independent from the specific system or domain. In this sense, their

understanding can help solving problems in a somehow generic way: the approaches

can be applied to other cases – above all complex, adaptive and self-regulating sys-

tems. Cybernetics particularly treats the aspects of communication and control by

focusing on circular feedback mechanisms in complex systems [11]. EPS need a

dynamically modifiable organization. Their structure as well as constituents’ interac-

tions is fundamental for the good functioning of the systems. The trade-off between

system autonomy and human control is a challenge for engineers.

Artificial Life including Swarm Theory and Mobile Robots. Scientists attempt to

create life-like behaviors with the capability of evolution on computers and other

“artificial” media. EPS are very similar to artificial living systems. They have a modi-

fiable structure, will exhibit some kind of self-organization, can adapt to their envi-

ronment, and react to stimuli. They are capable of evolving according to the circum-

stances, namely in terms of equipment states, and can incorporate newly available

technology. As any living organism, they will include efforts to keep themselves in a

constant well-functioning state through self-surveillance and self-management.

The concepts of swarm-building living organisms, such as stigmergy and coordina-

tion mechanisms found in schools of fish and bird flocks can for instance be used by

mobile robots for the coordination with their fellows. The robots’ autonomy and their

capacity of collaboration are fundamental. Being reactive and proactive devices, they

often include reasoning capabilities.

Agentified modules in EPS can be seen like the members of a swarm: their coordi-

nation can be based on similar strategies. Even if their mechanical properties are

diverse, from a software point of view, they have similar or identical characteristics.

They can participate in a coalition or withdraw from it, without disturbing the rest of

the group, and thus permit true and immediate Plug&Produce functionality.

Autonomic Computing [12]. Although at another level than the other areas de-

scribed above, Autonomic Computing provides a fundamental source of inspiration

for EPS. Large computer-based systems, forming large networks and having complex

and multiple interactions, become increasingly difficult to manage. As a consequence,

software will be designed to itself undertake most management tasks, such as self-

configuration, self-healing, self-protection and self-optimization. User interaction will

be minimized and reprogramming avoided. Valid for computers, the concept of auto-

nomic systems applies also to manufacturing systems in general and EPS in particu-

lar. Complexity must be hidden from the user. Systems need easy-to-use human ma-

chine interfaces.

47

3.2 Relevant Concepts

Out of these numerous fields of scientific studies, a set of the most relevant concepts

is identified. Many of them are included in several domains and therefore no specific

origin is indicated here.

Depending on the context, an Agent can be a human person, an association, an ani-

mal, or a piece of software, possibly connected to some hardware. The fundamental

characteristics are identity, intelligence and the ability to act and react in order to

persecute goals. Agents have at least a certain degree of autonomy and can compete

or collaborate with others. The realization of Multi-Agent Systems can adopt various

software technologies: early attempts used object-oriented or component-based lan-

guages and evolved towards programming languages and platforms directly support-

ing the concepts of agents [6]. Also web-services are an option, as used by Schneider

Electric in their Service-Oriented Architecture [13]. When extended by a proactive

part, web-services are de facto very close to agents. There are numerous successful

experiences with agent-based systems in industry [14-17]. Rockwell Automation even

develops agent-based systems where the agents run inside the PLC itself [18] instead

of on separate computers. In EPS, Agents naturally represent the basic building

blocks embedded into the different components of the production system.

Self-* capabilities as defined by AgentLink III [19] can concern installation, man-

agement, healing, configuration and other activities. EPS modules with self-* capa-

bilities allow to minimize user interaction, i.e. to increase system autonomy. Self-

Organization is of particular relevance: it is abundant in nature and a promising fea-

ture for artificial systems. A distributed diagnosis system for EPS, based on device

Self-Diagnosis, is currently being developed at UNINOVA, Portugal.

Emergence. Complex systems most often consist of at least two different levels: the

macro-level, considering the system as a whole, and the micro-level, considering the

system from the point of view of the local components. Local components behave

according to local rules and based on preferably local knowledge; a representation of

the entire system or knowledge about the global system functionality is neither pro-

vided by a central authority nor reachable for the components themselves. They com-

municate, interact with each other and exchange information with the environment.

From the interaction in this local world emerge global phenomena, which are more

than a straight-forward composition of the local components’ behaviors and capabili-

ties. Typically, there is a two-way interdependence: not only is the global behavior

dependent on the local parts, but their behavior is also influenced by the system as a

whole. Emergent phenomena are scalable, robust, and fault-tolerant, i.e. insensitive to

small perturbations and local errors as well as component failure, thanks to redun-

dancy. They exhibit graceful degradation, meaning that there is no total break-down

because of minor local errors.

Fitness functions and landscapes. In nature, organisms must be fit for survival and

in this sense react to the requirements of the ever-changing environment. The closer

an organism matches the fitness function, the better adapted it is to the current life

48

condition. The criteria for endurance or elimination of new characteristics are most

often multiple and form a “fitness landscape”. In the scope of EPS, process require-

ments are the system’s fitness functions / landscapes. Certain specifications are abso-

lute: the marks must be absolutely reached – otherwise the process is not fulfilled.

Others may indicate a direction, which the system can try to converge to (e.g. save

energy, minimize cycle time, etc.).

Edge of Chaos, Far-from-equilibrium, Self-organized criticality. Constantly stable

equilibrium states would block evolution. Dynamic systems get again and again into

states where a little stimulus can trigger a major reaction. This gives the systems en-

ergy to evolve and makes new phenomena emerge. Illustrative explanations can be

found in the books Tipping Point [20] and Critical Mass [21].

Complex Adaptive Systems (CAS) are systems that emerge over time into a coher-

ent form, and adapt and organize themselves without any singular entity deliberately

managing or controlling it [22]. Supply Networks have been recognized as CAS [23],

and also EPS share many characteristics of them. They are many-body systems, com-

posed of numerous elements of varying sophistication, which interact in a multi-

directional way to give rise to the systems global behavior. The system is embedded

in a changing environment, with which it exchanges energy and information. Vari-

ables mostly change at the same time with others and in non-linear manner, which is

the reason why it is so difficult to characterize the system’s dynamical behavior.

4 Self-Organization and Emergence in EPS

In areas such as biology and artificial life, emergence and self-organization have been

discussed for many years and accordingly, definitions exist. Also for Multi-Agent

Systems, these topics have been investigated [24, 25]. Their interpretation in scope of

EPS is detailed here.

4.1 Self-Organization in EPS

Reasons for implementing self-organization in EPS are to minimize and facilitate user

interaction, i.e. to hide complexity and increase system autonomy. Building and

configuring a system composed of numerous entities with multi-lateral interactions is

a highly complex task; the more autonomy the system has, the easier it gets for the

user. Production systems tend to have many components of diverse nature which

interact in many coupled ways. Agents need the capacity of (re-)organizing their

collaboration themselves, in different forms and compositions, according to the

needs, without passing through a central coordination point.

Self-organization is robust and adaptive with regard to its environment. In pres-

ence of perturbations and change, the system is capable of changing its organization

while still maintaining its functionality. This means in practice that the control system

should be capable of handling problems and if necessary finding alternative produc-

49

tion ways. A major challenge in manufacturing applications is to let the system self-

organize and at the same time, determine its behavior. Different from natural self-

organized systems, artificial systems respectively EPS may require a kind of leader, a

broker or (eventually human) decision maker. The control influence of this authority

may be punctual in time and scope, e.g. at important strategic points.

4.2 Emergence in EPS

To bring the classical notions of emergence, discussed before, closer to the reality of

engineered systems, two classes of emergence are proposed: For “full / complex

emergence”, the global level must show further development. There is non-linear

dependence of the global functionality on the components and their interactions be-

tween themselves and the environment. “Basic / primitive emergence” means that the

local-to-global dependence may be “quasi-linear” – but still, the appearance of the

global phenomenon is not self-evident and needs some kind of “inspiration”. An

example is the classical Pick & Place mechanism: there are many different ways of

putting together a gripper with translation / rotation axes – but not all of them lead to

the desired functionality.

Not all equipment units are of the same granularity: an entire robot may as well be

defined as a module, as a single actuator or a gripper, a gripper finger may be. Sen-

sors and other fine granularity devices can play an important role in the emergence of

complex skills: augmented with the right sensors, an axis does not only move, it can

then detect the presence of other objects, determine distances or execute its own

movement as a function of the state of others.

Some of the emergent phenomena will be favorable to the accomplishment of the

system’s task and have considerable potential for advanced system behaviors, such as

the emergence of complex capabilities out of simple ones. These favorable emergent

phenomena could and should be exploited. Others may be less adapted, disturbing or

even harmful: e.g. system integration is supposed to function without unexpected

symptoms. In nature, unsuccessful properties will be eliminated by the survival-of-

the-fittest selection. Obviously, such a mechanism is not viable in manufacturing

environment: harmful behavior cannot be allowed at any moment. How to cope with

this problem in the case of EPS? Simulation can be helpful. Safety measures have to

be taken in order to avoid problematic and dangerous situations.

5 Vision of Future EPS

Computing is becoming ubiquitous; little computing power devices will be present in

every device. Manufacturing systems can then become powerful, easy-to-use and

gradually more autonomous. EPS of the future might autonomously cover a large

range of procedures, far more than today’s production systems can. They will receive

specifications of what to do, but not how to achieve it and which resources to use.

This could lead to the following scenario:

50

To release an order into the system, product agents will be accordingly config-

ured. They will carry their assembly plan and ask to be treated by operation agents.

The kind of actions to be executed on the product parts, including specifications on

precision, cycle time and other special needs, will be identified. This means that the

exact process requirements will be determined, e.g. the way of picking a part, the

geometrical trajectory to be made, the way of bringing parts from a feeder to its place

of insertion, etc. The system must be capable to find and organize the right resources

for each function, to grant for their successful execution as well as sustainable system

management, as will be detailed below.

The use of the equipment resources is yet to be chosen: this happens by exploring

the existing system with the help of a dynamically updated map of the shop floor

respectively the present modules as well as the modules available in the storage de-

partment or eventually in vendors’ module pools. In collaboration between operation

agents and resource agents, several possibilities of executing the required processes

will be determined and the best will be chosen. The criteria for this selection can be a

standard set or specified by the user. Finally, the user will be informed about possible

necessary addition, displacement or removal of modules. The required resources will

be autonomously configured / calibrated for the processes, and the needed resource

coalitions will be formed to create the complex skills. No re-programming is needed.

Agents work autonomously and collaborate with other agents. Modules register in a

resource so-called cluster and, from this platform, to dynamically form coalitions with

other resource agents according to the incoming production requirements.

The entire real time execution is then taken over by the system, which functions

with a high degree of autonomy, too. Modules at fine granularity, incorporating reac-

tive and proactive intelligence, will exhibit self-* capabilities. Systems are able to do

self-surveillance and self-maintenance, i.e. to observe their internal state and if neces-

sary take corresponding measures, to schedule regular maintenance, to announce the

eventual need for staff interaction before problems become acute. Autonomic systems

self-optimize, meaning that they continuously search for ways to optimize their op-

eration. They can self-diagnose and self-heal in order to predict and avoid respec-

tively solve most problems autonomously and, in case of the need for user interaction,

make it as easy as possible by indicating the defective part, the problematic part inter-

action and proposing corresponding corrective measures to the shop floor staff.

Of course, such a fundamental change in the way systems are built and especially

run cannot be achieved from day to the next; the approach has to advance step by

step. E.g. concerning decision making, the systems can neither be expected to become

fully autonomous at once nor can users trust them immediately. Gradually increasing

independence is more sustainable. At first, the system automatically collects informa-

tion in order to support human decision making. In a next phase, it gives advice and

proposes solutions, taking note of user preferences. Later, the system indicates the

best-fitting solution as well as alternatives and requests user confirmation. And fi-

nally, after these learning phases, the system takes decisions alone.

In this sense and as a conclusion, systems might evolve in a way that they develop

capabilities which the system designers have never thought of: systems could eventu-

ally offer services which they have not originally been built for.

51

6 Conclusion

In order to cope with today’s and tomorrow’s manufacturing needs, new solutions are

required. Evolvability is a key to success: the capability of systems to evolve together

with the production requirements as well as the strong product-process-system link

are crucial. EPS provide ontology-based process-specific modularity at a fine granu-

larity and a distributed control approach using the Multi-Agent paradigm. Self-

Organization and Emergence allow system autonomy, which can considerably facili-

tate system installation and operation by hiding complexity.

EPS share many aspects of Complex Adaptive Systems and therefore need to be

addressed as such. Traditional engineering cannot offer corresponding tools. Com-

plexity Theory and other emerging scientific domains have the potential of providing

valuable help to cope with CAS and the engineering of such systems, offering the

possibility of implementing advanced system capabilities.

The ideas described in this article require a stepwise approach. Some of them still

need theoretical elaboration, while others are already fully or partially implemented

on a prototype at UNINOVA, Portugal. The NOVAFLEX assembly system has been

agentified: each module is an agent, and the multi-agent control system is operational.

The lab installations are built of legacy components from diverse suppliers and in-

clude two industrial robots, different grippers, a warehouse and conveyor circuits. A

distributed diagnosis system, based on a Service-Oriented Architecture and using

device Self-Diagnose, is currently being developed. In parallel, tiny computing de-

vices for supporting MAS are being elaborated. Integrated in any kind of equipment

unit, they will make computing capacities ubiquitous, also in the manufacturing

world.

References

1. M. Onori, J. Barata, and R. Frei, "Evolvable Assembly Systems Basic Principles " pre-

sented at BASYS, Niagara Falls - Canada, 2006.

2. T. Maraldo, M. Onori, J. Barata, and D. Semere, "Evolvable Assembly Systems: Clarifica-

tions and Developments to Date," presented at CIRP / IWES 6th International Workshop

on Emergent Synthesis, Kashiwa - Japan, 2006.

3. A. Tharumarajah, A. J. Wells, and L. Nemes, "Comparison of the bionic, fractal and holo-

nic manufacturing system concepts," International Journal Computer Integrated Manufac-

turing, vol. 9, pp. 217-226, 1996.

4. M. Ulieru, "Emerging Computing for the Industry: Agents, Self-Organisation and Holonic

Systems," presented at Workshop on Industrial Informatics, IECON 2004, Busan, South

Korea, 2004.

5. K. Ueda, "Emergent Synthesis Approaches to Biological Manufacturing Systems," pre-

sented at DET, Setubal, Portugal, 2006.

6. M. J. Wooldridge, An Introduction to Multiagent Systems. New York: J. Wiley, 2002.

7. J. Barata, G. Cândido, and F. Feijão, "A Multiagent Based Control System Applied to an

Educational Shop Floor," presented at BASYS, Niagara Falls - Canada, 2006.

8. K. A. Delic and R. Dum, "On the Emerging Future of Complexity Sciences," ACM Ubiq-

uity, vol. 7, 2006.

52

9. M. Gell-Mann, "What is Complexity?," in Complexity, vol. 1,

www.santafe.edu/~mgm/complexity.pdf ed: John Wiley and Sons, Inc. , 1995.

10. S. Y. Auyang, Foundations of Complex -System Theories in Economics, Evolutionary

Biology, and Statistical Physics: Cambridge University Press, 1998.

11. F. Heylighen, C. Joslyn, and V. Turchin, "What are Cybernetics and Systems Science?," in

Principia Cybernetica Web Brussels: http://pespmc1.vub.ac.be/CYBSWHAT.html, 1999.

12. J. O. Kephart and D. M. Chess, "The Vision of Autonomic Computing," IEEE Computer,

vol. 0018-9162/03, pp. 41-50, 2003.

13. A. W. Colombo, F. Jammes, H. Smit, R. Harrison, J. L. M. Lastra, and I. M. Delamer,

"Service-oriented architectures for collaborative automation," presented at IECON, 2005.

14. W. Shen and D. H. Norrie, "Agent-Based Systems for Intelligent Manufacturing: A State-

of-the-Art Survey," Knowledge and Information Systems, an International Journal, vol. 1,

pp. 129-156, 1999.

15. H. V. D. Parunak, "Agents in Overalls: Experiences and Issues in the Development and

Deployment of Industrial Agent-Based Systems," International Journal of Cooperative In-

formation Systems, 2000.

16. V. Marik and D. C. McFarlane, "Industrial Adoptation of Agent-Based Technologies,"

IEEE Intelligent Systems, vol. 1542-1672/04, pp. 22-30, 2004.

17. L. Monostori, J. Vancza, and S. R. T. Kumara, "Agent-Based Systems for Manufacturing,"

presented at BASYS, Canada, 2006.

18. V. Mařík, P. Vrba, K. H. Hall, and F. P. Maturana, "Rockwell automation agents for manu-

facturing," presented at AAMAS, Utrecht, NL, 2005.

19. M. Luck, P. McBurney, O. Shehory, and S. Willmott, Agent Technology Roadmap, 2005.

20. M. Gladwell, The Tipping Point: how little things can make a big difference. London:

Abacus, 2000.

21. P. Ball, Critical Mass: how one thing leads to another. London: Arrow Books, 2004.

22. J. H. Holland, Hidden Order: How Adaptation Builds Complexity, 1995.

23. T. Y. Choi, K. J. Dooley, and M. Rungtusanatham, "Supply Networks and Complex Adap-

tive Systems: Control versus Emergence," Operations Management, vol. 19, pp. 351-366,

2001.

24. G. Di Marzo Serugendo, M.-P. Gleize, and A. Karageorgos, "Self-Organisation and Emer-

gence in MAS: An Overview," Informatica, vol. 30, pp. 45-54, 2006.

25. S. A. Brueckner, G. Di Marzo Serugendo, A. Karageorgos, and R. Nagpal, "Engineering

Self-Organising Systems," in LNAI 3464. Berlin Heidelberg: Springer, 2005, pp. 297.

53